Overview

The 953C works well in a wide range of applications. Excavating, clearing, stripping topsoil, landscape contouring, grading, dozing, backfilling, hard bank digging, carrying material, and truck loading all can be accomplished with one machine. Reliable, durable operation. Rugged construction, self-diagnosis of electrical and power train systems, and easy maintenance help ensure extended service life with low operating costs.

Specifications

| Flywheel Power | — |

| Operating Weight | — |

| Capacity - General Purpose | — |

Benefits & Features

Specifications

| Flywheel Power | — |

| Engine Model | Cat 3126B ATAAC |

| Net Power - Caterpillar | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Track Shoe Type | Double Grouser, Extreme Service |

| Track Shoe Width - Standard | — |

| Track Shoe Width - Optional | — |

| Track Rollers - Each Side | 6 |

| Number of Shoes - Each Side | 37 |

| Track on Ground | — |

| Ground Contact Area - Standard Shoe | — |

| Ground Contact Area - Optional Shoe | — |

| Ground Pressure - Standard Shoe | — |

| Ground Pressure - Optional Shoe | — |

| Grouser Height - Double Grouser | — |

| Track Gauge | — |

| Type | Hydrostatic drive with infinite machine speeds to 9.2 km/h (5.7 mph) |

| Drive Pump | Two, variable-displacement, slipper-type axial piston pumps |

| Track Motor | Two, variable-displacement, link-type piston motors |

| Relief Valve Setting | — |

| Type | Vane |

| Output | — |

| Main Relief Valve Setting | — |

| Lift Cylinder - Bore | — |

| Lift Cylinder - Stroke | — |

| Tilt Cylinder - Bore | — |

| Tilt Cylinder - Stroke | — |

| Output - Maximum | — |

| Relief Valve Setting | — |

| Cycle Time - Raise | — |

| Cycle Time - Dump | — |

| Cycle Time - Lower, Empty, Float Down | — |

| Cycle Time - Raise and Dump | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase - With Filter | — |

| Final Drive - Each | — |

| Hydraulic System - Equipment, Power Train and Tank | — |

| Hydraulic Tank | — |

| Pump Drive Box | — |

| Pivot Shaft | — |

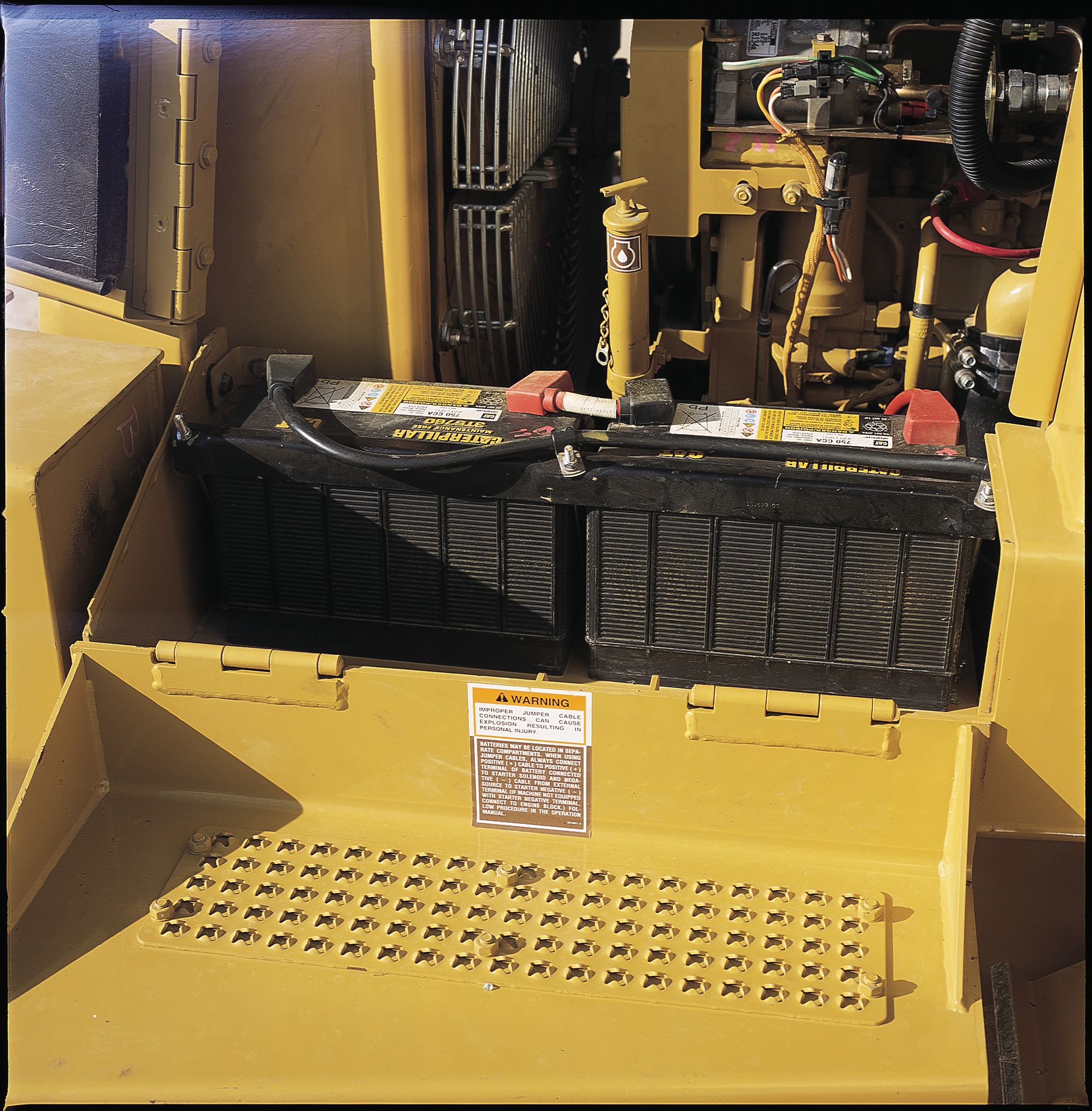

| Type | 24V DC |

| Battery Capacity | 750 CCA |

| Battery Voltage | 12 |

| Battery Quantity | 2 |

| Alternator | 70 Amps, Heavy-Duty Brushless |

| Operating Weight | — |

| Shipping Weight - Without Bucket | — |

| Capacity - General Purpose | — |

| Capacity - Multi-Purpose | — |

| Bucket Width - General Purpose | — |

| Bucket Width - Multi-Purpose | — |

| Maximum Travel Speed | — |

| Type | Radial |

| Number of Pockets | 3 |

| Overall Width/Beam | — |

| Shank Cross Section | 50 x 109 mm 2.0 x 4.3 in |

| Ground Clearance | — |

| Penetration | — |

| Ripping Width | — |

| Cylinders - Bore | — |

| Cylinders - Stroke | — |

| Addition to Machine Length Due to Ripper in Transportation Position | — |

| ROPS/FOPS | ROPS/FOPS |

| Brakes | Brakes |

| Cab | Cab |

Benefits & Features

Engine

Cat 3126B Diesel Engine

The Cat 3126B diesel engine is a six cylinder, four-cycle design that provides long, effective power strokes for high torque and more complete fuel combustion. The 3126B is rated at 95 net kW (128 net hp) at 2000 rpm. The 3126B is equipped with an electronic air inlet heater. The heater warms the air in the air inlet manifold for easier starting and reduced white smoke on cold starts.

Rear Engine Location

Rear engine location allows excellent forward visibility, while serving as a working counterweight. It also helps reduce radiator plugging while providing easy service access to the engine and other major components.

Fuel System

The Hydraulic-actuated Electronic Unit Injection (HEUI) is a unique and proven high-pressure, direct injection fuel system for diesel engines. High injection pressures and short injection duration provide fast response, clean burning and added fuel savings.

ADEM™ III

The Advanced Diesel Engine Management - Electronic Control Module continuously monitors important engine conditions and functions. It precisely controls each time the HEUI injects fuel into a cylinder and signals the machine Electronic Monitoring System (EMS III) if a problem occurs with the engine.

Turbocharger and Aftercooler

A well-matched turbocharger and air-to-air aftercooler results in increased power. The exhaust driven turbocharger packs more air into the cylinders, while the air-to-air aftercooler cools the pressurized air from the turbocharger, making the engine intake air denser. The increased air in the cylinders results in more power, improved combustion, and reduced exhaust emissions.

Extended Life Design

The engine features an extended life design including seven main bearings that provide a large bearing surface area to distribute force loads in the engine. Durable single piece aluminum alloy pistons are standard for long life.

Cooling System

The cooling system incorporates into a single cooling unit the hydraulic oil cooler, the engine radiator, and the air-to-air aftercooler. By locating the cooling system in the rear of the loader, they are away from the dust and debris stirred up by the bucket while working.

Starting System

The ADEM III controller controls the electric starter motor and the starter relay. The ADEM III prevents fuel from being supplied for starting until sufficient oil pressure is present. This prevents wear on the bearings due to operating without adequate lubrication.

Hydrostatic Drive

Shifting

The hydrostatic drive eliminates the need for transmission shifting, which allows the operator to concentrate on working, maneuvering, and production.

Machine Speed

The Electronic Hydrostatic Control (EHC) automatically adjusts machine speed to give the equipment hydraulic system priority, while the hydrostatic system takes advantage of all remaining engine power.

Electronic Hydrostatic Control (EHC)

The EHC maintains engine rpm in optimum operating range and balances the two track drive systems for straight travel without machine drift.

Electronic Monitoring System (EMS III)

The EHC interfaces with the EMS III for system diagnostics and calibrations. It is self-diagnosing, and fully compatible with Electronic Technician (Cat ET) software. This allows quick and easy calibrations and troubleshooting.

Variable Displacement Pumps and Drive Motors

Variable displacement pumps and variable displacement drive motors are electronically controlled by the EHC, offering high efficiency and precise travel. Each track is independently driven by a separate hydraulic circuit consisting of one variable displacement pump, connected by Cat XT-6™ hydraulic hose and couplings to a variable displacement piston motor.

Separate Hydraulic Pumps

Separate hydraulic pumps offer easy servicing.

Maneuverability

Independent power is provided to each track, which provides great maneuverability, speed, and side slope operation. Controlling independent power and speed for each track allows the operator to maintain full power to both tracks while turning, achieving a “Power Turn”. Power Turns allow increased productivity when dozing or backfilling. For additional maneuverability, the operator can use counter rotation, which allows spot turns in tight locations.

Travel Speeds

Travel speeds are infinitely variable between zero and top speed. Two speed modes, "travel mode" and "work mode", provide two different speed ranges to best match machine speed and torque to the job conditions for maximum productivity.

Operator Station

1. Heating and Air Conditioning

The air circulation system delivers filtered, pressurized, and temperature-controlled air through 10 louvered vents. Air conditioning is standard on cab-equipped machines. Heater with controls is standard on both cab and canopy-equipped machines.

2. Caterpillar Air-suspension Seat

The Caterpillar air-suspension seat, with side-to-side isolator, is ergonomically designed and fully adjustable for maximum operator comfort and control. Cushioned side bolsters prevent side movement. The backrest centerline conforms to the operator's spinal curve. The contoured base curves away from lower back to reduce pressure. Retractable seat belt is 75 mm (3 in) wide for positive, comfortable restraint.

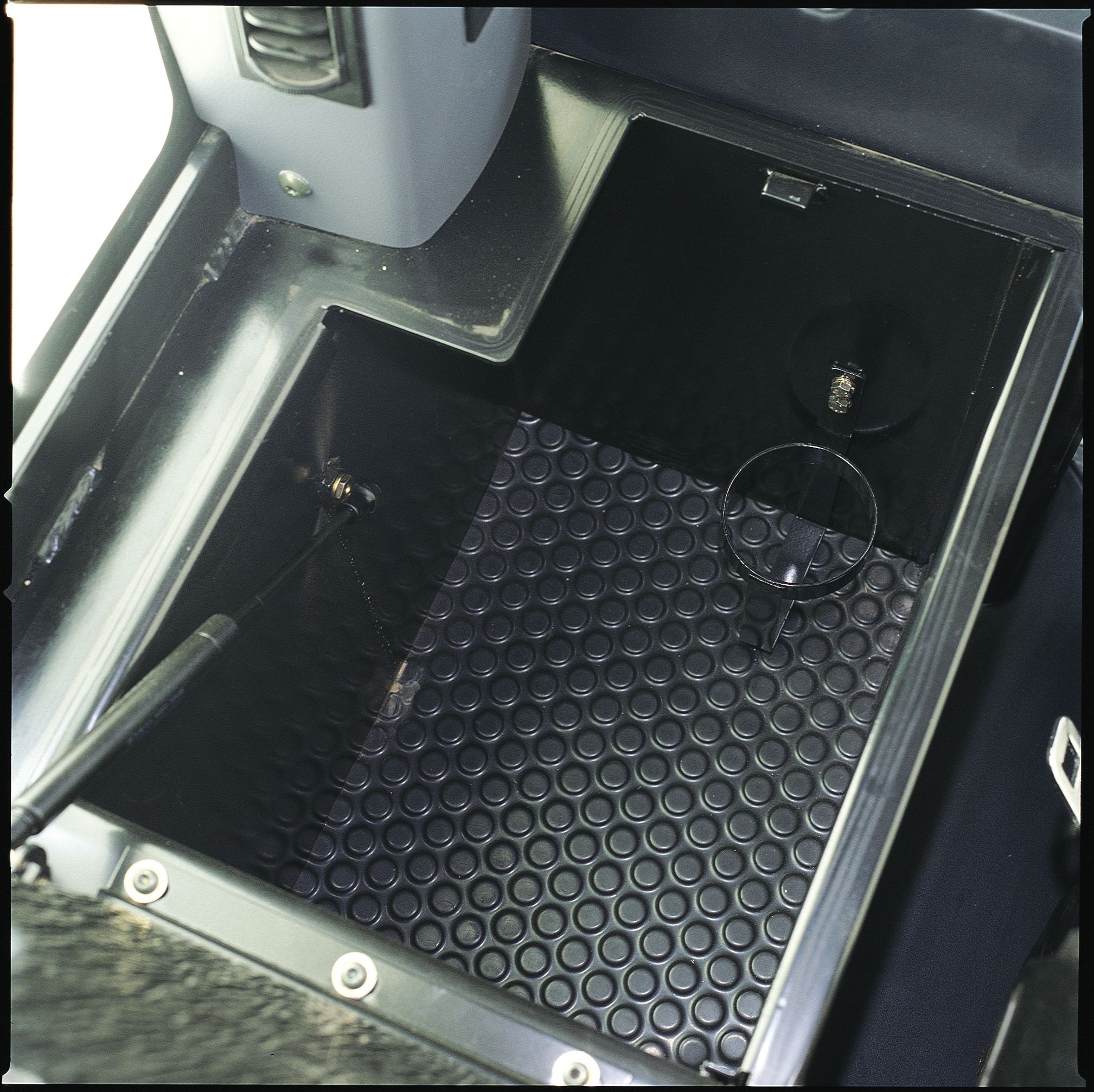

3. Storage Space

Storage spaces include a lockable storage box, a lunch box compartment, beverage holder, and coat hook.

4. Armrests

Adjustable armrests can be positioned up or down. The right armrest is adjustable forward and backward. Each armrest can be inclined to different angles for excellent operator comfort and control.

5. Dash Board

The newly designed smooth, rounded dashboard with integral defroster vents, provide all of the necessary functions and instrumentation within the operator's normal line of sight.

6. Hydrostatic Drive System Controls

The hydrostatic drive system controls allow quick speed and directional changes from a single control lever for maximum maneuverability. Pedal steering allows precise control of each track independently and on demand counter rotation. The brake pedal is supplemental to dynamic hydraulic braking provided by the hydrostatic drive system.

7. Speed Switches

The speed mode switch (B) allows the operator to choose between "work mode" for fine control, and "travel mode" for maximum drive speed, to best match the machine speed to various job conditions. The electronic engine speed selector switch (A) is used by the operator to set engine RPM.

8. Pilot Operated Controls

Pilot operated implement controls allow easier operation and greater productivity. Choice of single-lever pilot control (standard) or two-lever (optional) is available for bucket lift and dump. Automatic adjustable magnetic lift and bucket kickouts allow the operator to concentrate on positioning the machine, resulting in higher productivity.

9. Viewing Area

The viewing area includes tinted glass to reduce glare and provides an excellent visibility to the bucket, tracks, and around the engine enclosure to the rear. Sun visor, windshield wipers and washers are all standard features on the cab. The front wiper has variable speed, intermittent control.

10. Rearview Mirror

The rearview mirror is located above the front windshield, maximizing the operator's visibility.

Radio Installation Arrangement

The optional radio installation arrangement includes a 24 to 12 volt converter and speakers. A heavy-duty AM/FM radio/cassette player is also available.

Dome Light

A dome light is located above the left door.

ROPS/FOPS

Sound-suppressed Rollover Protective Structure (ROPS)/Falling Objects Protective Structure (FOPS) cab is resiliently mounted for reduced vibration and a quiet working environment. The steel roof, which was previously available as an option, is now standard.

Machine Security System

The Caterpillar Machine Security System (MSS), an anti-theft feature, is available as an attachment. When installed, a microchip is imbedded in the rubber grip of the key. The engine can only be started if the key has the appropriate pre-programmed microchip.

Light Guard

A screened light guard is available as an attachment to protect the ROPS mounted lights and the front of the roof.

Operator Sound Levels

The cab is isolated from structural noises by its resilient mounting. Extra insulation materials are added to block noise transmission into the cab.

Electronic Monitoring System (EMS III)

Electronic Monitoring System (EMS III) Functions

The Caterpillar EMS III offers three main functions. These include quick and simple calibration of the hydrostatic drive system, prevention of damage by alerting the operator if a machine fault has occurred, and monitoring of hydrostatic and electrical systems to aid service personnel in troubleshooting and repairs.

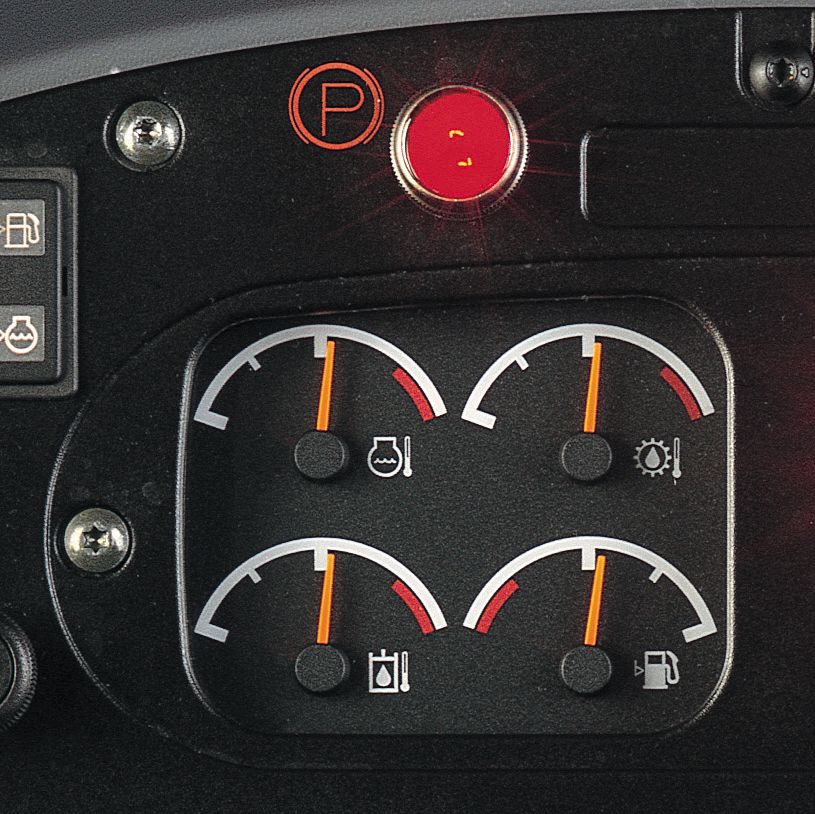

Gauge Cluster

The gauge cluster contains four gauges, which monitor: · Engine coolant temperature · Pump drive oil temperature · Hydraulic tank oil temperature · Fuel level

Alert Indicators

The alert indicator cluster groups the individual alert indicators for: · Low fuel pressure · Case drain filter bypass · Charge filter bypass · High pump drive (Splitter Box)oil temperature · Low hydrostatic system charge pressure · Low engine oil pressure · Check engine detected by the ADEM III · Low/high alternator output · System warning for hydrostatic drive system · Air inlet heater activated

Digital Message Display

The digital display can show the operator's choice of hour meter, engine rpm, odometer, or service codes.

Three Level Warning System

EMS III also functions as a warning system with three levels of warning.

EMS III - Self-test

The EMS III self-test verifies that the main display module is operating properly every time the key start switch is turned from the "off" to the "on" position.

Undercarriage

Undercarriage

The oscillating track roller frame design decreases ground induced impact loads to the machine, increases machine stability on rough terrain, and provides a smoother, more comfortable ride for the operator.

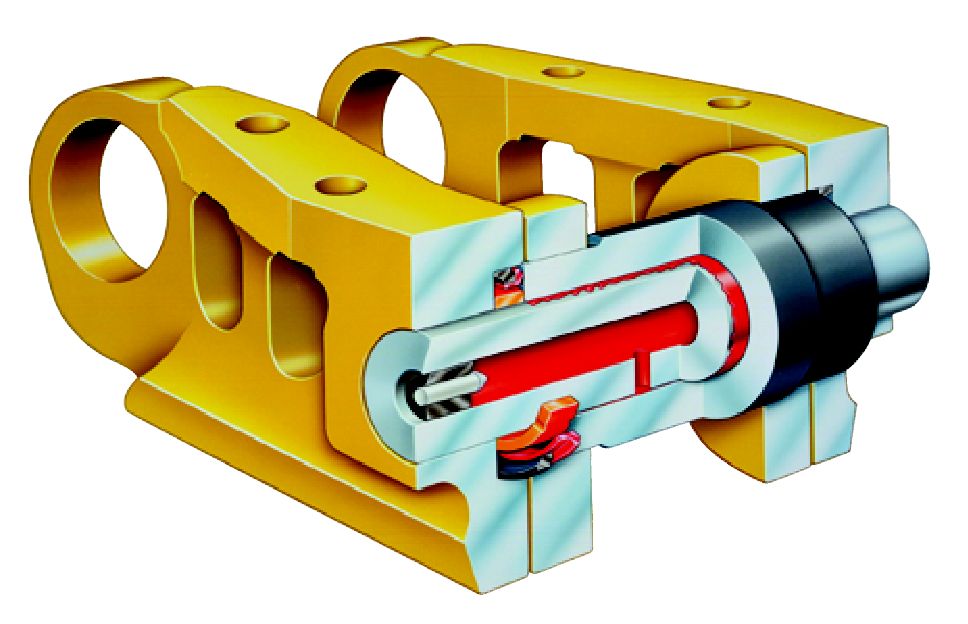

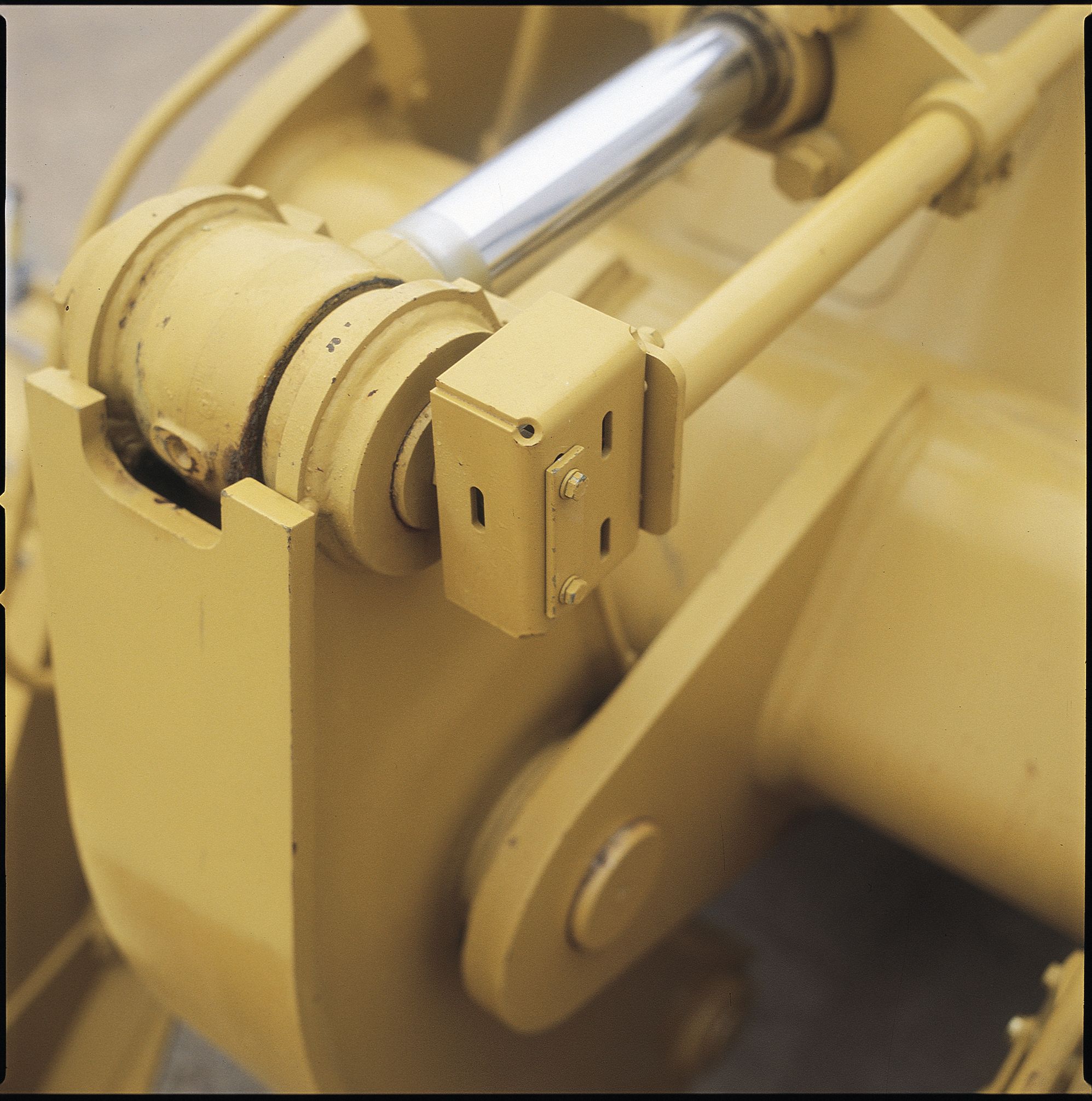

Pivot Shaft

Steel pivot shafts attach the rear ends of the track roller frames to the loader mainframe and carry most of the weight. The pivot shafts transfer ground induced shock loads from the track roller frames to the loader mainframe rather than through the final drives. The result is longer final drive life.

Track and Carrier Rollers

Six track rollers spread the machine weight over a larger area. This improves stability and provides a more comfortable ride for the operator. A single upper carrier roller on each side mounts to the machine mainframe. This mounting arrangement helps resist mud packing of the undercarriage.

Track Adjuster

The track adjuster and mechanical recoil system uses a large recoil spring and grease filled adjustment cylinder, which allows the idler to move forward and back to maintain proper track tension as it absorbs undercarriage shock loads.

Equalizer Bar

The equalizer bar is pinned in its center to the machine mainframe and at the ends to each track roller frame. This allows the forward ends of the track roller frames to oscillate, or move vertically, to keep more track on the ground in uneven underfoot conditions. The equalizer bar also provides a more stable work platform for the operator, who will be comfortable working at faster speeds for increased productivity.

Swing-Link Idler

Permits horizontal idler movement, absorbing shock loads and maintaining proper track tension, while eliminating the need for shims and wear strips. The removal of wear strips eliminates a point of service and maintenance. Cat idler provide superior structural support

Sealed and Lubricated Track

Sealed and lubricated track keeps maintenance costs down by reducing pin and internal bushing wear, which can extend the life of the track and the undercarriage components. Lubricating the pin helps reduce component friction for less track noise and greater power train efficiency.

Rotating Bushing Track

Rotating Bushing Track is designed to extend system life and lower costs in highly abrasive low to moderate impact applications. RBT features bushings, which rotate when in contact with the sprocket, greatly reducing bushing and sprocket wear. This design eliminates bushing turn maintenance expense. Rotating Bushing Track is available as optional undercarriage.

Track Links

The standard track links are the newest generation of Extended Wear Life (EWL) track. Included is more wear material for longer track life. A two-piece, split master link allows easy track removal and installation.

Sprockets

The Tough Steel™ sprocket segments are a new addition, extending sprocket segment life. The five segments are bolted onto each final drive sprocket hub. Segments can be removed or replaced without breaking the track. Driven by every second sprocket tooth, the track chain makes two complete revolutions before each tooth contacts a bushing once. The result is long, even wear of the sprocket teeth.

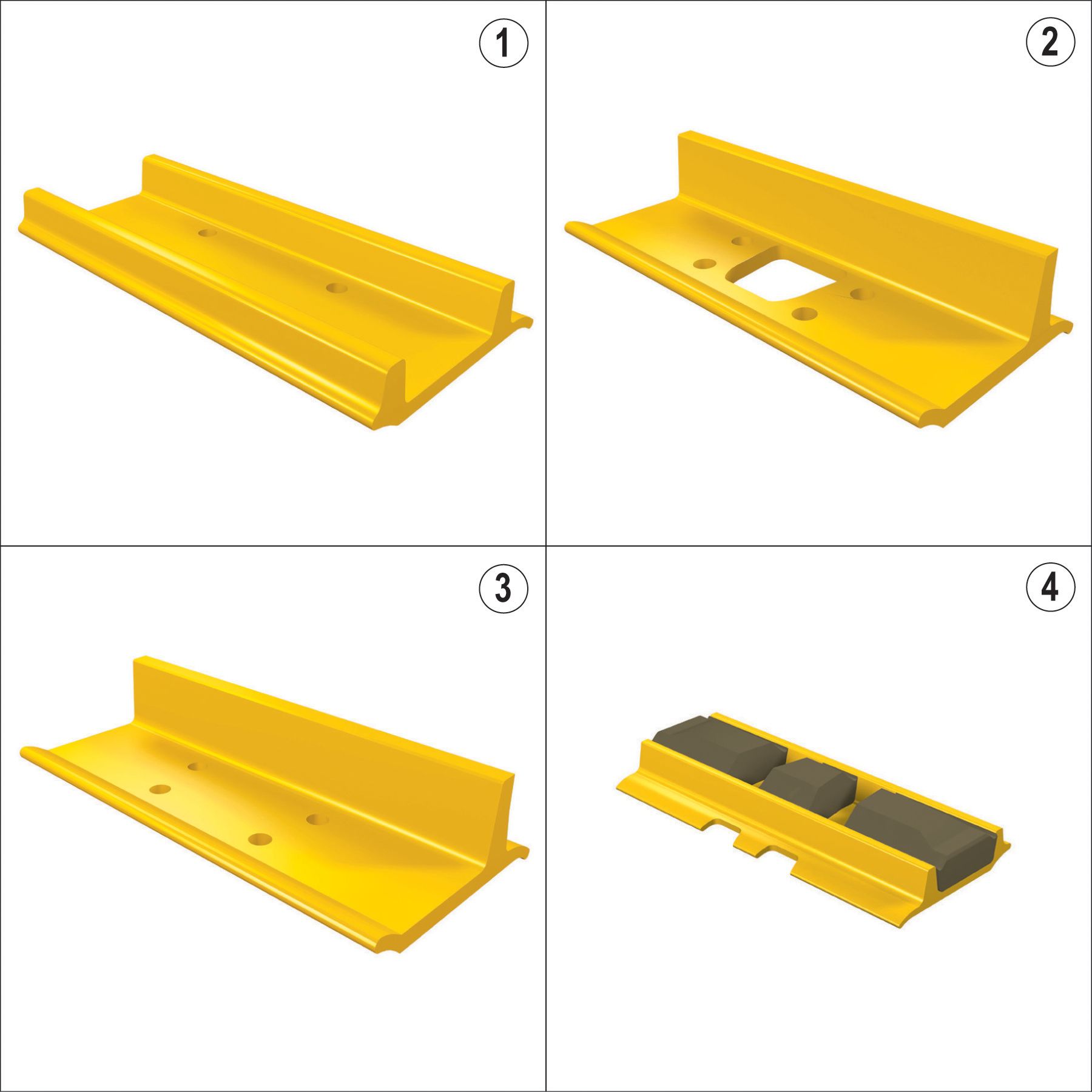

Shoe Options

There are several shoe options to choose from with the Caterpillar oscillating undercarriage. Wide, double grouser is now standard. Consult your Cat dealer for more information.

Structure

Mainframe and Loader Tower

The mainframe and loader tower is a single, welded fabrication with castings and forgings incorporated at points of high stress to distribute those stresses over wide areas for long structural life.

Design

Strong box-section mainframe design, with continuous, deep-penetration welds resist twisting loads to protect components from excessive wear or damage without adding extra weight to the machine. The frame rails consist of two box sections, which are joined at the rear by a box-section cross member. Mounting points for the final drives, pivot shafts, and operator's platform are integrated into each mainframe side rail.

Four-Plate Loader Tower

The four-plate loader tower is integral with the basic mainframe. The loader tower distributes forces evenly from the lift arms to the mainframe, which eliminates twisting for maximum structural durability. The loader tower provides solid mounting points for lift arms, lift cylinders, and Z-Bar tilt cylinder.

Castings

Steel Castings (shown in red) are used in areas of high stress concentration. Large radius curves dissipate stresses that could cause fatigue and cracking.

Steel Frame

Fatigue resistant steel frame sections along with castings provide flexibility, durability and excellent resistance to impact loads.

Durability

Structures are designed to provide durability and extended service life to support multiple rebuilds.

Z-Bar Linkage

Breakout force is exceptionally high due to mechanical advantage of Z-bar linkage design, and hydraulic pressure applied to the head end of the tilt cylinder. Using a single tilt cylinder and linkage provides the operator a better view of the work area, bucket, and cutting edge.

Simultaneous Lift and Dump

Simultaneous lift and dump for fast truck loading and smooth grading, and the ability to meter material from bucket.

Return-to-Dig

The "Return-to-dig" switch assembly is located on the tilt cylinder and rod. It sets the angle the bucket will return to after it is dumped, when the bucket lever is placed in the Tilt-back -- hold position.

Lift Arms

The two arms are welded into a single unit, using a weld-fabricated cross-tube. The fabricated cross-tube and tilt lever use forging at high stress points to spread the loads for long life.

Work Tools

Versatility

The large variety of tasks an operator can perform with the standard machine and attachments has lead to the Caterpillar track loader's reputation for versatility.

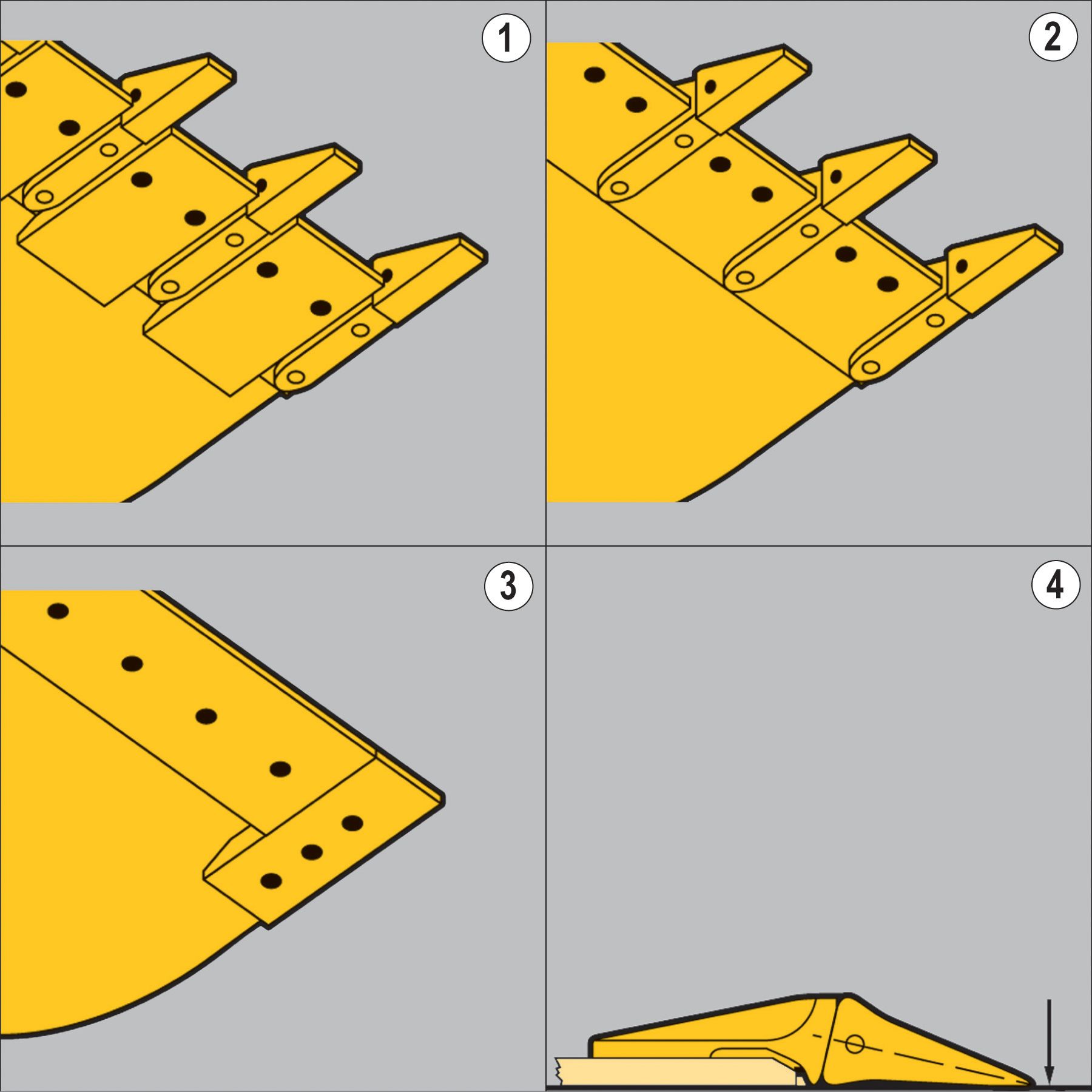

General Purpose Bucket

The General Purpose (GP) bucket is designed for excellent loadability and long life in applications such as hard bank excavating, stripping, and stockpile loading. High-strength, low-alloy steel helps the bucket resist dents and abrasions. Shell-tine reinforcements support the rear of the bucket for increased structural strength.

Multi-Purpose Buckets

The Multi-purpose (MP) bucket is designed for a broad range of applications, such as loading, stripping, clearing, bulldozing, picking up debris, and fine grading. The bucket clamps hydraulically to grip logs or handle other tough-to-grasp materials.

Pallet Forks

When used with a quick coupler, Pallet Forks increase the versatility of the machine. Thay are ideal for handling a variety of materials. Various tine arrangements and top clamps are available.

Ripper-Scarifier

The ripper-scarifier adds extra versatility to expand the application of the machine. Hinged-type, with three shanks, beam mounted with two pins pressed into each side of the mainframe. Raised and lowered with two wide-mounted cylinders. Six-pin linkage requires no lubrication.

Bucket Protection Options

Caterpillar offers several types of adapters, tips, and cutting edges, which increase bucket life and maximize performance. (1) Bolt-on adapters, tips, and bolt-on reversible edge segments provide a clean working floor and increase bucket capacity. Heavy-duty segments are available with 62 percent more wear material than standard segments. (2) Bolt-on, 2-strap adapters, and tips, including corner adapters, offer excellent penetration. (3) Bolt-on, reversible, cutting edges are ideal when penetration is not a consideration, such as in clean-up work or stockpiling applications. (4) Weld-on, top-strap adapters are also available with a GP bucket. They are flush-mounted with the bottom of the cutting edge to provide a smooth bucket bottom and unrutted work surface. These adapters can be used with any of the tip options (not with a bolt-on protection system).

Tip Options

Caterpillar GET offers a variety of tips to better accommodate your needs in any working environment, whether that is high impact or general-purpose applications. These and other GET options are available from your Caterpillar Dealer.

Special Application Arrangements

Waste Handling/Demolition Arrangements

Waste Handling/Demolition arrangements provide added versatility and are designed to make the 953C perform well in sanitary landfills, waste handling or demolition applications where the machine spreads, compacts, sorts, shreds and crushes materials.

Super Low Ground Pressure

The Super LGP 953C is designed for work in extreme soft underfoot conditions. For enhanced flotation and stability, the idler is extended to the front of the machine and a track roller is added. Larger track shoes increase the ground contact area for reduced ground pressure.

Shiphold Arrangement

Shiphold arrangements allow the 953C to work in the confined and harsh shiphold environment where the machine assists in the off-loading of bulk materials, such as iron ore, steel scrap, coal, minerals, and grain. For other custom arrangements, contact your Caterpillar Dealer.

Tunneling Arrangement

Working in a tunnel calls for extreme maneuverability, clean exhaust, and special safety equipment. The 953C can be a star performer when it is properly equipped for this work. The maneuverability provided by the hydrostatic drive allows it to turn within its own length.

Additional Arrangements

Many other arrangements are available. For other custom-designed arrangements for specific applications, contact your Caterpillar Dealer.

Serviceability

Reduced Maintenance

The 953C has many service features incorporated in the machine including: · Caterpillar Extended Life Coolant for extended change intervals. · Sealed electrical connectors lock out dust and moisture. · Caterpillar XT™ hydraulic hose, in medium and high-pressure circuits, provide high abrasion resistance and far exceeds industry standards. · O-Ring Face Seals (ORFS) hydraulic couplings eliminate fluid leaks, provide positive seals, and are reusable for lower operating costs. · Removable floor panels in the cab to access engine, and hystat and implement pumps. · Extended change intervals for engine and hydraulic/hystat oil. · Scheduled Oil Sampling Fluids Analysis helps avoid unnecessary downtime. S·O·SSM fluid taps are included to make oil sampling easier.

Easy Component Access

The rear engine design and large engine access doors make it easy to reach the engine, electrical components, hydrostatic system, battery, and toolbox. Hydraulic and fuel filters are located close to each other. Removable cab floor panels create easy access to internal components. The hydrostatic drive system features separate pumps and motors for low replacement or rebuild cost. All lubrication points are accessible from ground level. The swing-out grille, now standard, reduces downtime and the cost for cleaning, inspection, and repair of the cooling package.

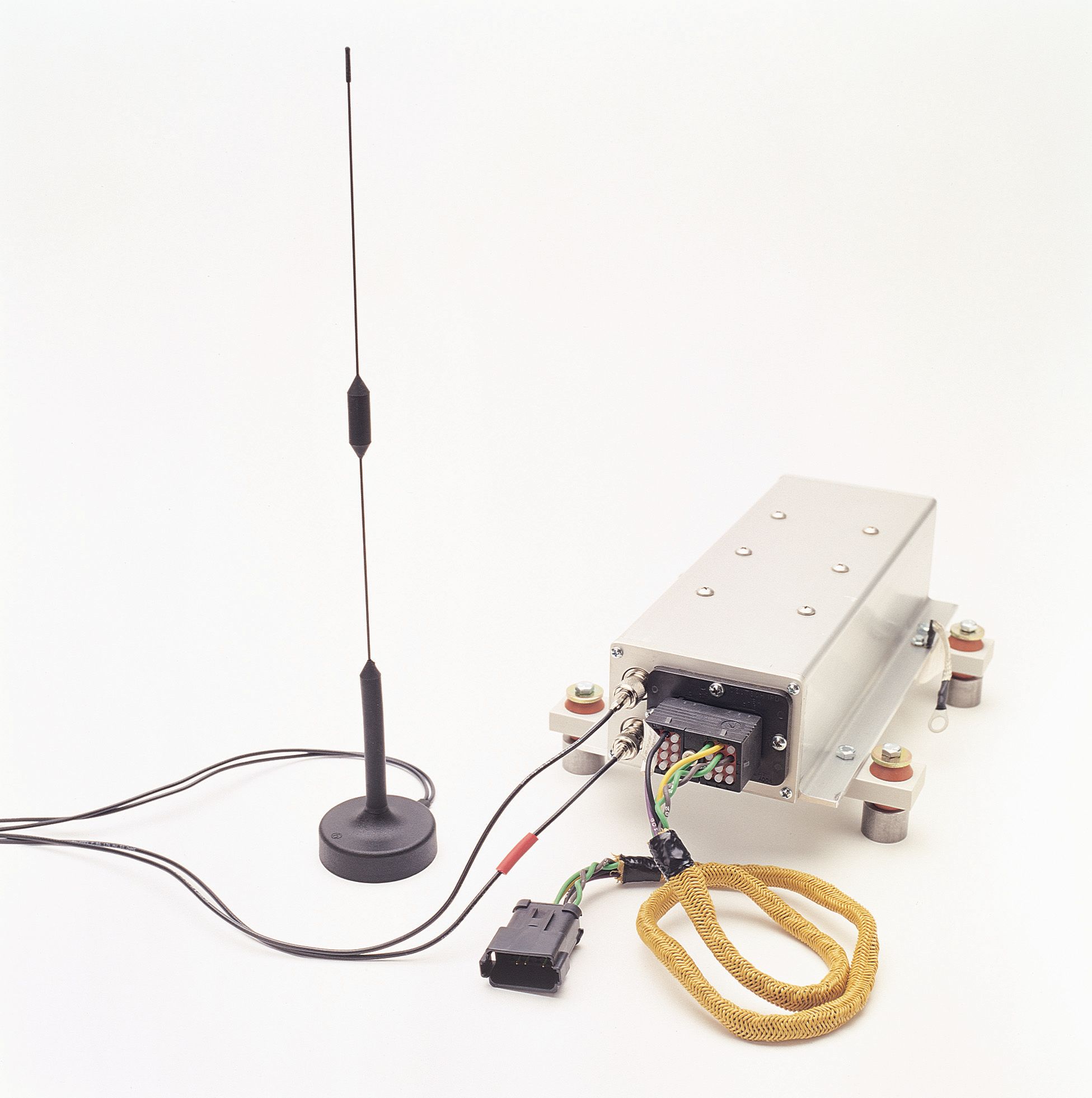

Product Link

This option allows the customer or dealer to obtain machine diagnostics and location from their offices. Product Link provides updates on service meter hours, machine condition, machine location, and integrated mapping/route planning.

Easy Diagnosis

The Electronic Monitoring System (EMS III) and self-diagnosing Electronic Hydraulic Control (EHC) work together to warn against both occurring and impending faults to reduce downtime.

Total Customer Support

Product Support

Your Cat Dealer offers a wide range of services that can be set up under a Customer Support Agreement (CSA) when you purchase your equipment. The dealer will help you choose a plan that can cover everything from the machine and attachment selection to replacement. This will help you get the best return on your investment.

Remanufactured Components

Save money with remanufactured parts. You receive the same warranty and reliability as new products at a cost savings of 40 to 70 percent.

Service Capability

Whether in the dealer's fully equipped shop or in the field, you will get trained service technicians using the latest technology and tools.

Selection

Make detailed comparisons of the machines you are considering before you buy. How long do components last? What is the cost of preventive maintenance? What is the true cost of lost production? Your Cat Dealer can give you answers to these questions.

Purchase

Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has training videotapes, literature, and other ideas to help you increase productivity.

Replacement

Repair, rebuild, or replace? Your Cat Dealer can help evaluate the cost involved so you can make the right choice.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time of your purchase. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help avoid unscheduled repairs.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, back-up

- Alternator (24-volt, 70-amp)

- Batteries, 750 CCA, high-output, maintenance free

- Electronic Hydrostatic Control (EHC)

- Electronic Monitoring System (EMS III)

- Lights (2), ROPS mounted, forward facing (halogen)

- Power outlet, 12-volt

- Starting motor, 24-volt electric

- POWER TRAIN

- Air inlet heater

- Blower fan

- Engine, Cat 3126B HEUI diesel with ATAAC

- Filters, air (radial seal)

- Fuel priming pump, manual

- Pedal steering

- Pre-cleaner, air intake

- Radiator guard, HD, perforated

- UNDERCARRIAGE

- Sprocket guards

- Sprocket rims, segmented

- Track, sealed and lubricated (37 section)

- Track adjuster, hydraulic

- Track guiding guards, end section

- Track idlers, lifetime lubricated

- Track rollers (6), one upper carrier roller

- Track shoes, 500 mm (19.7 in), double grouser, extreme service

- OTHER STANDARD EQUIPMENT

- Bucket positioner, automatic

- Bumper, rear

- Coolant, extended life

- Cooler, hydraulic oil

- Crankcase guard, full

- Hitch, front retrieval

- Engine enclosure, lockable doors

- Lift kickout, automatic

- O-ring face seal couplings

- Radiator grille, swing-out

- S·O·S valves

- Vandalism protection - fuel tank cap with padlock,

- XT Hoses

- OPERATOR ENVIRONMENT

- Air conditioner

- Armrests, adjustable

- Ashtray, lighter (24-volt)

- Cab, pressurized and sound suppressed

- Coat hook

- Control, single lever, pilot operated

- Cup Holder

- Heater and defroster

- Horn

- Instrumentation, gauges

- Instrumentation, warning indicators

- Key start

- Mirror, review (internal)

- Parking brake switch, Brake-on indicator light

- Radio ready, 24-volt to 12-volt converter,

- Seat, (cloth) air-suspension with side-to-side isolator

- Seat belt, retractable

- Sound Suppression, Spectator

- Speed mode switch, (Work-Travel)

- Storage compartments under armrests

- Wipers/washers (front and rear)

Optional Equipment

- Buckets:

- General purpose 1.75 m3 (2.25 yd3) 951kg (2097 lb)

- Multi-purpose 1.5 m3 (2.0 yd3) 1413 kg (3115 lb)

- General purpose with flush-mounted adapters 1.75 m3 (2.25 yd3) 1052 kg (2320 lb)

- Bucket bolt-on adapters and tips for GP or MP bucket, set of 8, includes corner adapters

- Long 143 kg (315 lb)

- Short 141 kg (311 lb)

- Bucket tips for use with flush adapters (on GP bucket), set of 8

- Long 35 kg (77 lb)

- Short 33 kg (73 lb)

- Controls (for equipment hydraulic system)

- Two-lever controls

- 3rd valve for use with lines for front or rear attachments 46.5 kg (103 lb)

- Diverter valve for use when both front and rear lines are required 87.5 kg (193 lb)

- Counterweights - 2 arrangements

- Light 170 kg (375 lb)

- Heavy 375 kg (827 lb)

- Guards:

- Cab/canopy lights 11 kg (24 lb)

- Heavy-duty bottom guards 51.7 kg (114 lb)

- Idler 78 kg (172 lb)

- Seal protection - final drive, pivot shaft, and idler seals 10 kg (22 lb)

- Track roller 110 kg (243 lb)

- Starting aids:

- Batteries, Cat premium, heavy-duty (900 CCA) 4 kg (9 lb)

- Engine coolant heater, 120- or 220-volt 0.5 kb (1.0 lb)

- Track shoes:

- 380 mm (15 in) single bar grouser -290 kg (-639 lb)