Overview

The G-Series 613 carries on a unique tradition of clearing, cut and fill, and finish grade earthwork with a new emphasis on operator comfort and performance. The tractor frame has been redesigned to support a spacious new cab with a Cat Comfort seat that rotates 30 degrees for ease of loading. The cab is standard and comes with air conditioning and heat. Performance improvements - primarily in the cut - are the result of a new power train that features the Cat C6.6 with a horsepower increase and new torque converter. The result is more rimpull that when combined with more hydraulic flow to the elevator yields 13% faster loading. Order the machine with indicate-only AccuGrade and you'll move dirt more efficiently and profitably.

Specifications

| Flywheel Power - Tractor/Scraper | 135 kW (181 hp) |

| Scraper Capacity - Heaped | — |

| Top Speed - Loaded | — |

Benefits & Features

Specifications

| Flywheel Power - Tractor/Scraper | 135 kW (181 hp) |

| Tractor Engine | Cat® C6.6 ATAAC |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power | — |

| Top Speed - Loaded | — |

| 1 Forward | — |

| 2 Forward | — |

| 3 Forward | — |

| 4 Forward | — |

| 5 Forward | — |

| 6 Forward | — |

| Reverse | — |

| Bowl Cylinder Bore | — |

| Bowl Cylinder Stroke | — |

| Floor Cylinder Bore | — |

| Floor Cylinder Stroke | — |

| Ejector Cylinder Bore | — |

| Ejector Cylinder Stroke | — |

| Steering Circuit | — |

| Scraper Circuit | — |

| Supplemental Steering Circuit | — |

| Relief Valve - Steering Circuit | — |

| Relief Valve - Implement Circuit | — |

| Compensator Settings - Elevator Circuit | — |

| Scraper Capacity - Heaped | — |

| Rated Load | — |

| Capacity - Struck | — |

| Depth of Cut - Maximum | — |

| Width - Cut - To Router Bits | — |

| Ground Clearance - Maximum | — |

| Cutting Edge Thickness | — |

| Hydraulic Penetration Force | — |

| Depth of Spread - Maximum | — |

| Length - Overall | — |

| Width - Flight Face | — |

| Length - Flights | — |

| Spacing of Flights | — |

| Number of Flights | 15 |

| Width - 180° Turn | — |

| Steering Angle - Right | 90° |

| Steering Angle - Left | 90° |

| Hydraulic Output | — |

| Ground-Driven Secondary Steering System | — |

| Fuel Tank | — |

| Crankcase | — |

| Transmission | — |

| Differential | — |

| Final Drive - Each | — |

| Cooling System | — |

| Hydraulic Reservoir | — |

| Total Operating - Empty | — |

| Front Axle | — |

| Rear Axle | — |

| Total Shipping | — |

| Tractor Shipping | — |

| Scraper Shipping | — |

| Total Operating - Loaded | — |

| Front Axle Weight - Loaded | — |

| Rear Axle - Weight - Loaded | — |

| Height - Overall Shipping | — |

| Length - Overall Machine | — |

| Width - Overall Machine | — |

| Height - Top of Cab | — |

| Height - Scraper Blade Maximum | — |

| Width - Tractor | — |

| Width - Inside of Bowl | — |

| Width - Rear Tire Center Lines | — |

| Width - Outside Rear Tires | — |

| Rim Radius | — |

| Front of Tractor to Front Axle | — |

| Wheel Base | — |

| Rear Axle - Rear of Machine | — |

| Ground Clearance - Tractor | — |

| ROPS/FOPS | ISO 3471-1994, SAE J1040-MAY 2003; ISO 3449-2005 |

| Brakes | ISO 3450-1996 |

Benefits & Features

Operator Station

Operator Comfort

- Air conditioning and heat standard

- Hand holds and room to enter and exit freely

- Fully adjustable steering wheel and seat accommodate operator sizes, rotates for easy loading, durable yet soft cloth surface, adjustable seat suspension for hauling

- Arm rests, left foot rest for support and reduced fatigue

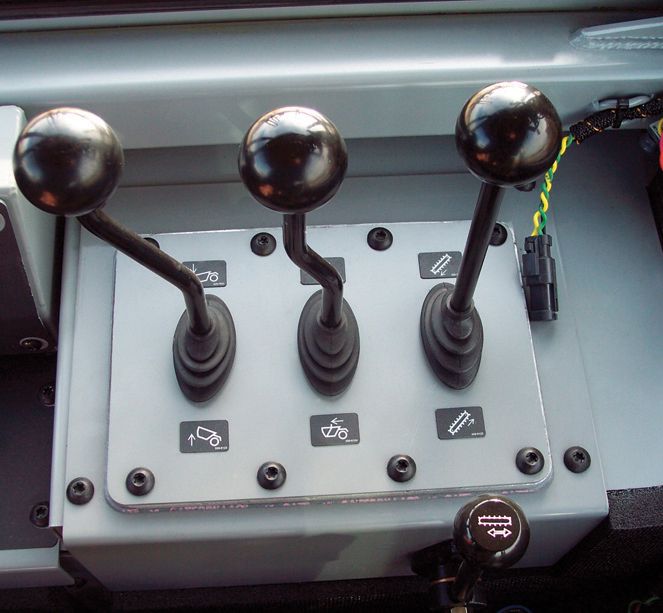

- Ergonomic, low-effort controls with auto-kickouts and detents improve efficiency and speed

- Radio ready

Productivity

- AccuGrade™ ready

- Cab mounted display for accurate material placement

- Excellent visibility to cutting edge facilitates fine grading, with more glass than 613C II

- Rotating seat for viewing the cutting edge and loading

- Fatigue-fighting comfort in the seat, roomy interior

- With all-new hydraulic system, implement and steering controls are quick to respond to operator input

- 76 dB(A) operator sound levels

Safety

- Improved visibility to the work site

- Steering disabled when operator is not in seat and machine speed is zero

- Low cab sound levels reduce fatigue

- Integrated ROPS protects the operator when combined with seat belt use

- Primary and secondary braking systems hydraulically actuated eliminates the air-over-hydraulic system

- Parking brake with 304 mm (12 inch) drum has more slope holding ability

- Front and rear windshield wipers

Instruments

- Simple gauge cluster is easy to read

- Backlit switches are close at hand

- Messaging alerts technicians and operator to service needs

Power Train

Cat C6.6 Engine with ACERT™ Technology

- Net power increase from the C6.6 engine (135 kW/181 hp)

- Electronically controlled for quick load response and emissions control

- Common rail fuel injection facilitates emissions compliance through pilot ignition and control over injection timing and pressures

- 500 hr engine oil and oil filter change intervals

- Easy access fuel filters

- Modular cooling package with swing out cores facilitates maintenance

Torque Converter

- New torque converter, proven in the D6N, increases rimpull by 11% in 2nd gear and shortens load times

- Efficient at delivering power to the ground converting fuel dollars into more dirt moved

- Built tough for constant directional changes typical of track-type tractor applications

Transmission

- Planetary powershift manual transmission

- 6 speeds forward / 1 reverse

- Design proven for the application

Differential Lock

- Foot activated differential lock evenly distributes power, minimizing wheel spin

- Improves traction in slippery underfoot conditions

Hydraulics

Braking

Primary, secondary and tertiary braking is hydraulically controlled without the need for an air system.

Hoses

- All new routings avoid rubs and facilitate service.

- New service port on the bowl side improves access to hoses reducing service time.

Hydraulic Tank

• New tank offers simpler construction, better accessibility, greater capacity, low oil turbulence and aeration with reverse flow filtration for cleaner oil.

Pumps, Motors, Valves

- All new pumps work more efficiently and are sized for performance improvement.

- New elevator pump provides higher flow and turns the elevator at slightly faster speeds.

- New implement valve offers faster response to operator input.

- Steering disable valve engages when machine is in Park, operator is absent from the seat and ground speed is zero. Eliminates unwanted articulation when entering or exiting the cab.

AccuGrade™ Grade Control

Features

- The 613G offers indicate-only AccuGrade system.

- The AccuGrade system is cross slope, single GPS technology.

- AccuGrade allows the operator to manually place or cut dirt exactly where it's called for.

- This system is accurate and efficient, allowing the 613G to work on stake-less job sites.

- For easy mounting of the satellite receiver, the 613G features purpose built platforms and hand-holds assembled and durability tested at the factory.

- These platforms align for safe removal of the GPS (Global Positioning System) receiver when the machine is articulated 90 degrees to the right.

- The system, along with the mast, is purpose built to work with the 613G's cutting edge.

- Each component has been designed and validated to withstand scraper applications and life expectancies.

Electrical

Key Updates

- LED lights offer superior life and reliability on the rear of the scraper.

- HID lighting options available on flood lamps offer 6X the output of conventional halogens.

- Front head lamps feature low and high beam settings with directional lamps for roading.

- An optional air horn gets respect under all job site conditions.

- Polyurethane coated harnesses, found across the hitch, are weather resistant and improve durability.

Serviceability

- Accessibility to filter and fluid sight gauges are either at ground level or have platforms with anti-skid plate.

- Thoughtful hydraulic hose routings reduce wear and improve accessibility.

- Electrical wiring harnesses over the hitch use weather resistant polyurethane jacketing.

- Smaller harness sections are easy to replace and resist pinching and stretching.

- Cab tilts for access to left side of the engine.

- Fuse and breaker box located in the cab for easy access.

- Recessed battery reduces the opportunity for damage.

- Electric priming located on primary fuel filter.

- Grease point for elevator pivot joint located outside the bowl at ground level.

- New elevator rollers include grease fittings for longer life.

- New, clean fuel tank design reduces fuel contamination risk.

- Fold out radiator cores make cleaning fast and simple.

- Fault code messaging through the Electronic Monitoring Center simplify service.

Data not available.

Standard Equipment

- Bowl

- 8 m³ / 11 yd³ heaped

- Elevator

- Backup alarm

- AccuGrade ready option weldments

- Electrical

- Alternator, 80 ampere

- Electrical system, 24 volt

- Batteries (2), 70 ampere hr.

- Lighting system

- AccuGrade ready option wiring

- Starting/charging receptacle

- Operator Environment

- Tractor

- Powertrain

- Tractor

- Scraper

- Other Standard Equipment

- Tractor

- Scraper

- Tires, Rims, & Wheels

- Antifreeze

Optional Equipment

- Ground Engaging Tools

- Teeth, GET, Long set of 4

- Antifreeze, -50°C (-58°F)

- NOTE: Standard machine is protected with Extended Life Coolant to -36°C (-33°F)

- Packing

- Domestic Packing

- Export Packing

- Additional Packing

- Note

- Custom Product Ordering Instructions

- Electrical

- Lights, 5x5 flood, Work Lamps

- Other Attachments

- Tractor

- Scraper

- AccuGrade