Overview

Engineered for reliable production in the toughest conditions. The 587T's high horsepower and rugged components are designed for tough and varied working conditions. This machine offers the reliability and durability expected from Cat Pipelayers.

Specifications

| Engine Model | C15 |

| Flywheel Power | — |

| Lift Capacity | — |

Benefits & Features

Specifications

| Engine Model | C15 |

| Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Operating Weight | — |

| Lift Capacity | — |

| Shipping Height | — |

| Shipping Width | — |

| Length | — |

Benefits & Features

Pipelayer

Winches

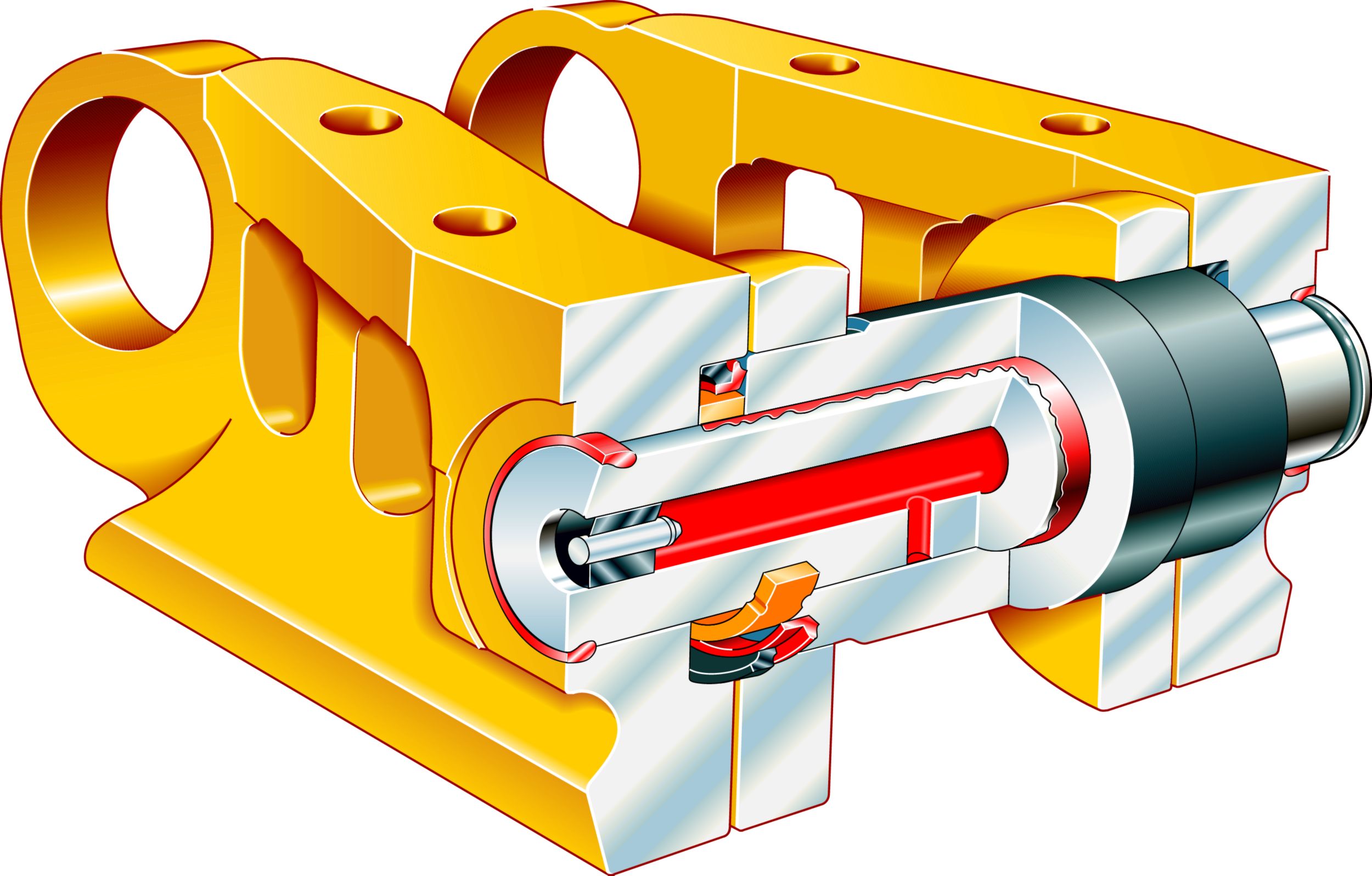

- Boom and hook drawworks are driven by independent hydraulic winches.

- Oil-disc brakes provide smooth operation, positive retention of boom and hook positions.

- Modular design allows fast replacement, easy field service and testing.

- High parts interchangeability between hook and boom winch assemblies.

- Infinitely variable speed controls for both boom and hook allow precise control.

Counterweight

- Counterweight is extended hydraulically for improved load balance and clearance.

- Counterweight segments are contoured to provide a low center of gravity and enhanced forward and right side viewing area. Segments are splined to the counterweight assembly for ease of assembly and disassembly.

Drawbar

• Able to tow wide range of attachments.

Boom

- 8.5 m (28 ft) Boom is standard equipment with large box section.

- Replaceable, boom-mount bearings.

- High tensile strength steel construction.

- Allows for smaller sections for improved visibility.

- Lighter weight for increased payload.

- Durable for long life.

Blocks and Hook

- Heavy-duty lifting components include the following:

- Hook and boom blocks with sealed roller bearings.

- Forged hook with latch and serviceable handle.

- Ductile iron sheaves.

- High performance cable for improved life, crush resistance, flexibility and strength.

Structure

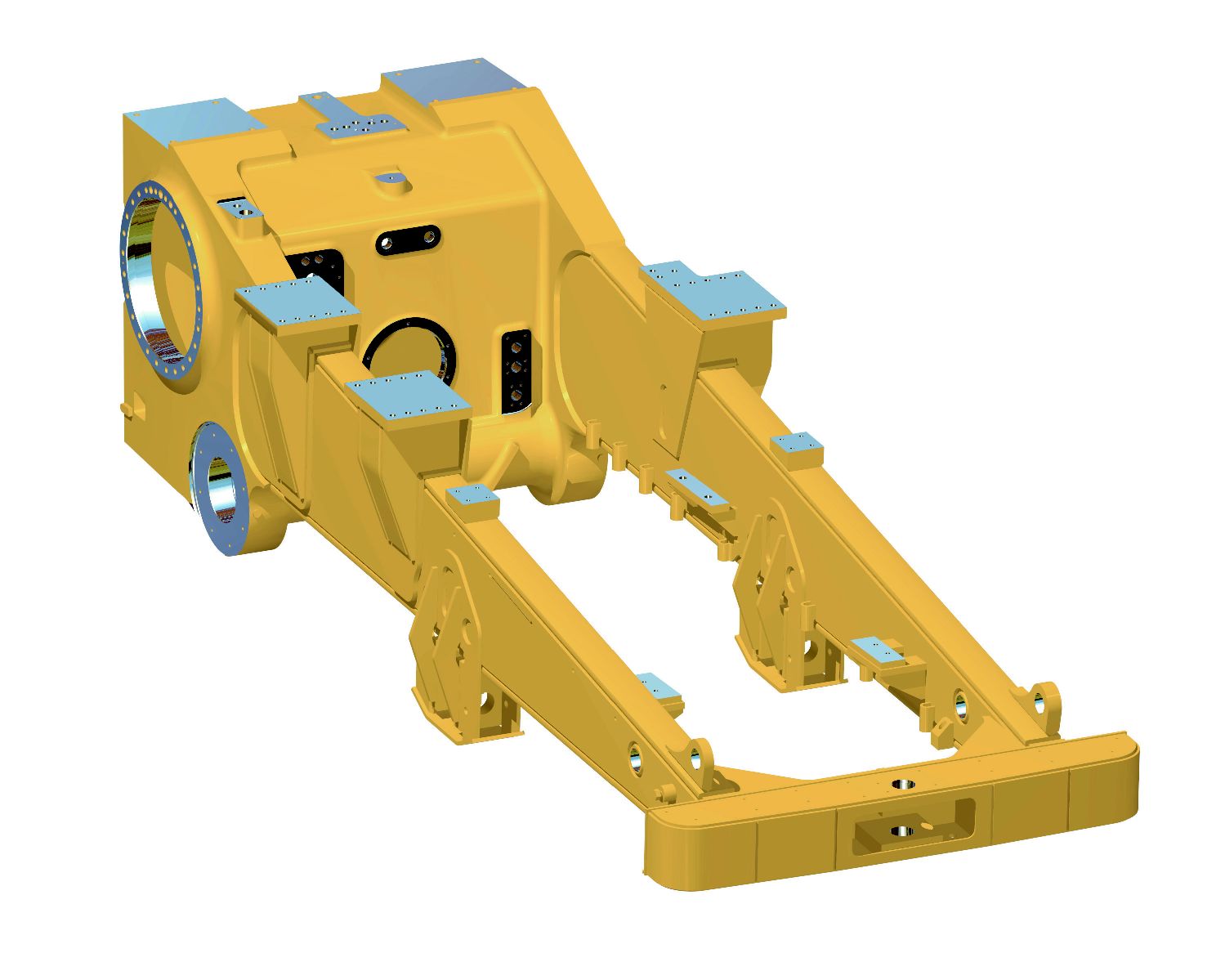

Mainframe Strength

The 587T mainframe is built to absorb high impact shock loads and twisting forces.

Front Bumper

A front bumper is mounted to the frame rails and provides both protection and a towing device. Pipelayer frame mounts are also an integral part of the frame.

Optional Roll Over Protective Structure

Provides increased operator protection. • Available with or without cab.

Operator Station

Seat

Ergonomically designed and fully adjustable for maximum comfort. The seat cushion reduces the pressure on the lower back and thighs while allowing unrestricted arm and leg movement.

Clear Full-Circle View

A tapered hood and “notched” fuel tank give the operator a clear line of sight to the front, rear and side work areas. The new streamlined design of the Caterpillar 587T Pipelayer offers several operator visibility improvements for more precise maneuvering and placement of pipe.

Finger Tip Control (FTC)

Finger tip controls are clustered to the operator's left for easy one-handed operation, controlling steering, direction and gear selection.

Access Ladder

Direct access to the operator's station utilizing ladder on left side of the machine.

Monitoring System

Provides the operator instant feedback on the condition of operating systems and records such performance data as high/low gauge readings to help diagnose problems and manage undercarriage. Has gauges that monitor the temperature of the engine coolant, hydraulic oil and power train oil, plus the fuel level. Also has a digital and gauge type tachometer.

Ergonomic Work Tool Controls

Pipelayer controls are low effort and allow simultaneous, precise positioning of the hook and boom with one hand.

Variable Load Line Speed Range

Allows the operator to regulate line speed.

Power Supply

The voltage converter provides two 12-volt power supplies.

Counterweight Control

Adjusts the position of the counterweight for added machine stability.

Engine Speed Control

A rocker switch and decelerator pedal control engine speed. Idle can be set to desired level. High or low idle is delivered with a touch of the finger.

Optional Enclosed Cab

Optional Enclosed Cab

Designed for operator comfort and productivity in any climate. Fully insulated with a heater. Air conditioning and roll over protection structure available as additional options.

Excellent Visibility

The optional cab provides excellent visibility, designed with the maximum glass area. There is also an additional option of dual pane windows available for cold weather environments.

Skylight Window

The cab is equipped with a skylight window to view the boom and upper block.

Screened Side Windows

The side windows are screened to allow better ventilation and ground communication.

Wipers

The optional cab is equipped with wipers on the front, rear and door windows to provide a clearer view during inclement weather.

Lights

Eight additional halogen lights come with the cab arrangement, 3 facing forward, 2 to the rear, 2 to the boom side and 1 to the winch side.

Electronic Steering and Transmission Controls

Finger Tip Control (FTC)

Finger tip controls are clustered to the operator's left for easy one-handed operation, controlling steering, direction and gear selection.

Drive Train

Torque Divider

A high efficiency torque divider with freewheel stator provides high torque multiplication while shielding the drive train from sudden torque shocks and vibration.

Elevated Final Drives

- Isolated from ground and equipment induced impact loads for extended power train life.

- Crown-shaved drive gears provide smooth, quiet, low maintenance operation.

- Splash lubrication and Duo-Cone™ Seals extend service life.

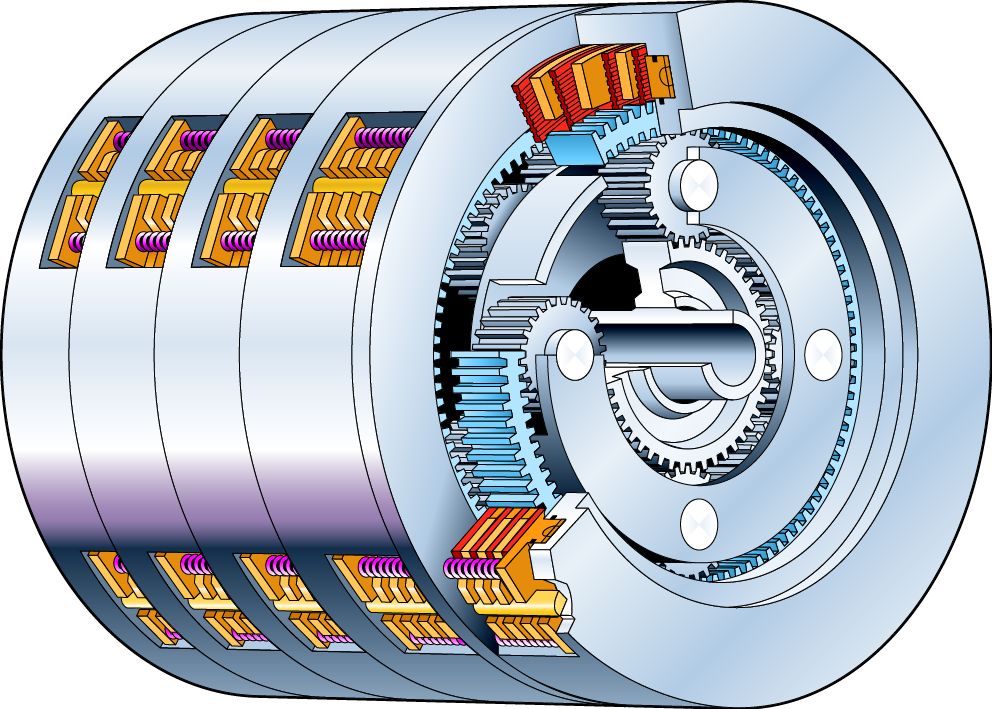

Planetary Power Shift Transmission

- Three speeds forward and three speeds reverse, utilizing large diameter, high capacity, oil-cooled clutches.

- Modulation system permits fast speed and direction changes.

- Modular transmission and differential slide into rear case for servicing ease.

- Oil-to-water cooler for maximum cooling capacity.

- Forced oil flow lubricates and cools clutch packs to provide maximum clutch life.

Electronic Clutch Pressure Control

The Finger Tip Control (FTC) system has an additional drive train feature for added performance, Electronic Clutch Pressure Control (ECPC). This feature provides smoother shifting by modulating individual clutches. ECPC also provides the auto-shift and auto-kickdown feature.

Steering Clutch and Brake

Fade resistant and adjustment free. The multi-disc, oil-cooled steering clutches are hydraulically applied and electronically controlled. The brakes are applied by springs and hydraulically released for safe and reliable braking performance.

Drawbar Pull vs. Ground Speed

As loads on the tractor increase, the 587T offers unmatched lugging capability and smooth shifting as the need occurs to change gears under varying loads. The 3-speed forward, 3-speed reverse transmission offers excellent runout speeds.

Modular Power Train

The modular power train design permits quick removal and installation of major components such as the engine, transmission and final drives.

Power Train

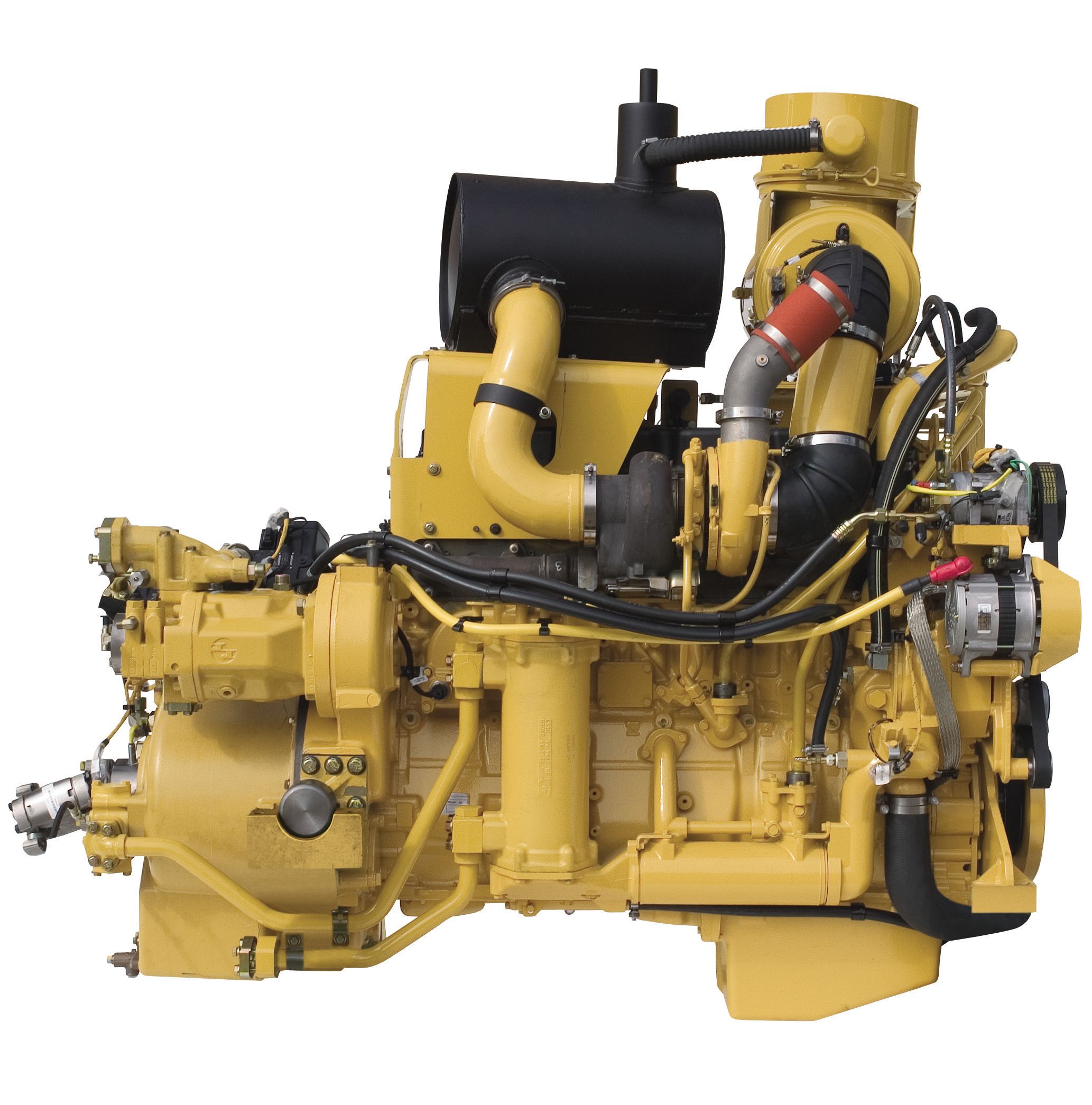

Engine

The Cat C15 engine with ACERT™ Technology provides the power for the 587T. Performing at full-rated net power of 273 kW (366 hp) at 1,800 rpm, the large displacement and high torque rise provides the 587T the power needed on challenging jobs. Matched to the high-efficiency torque divider and electronically controlled power shift transmission, it will provide years of dependable service.

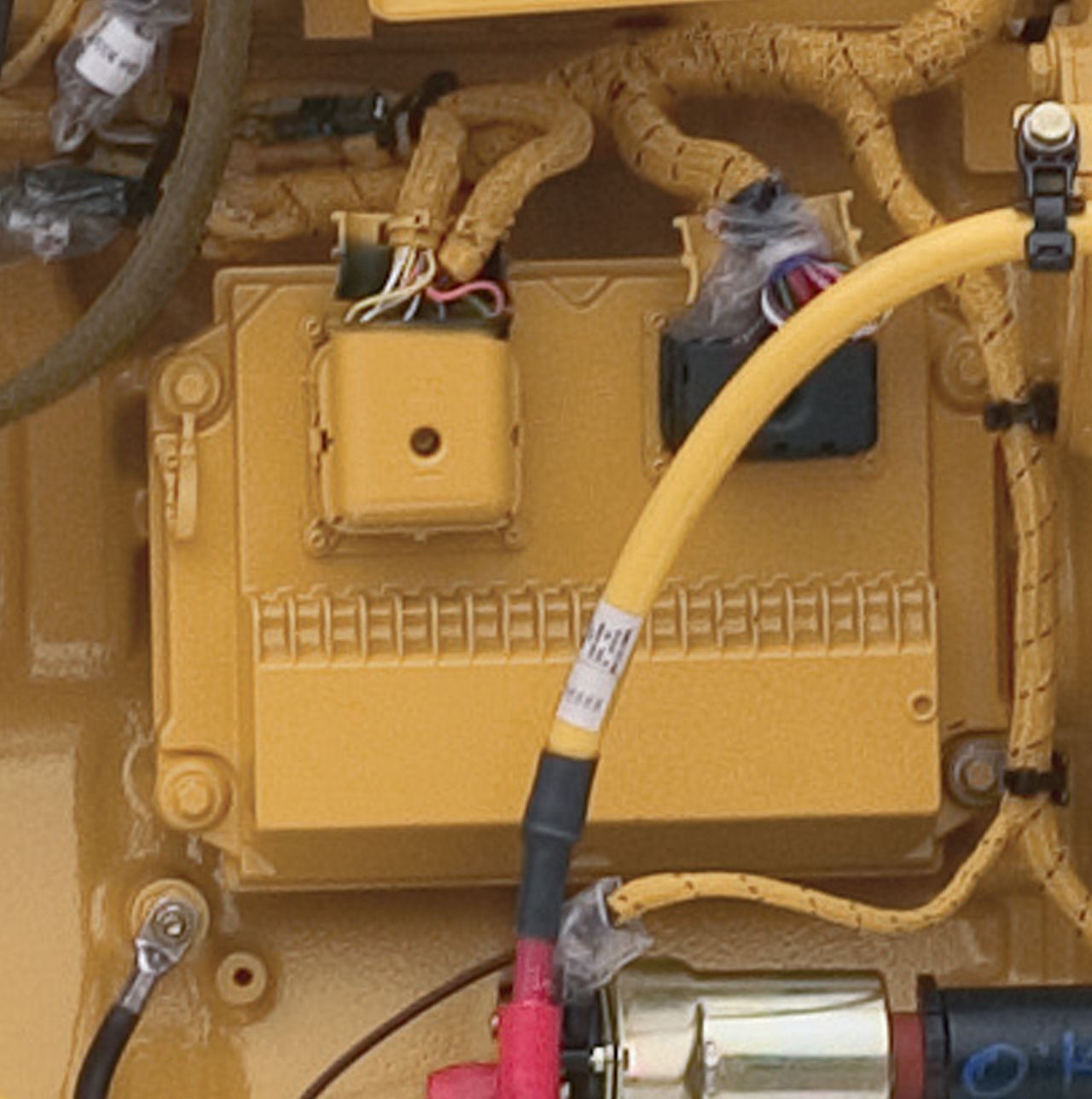

ADEM™ A4 Engine Controller

The ADEM A4 electronic control module manages fuel delivery to get the best performance per liter (gallon) of fuel used. It provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs. It tracks engine and machine conditions while keeping the engine operating at peak efficiency.

Fuel Delivery

Multiple injection fuel delivery involves a high degree of precision. Precisely shaping the combustion cycle lowers combustion chamber temperatures generating fewer emissions and optimizing fuel combustion; translating into more work output for your fuel cost.

MEUI Fuel System

A highly evolved fuel system with a proven record of reliability in the field. MEUI combines the technical advancement of an electronic control system with the simplicity of direct mechanically controlled unit fuel injection. The MEUI system excels in its ability to control injection pressure over the entire engine operating speed range. These features allow the C15 to have complete control over injection timing, duration, and pressure.

ATAAC and Turbocharging

Air-to-air aftercooling keeps air intake temperatures down and, in concert with the tight tolerance combustion chamber components, maximizes fuel efficiency and minimizes emissions. Significant improvements in air flow are generated by a water-cooled turbocharger, unique cross-flow head and single overhead cam.

Service

Easier maintenance and repair through monitoring key functions and logging critical indicators. Electronic diagnostic access is possible with a single tool, the Cat Electronic Technician.

Undercarriage

Final Drives

Final drives and associated power train components are raised above the work area, isolating them from ground induced impact loads, as well as pipelayer loads, extending power train component life.

Sprockets

Sprocket position keeps sprocket teeth, bushings and final drives away from the abrasive materials and moisture, resulting in longer final drive gear and seal life.

Rollers and Idlers

Feature symmetric Duo-Cone™ seals for long sealing life to prevent oil loss and dirt entry. Toric rings maintain performance over a wide range of temperatures. Rollers and idlers are serviceable and rebuildable to provide value.

Roller Frames

Roller frames are tubular to resist bending and twisting, with added reinforcement where operating loads are highest. • The recoil system is sealed and lubricated.

Sprocket Segments

Made exclusively of Caterpillar Tough Steel™ for longer wear life and precision machined after heat treat for proper fit. Segments can be removed or replaced without breaking the track.

Positive Pin Retention (PPR) Sealed and Lubricated Track

Designed for high-impact and high load applications. The PPR exclusive Caterpillar design locks the link to the pin.

Track Shoes

Track shoes are 864 mm (34 in) single grouser design and made from heat treated, rolled steel for added strength. Wide track and clipped shoes are available as an option to match working conditions. Long track frame and wide gauge enhance track contact area, providing a stable working base.

Serviceability and Customer Support

Serviceability

Minimizes maintenance and repair downtime. New sight gauges, filter locations, improved access to oil and coolant sampling ports, and an engine compartment mounted work lamp, make daily and periodic service faster and easier.

Engine Oil FIlter

Engine oil filter is located on the engine for easy servicing access and minimal downtime. Save further time with the optional quick oil change attachments.

Water Separator and Fuel Filter

Easily located just inside the engine access panel, the water separator functions as the primary fuel filter, just ahead of the secondary fuel filter.

Quick Disconnect Fittings

Allow for fast diagnosis of the power train, hydraulics and attachment oil systems.

S•O•SSM Analysis

Scheduled Oil Sampling made easier through live sampling ports for the engine oil, hydraulics and coolant.

Caterpillar Product Link PL300 (optional)

This option allows the customer or dealer to obtain machine diagnostics and location information from their offices. Product Link PL300 provides updates on service meter hours, machine condition and machine location, as well as integrated mapping/route planning. Built-in flexibility allows for future technology development.

Purchase

Consider the financing options available, as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Product Support

Plan for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time you purchase your machine. Programs such as Custom Track Service (CTS), S•O•S analysis, Technical Analysis and guaranteed maintenance contracts give peak life and performance to your machine.

Parts Program

You will find nearly all parts at your dealer parts counter. Cat Dealers use a worldwide computer network to find in-stock parts to minimize machine downtime. Ask about your Cat Dealer's exchange program for major components. This can shorten repair time and lower costs.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, Back up

- Alternator, 95-amp

- Batteries, 4, maintenance free

- Converter, 12V, 10 amp with 1 outlet

- Diagnostic connector (starting and charging system)

- Horn, forward warning

- Lighting system

- Starting receptacle

- OPERATOR ENVIRONMENT

- Armrest, adjustable

- Deactivation switch, hydraulic controls

- Pedal, Decelerator

- Pedal, Brake

- Horn

- Hour meter

- Gauge package:

- Governor switch, electronic

- Key start, single

- Monitoring System, Electronic warning

- Seat, vinyl suspension

- Seat belt, retractable

- Service indicator, air cleaner

- Steering system, Electronic Fingertip Control

- Storage compartment

- PIPELAYING EQUIPMENT

- Block and Hook, heavy duty with roller bearings

- Boom, 8.5 m (28 ft)

- Counter weight, extendible segmented 12 900 kg (28,440 lb)

- Drawworks, hydraulically actuated and controlled

- Hook latch

- POWER TRAIN

- Advanced Modular Cooling System (AMOCS)

- Aftercooler, air to air (ATAAC)

- Engine, C15 with ACERT™ Technology

- Coolant, extended life with protection to -37° C (-34° F)

- Filter, air with electronic service indicator

- Electric starting, 24 volt direct

- Fan, hydraulically driven

- Final drives, four planet, double-reduction planetary

- Fuel priming pump

- Muffler

- Parking brake, electronic

- Precleaner with dust ejector

- Prescreener

- Shift management, automatic directional/downshift

- Ether starting aid

- Torque divider

- Transmission, electronically-controlled powershift, 3F/3R

- Transmission control module, electronic

- Turbocharger, wastegate

- Water separator

- UNDERCARRIAGE

- Carrier roller

- Undercarriage, non-suspended with 9-roller, tubular track roller frame

- Lifetime Lubricated rollers and idlers

- Sprocket, segmented

- Track:

- OTHER STANDARD EQUIPMENT

- Front bumper with towing device

- Drawbar, rigid heavy duty

- Ecology drains

- Diagnostic pressure taps

- Guards:

- Hydraulics, pilot operated pipelayer system

- Parts book, CD rom

- Oil cooler, hydraulic

- Product link ready

- Vandalism protection for fluid compartments

- Equalizer bar, pinned

- Steering, electronic clutch brake

- Hood, solid

- Hydraulic Pumps, work tool

- SOSSM Sampling Ports

Optional Equipment

- ELECTRICAL

- Alternator, 150 amp

- Batteries, heavy duty

- OPERATOR ENVIRONMENT

- Air conditioning

- Cab (includes)

- Dual pane windows

- Pedals, dual brake

- PIPELAYING EQUIPMENT

- Protection pads, boom and load

- POWER TRAIN

- Enclosures, arctic engine

- Fan, auto reversible

- Fast Fuel System

- Starting, low temperature

- Heater, engine coolant

- Heater, diesel fuel

- Oil change system, quick

- Prelube, engine, automatic

- Coolant, Extended Life -50° C (-58° F)

- OTHER OPTIONAL EQUIPMENT

- Cold weather arrangement

- Guards:

- Tool kit (dealer installed)

- ROPS, roll over protection system

- Product link, PL300

- Vandalism Protection

- Parts Book, paper