Overview

The 24M delivers multiple technological breakthroughs to give you the best return on your investment.

Specifications

| Blade Width | — |

| Engine Model | Cat® C18 ACERT™ |

| Gross Vehicle Weight - Maximum - Front Axle | — |

Benefits & Features

Specifications

| Engine Model | Cat® C18 ACERT™ |

| Bore | — |

| Stroke | — |

| Speed at Rated Power | 1800 RPM |

| Maximum Torque | — |

| Base Power (All Gears) - Net | — |

| Displacement | — |

| Number of Cylinders | 6 |

| Derating Altitude | — |

| Standard - Fan Speed - Maximum | 1300 RPM |

| Standard - Fan Speed - Minimum | 60 RPM |

| Standard - Ambient Capability | — |

| Forward/Reverse Gears | 6 Fwd / 3 Rev |

| Transmission | Automatic, electronic power shift |

| Brakes - Service | Oil-actuated, oil-disc |

| Brakes - Service - Surface Area | — |

| Brakes - Parking | Spring applied, hydraulically released |

| Brakes - Secondary | Oil-actuated, oil-disc |

| Circuit Type | Electro-hydraulic load sensing, closed center |

| Pump Type | Variable piston |

| Pump Output | — |

| Maximum System Pressure | — |

| Standby Pressure | — |

| Top Speed - Forward | — |

| Top Speed - Reverse | — |

| Turning Radius - Outside Front Tires | — |

| Steering Range - Left/Right | 47.5° |

| Articulation Angle - Left/Right | 25° |

| Forward - 1st | — |

| Forward - 2nd | — |

| Forward - 3rd | — |

| Forward - 4th | — |

| Forward - 5th | — |

| Forward - 6th | — |

| Reverse - 1st | — |

| Reverse - 2nd | — |

| Reverse - 3rd | — |

| Fuel Capacity | — |

| Cooling System | — |

| Hydraulic System - Total | — |

| Hydraulic System - Tank | — |

| Engine Oil | — |

| Transmission - Differential - Final Drives | — |

| Tandem Housing - Each | — |

| Front Wheel Spindle Bearing Housing | — |

| Circle Drive Housing | — |

| Circle - Diameter | — |

| Circle - Blade Beam Thickness | — |

| Drawbar - Height | — |

| Drawbar - Thickness | — |

| Front-Top/Bottom Plate - Width | — |

| Front-Top/Bottom Plate - Thickness | — |

| Front-Side Plates - Width | — |

| Front-Side Plates - Thickness | — |

| Front Axle - Wheel Lean - Left/Right | 18° |

| Front Axle - Total Oscillation per Side | 32° |

| Height | — |

| Width | — |

| Sidewall Thickness - Inner | — |

| Sidewall Thickness - Outer | — |

| Drive Chain Pitch | — |

| Wheel Axle Spacing | — |

| Tandem Oscillation - Front Up | 20° |

| Tandem Oscillation - Front Down | 20° |

| Blade Width | — |

| Moldboard - Height | — |

| Moldboard - Thickness | — |

| Arc Radius | — |

| Throat Clearance | — |

| Cutting Edge Width | — |

| Cutting Edge Thickness | — |

| End Bit - Width | — |

| End Bit - Thickness | — |

| Circle Centershift - Right | — |

| Circle Centershift - Left | — |

| Moldboard Sideshift - Right | — |

| Moldboard Sideshift - Left | — |

| Maximum Blade Position Angle | 35° |

| Blade Tip Range - Forward | 40° |

| Blade Tip Range - Backward | 0° |

| Maximum Shoulder Reach Outside of Tires - Right | — |

| Maximum Shoulder Reach Outside of Tires - Left | — |

| Maximum Lift Above Ground | — |

| Maximum Depth of Cut | — |

| Ripping Depth - Maximum | — |

| Ripper Shank Holders | 7 |

| Shank Holder Spacing - Minimum | — |

| Shank Holder Spacing - Maximum | — |

| Penetration Force | — |

| Pry-Out Force | — |

| Gross Vehicle Weight - Maximum - Front Axle | — |

| Gross Vehicle Weight - Maximum - Rear Axle | — |

| Gross Vehicle Weight - Base - Front Axle | — |

| Gross Vehicle Weight - Base - Rear Axle | — |

| Gross Vehicle Weight - Maximum - Total | — |

| Gross Vehicle Weight - Base - Total | — |

| Height - Top of Cab | — |

| Length - Counterweight to Ripper | — |

| Width - Outside Front Tires | — |

| Length - Front Axle to Mid Tandem | — |

| Length - Front Tire to Rear of Machine | — |

| Length - Front Axle to Moldboard | — |

| Length - Between Tandem Axles | — |

| Width - Outside Rear Tires | — |

| Width - Tire Center Lines | — |

| Height - Front Axle Center | — |

| Height - Exhaust Stack | — |

| Height - Top of Cylinders | — |

| Ground Clearance - Rear Axle | — |

Benefits & Features

Operator Station

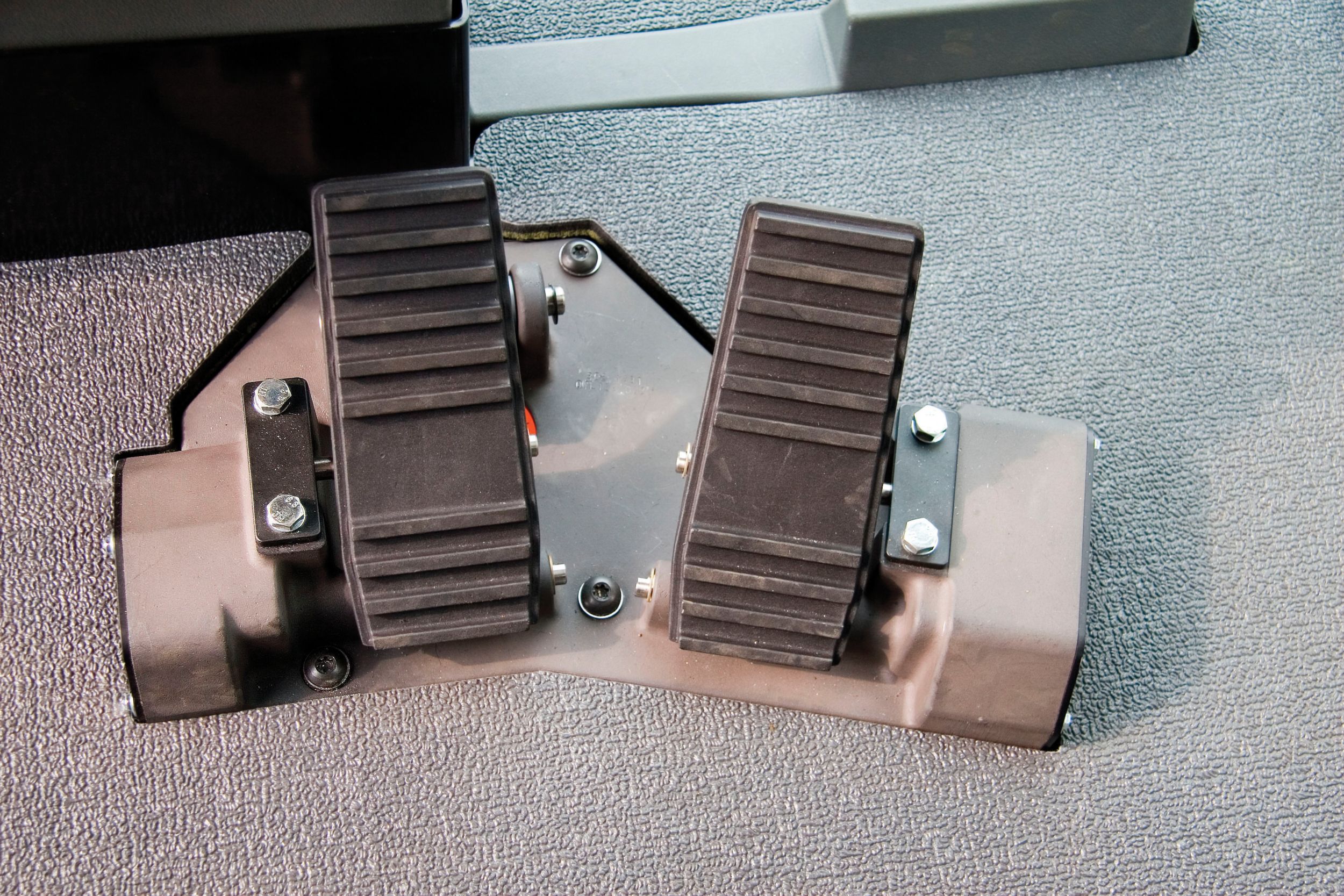

Advanced Joystick Controls

Two electro-hydraulic joysticks reduce hand and wrist movement as much as 78% compared to conventional lever controls for greatly enhanced operator efficiency. The intuitive pattern is easy to learn, and provides the precise implement control you expect from Caterpillar.

Ripper Control

The ripper control is ergonomically positioned to allow simple, comfortable operation.

Visibility

The exceptional forward view is made possible by a unique raised cab design and a one-piece front window, improving operator confidence and productivity. The large side windows offer a clear view of the moldboard heel and tandem tires. A wide rear window provides good visibility behind the machine. Glare reducing paint on the front frame, lift arms and rear enclosure help reduce glare, resulting in safer operation at night.

In-Dash Instrument Cluster

The instrument panel, with easy-to-read, high-visibility gauges and warning lamps, keeps the operator aware of critical system information.

Controls and Switches

Reliable, long-life rocker switches are located on the right side cab post and front instrument cluster, within easy reach for the operator. Controls and switches are backlit for increased safety during night time operations.

Cat Messenger

Cat Messenger provides real-time machine performance and diagnostic data. The operator can quickly view critical performance and operating information, in multiple languages, helping to maximize the life and productivity of the machine.

Low Interior Sound and Vibration Levels

Isolation mounts for the cab, engine and transmission significantly reduce sound and vibration. The quiet interior with low vibration levels provide a comfortable work environment.

Cat Comfort Series Seat

The Cat Comfort Series air suspension seat has an ergonomic high-back design, with extra thick contoured cushions and infinitely adjustable lumbar support that evenly distributes the operator's weight. Multiple seat controls and armrests are easy to adjust for optimal support and comfort all day.

Comfort and Convenience

Caterpillar has built the most comfortable cab in the industry by replacing the control levers and steering wheel with two joystick controls. Extra leg and foot room create a spacious, open cab. Multiple adjustment capabilities for the arm rest, wrist rest and joystick pods help keep the operator comfortable throughout a long shift.

Modular HVAC System

HVAC Precleaner

Additional Cab Features

Additional cab features include cup holder, lighter, ashtray, coat hook, storage area, night time light and power port. Optional rear view camera, 25-amp power converter and satellite radio are also available.

Steering and Implement Controls

Ease of Operation

The revolutionary joystick controls make the 24M easier to operate without sacrificing control. The intuitive joystick control pattern allows both new and experienced operators to become productive quickly. Logical grouping of hydraulic functions in the joysticks allow any operator to easily control several functions at the same time. This allows the operator to be more productive and remain comfortable throughout the work shift.

Electronic Throttle Control

Electronic Throttle Control (ETC) provides the operator with easy, precise, and consistent throttle operation. An automatic and manual mode on a single switch offers flexibility for different applications and operator preference.

Ripper Control Pod

An infinitely variable roller switch controls the rear ripper for easy and comfortable control.

Articulation Return-to-Center

This exclusive feature automatically returns the machine to a straight frame position from any articulation angle with the touch of a single button. Return-to-Center helps improve productivity and safety by allowing the operator to focus on controlling the moldboard.

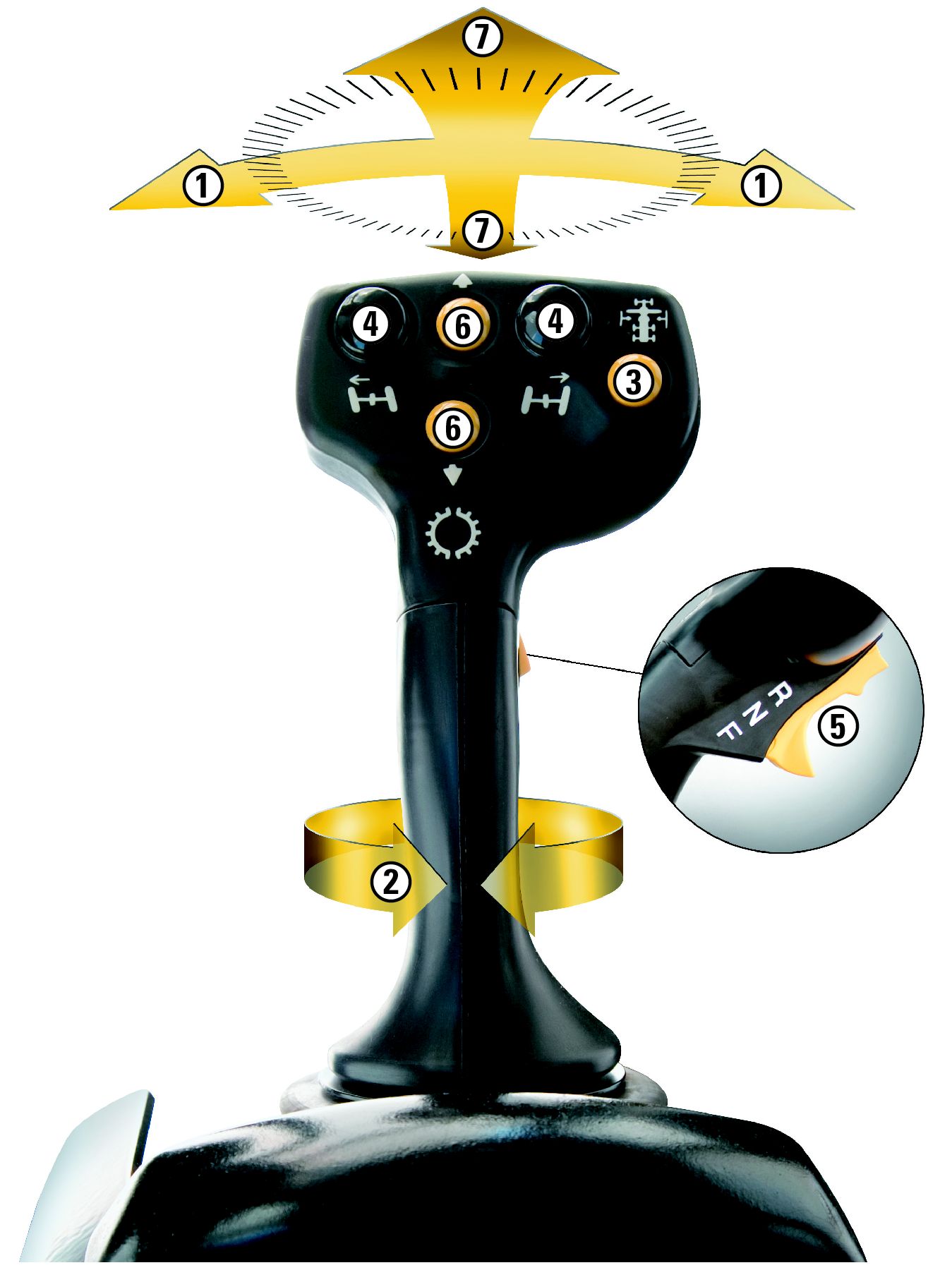

Left Joystick Functions

The left joystick primarily controls the machine direction and speed. 1 - Steering: Lean joystick left and right 2 - Articulation: Twist joystick left and right 3 - Articulation Return to Center: Yellow thumb button 4 - Wheel Lean: Two black thumb buttons 5 - Direction: Index trigger shifts transmission to forward, neutral or reverse 6 - Gear Selection: Two yellow thumb buttons upshift and downshift 7 - Left moldboard lift cylinder: Push joystick to lower, pull joystick to raise Left moldboard lift cylinder float: Pushing joystick through detent engages float

Right Joystick Functions

The right joystick primarily controls the Drawbar, Circle and Moldboard functions. 1 - Right moldboard lift cylinder: Push joystick to lower, pull joystick to raise Right moldboard lift cylinder float: Pushing joystick through detent engages float 2 - Moldboard slide: Lean joystick left and right 3 - Circle turn: Twist joystick left and right 4 - Moldboard tip: Thumb switch fore and aft 5 - Drawbar center shift: Thumb switch left and right 6 - Electronic Throttle Control: Top trigger button is resume and decrement 7 - Differential Lock/Unlock: Bottom trigger button

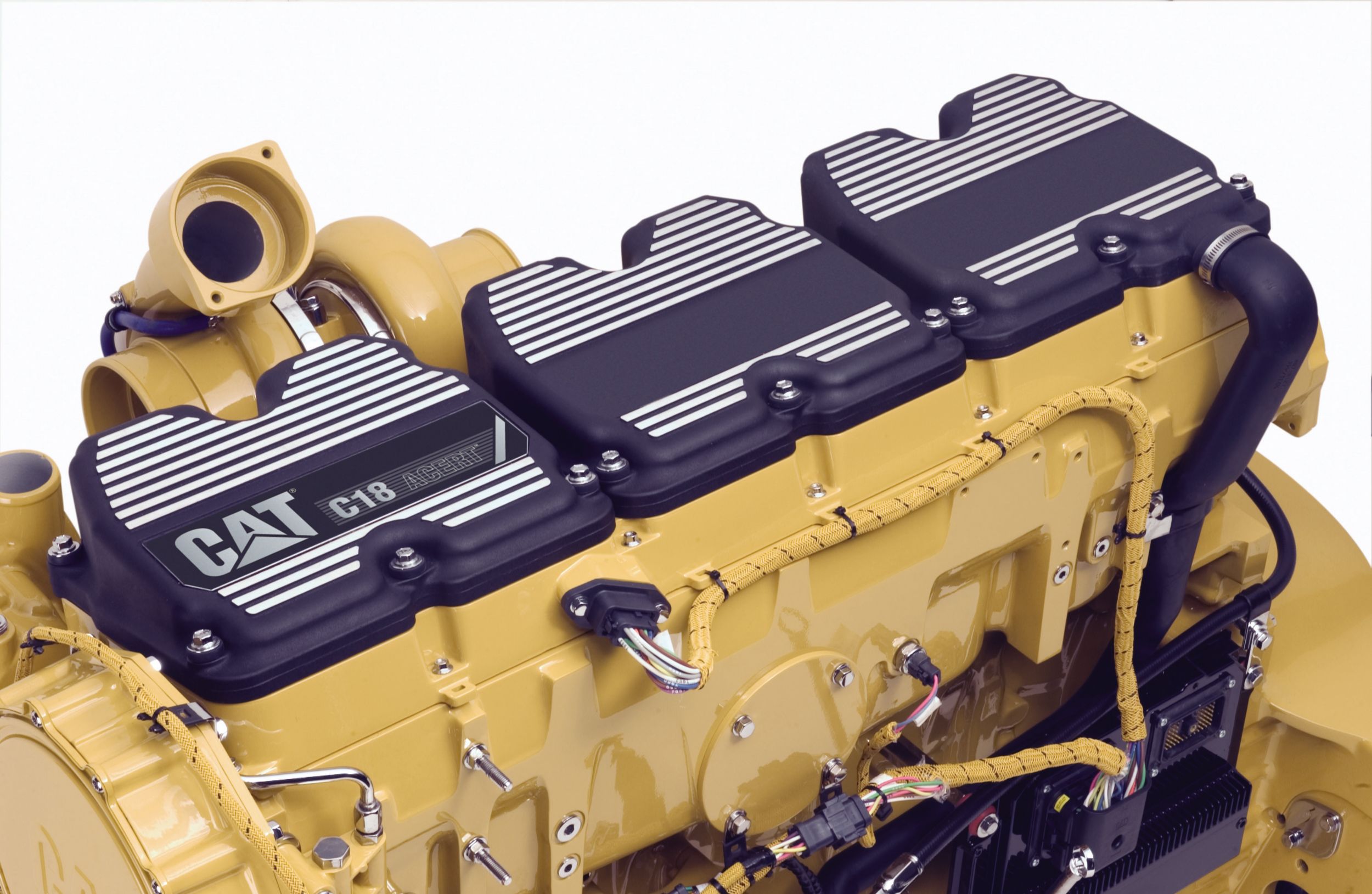

Engine

ACERT™ Technology

ACERT™ Technology allows Cat engines to supply more power per unit of displacement without causing premature wear. This breakthrough technology reduces emissions during the combustion process by using advanced technology in the air and fuel systems, in conjunction with integrated electronics. ACERT Technology enhances overall engine performance while dramatically reducing exhaust emissions.

Superior Lugging Performance

The Cat C18 engine meets specific performance requirements for 24M applications. Its superior torque and lugging capability can pull through sudden, short-term increases in loads, maintaining consistent, desirable grading speeds to get the work done faster without downshifting.

Exhaust Emissions Compliant

The Cat C18 with ACERT Technology meets or exceeds all U.S. EPA Tier 3 and European Union Stage IIIa emissions control standards.

Hydraulic Demand Fan

The hydraulic demand fan automatically adjusts cooling fan speed according to engine cooling requirements. This system reduces demands on the engine, putting more horsepower to the ground and improving fuel efficiency.

Compression Brake

The optional three phase compression brake enables higher travel speeds downhill, while reducing wear on brake components. This improves overall productivity and lowers maintenance costs.

Ether Starting Aid

This standard feature helps cold-weather startups in extreme temperatures. The system monitors engine coolant temperature to prevent ether from being injected into a hot engine.

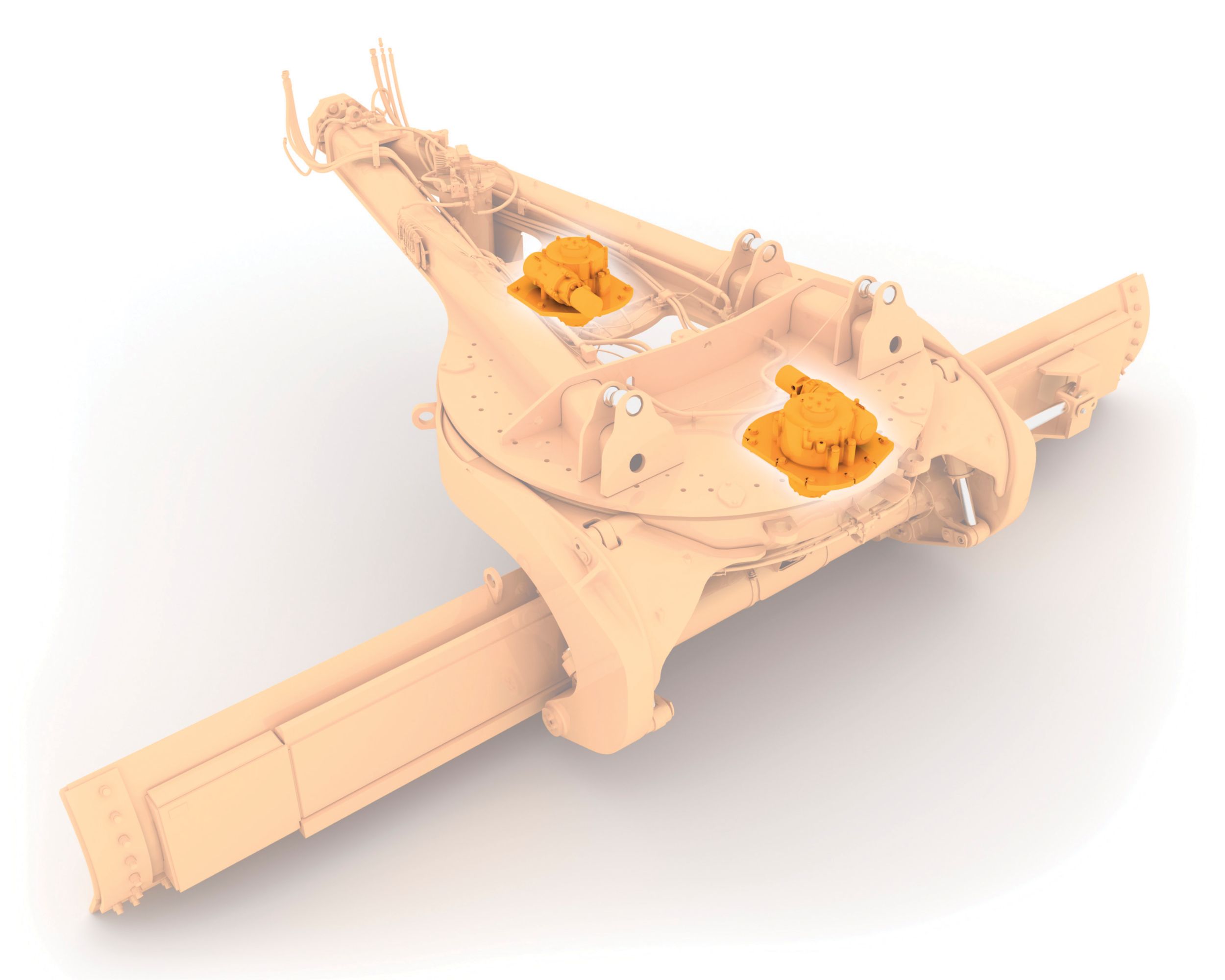

Structures, Drawbar, Circle and Moldboard

Front Frame Structure

Continuous top and bottom plate construction provides consistency and strength. The flanged box section design removes welds from high stress areas, improving reliability and durability.

Rear Frame Structure

Two steel plates running the full length of the rear frame are integrated with the box section hitch. This helps resist torsion loads and ensure structural durability. The integrated steel tube unifies the rear frame and supports the engine, while helping the frame withstand heavy-duty applications.

Articulation Hitch

A large tapered roller bearing at the lower pivot carries loads evenly and smoothly. A mechanical locking pin prevents frame articulation to ensure safety when servicing or transporting the machine.

Drawbar Construction

The A-frame drawbar features a box-section design for high strength and optimum durability.

Circle Construction

A one piece forged steel circle is built to stand up to high stress loads and provide structural durability. Six bolt-on tooth segments can be individually replaced and serviced for reduced downtime and cost.

Replaceable Wear Inserts

Tough, durable wear inserts reduce rotational friction for maximum circle torque and longer component life. They are located between the drawbar and circle, and between the support shoes and circle. High load-resistant brass wearstrips are placed between the blade mounting group and moldboard. This sacrificial wear system can be replaced easily and helps keep components tight for fine grading.

Adjustable Rear Circle Drive

An adjustable rear circle drive makes serviceability easier and faster, and also reduces component wear by keeping components tight.

Yoke Plate

Full-length yoke plate gives strength, support and protection to the circle.

Aggressive Blade Angle

With a long wheelbase the operator can obtain aggressive moldboard angles, so material rolls more freely along the length of the blade. This is particularly helpful when handling very dry materials or cohesive soils. Better material control gets the job done faster, requires less power and saves fuel.

Moldboard

The optimal curvature and large throat clearance help move material quickly and efficiently. Heat-treated moldboard rails, hardened cutting edges and end bits, and large diameter bolts assure reliability and longer service life.

Push Plate/Counterweight

A front mounted push plate/counterweight can be added on the 24M.

Ripper

The 24M standard ripper is made to penetrate tough material fast and rip thoroughly for easier material movement with the moldboard. The ripper includes three shanks with the ability to add four more if needed.

Power Train

Smooth Shifting Transmission

The 24M combines several key innovations to ensure smooth, powerful shifts throughout the gear range.

Electronically Controlled Shifting

The full Electronic Clutch Pressure Control (ECPC) system smooths shifting between all gears and directional changes. This provides outstanding control and also extends the life of the transmission by reducing stress on gears.

Lockup Clutch Torque Converter

Permits the machine to operate in direct drive for more efficient operation at higher torque converter output speeds.

Engine Over-Speed Protection

Helps protect the transmission and extend component life by preventing downshifting until a safe travel speed has been established.

Programmable Autoshift

The operator can easily customize various shift parameters through Cat Messenger to match the specific application requirement. This standard feature automatically shifts the transmission at optimal points so the operator can focus on the work, improving safety, productivity and ease of operation.

Modular Rear Axle

The 24M incorporates a bolt-on modular rear axle design, which offers easy access to differential components, improves serviceability and contamination control, and lowers operating costs.

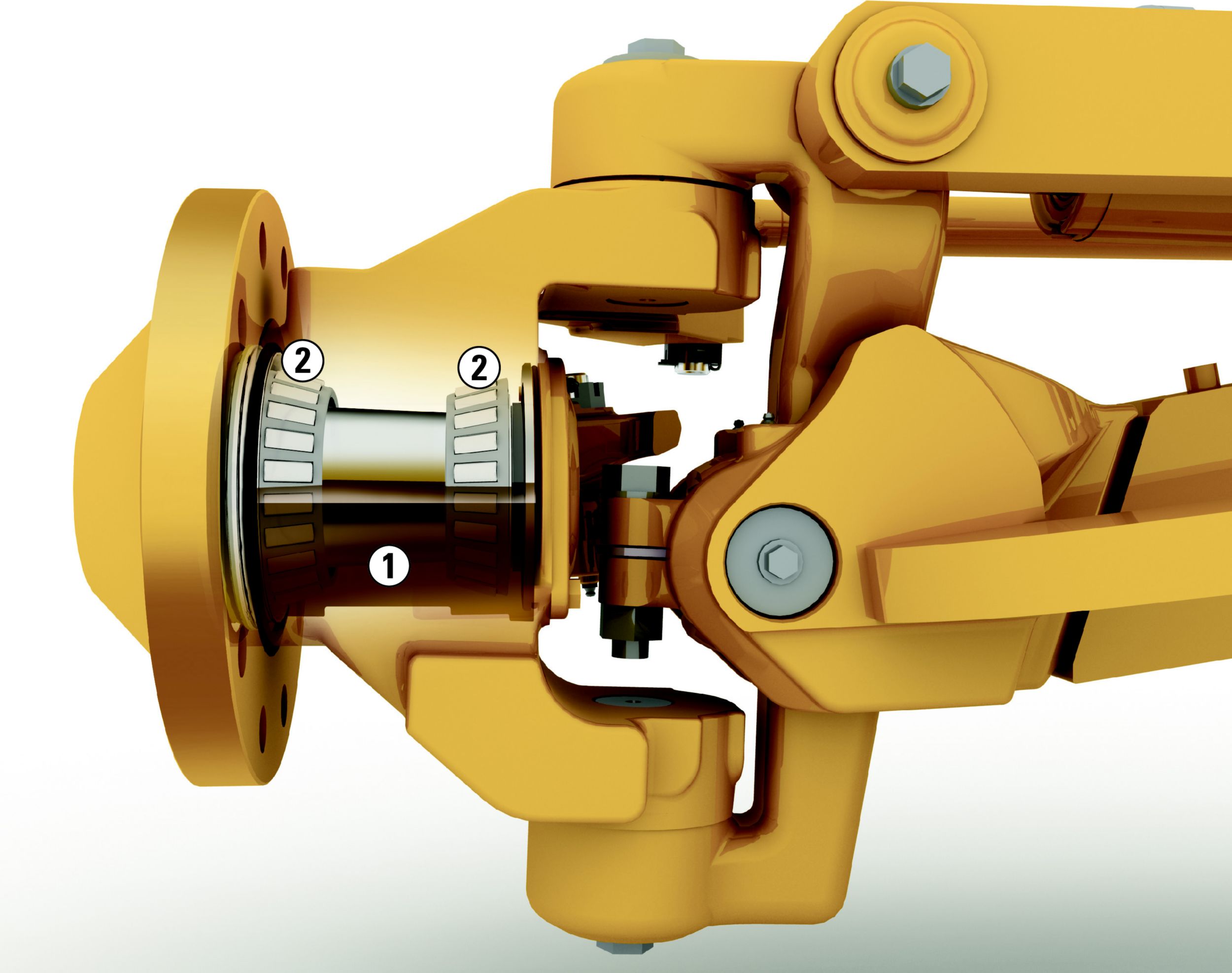

Front Axle

The Cat sealed spindle keeps the bearings free from contaminants and lubricated in a light-weight oil (1). This durable, low-maintenance design reduces your owning and operating costs. Two tapered roller bearings (2) support the wheel spindle. The Cat “Live Spindle” design places the larger tapered roller bearing outboard where the load is greater, extending bearing life.

Gear Selection

Six forward and three reverse gears give the operator a wide operating range. The specifically designed range of gears ensures maximum productivity in all mining applications.

Hydraulic Brakes

The oil bathed, multi-disc service brakes are hydraulically actuated, providing smooth predictable braking and lower operating costs. With brakes located at each tandem wheel, the 24M offers large total brake surface area, delivering dependable stopping power and longer brake life.

Hydraulics

Advanced Electro-Hydraulic System

The 24M incorporates a state-of-the-art electro-hydraulic system. This technology is the foundation for revolutionary changes of the machine and implement controls. Advanced joystick controls provide unmatched controllability with precise and predictable hydraulic movements, and the reliability you expect from Caterpillar.

Load Sensing Hydraulics (PPPC)

The time proven load-sensing system and the advanced Proportional Priority Pressure-Compensating (PPPC, or “triple-PC”) electro-hydraulic valves on the 24M are designed to provide superior implement control and enhanced machine performance in all applications. Continuous matching of hydraulic flow and pressure to power demands creates less heat and reduces power consumption.

Consistent and Predictable Movement

PPPC valves have different flow rates for the head and rod ends of the cylinder. This ensures consistent extension and retraction speeds for each cylinder, and gives the operator a consistent and predictable response every time an implement control is moved.

Blade Float

Blade float is built into the blade lift control valves. The blade float feature allows the blade to move freely under its own weight. By floating both cylinders, the blade can follow the contours of the haul roads. Floating only one cylinder permits the toe of the blade to follow a hard surface while the operator controls the slope with the other lift cylinder.

Variable Float

The optional variable float feature lets the operator select the amount of down force the blade has when it is in float. This allows the operator to easily follow the contour of the haul road when removing only the loose material, increasing productivity and cutting edge life.

Balanced Flow

Hydraulic flow is proportioned to ensure all implements operate simultaneously with little effect on the engine or implement speeds. If demand exceeds pump capacity, all cylinder velocities are reduced by the same ratio. The result is improved productivity in all applications.

Cat® XT™ Hose

Cat hose technology allows high pressures for maximum power and reduced downtime. Intelligent routing minimizes exposure to damage. Hose clips prevent hose rubbing and excessive vibration for lower owning and operating costs.

Independent Oil Supply

Large, separate hydraulic oil supply prevents cross-contamination and provides proper oil cooling, which reduces heat build-up and extends component life.

Integrated Electronic Solutions

“Smart Machine”

The 24M fully integrates all core systems creating a “Smart Machine.” The Cat data link shares key data among systems, optimizing machine performance while preventing potential machine damage.

Electronic Technician (Cat ET)

Cat ET is a two-way communication tool that gives service technicians easy access to stored diagnostic data and lets them configure the machine parameters through the Cat Data Link. This integrated feature reduces machine downtime and lowers operating costs.

Diagnostics

Cat Messenger, combined with full systems integration, enhances the diagnostic capability of the 24M. Machine system errors are displayed in text as well as with fault codes, allowing service technicians and operators to quickly analyze critical data, increasing machine availability.

Machine Security System (MSS)

The optional MSS uses electronically coded keys to limit usage by specific individuals or times of the day. MSS deters theft, vandalism and unauthorized use.

Product Link

The optional Product Link system streamlines diagnostic efforts, and reduces downtime, maintenance scheduling and costs by providing a communication flow of vital machine data and location. Product Link gives automatic updates on machine parameters such as machine hours, machine condition, location, fault codes and alarms.

Optional Automatic Blade Control

The Cat AccuGrade System automatically controls the blade, improving operator efficiency and productivity.

AccuGrade Attachment Ready Option

The AccuGrade system is fully integrated into the machine design, making installation quick and easy. Integral hydraulic and electrical components are standard on the 24M (Grade Control Ready). The AccuGrade Attachment Ready Option provides additional mounting brackets, cab controls and electrical harnesses for easy installation of the Cross Slope electronics kit.

Cat Messenger

Standard on the 24M, Cat Messenger provides real-time machine performance and diagnostic data with an easy-to-use interface. Messenger monitors all system data and alerts the operator of any faults through a digital text display that can be shown in multiple languages.

Low Battery Elevated Idle

After the 24M is at low idle for an extended period and low system voltage is detected, idle speed is raised. This ensures adequate system voltage and improves battery reliability.

Automatic Engine Deration

Protects the C18 engine by automatically lowering engine torque output and alerting the operator if critical conditions are detected.

Safety

Operator Presence System

The Operator Presence System keeps the parking brake engaged and hydraulic implements disabled until the operator is seated and the machine is ready for safe operation.

Secondary Steering System

The standard secondary steering system automatically engages a ground driven hydraulic pump in case of a drop in steering pressure, allowing the operator to steer the machine to a stop.

Speed Sensitive Steering

The steering software automatically provides an infinitely variable ratio between the joystick and the steer tires, resulting in less sensitive steering as the ground speed increases.

Low Sound and Vibration Levels

Isolation mounts for the cab, engine and transmission maximize operator comfort and help to minimize sound and vibration. These modifications provide a quieter and more comfortable working environment, optimizing operator focus.

Hydraulic Lockout

A simple switch located in the cab disables all implement functions while still providing machine steering control. This safety feature is especially useful while the machine is roading.

Brake Systems

Brakes are located at each tandem wheel to eliminate braking loads on the power train. In addition, the brake systems are redundant and utilize accumulators to enable stopping in case of machine failure, further increasing operational safety.

Circle Drive Slip Clutches

Two standard circle drive slip clutches protect the drawbar, circle and moldboard from shock loads when the blade encounters an immovable object. It also reduces the possibility of abrupt directional changes in poor traction conditions, protecting the machine, operator and surroundings.

Blade Lift Accumulators

This standard feature uses accumulators to help absorb impact loads to the moldboard by allowing vertical blade travel. Blade lift accumulators reduce unnecessary wear and help to avoid unintended machine movement for increased operator safety.

Rearview Camera

Visibility is further enhanced with an optional Work Area Vision System (WAVS) through a 178 mm (7 in) LCD color monitor in the cab. Developed specifically for rugged applications, it improves productivity and increases operator awareness of surroundings.

High Intensity Discharge (HID) Lighting

Optional HID lights can replace the standard halogen lamps. The powerful HID lights are four times brighter, improving night time visibility and safety.

Electrical Disconnect Switch

A battery disconnect switch provides ground-level lockout of the electrical system to prevent inadvertent starting of the machine.

Engine Shutoff Switch

An engine shutoff switch is located at ground level on the left rear of the machine, allowing anyone nearby to shut it down in case of an emergency.

Window Cleaning Platform

The optional window-cleaning platform provides an easier and safer access to all windows and improves ingress/egress to the cab with access from the rear.

Steel Tandem Walkways

Perforated raised steel walkways cover the tandems. This provides a sturdy platform for standing and walking, and additional protection for the brake lines. A stairway lamp illuminates the walkway and can be activated at ground level during entry and shut off with a switch in the cab.

Fire Supression Mounting Plate

The standard fire suppression mounting plate places the tanks in the optimum position for improved visiblity, ingress/egress and durability.

Rear Fenders

To help reduce objects flying from the tires, as well as a build-up of mud, snow or debris, optional rear fenders can be added.

Additional Safety Features

The 24M has many additional standard safety features, including laminated glass on the front windows, back-up lights, sounding alarm, lockable doors, black glare-reducing paint on the front frame, engine enclosure and lift arms and conveniently located grab rails for added safety.

Serviceability and Customer Support

Grouped Service Points

The 24M groups daily service points in the left side service center to help ensure proper maintenance and inspection routines.

Extended Service Intervals

The 24M extended service intervals, such as 500-hour engine oil changes and 4000-hour hydraulic oil changes, reduce machine service time and increase availability.

Fast-Fill Fuel

The 24M offers a standard Fast-Fill that allows customers to refuel in less than four minutes for fast, accurate filling and reduced downtime.

Ecology Drains

Conveniently located ecology drains shorten service times and help keep the environment safe by preventing spills.

Automatic Lubrication System

The standard Lincoln Centro-Matic® AutoLube System maintains the proper grease lubrication on working surfaces, significantly extending component life. Contaminants are purged from open pins and bushings to help prevent dirt from damaging critical components.

Grouped Components Rebuilds

Rebuilds take your machine out of service. Caterpillar designs components to be rebuilt in groups, maximizing uptime.

Diagnostics and Monitoring

The 24M integrates Cat Messenger, Cat Electronic Technician and S•O•SSM Sampling ports for easy monitoring and fast troubleshooting, keeping your machine up and running.

Machine Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers help you size the right machine for your operations and can estimate component life, preventative maintenance cost, and the true cost of production.

Purchase

Consider the financing options available, as well as day-to-day operating costs. Look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Maintenance Services

Repair option programs guarantee the cost of repairs up front. Diagnostics programs such as Scheduled Oil Sampling, S•O•SSM analysis, Coolant Sampling and Technical Analysis help avoid unscheduled repairs.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers use a world-wide computer network to track in-stock parts to minimize machine down time. Save money with genuine Cat Reman parts. You receive the same warranty and reliability as new products at substantial cost savings.

Data not available.

Standard Equipment

- OPERATOR ENVIRONMENT

- Air conditioner/heater, modular

- Armrest, adjustable

- Articulation, automatic Return-to-Center

- Ashtray and lighter

- Cat Messenger, operator information system

- Coat hook

- Cup holder

- Display, digital speed and gear

- Door, driver access (left and right sides)

- Fan, defroster, rear window

- Gauges - articulation, engine coolant temp,

- Hour meter, digital

- Joystick hydraulic controls

- Lights, night time cab

- Mirror, inside rearview, wide angle

- Power port, 12V

- Precleaner, Cab HVAC

- ROPS cab, sound suppressed

- Seat, air suspension, cloth

- Seat belt, retractable 76 mm (3 in)

- Step, driver access (left and right sides)

- Storage area for cooler/lunchbox

- Sun shade

- Throttle control, electronic

- Windows, laminated glass:

- Windows, side and rear (3)

- Wiper/washer, rear

- Wrist rests, adjustable

- POWER TRAIN

- Air cleaner, dual stage, dry type, automatic dust ejector,

- Air-to-air after cooler (ATAAC)

- Belt, serpentine, automatic tensioner

- Brakes, four-wheel hydraulic

- Differential, lock/unlock

- Electronic over speed protection

- Engine, Cat® C18 with ACERT™ Technology

- Ether starting aid

- Fuel tank, fast fill, ground level

- Fuel-water separator

- Hydraulic demand fan

- Muffler, under hood

- Parking brake - multi-disc, sealed, oil-cooled

- Priming pump, fuel

- Rear axle, modular

- Sediment drain, fuel tank

- Transmission, 6F/3R, power shift

- Transmission, autoshift

- ELECTRICAL

- Alarm, back up

- Alternator, 150 ampere, sealed, filtered air intake

- Batteries, maintenance free, 1500 CCA

- Breaker panel

- Electrical system, 24V

- Grade Control Ready - Cab harness, software,

- Lights, reversing

- Lights, stop and tail, LED

- Product Link Ready

- Starter, electric, heavy-duty

- Starting receptacle, plug-in

- Wiring for communications radio

- Wiring for roof mounted beacon

- OTHER STANDARD EQUIPMENT

- Accumulators, blade lift

- Auto-lube, Lincoln, Centro-Matic®

- Brake accumulators, dual certified

- Bumper, rear, integrated with hitch

- Clutch, circle drive slip (2)

- Cutting edges

- Doors (8), engine compartment, locking

- Drain, ecology, engine oil, high-speed (Wiggins)

- Drawbar - 8 shoe with replaceable wear strips

- Endbits, 25 mm (1 in) DH-2 steel

- Extended Life Coolant to -50° C (-58° F)

- Frame, articulated, with safety lock

- Ground level engine shutdown

- Ground level fueling

- Guards, valve

- Horn, electric (2)

- Hydraulics, base 8 implement controls

- Hydraulics, load-sensing

- Lockout, hydraulic implement for roading

- Moldboard

- Paint, glare reducing - top of front frame, rear enclosure

- Radiator cleanout access

- Ripper, rear

- Secondary steering

- Serviceability, LH side

- S•O•SSM ports: engine, hydraulic, transmission, coolant, fuel

- Tandem walkway/guards

- TIRES, RIMS, & WHEELS

- Partial allowance for tires and multi-piece rims

Optional Equipment

- ELECTRICAL kg lb

- Converter, communications 2 5

- Lights:

- GUARDS

- Guard, transmission 227 500

- Guards, mud 23 50

- OPERATOR ENVIRONMENT

- Access, Dual Platform 635 1400

- Access, Left hand Platform 374 825

- Mirrors, outside:

- Radio ready, AM/FM or Satellite 2 5

- POWER TRAIN

- Engine, compression brake

- OTHER ATTACHMENTS

- AccuGrade ARO 18 40

- Camera, rearview 9 20

- Cat Product Link 321SR 5 10

- Fenders, rear 574 1265

- Float, variable 91 200

- Horn, air

- Security system 2 5

- Sound suppression 28 62

- Starting, cold weather 77 169

- WORK TOOLS / G.E.T.

- Cutting Edges

- Push plate, counterweight 269 592

- Ripper tooth 72 158