Overview

The Cat 365B Material Handler is specifically designed for the scrap and material handling customer. This machine uses the most sophisticated manufacturing technology to ensure the highest level of manufacturing quality. This quality, with high Cat design standards, means that the 365B Material Handler will deliver the reliability and productivity you demand from Caterpillar.

Specifications

| Engine Model | Cat® 3196 |

| Net Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® 3196 |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Engine Manufacturer | Caterpillar |

| Aspiration | Turbocharged |

| After-Cooled | Yes |

| RPM | 2000 |

| Weight / HP Ratio | — |

| Displacement / HP Ratio | — |

| Derating Altitude | — |

| Maximum Reach | — |

| Cab Riser - Fixed | — |

| Generator Set | — |

| Travel Speed | — |

| Maximum Reach - Below Ground | — |

| Ground Level Lift at Radius | — |

| Stick Length | — |

| Front Lift Capacity (MAX) | — |

| Side Lift Capacity (MAX) | — |

| Maximum Flow - Each of Two Pumps | — |

| Maximum Pressure - Implements | — |

| Maximum Pressure - Heavy Lift | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Rotate Circuit for Grapple Maximum Flow | — |

| Rotate Circuit for Grapple Operating Pressure | — |

| Main Pumps Type | Variable displacement |

| Main Pumps Number | 2 |

| Swing System - Maximum Flow | — |

| Operating Weight | — |

| Upper | — |

| Counterweight | — |

| Undercarriage - Including Carbody | — |

| Two-Piece Front - With Cylinders | — |

| Counterweight Weight | — |

| Maximum Drawbar Pull | — |

| Operating Height - To Top of Cab (Fixed) | — |

| Shipping Height - Cab Tipped | — |

| Operating Width | — |

| Shipping Width | — |

| Shipping Length | — |

| Tail Swing Radius | — |

| Height - Top of Exhaust | — |

| Counterweight Clearance | — |

| UC with Standard Shoe Width | — |

| Swing Torque | — |

| Swing Speed | — |

| Track Shoes | — |

| Shoes Per Side | 47 |

| Rollers - Each Side | 8 |

| Overall Track Length | — |

| Standard Type | Double grouser |

| Standard Ground Pressure | — |

| Width - Shoe - Option 1 | — |

| Type of Shoe - Option 1 | Flat |

| Sealed Track | Standard |

| Finals within Std. Shoe Width | Yes |

| Variable Gauge - Minimum | — |

| Variable Gauge - Maximum | — |

| Number of Carrier Rollers - Each Side | 3 |

| Track on Ground | — |

| Fuel Tank | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

Benefits & Features

The Caterpillar 365B Material Handler

Operator Station

The work station is designed to be quiet and comfortable for the operator, assuring high productivity during a long work day. The Caterpillar designed electronic control system uses VIDS (Vital Information Display System) as the easy interface between the machine and the operator or the serviceman.

1.9m (6'5") Cab Riser

Cat designed and built cab riser gets your operator to an operating height with excellent visibility for loading or unloading your processing equipment, trucks, rail cars, and barges. Access to the cab is provided by a platform which extends around the riser to allow windshield cleaning. The cab riser can also be manually tilted forward 90 degrees for shipping.

33 kW hydraulically driven generator set

The exclusive Caterpillar genset can power magnets up to 1981mm (78 in.) in diameter. A Caterpillar patented state-of-the-art electronic magnet controller and generator are linked to provide trouble free service. The new controller completely eliminates traditional contactor maintenance and it is supported and warranted through your Cat dealer.

Long Square Undercarriage

Long (L) square undercarriage is standard to maximize stability and lifting capacity. The wide track gauge provides the over-the-side stability required to handle heavy loads and improve productivity, but is also retractable to provide a narrow gauge and reduced shipping width.

365B MH two-piece fronts by Caterpillar

- 365B MH two-piece fronts by Caterpillar meet your material handling needs with excellent lift performance and working range both in close and at full reach.

- The material handling front offers a maximum horizontal reach of 18.9m (61'11") from swing center and a maximum vertical pin height of 19.2m (62'10") at 9.7m (31'11") from swing center. This front is an excellent match for a two and a half cubic yard scrap grapple.

- The cambered boom barge unloading front offers a maximum horizontal reach of 16.9m (55'6") from swing center and a maximum vertical pin height of 14.5m (47'5") at 12.4m (40'8") from swing center. This front is an excellent match for a three cubic yard scrap grapple.

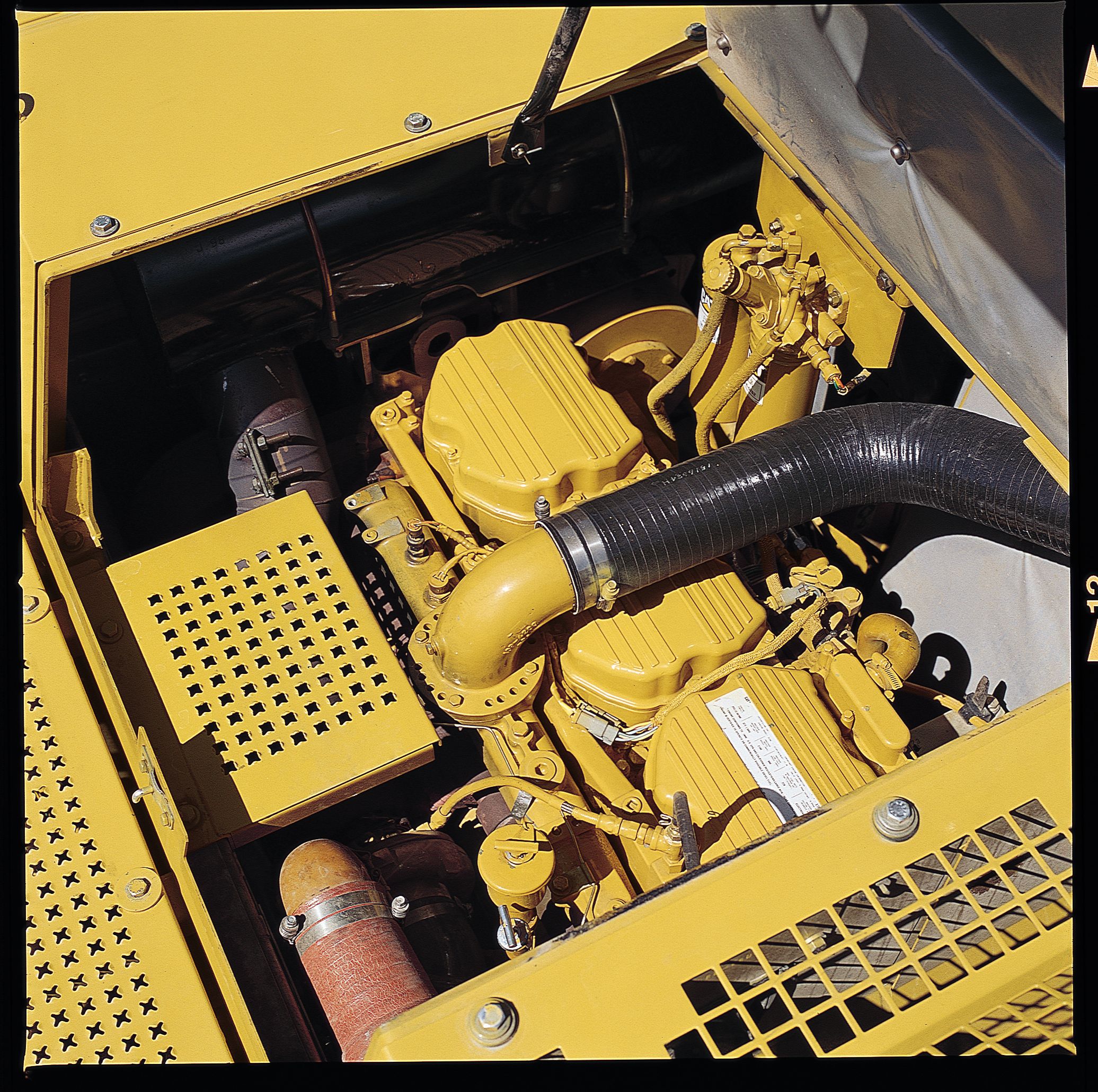

Innovative Cat 3196 ATAAC diesel engine

Delivers large-engine performance from a compact engine design. The six-cylinder 287 kW (385 hp) engine is turbocharged and air-to-air aftercooled. With high horsepower and low displacement, this engine provides excellent fuel economy and durability that can significantly reduce operating costs.

Material Handler Hydraulic Systems

Auxiliary hydraulics are specifically designed to meet your hydraulic attachment requirements. The grapple open/close circuit works with the other implement circuits to deliver smooth, simultaneous, multi-function control. Load sensing PPPC (Proportional Priority Pressure Compensation) system now with Caterpillar developed Hydrac electronic actuation combines a proven system with state-of-the-art electronic control for high efficiency and excellent controllability.

Cooling Cores

Easy clean-out engine and hydraulic cooling cores are provided for operating in debris-laden environments. Ample space between the oil cooler and radiator cores maximizes cooling capacity and allows for simple, efficient cleaning.

Serviceability

Faster, easier maintenance

Means improved uptime and a better value. • Service points are centrally located with easy access to facilitate routine maintenance.

Improved filters and filter locations

- Make maintenance easier.

- Hydraulic capsule filters are mounted outside the tank to prevent spills and system contamination during replacement.

- Radial seal main air cleaner has double layered filter element for more efficient filtration. No tools are required to change the element. Operator is alerted to clogged condition by a message on VIDS.

- Pilot hydraulic system filter keeps contaminates away from the pilot system. This system includes a Scheduled Oil Sampling port to simplify sampling.

- Swing and travel motor case drain filter removes contaminates, keeping them from returning to the tank.

Water Separator

Removes water from fuel even when under pressure and is located in the battery compartment for easy access.

Remote greasing block

On the boom and stick and three grease points for the swing bearing deliver grease to hard to reach locations.

Electronic System Control

Has diagnostic capabilities for Cat Dealers' use. A single connection point allows Electronic Technician (ET) to communicate with all machine controllers. • Dealer service technicians can quickly and easily diagnose and adjust machine components, maximizing uptime.

Complete Customer Support

Cat Dealers

Your Cat Dealer offers a wide range of services that can be set up under a customer support agreement when you purchase your equipment. To help you get the best return on your investment, the dealer will help you choose a plan that can cover everything from machine and attachment selection to replacement.

Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements? What production is needed? What is the true cost of lost production? Your Cat Dealer can give you precise answers to these questions.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Maintenance

What is the cost of preventative maintenance? More and more equipment buyers are planning for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help you evaluate the cost involved so you can make the right choice.

Product support

You will find nearly all parts at our dealer parts counter. Cat Dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured parts. You receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Data not available.

Standard Equipment

- Electrical

- 70 Ampere Alternator

- Light, storage box mounted (one)

- Light, cab mounted (two)

- Light, upper frame (one)

- Guards

- Guard, Heavy duty bottom - including swivel guard with bolt head protection and heavy duty track motor guards

- Operator Environment

- Automatic climate control with air conditioner, heater and defroster

- Polycarbonate windows except laminated glass in front windshield/tempered glass left upper windows and sliding upper door window

- Cab Riser, 1.9 m, manual tilt

- Alternate rear window exit

- Instrument panel and gauges (VIDS)

- Neutral lever lock out for all controls

- Openable front windshield upper & lower with assist device

- Platform with provisions for two attachment related pedals

- Polycarbonate skylight

- Pressurized cab

- Positive filtered ventilation

- Radio mounting (DIN) with - antenna and mounting for 2 stereo speakers

- Seat KAB 524P with: • suspension and adjustable armrest • high back and headrest • retractable seatbelt (76 mm width) • four way adjustable (up-down, front-rear)

- Seat mounted multifunction joystick type (wrist lever) controls (electric signal)

- Start up level check for hydraulic oil, engine oil, and engine coolant

- Storage compartment suitable for lunch box

- Sun shade for skylight and front windshield

- Windshield wipers & washers (vertical type) - lower & upper

- 12V - 7A Power supply with socket

- Travel control pedals with removable hand levers

- Powertrain

- Diesel Engine - Cat 3196 ATAAC • Low emission/low noise version • 2300m/7500 ft. altitude capability • Air inlet heater for low ambient starting

- Automatic engine speed control with return to idle push button

- Automatic swing parking brake

- Radial seal air filter with Donaclone precleaner

- Separated cooling system with variable speed fan

- Two speed travel with automatic shift change

- Water separator in fuel line

- Undercarriage

- Hydraulic track adjusters

- Idler and center section track guiding guards

- Track type sealed undercarriage with: • 750 mm double grouser shoes

- Std. Long track roller frames

- Square carbody and undercarriage for stability

- Hydraulic Systems

- Boom and stick lowering check valves

- High pressure grapple open & close hydraulic circuit

- Medium pressure aux. hydraulic circuit for powering rotating grapples

- Aux. pump and lines to drive generator

- Separate hydraulic filter with reusable metal tube for filter element

- Other Standard Equipment

- Caterpillar Extended Life Coolant at 44% concentration with protection of -29°C (-20°F)

- Door and cap locks plus Caterpillar one key security system

- Electrical source for service light

- Fire wall between pump compartment and engine

- Mirrors - Rearview, Frame-right, Cab-left

- Overheat protection system

- Material handling counterweight, 13.8T

- High ambient cooling

- Spaced coolers for easy cleaning

- Cat walks left and right hand

- Reinforced upper frame for cab riser

- Material handling boom foot pin in upper hole on frame (145mm)