Overview

The 330D MH Waste Handler incorporates many design features specifically for transfer station applications that will improve uptime and productivity.

Specifications

| Engine Model | Cat® C9 ACERT™ |

| Net Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C9 ACERT™ |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Maximum Reach | — |

| Maximum Flow - Each of Two Pumps | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Operating Weight | — |

| Upper | — |

| Counterweight | — |

| Undercarriage - Including Carbody | — |

| Two-Piece Front - With Cylinders | — |

| Stick | — |

| Boom | — |

| Maximum Drawbar Pull | — |

| Operating Width | — |

| Shipping Length | — |

| Tail Swing Radius | — |

| Ground Clearance | — |

| Swing Torque | — |

| Swing Speed | — |

| Track Shoes | — |

| Gauge | — |

| Shoes Per Side | 49 |

| Rollers - Each Side | 9 |

| Fuel Tank | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Maximum Drawbar Pull | — |

| Maximum Travel Speed | — |

Benefits & Features

Front Linkage

Heavy-Duty Boom and Stick

The heavy duty reach boom and heavy duty 10.5 ft stick are more robust than the standard reach boom and stick. The "heavy-duty" features include thicker plates throughout the design to handle the increased loading experienced in transfer station applications.

The front linkage has a maximum horizontal reach of 9.4 m (31 ft) and maximum vertical pin height of 8.8 m (29 ft). Thus, the working range of the machine provides an excellent match for loading hauling units from a platform or from level ground.

Welded Box-Section Structures

The boom and stick are designed and built for maximum durability and performance. Efficient design of welded box-section structures with thick, multi-plate fabrications and internal baffle plates in high stress areas maximizes strength and durability required for the loading conditions of transfer stations and demolition applications.

Stress Relieved Boom and Stick

The boom and stick are stress relieved to maximize the strength of the weld joints. The process of stress relieving also allows for the structure weight to be minimized, allowing heavier payload capacity.

Waste Handler Structures

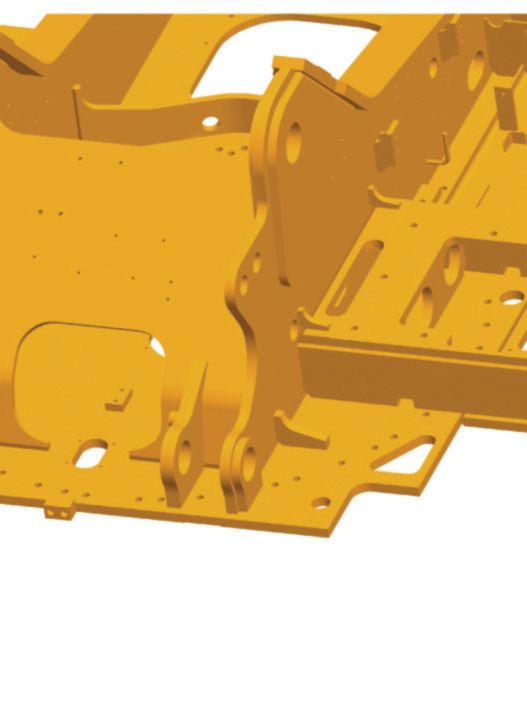

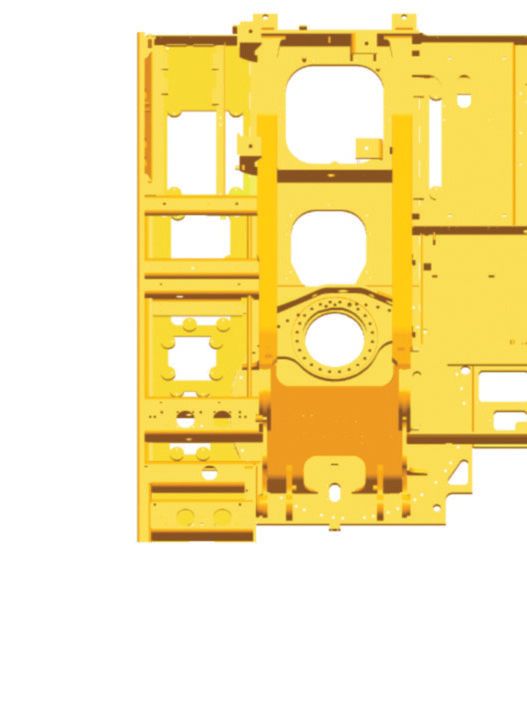

Heavy-Duty Upper Frame

Upper box-section reinforcement on the upeer frame provide additional strength for improved durability.

Horizontal mounting plate provides more surface area for swing drive and swing bearing mounting bolts to handle increased loading.

The heavy-duty upper frame has many specifically designed features for added strength and improved durability in waste handling applications. It is composed of higher strength material and thicker steel sections to handle the increased loading activity seen in waste transfer stations and demolition applications.

Boom tower double plates add thick steel reinforcements to handle the greater stresses caused by increased loading.

Box-section cylinder mounts allow for improved resistance against increased torsional loads and payloads.

Waste Handler Guarding

Rubber Bumpers

The rubber bumpers provide much needed guarding to protect the sheet metal of the machine from being damaged while maneuvering in tight areas.

Swivel Guard

The swivel guard, designed specifically for waste applications, protects the swivel from the wrapping of debris. This will allow more uptime through the decrease in maintenance associated with removing video tape and wire from the swivel.

Swing Bearing Guard

The swing bearing guard is a bolt on guard that protects the swing bearing from any damage by shielding it from any potential sources of wrapping such as video tapes and wire. It also prevents packing of debris around the swing bearing.

Falling Object Guards

The optional falling object guard protects the cab and front windshield from debris in transfer stations.

Waste Handling Features

Trash Resistant Cooling System

A Trash Resistant Cooling arrangement reduces cooling system maintenance and downtime when operating in environments with large amounts of airborne debris such as feeding shredders in scrap applications, waste transfer stations, demolition and forestry applications. This package will also help avoid costly engine and hydraulic repairs and downtime resulting from overheating caused by a plugged cooling system. This arrangement is standard on the 330D MH Waste Handler.

Trash Resistant Cooling Features

- Debris Filters - These stainless steel mesh filters trap debris before it enters the house, keeping it out of the radiator and oil cooler. These filters can be easily removed and cleaned. A second set of filters minimizes downtime, allowing the operator to keep working while the first set is cleaned.

- Hydraulic Automatic Reversing Fan on the oil cooler.

Cooling System

The cooling fan is hydraulically driven and controlled by the ECM. The optimum fan speed is calculated based on the ambient temperature, coolant temperature and hydraulic oil temperature. This unique feature assists in the management of engine power and improves noise efficiency. The C9 delivered a completely new layout that separates the cooling system from the compartment. The auto reversing fan is controlled by the ECM and is adjustable.

Heavier Counterweight

The 330D MH Waste Handler has been outfitted with a counterweight that is 25% heavier than a standard 330D L counterweight for better stability while handling waste or demolition debris.

Cab Riser

The standard 2.6 m (8.5 ft) cab riser provides for elevated operating height to improve visibility while loading waste into a hauling unit and allows the operator to see over obstructions in the transfer station.

Turbine Precleaner

The standard turbine precleaner helps keep debris away from the cooling system by removing debris from the air intake. The 330C MH Waste Handler is also equipped with the SyKlone Optimax dual stage engine precleaner which purges remaining debris from intake air, providing longer air filter and engine life.

SyKlone Gideon Cab Air Precleaner

This cab air precleaner extends cab air filter life, increases operator comfort by effectively eliminating dust and odor, and keeps evaporator and heater coils clean.

Cab Mounted Beacon

The cab mounted beacon flashes whenever the master disconnect is on.

In-cab Master Disconnect

An additional master disconnect switch is provided in the cab for easier operator access.

Engine and Hydraulics

Engine

Six-cylinder, turbocharged engine built for power, reliability, and economy will allow the machine to consistently perform at high levels. The CAT® C9 engine is designed for low emissions and will meet EPA Tier 3 emissions requirements.

Performance

The 330D MH, equipped with the C9 engine with ACERT™ Technology, provides 9% more horsepower as compared to the C9 in the 330C MH.

Electronic Control Module

The Electronic Control Module (ECM) works as the 'brain' of the engine's control system, responding quickly to operating variables to maximize engine efficiency. Fully integrated with sensors in the engine's fuel, air, coolant and exhaust systems, the ECM stores and relays information on conditions such as RPM, fuel consumption and diagnostic information.

Automatic Engine Speed Control

The two-stage, one-touch control maximizes fuel efficiency and reduces sound levels.

ADEM™ A4 Engine Controller

The ADEM™ A4 electronic control module manages fuel delivery to get the best performance per liter of fuel used. The engine management system provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs. It tracks engine and machine conditions while keeping the engine operating at peak efficiency.

Hydraulic Cross Sensing System

Improves productivity with faster implement speed and quick, strong pivot turns.

Fine Swing Control

Fine swing control cushions swing start and stop for better implement control.

Hydraulic Cylinder Snubbers

The hydraulic cylinder snubbers at the rod-end of the boom cylinders and both ends of the stick cylinders cushion shock to improve cylinder life.

Controllability

The hydraulic system offers very precise operator control to reduce fatigue and improve operator efficiency translating into enhanced machine performance and productivity.

Boom and Stick Regeneration Circuit

Boom and stick regeneration circuit increases efficiency and reduces cycle time for higher productivity and lower operating costs.

Work Tools

Trash Grapple

The Cat Work Tools trash grapple has been designed to meet the requirements of waste handling. Powered by the bucket cylinder, the trash grapple mechanically works to compact trash while placing it into the bed of the hauling unit. This helps to maximize the amount of waste that can be placed into one unit, maximizing efficiency.

Complete Customer Support

Product Support

You will find nearly all parts at our dealer parts counter. Cat® dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured components.

Machine Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements, machine attachments and operating hours? What production is needed? Your Cat dealer can provide recommendations.

Customer Support Agreements

Cat dealers offer a variety of product support agreements, and work with customers to develop a plan the best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has videotapes, literature and other ideas to help you increase productivity, and Caterpillar offers certified operator training classes to help maximize the return on your investment.

Maintenance Services

Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling, Coolant Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild, or replace? Your Cat Dealer can help you evaluate the costs involved so you can make the right choice.

Data not available.

Standard Equipment

- Electrical

- 65 ampere alternator

- Base machine light (frame)

- Lights, cab mounted (Two)

- Horn

- Pre-Start monitoring system - checks for low fluids

- Operator Environment

- Air conditioner, heater, defroster with automatic climate control

- AM/FM radio with antenna and 2 speakers

- Ashtray with 24 volt lighter

- Beverage/cup holder

- Bolt-on Falling Object Guarding System (FOGS) capability

- Cab Glass

- Coat hook

- Floor mat

- Instrument panel and gauges

- Joysticks, console mounted, pilot operated

- Light - interior

- Literature compartment

- Monitor, full graphic color display

- Neutral lever (lock out) for all controls

- Polycarbonate side windows

- Positive filtered ventilation

- Pressurized cab

- Seat, suspension, with high back and head rest

- Seat belt, retractable (76 mm [3 in])

- Storage compartment suitable for lunch box cooler

- Sun shade (for skylight)

- Travel control pedals with removable hand levers

- Windshield wiper and washer (upper and lower)

- Hydraulic Cab Riser

- Engine/Power Train

- C9 with ACERT Technology

- Cooling Package

- Radial seal air filter

- Auto reversing fan

- Automatic engine speed control with one-touch low idle

- Two speed auto-shift travel

- Filters on rear door for cooling

- Undercarriage

- Grease lubricated track

- Hydraulic track adjusters

- Idler and center section track guards

- Track shoes - 800 mm (32 in) triple grouser

- Heavy-duty track rollers

- Swing bearing guard

- Other Standard Equipment

- Automatic swing parking brake

- Auxiliary hydraulic valve

- Counterweight with lifting eyes

- Door locks, cap locks, and Caterpillar® one key security system

- Fine swing control

- Fully pressurized hydraulic system

- Heavy lift

- Mirrors (frame-right, cab-left)

- S•O•SSM quick sampling valves for engine and hydraulic oil

- Travel alarm

- Wiring provision for Product Link

- Heavy duty upper frame

- Heavy counterweight (25% over standard)

- Heavy duty swing bearing

- Rubber bumpers

- Swivel guard

Optional Equipment

- Front linkage

- Booms

- Sticks

- Bucket Linkage

- Boom lowering control device

- Electrical

- Power supply (12V-10 Amp)

- Power supply (12V - 20 Amp)

- Beacon

- Easy access electrical disconnect

- Guarding

- Falling Object Guarding System (FOGS)

- Track Guiding Guards

- Operator Environment

- Rear window, secondary exit

- Precleaner arrangement

- Seat, high back with air suspension and heater

- Third pedal, straight travel

- Cab air filter system

- Undercarriage

- Track Shoes

- Work Tools

- Grapples (waste)