Overview

More powerful engine, improved cooling system, longer track length, increased hydraulic pressure, and cab riser options lead to increased productivity and lower operating cost.

Specifications

| Engine Model | Cat® C7 ACERT™ |

| Net Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C7 ACERT™ |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349:2011 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Engine Manufacturer | Caterpillar |

| Aspiration | Turbo |

| Derating Altitude | — |

| Maximum Reach | — |

| Cab Riser - Fixed | — |

| Cab Riser - Hydraulic | — |

| Generator Set | — |

| Maximum Flow - Each of Two Pumps | — |

| Maximum Pressure - Implements | — |

| Maximum Pressure - Heavy Lift | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Rotate Circuit for Grapple Maximum Flow | — |

| Rotate Circuit for Grapple Operating Pressure (1) | — |

| Generator Auxiliary Pump Maximum Flow | — |

| Rotate Circuit for Grapple Operating Pressure (2) | — |

| Generator Auxiliary Pump Maximum Pressure | — |

| Operating Weight | — |

| Upper | — |

| Counterweight | — |

| Undercarriage - Including Carbody | — |

| Two-Piece Front - With Cylinders | — |

| Grapple/Adapter | — |

| High Range Maximum Travel Speed | — |

| Maximum Drawbar Pull | — |

| Swing Torque | — |

| Swing Speed | — |

| Track Shoes | — |

| Gauge | — |

| Shoes Per Side | 50 |

| Rollers - Each Side | 9 |

| Overall Track Length | — |

| Number of Carrier Rollers - Each Side | 9 |

| Fuel Tank | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Maximum Drawbar Pull | — |

| Maximum Travel Speed | — |

Benefits & Features

325D MH Material Handler

Fixed Cab Riser

CAT® designed and built, 6'5" (1.95 m) manual tilt cab riser provides for operating height with excellent visibility for loading and unloading processing equipment, trucks, and rail cars. Access to the cab is provided by a ladder leading up to the platform extending around the cab riser. This platform will allow for windshield cleaning. The cab riser can be manually tilted forward 90 degrees for shipping.

Hydraulic Cab Riser

Optional hydraulic cab riser provides up to 8'6" (2.6 m) of additional operating height. There is easy access to the cab platform provided by handrails attached to the riser.

Operator Controls

The ability to modulate the grapple open-close function is also provided on the right side joystick. The rotate function is modulated by using a slider switch mounted on the joystick.

Cooling System

External debris filters allow easy access for cleaning. This prevents clogging from dirt and dust coming into the cooling system. The optional automatic reversing fan purges dirt and dust from cooling system.

Generator Set

An optional 20 kW generator set can power magnets up to 66" (1.68 m) in diameter.

325D MH Two-Piece Caterpillar Front Linkage

The CAT® Two-Piece Front Linkage

Offers a maximum horizontal reach of 50'11" (15.5 m) from swing center and maximum vertical height of 53'11" (16.4 m). It is an excellent match for a 0.75 yd3 (0.57 cubic meter) Orange Peel Grapple or a 57" (1.45 m) Walker Magnet. The optional 46'4" (14.1 m) two-piece front linkage has a maximum vertical height of 49'11" (15.2 m) and is an excellent match for a 1.25 yd3 (0.96 cubic meter) Orange Peel Grapple or the 66" (1.68 m) Walker magnet.

Booms and Sticks

Designed and built for performance and long service life.

Welded Box-Section Structures

Efficiently designed with thick, multi-plate fabrications in high stress areas, which allows structures to flex, dissipating stress and maximizing strength.

Stress Relieving Booms and Sticks

Maximize strength and minimizes structure weight.

Dual Stick Cylinders

Provides excellent geometry for working close to the machine or at full reach.

Heavy Lift

Provides additional lifting capacity for handling of heavy, robust objects.

Engine

Cat® C7 ACERT™

The Cat® C7 with ACERT™ Technology introduces a series of evolutionary, incremental improvements that provide breakthrough engine technology. The building blocks of ACERT™ Technology are fuel delivery, air management, and electronic control. ACERT™ Technology optimizes engine performance while meeting U.S. EPA Tier 3 engine emissions regulations.

Performance

The 325D MH, equipped with the C7 engine with ACERT™ Technology, provides 12% more horsepower as compared to the 3126B ATAAC HEUI in the 325C MH.

Automatic Engine Control Speed Control

The two-stage, one-touch control maximizes fuel efficiency and reduces sound levels.

ADEM™ A4 Engine Controller

ADEM™ A4 electronic control module manages fuel delivery to get best performance per gallon of fuel used. The engine management system provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs. It tracks engine and machine conditions while keeping the engine operating at peak efficiency.

Electronic Control Module

The Electronic Control Module (ECM) works as the "brain" of the engine's control system, responding quickly to operating variables to maximum engine efficiency. Fully integrated with sensors in the engine's fuel, air, coolant, and exhaust systems, the ECM stores and relays information on conditions such as rpm, fuel consumption, and diagnostic information.

Fuel Delivery

The Cat® C7 features electronic controls that govern the fuel injection system. Multiple injection fuel delivery involves a high degree of precision.

Air Cleaner

The radial seal air filter features a double-layered filter core for more efficient filtration and is located in a compartment behind the cab. A warning is displayed on the monitor when dust accumulates above the preset level.

Noise Reduction Technologies

The engine mounts are rubber-isolating mounts matched with the engine package. Further noise reduction has been achieved through design changes to the isolated top cover, oil pan, multiple injection strategy, insulated timing cover, sculpted crankcase and gear train refinements.

Structures

High, Square Undercarriage

Provides excellent over-the-side stability required to handle heavy loads and improve productivity. Excellent ground clearance provided to clear obstacles. Longer track roller frames increase over-the-front stability. Stands up in the toughest applications. Modified X-shaped, box section carbody provides excellent resistance to torsional bending. Upper structure weight and stresses are distributed evenly across the full length of the roller track frame.

Heavy Duty Upper Frame

The upper frame is specifically designed for the scrap and material handling applications. It is built of higher strength material and thicker steel sections to handle increased swing loads from the longer front and heavier counterweights used in material handling.

Work Tools - Attachments

Work Tool Selection

When choosing a work tool, please consider the work tool application, the variation of the density of material to be handled and productivity requirements. Check with your CAT® dealer for more details on specifications, sizes, and other work tool types.

Walker Magnets

The Walker 57" (1.45 m) or 66" (1.68 m) Lift Master magnets can be used with the 325D MH. These magnets have been designed and engineered for scrap processing applications. Ask your dealer salesperson for information on the Walker Magnet.

Orange Peel Grapples

The 0.75 yd3 (0.57 cubic meter) and the 1.25 yd3 (0.96 cubic meter) Orange Peel Grapples are available attachments.

Serviceability and Complete Customer Support

Ground Level Service

The design and layout of the 325D MH was made with the service technician in mind. Many service locations are easily accessible at ground level allowing critical maintenance to get done quickly and efficiently.

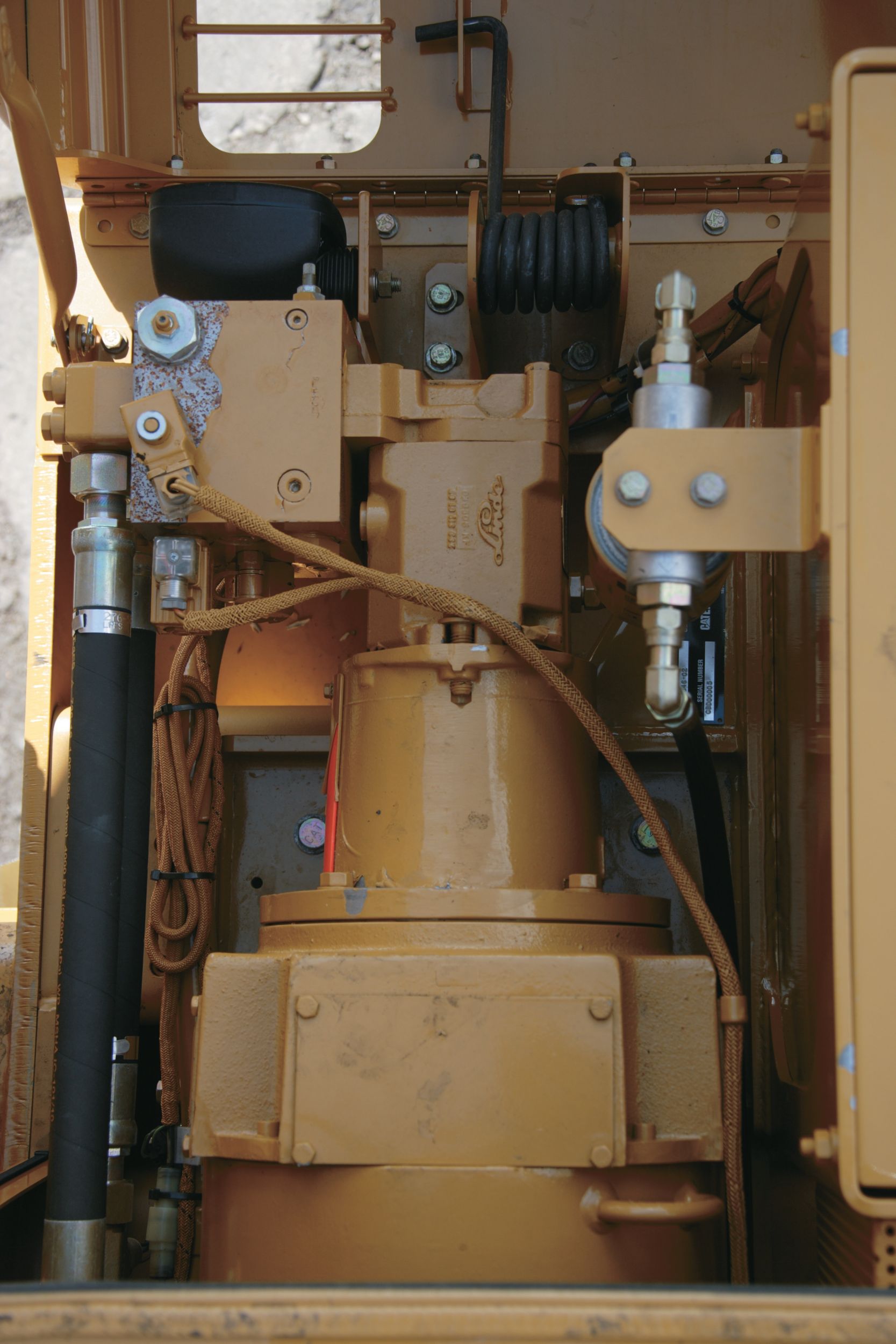

Pump Compartment

A service door on the right side of the upper structure allows ground-level access to the pump and pilot filter.

Radiator Compartment

The left rear service door allows easy access to the engine radiator, oil cooler and air-to-air-after-cooler. A reserve tank and drain cock are attached to the radiator for simplified maintenance.

Air Filter Compartment

The air filter features a double-element construction for superior cleaning efficiency. When the air cleaner plugs, a warning is displayed on the monitor screen inside the cab.

Capsule Filter

The hydraulic return filter, a capsule filter, is situated outside the hydraulic tank. This filter prevents contaminants from entering the system when hydraulic oil is changed and keeps the operation clean.

Fan Guard

Engine radiator fan is completely enclosed by fine wire mesh, reducing the risk of an accident.

Diagnostic and Monitoring

The 325D MH is equipped with S•O•SSM sampling ports and hydraulic test ports for the hydraulic system, engine oil, and for coolant. A test connection for the CAT® Electronic Technician (CAT® ET) service tool is located in the cab.

Extended Service Interval

The 325D MH service and maintenance intervals have been extended to reduce machine service time and increase machine availability

CAT® Dealer Maintenance

Choose from your CAT® Dealer's wide range of maintenance services at the time you purchase your machine. Preventive Maintenance will help you to avoid unscheduled repairs and diagnostic programs such as Scheduled Oil Sampling and Technical Analysis are available.

Product Support

You will find nearly all parts at our dealer parts counter. CAT® dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured components.

Machine Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements, machine attachments and operating hours? What production is needed? Your CAT® dealer can provide recommendations.

Customer Support Agreements

CAT® dealers offer a variety of product support agreements, and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Data not available.

Standard Equipment

- BOOM

- 29'0" (8.85 m) Material Handling Boom Includes high pressure tig welded steel tubes

- ELECTRICAL

- 80 Ampere alternator

- Lights, cab mounted (two)

- Horn

- Light, storage box mounted

- OPERATOR ENVIRONMENT

- Bolt on FOGS capability

- Polycarbonate windows except laminated glass in retractable front windshield / tempered glass in removable lower windshield and sliding upper door window

- Rear window emergency exit

- KAB 84/ E4P Suspension seat with adjustable arm rest and 3" retractable seat belt (cloth)

- Monitor

- Pop up skylight with sunscreen

- Windshield wiper / washers (upper/lower)

- Positive filtered ventilation

- Bi-level air conditioner, heater, and defroster

- Instrument panel and gauges

- Interior lighting

- Coat hook

- Ashtray with lighter

- Literature compartment

- Storage compartment suitable for lunch box

- Neutral lever for all controls

- Adjustable pilot operated joystick type (wrist lever) controls with integral electrical switches for operation of the grapple rotate (modulated) and magnet lift/drop

- Modulated grapple open-close controls using right side joystick

- Toggle switch in RH console to switch between magnet and grapple operation

- Travel control pedals with removable hand levers

- Platform next to cab for improved access

- Washable floor mat

- Sunscreen on windshield

- Beverage holder

- AM/FM Radio with two stereo speakers

- POWER TRAIN

- Cat® C7 diesel engine with 24-volt electric starting and air intake heater

- Emissions package to meet EPA Tier 3 requirements

- Radial seal air filter

- Automatic engine speed control with manual return to idle (not functional when hydraulic generator is in operation)

- Water separator in fuel line

- Two speed auto-shift travel

- Side by side cooling package (high ambient)

- Removable external debris filter covering air inlets

- Muffler

- Air precleaner

- Block heater

- Electric priming pump

- UNDERCARRIAGE

- High square carbody

- Hydraulic track adjusters

- Track type undercarriage with grease lubricated seals

- Idler and center section track guiding guards

- 24" (600 mm) Triple Grouser Shoes (50 sections)

- Heavy duty track rollers

- OTHER STANDARD EQUIPMENT

- Heavy duty upper frame with bottom guards

- Door locks and caps locks and Caterpillar One Key Security System

- Mirrors (frame-right, cab-left)

- 16,980 lb (7.70 kg) Material Handling Counterweight

- Automatic swing parking break

- Fine swing control

- Travel alarm

- Extra batteries, heavy duty starter

- Secondary engine shut off switch

- Ether and cold weather starting aids

- Cold start receptacle

- Crosshead adapter

- Product Link ready

- HYDRAULIC SYSTEMS

- Fully pressurized hydraulic system

- Auxiliary pump and lines to drive generator

- Medium pressure auxiliary hydraulic circuit for powering rotating grapples (includes pump, valve with flow control, and lines)

- High pressure grapple open / close hydraulic circuit with shut off valves at the end of the stick

- Boom and stick lowering check valve

- Regeneration circuit for boom and stick

- Heavy Lift Mode

Optional Equipment

- One of two cab risers MUST be chosen:

- 6'5" (1.9 m) manual tilt cab riser

- 8'6" (2.6 m) hydraulic cab riser

- One of two stick options MUST be chosen:

- Stick, 19'8" (6.0 m) Material Handling providing a linkage with a maximum reach of 46'4" (14.1 m)

- Stick, 24'3" (7.42 m) Material Handling providing a linkage with a maximum reach of 50'11" (15.5 m)

- Magnet-Scrap Handling

- 57" (1.45 m) Walker Liftmaster Series

- 66" (1.68 m) Walker Liftmaster Series

- Grapple-four tine, Orange Peel

- 0.75 yd3 (0.57 cubic meter)

- 1.25 yd3 (0.96 cubic meter)