559CNon-Current

559C - 2013, Tier 4i, Americas NorthOverview

Cat knuckleboom loaders are known for superior multifunction capability, excellent visibility and heavy-duty booms and structures. Now the Cat C Series knuckleboom loaders feature a new more fuel efficient power system, an upgraded hydraulic system for greater reliability and significantly more lift at full reach than previous models.

Specifications

| Gross Power | — |

| Knuckleboom Length | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Gross Power | — |

| Engine Model | Cat® C6.6 ACERT™ Tier 4 Interim |

| Gross Power - 1,800 rpm | — |

| Operating Weight | — |

| Operating Weight - Without Grapple | — |

| Operating Weight - Less Grapple | — |

| Knuckleboom Length | — |

| Swing Speed | — |

| Tail Swing | — |

| Standard Knuckleboom Reach to Pin | — |

| Maximum Reach - Standard Boom | — |

| Swing Bearing - Diameter - Ball Path | — |

| Swing Torque | — |

| Hydraulic Tank | — |

| Fuel Tank | — |

| Swing Drive | — |

| Engine Oil | — |

| Cooling System | — |

| Cylinders - Main | two |

| Hydraulic Pressure - Swing | — |

| Cylinders - Stick | one |

| Hydraulic Pressure - System | — |

| Hydraulic Oil Flow at 1,800 rpm | 230/174 L (60/46 gal) |

| Cylinders - Stabilizers | four |

| Stabilizer Pad Size | 508 × 711 mm (20 × 28 in) |

| Stabilizer Spread - Maximum Down Reach | — |

| Stabilizer Reach Below Grade | — |

| Stabilizer Spread - Grade | — |

| Height - Top of Cab | — |

| OFPS | cab meets SAE J2267 |

| Height | — |

| Width | — |

Benefits & Features

Hydraulics

Powerful System

The custom-engineered hydraulic system forms the heart of the C Series. The system is designed for fast cycle times, smooth operation and maximum reliability in delimbing and loading operations.

Hydraulic Pump is Powerful, Responsive, and Quiet

Designed for continuous, efficient and reliable operation, the loader's axial piston hydraulic pump meets stringent requirements for noise, efficiency, controllability and durability.

Semi-monoblock Valve System

The valve system has proven reliability in forestry applications with its fuel efficient negative control system providing precise control of individual functions. Each section is tuned for optimized flow and pressure of the function, therefore increasing machine functionality and fuel efficiency.

Operating Modes

Three operating modes allow the operator to tailor the machine's performance to match the job requirements. The “economy” mode provides the best combination of fuel efficiency and performance; an intermediate “run” position provides additional flow capabilities when higher production is required, and a “power” mode allows the full potential of the machine to come on-line to handle large timber and the heaviest delimbing requirements. All of the operating modes provide the best multi-function ability, function response, control and fast cycle times.

Automated Control System

The Cat ECM provides best in class diagnostics, operator setup capability, and adjustment of attachment flows.

Electric Hydraulic Oil Fill Pump

The hydraulic oil sight gauge makes it easy to know when oil needs to be added. Adding hydraulic oil is fast and easy with the on-board service hose and electric fill pump. Hydraulic oil is pumped through the filtering system and into the tank, maintaining cleanliness requirements.

Power Train

Cat C6.6 ACERT Engine

The Cat C6.6 engine with ACERT Technology gives exceptional power and fuel efficiency, while meeting U.S. Environmental Protection Agency (EPA) Tier 4 Interim, EU Stage IIIB emission standards. This engine includes electronic governing, cold mode start strategy, automatic altitude compensation, electronic diagnostics and fault monitoring.

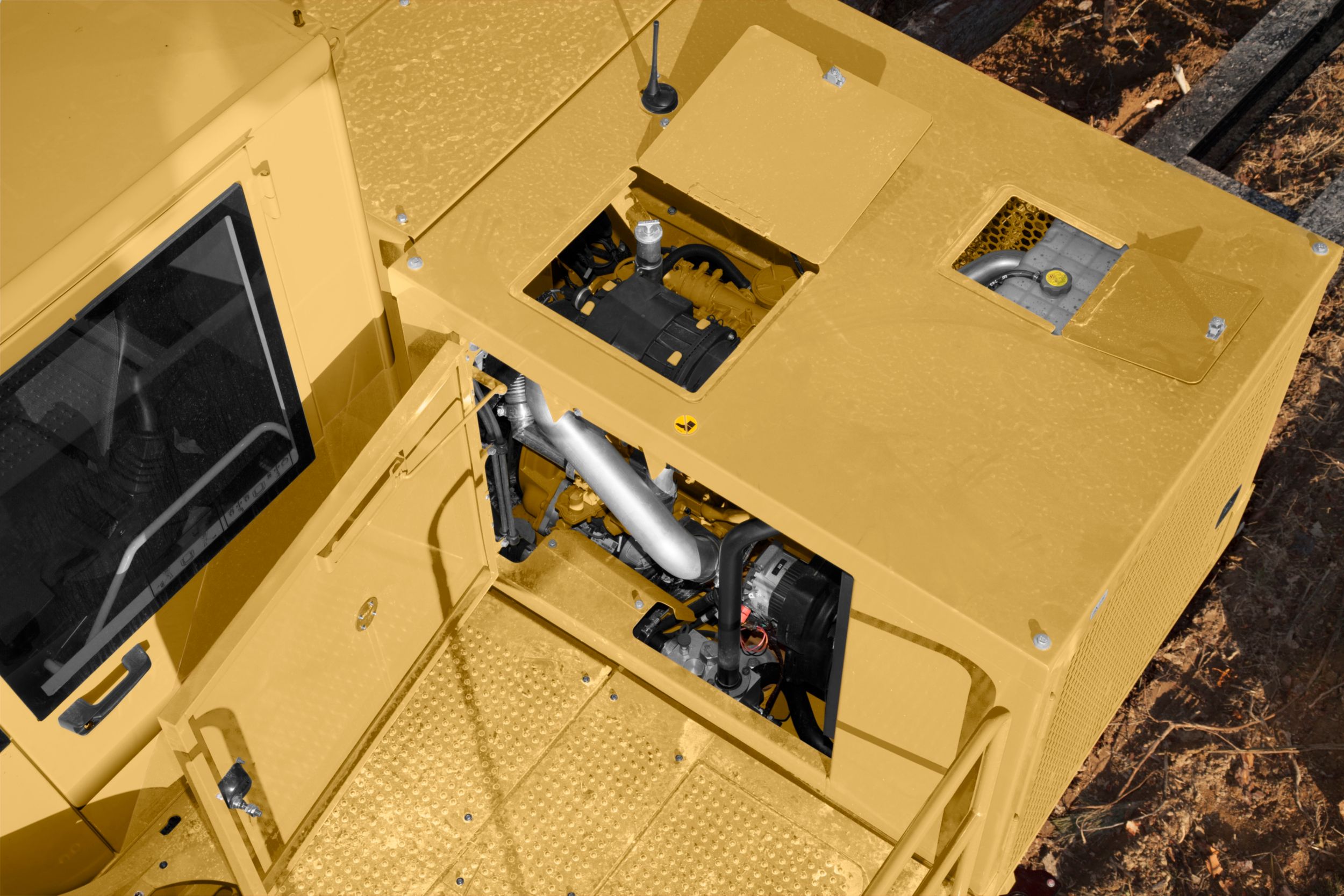

Exceptional Cooling Capability

An enlarged side by side engine coolant, hydraulic, and charge air cooling package allows efficient heat rejection. Individually isolated cooling cores eliminating core to core thermal stresses to greatly increase durability.

Speed Modulated Viscous Fan

The large 864 mm (34 in) diameter electronically controlled variable speed fan is speed modulated to provide cooling only as required, resulting in reduced noise levels and lower fuel consumption.

Operator Station

Front Window Guard

The HD front window guard provides an extra level of safety while handling large trees and building high wood piles.

Clear Visibility

The reverse slope front window stays clean while accumulated moisture and dust can be removed with the front window wiper/washer.

High Back Comfort Seat

The suspension seat features lumbar support and head rest that provide optimum comfort. Armrests are adjustable and cupped for better arm support.

Ergonomic Machine Controls

Hydraulic pilot actuated joystick controls with foot pedal swing for easy operator control of all functions.

Climate Controlled Cab

A high capacity air conditioning and heater system includes channeled air flow to louvered vents for full coverage of the operator and defrosting/defogging of windows.

Molded Consoles and Headliner

The molded console with storage trays eliminates cab clutter. The headliner helps reduce noise in the cab and houses HVAC louvers that allow the operator to adjust air flow. Two 12-volt power points and a factory installed CB mounting bracket, antenna cable, and power harness provide flexibility for additional electric and electronic equipment.

Safe Entry System

The walk up platform includes skid resistant deck and stair components for safe access. An enlarged doorway provides easy cab entry.

Electronics

Information Display

A premium gauge cluster includes LED warning indicators and a digital display which provides information about machine operation, control activation, system diagnostics and operator adjustable settings.

Solid State Controls

Standard industry relays are replaced by solid state controls in high cycle applications to provide substantially longer service life.

Structure and Subframe

Performance

High swing torque, swing speed and lift capacity of Cat knuckleboom loaders reduce cycle times and lower cost per ton.

Durability

The heavy-duty structures of these loaders makes them the right choice for high production, high cycle applications or when handling big hardwoods. The rugged upper frame includes cross plate head side reinforcement for severe delimbing applications.

Subframe Design

Simple, clean and engineered for long life providing a rock solid base for optimum stability.

Stabilizers

Wide stance stabilizer legs and cylinder mounted lock valves resist side pulling and provide 360 degree stability for heavy lifting.

Boom and Stick

Durability

Reliable, heavy-duty booms increase uptime and reduce repair costs.

Strength

The main booms are constructed in a box design with thick walls and strong welds.

Cast Pin Points

The ends and middle of the main booms are cast, which is stronger and lighter than fabricating.

Steel Tube Lines

Steel tube hydraulic lines provide extended life and effectively dissipate heat.

Grapples

- From log loading to pull through delimbing, a selection of grapple styles are available, including:

- TW (tapered wedge) jaw designs for easily grabbing trees from a pile and aggressively gripping trees for delimbing.

- SN (straight, narrow) jaw designs for easy log handling in loading and millyard applications.

High Tensile Steel

Grapple jaws are constructed of special high-tensile wear resistant steel. Critical areas of the jaws are reinforced and designed to protect the cylinder rods and hoses.

Optimum Configurations

Cylinder size and jaw configuration provide holding forces for large multi-stem loads as well as the ability to handle single logs.

Rounded Jaw Tips

Rounded jaw tips minimize damage to individual logs.

Heavy-duty Rotators

Heavy-duty rotators include high-pressure swivels for demanding applications. Each head assembly is constructed of high-tensile steel with heavy-duty bearings and hardened gears.

Delimber/Slasher Package

The Delimber/Slasher (DS) package is a complete factory installed timber merchandising system consisting of a knuckleboom loader and grapple, trailer with trailer-mounted delimber and ground saw slasher connections. The structural design on these loaders is proven to provide long life in punishing, pull-through delimbing applications. The package contains either a three-knife CTR 320 or a four-knife CTR 426 pull-through delimber to match application requirements. These delimbers are designed to allow quick, easy loading of trees and produce clean, delimbed stems in a flash. These delimbers also have central lubrication banks and ground level oil fill for quick, easy service. An automatic chain tensioner simplifies maintenance and extends bar and chain life. The delimbing trailers are built with structural reinforcing in critical areas for durability. Non suspension or single point tandem axle suspension is available and all trailers feature hydraulically adjustable landing gear that is adjustable from in-cab controls. This feature allows the operator to quickly position the loader in a proper operating position and make adjustments to maintain a stable base under the delimber.

Owning and Operating Costs

More Productive

The new Cat C Series is more fuel efficient and productive than the previous models. In controlled lab tests, the 559C was 22% more productive than the 559B. You can move more wood and lower your cost per ton.

Fuel Efficient

A choice of operating modes give you the flexibility to match hydraulic power to the job. For normal loading operations, the Economy Mode provides fast cycle times and the most fuel-efficient performance.

Designed for Logging Applications

The booms and base structures are specifically designed for loading and delimbing applications, providing the strength and durability that allows for a long service life.

Product Link™

Allows tracking of operational parameters to ensure optimum utilization and on time service intervals.

Automatic Idle Down

The loader control system includes an automatic engine idle down feature to reduce fuel consumption during periods of inactivity.

Serviceability

Ground Level Filter Access

Easy changing of engine, fuel, pilot and case drain filters.

Outer-Tank Capsule Filter Assembly

Eliminates contamination backflow during filter changes.

Eco-Valves

Allows capturing of fluids for easy draining without spillage.

Easy Fluid Changes

An electric refill pump to add oil into the hydraulic tank maintains system cleanliness by passing all oil through the filtering system.

Electric Fuel Priming Pump

Easy priming of the fuel system after a service interval, eliminating the potential of fuel contamination.

Swivel, Collector and Swing Motor Access

Large access openings provide easy serviceability of fittings and connectors. Oil level check is accessed on the platform.

Isolated Cooling Cores

Isolated cooling cores can be individually removed, reducing service times.

Customer Support

- Caterpillar is known the world over for the quality of customer support from its dealer network - the industry's best. No matter where you are, the expertise of a Cat dealer is always nearby. Your local Cat dealer is your forestry consultant who can recommend the machines, work tools and services to maximize your operation and provide the support to keep you at top productivity.

- 24-hour parts availability, where and when you need them, to minimize expensive downtime.

- Remanufactured parts that carry the same warranty as new parts at a reduced cost.

- Operator training to get the most out of your Cat equipment.

- Field services to provide on-site help when needed.

- Timely repair and replacement services.

- Customer Support Agreements to lower your operating costs.

- State-of-the-art diagnostic programs, such as S·O·SSM oil analysis, inspection services and trend reporting to help avoid unscheduled repairs.

- Financing programs for buying, renting or leasing Cat equipment.

- Cat Access Account, a fast and convenient way to pay for or rent anything offered at any Cat dealer or The Cat Rental Store.

- Cat Insurance to cover equipment losses from theft, collision, flood, upset or overturn, fire, vandalism and more.

- Product Link to manage your equipment fleet through remote monitoring.

- Cat Certified Rebuild to get a second life from your equipment.

Sustainability

Structures

Major structures and components are built to be rebuilt, reducing waste and replacement costs.

ACERT Engines

ACERT Technology reduces engine emissions at point of combustion with less moving parts for lower operating costs.

Data not available.

Standard Equipment

- ELECTRICAL

- 24V system

- Master disconnect

- Circuit breaker protection

- 95 Amp alternator

- Two (2) 12V maintenance free batteries

- Standard lighting package: - Two (2) cab mounted halogen light fixtures

- Electronic engine/machine monitoring system

- Two (2) 12V power points

- 20 circuit electric swivel

- OPERATOR ENVIRONMENT

- Cab with swing out front window guard (meets SAE J2267)

- Isolation mountings

- Dual joystick control (pilot hydraulic actuation) with foot pedal swing

- Electric stabilizer controls

- Integrated trailer landing gear control

- Pilot shut-off button

- Push button throttle control

- Reverse slope windshield

- Skylight

- Tinted safety glass

- Sunshade - dual position for front window/skylight

- High back suspension seat with lumbar support

- High capacity AC/heater system with outside air intake

- Defroster fan

- Windshield wiper/washer

- Dome light

- Horn

- Radio ready - includes speakers and AM/FM antennas

- CB Radio ready - includes mounting bracket, power and ground wires, antenna cable and antenna mount bracket

- Product Link ready

- Cup holder

- Fire extinguisher mounting bracket

- Diagnostic port

- Cell phone storage tray

- POWER TRAIN

- Cat C6.6 ACERT engine meets U.S. EPA Tier 4 Interim/EU Stage IIIB emission standards

- Electric fuel priming pump

- Air precleaner

- 2-stage air cleaner

- Enlarged cooling package with isolated cores

- 378 L (100 U.S. gal) fuel tank

- Fuel water separator

- Variable speed fan

- HYDRAULICS

- Twin 140 cm3 (8.54 in3) variable displacement pumps

- Excavator style “Negacon” system

- Bar slasher/delimber hydraulic package

- 302 L (80 U.S. gal) hydraulic tank

- Electric hydraulic oil fill pump

- STRUCTURE AND SUBFRAME

- Fabricated heavy-duty, extended length center mount subframe

- Flat top subframe deck with bolt-on skid resistant fenders

- Bolt-on subframe ladder

- BOOMS AND STICKS

- 9.8 m (32 ft) reach knuckleboom

- 229 mm (9 in) grapple mounting knuckle

- ANTIFREEZE

- 50% concentration extended life coolant

Optional Equipment

- DS SYSTEMS

- Non-suspension trailer with hydraulic landing gear

- Suspension trailer with hydraulic landing gear

- CTR 320 three-knife delimber

- CTR 426 four-knife delimber

- OTHER EQUIPMENT

- Cat Product Link

- AM/FM/CD/Satellite radio receiver

- Long-range front lights on cab

- Engine compartment lights

- Additional subframe ladders

- Auxiliary light package

- Slasher port adapter fittings

- Single “V” and double “VV” bolt on heels

- Single “V” extended and double “VV” extended bolt on heels

- 305 mm (12 in) grapple mounting knuckle

- Grapples