Overview

The 5110B is in a size class of its own. Designed and built to meet the durability and reliability expectations of Cat customers, this high production loading tool works as hard as a large mining shovel, but is as comfortable and easy to operate as a smaller excavator. With high bucket fill factors and fast cycle times, the 5110B moves more tons per hour at a lower total cost to give you the Cat working advantage. The purpose built 5110B L features an extended undercarriage and longer boom and stick options for high production capability in excavation, trenching, pipelaying, demolition and other demanding heavy construction and mining utility applications.

Specifications

| Engine Model | Cat 3412E HEUI™ |

| Gross Power | — |

| Net Power | — |

Benefits & Features

Specifications

| Engine Model | Cat 3412E HEUI™ |

| Gross Power | — |

| Net Power | — |

| Net Power - Caterpillar | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Main Implement - Circuit | Closed center load sensing |

| Main Implement - Pump | Piston, variable |

| Maximum Flow at 1915 rpm (1x) | — |

| Maximum Flow at 1800 rpm (2x) | — |

| Relief Valve Setting - Implement - Std. | — |

| Relief Valve Setting - Implement - Heavy Lift - Long | — |

| Relief Valve Setting - Travel | — |

| Number of Implement/Travel Pumps | 3 |

| Swing System - Circuit | Open center load sensing |

| Swing System - Pump | Piston, variable |

| Maximum Pump Flow at 1915 rpm | — |

| Relief Valve Setting - Accelerating | — |

| Relief Valve Setting - Decelerating | — |

| Number of Swing Pumps | 1 |

| Pilot System - Circuit | Open center |

| Pilot System - Pump | Gear |

| Maximum Pump Flow at 1915 rpm | — |

| Relief Valve Setting - Controls | — |

| Relief Valve Setting - Track Tension | — |

| Number of Pilot Pumps | 1 |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| Stick Cylinder - Bore | — |

| Stick Cylinder - Stroke | — |

| Bucket Cylinder - Bore | — |

| Bucket Cylinder - Stroke | — |

| Operating Weight - STD | — |

| Operating Weight - Long | — |

| Truck Payload Match | — |

| Cat Truck Match | 773E, 777D |

| Target Payload - Standard | — |

| Maximum Travel Speed - High | — |

| Maximum Travel Speed - Low | — |

| Maximum Drawbar Pull | — |

| Swing Speed | — |

| Swing Torque | — |

| Track Width - Rock | — |

| Track Width - General Purpose | — |

| Track Width - Soft Underfoot | — |

| Track Tensioning | Automatic |

| Shoes Per Side - Standard | 55 |

| Shoes Per Side - Long | 58 |

| Rollers Per Side - Standard | 9 |

| Rollers Per Side - Long | 10 |

| Carrier Idlers | 3 |

| Fuel Tank | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Brakes - Swing | ISO/DIS 13677 |

| Brakes - Travel | ISO 10265 |

| Cab - Sound | ISO 6394:1985 |

| Cab Vibration | EC 89/392EEC |

| Cab/FOGS | SAE J1356 FEB88 |

| Overall Height | — |

| Overall Width | — |

| Overall Length - Std | — |

| Overall Length - Long | — |

| Tail Swing Radius | — |

| Upper Structure Width | — |

| Cab Width | — |

| Height - Top of Cab | — |

| Height - Top of Counterweight | — |

| Counterweight Height | — |

| Counterweight Clearance | — |

| Ground Clearance | — |

| Track Length - Standard | — |

| Track Length - Long | — |

| Track Length - Ground - Standard | — |

| Track Length - Ground - Long | — |

| Track Gauge - Width | — |

| Width - Outside of Tracks | — |

Benefits & Features

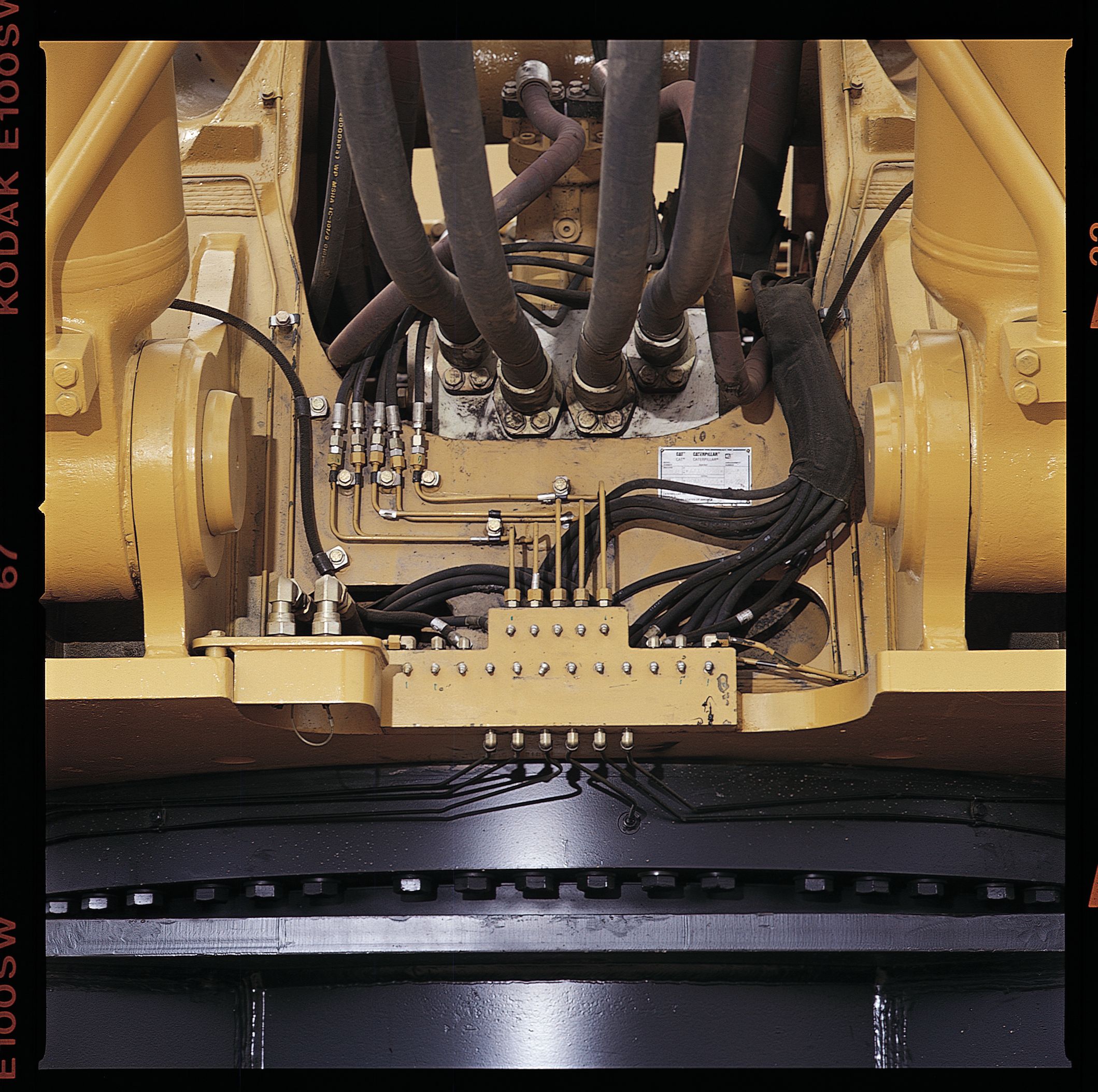

Hydraulics

Hydraulic System

5110B hydraulic system delivers efficient transfer of power from engine to bucket, tracks, and swing drives for smooth, multitasking operation.

PPPC System

Cat Proportional Priority Pressure Compensating (PPPC) hydraulic system assures smooth, efficient operation and controllability. Implements (boom, stick and bucket) work at a constant speed regardless of machine load and engine speed. When flow is required by more than one function at a time (boom up and stick out), automatic flow proportioning proportionally divides required flow for each function according to demand to ensure smooth, precise, multifunction operation.

Electronically Controlled Pumps

Computer controlled pumps regulate and match hydraulic output to engine power for maximum engine hydraulic power transfer efficiency. Hydraulic system draws full engine power for precise, full-powered hydraulic response. Load sensing control prevents excessive engine lugging for superior fuel efficiency.

Auxiliary Hydraulics

An optional auxiliary valve with control arrangement allows the 5110B L to operate high-pressure tools such as thumbs, hammers, shears and crushers. Flow settings can be adjusted to meet specific tool requirements. A separate medium pressure circuit is available for functions such as rotate.

Hydraulic Cooling

Separate variable-capacity temperature-sensing hydraulic cooling system with dedicated core radiator provides cooling on demand to maximize hydraulic efficiency. Extra-large standard cooling capacity allows operation in ambient temperatures up to 50°C (122°F). Optional high ambient cooling package provides additional cooling in extremely hot conditions.

Cat Hydraulic Hose

Field proven Cat XT high-pressure hydraulic hose is exceptionally strong and flexible for system reliability and long life in the most demanding conditions. Reusable couplings provide superior, leak free performance and prolong hose assembly life.

Hydraulic Tank

Minimally-pressurized oval shaped hydraulic tank reduces hydraulic system complexity and risk of excessive oil discharge if a leak occurs. Vacuum breaker valve lets in filtered air to prevent cavitation. Sight gauge allows for easy inspection of oil level.

Power Train

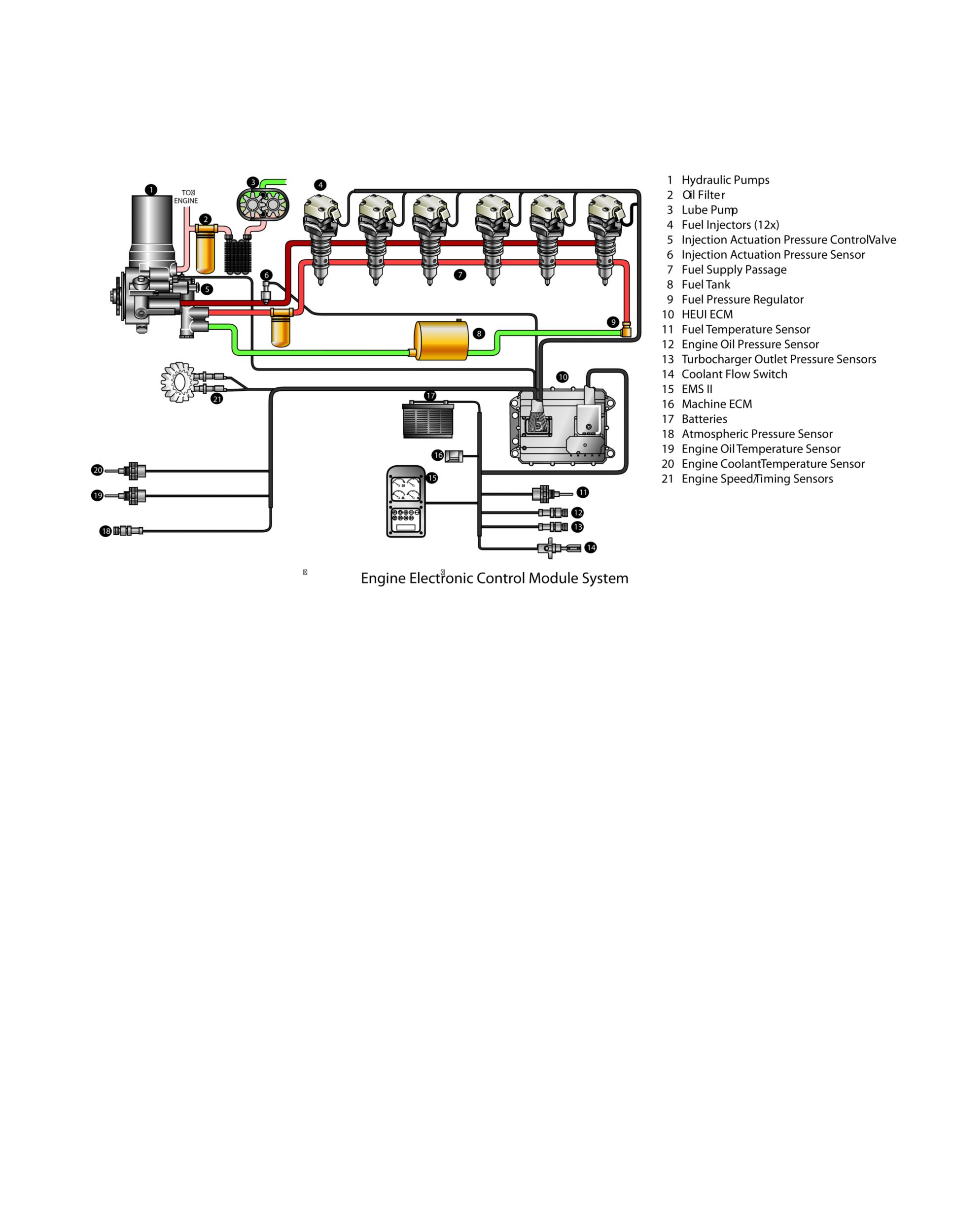

Engine

Cat 3412E HEUI™ engine delivers reliable power with low emissions, excellent fuel economy, and traditional Cat durability. Engine is matched to hydraulic pump output for smooth, multitasking operation.

Engine Design

The 3412E four-stroke, air-to-air after cooled (ATAAC) engine features large structures and a low RPM rating for excellent durability and long life. The 12-cylinder design features two banks of six cylinders with dual air cleaners, dual turbochargers, dual exhaust, and dual mufflers.

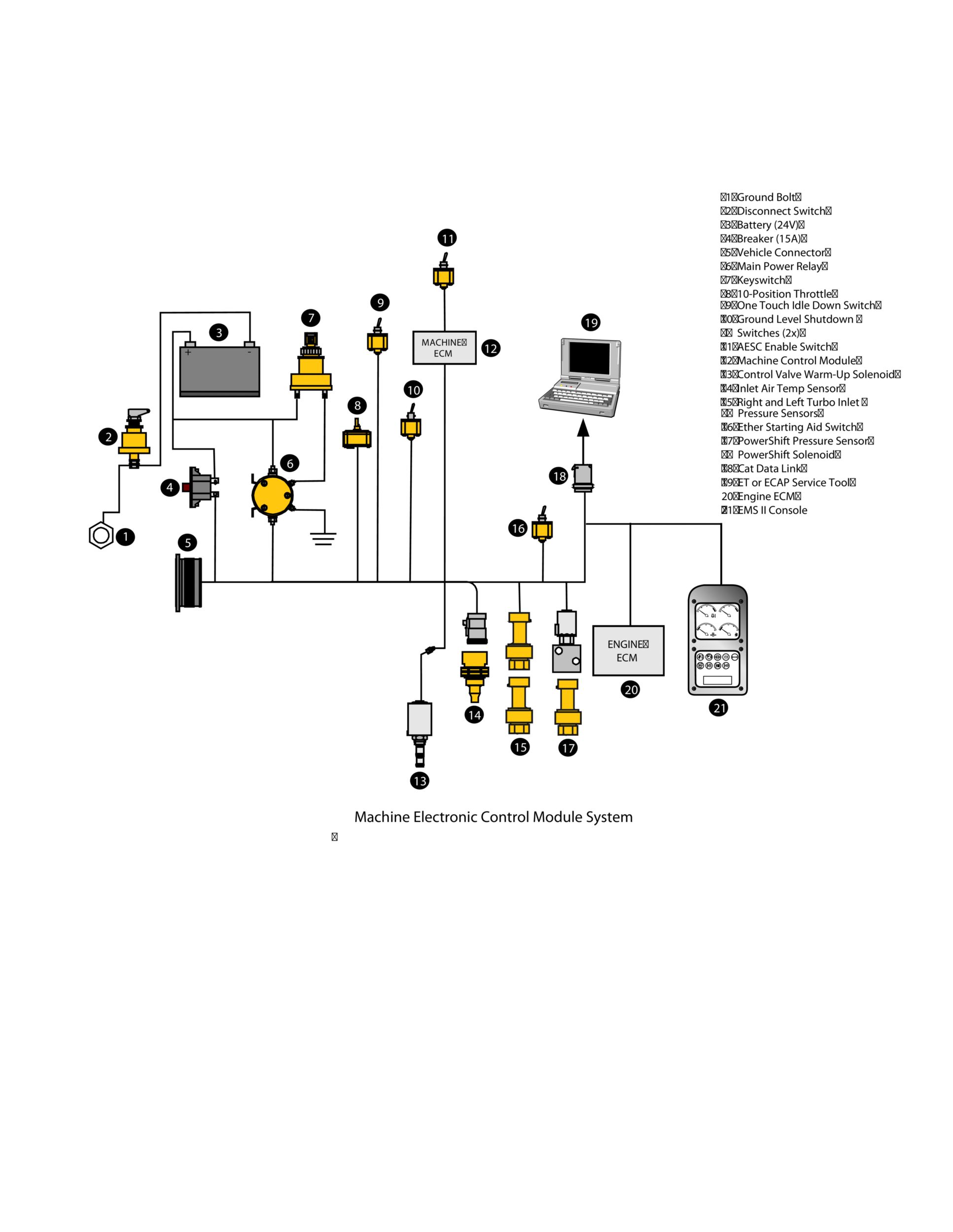

Electronic Control Module

The ECM is the electronic "brains" of the power system. Computerized system senses operating conditions and power requirements and adjusts engine for most efficient operation at all times.

HEUI™ Fuel System

Cat's proprietary fuel system utilizes hydraulically actuated, electronically controlled, unit injectors and electronically monitors operator and sensor inputs to optimize engine performance, reliability, emissions and fuel efficiency. Fuel system independently controls injection over entire engine operating speed range for complete control of injection timing, duration and pressure.

Automatic Engine Speed Control

Maximizes fuel efficiency and reduces engine noise by reducing engine speed when hydraulic controls are inactive.

Ether Starting Aid

Helps ensure engine starting in extreme cold operating conditions.

Cold Start Mode

Retards timing and elevates idle speed in frigid conditions for longer piston and liner life.

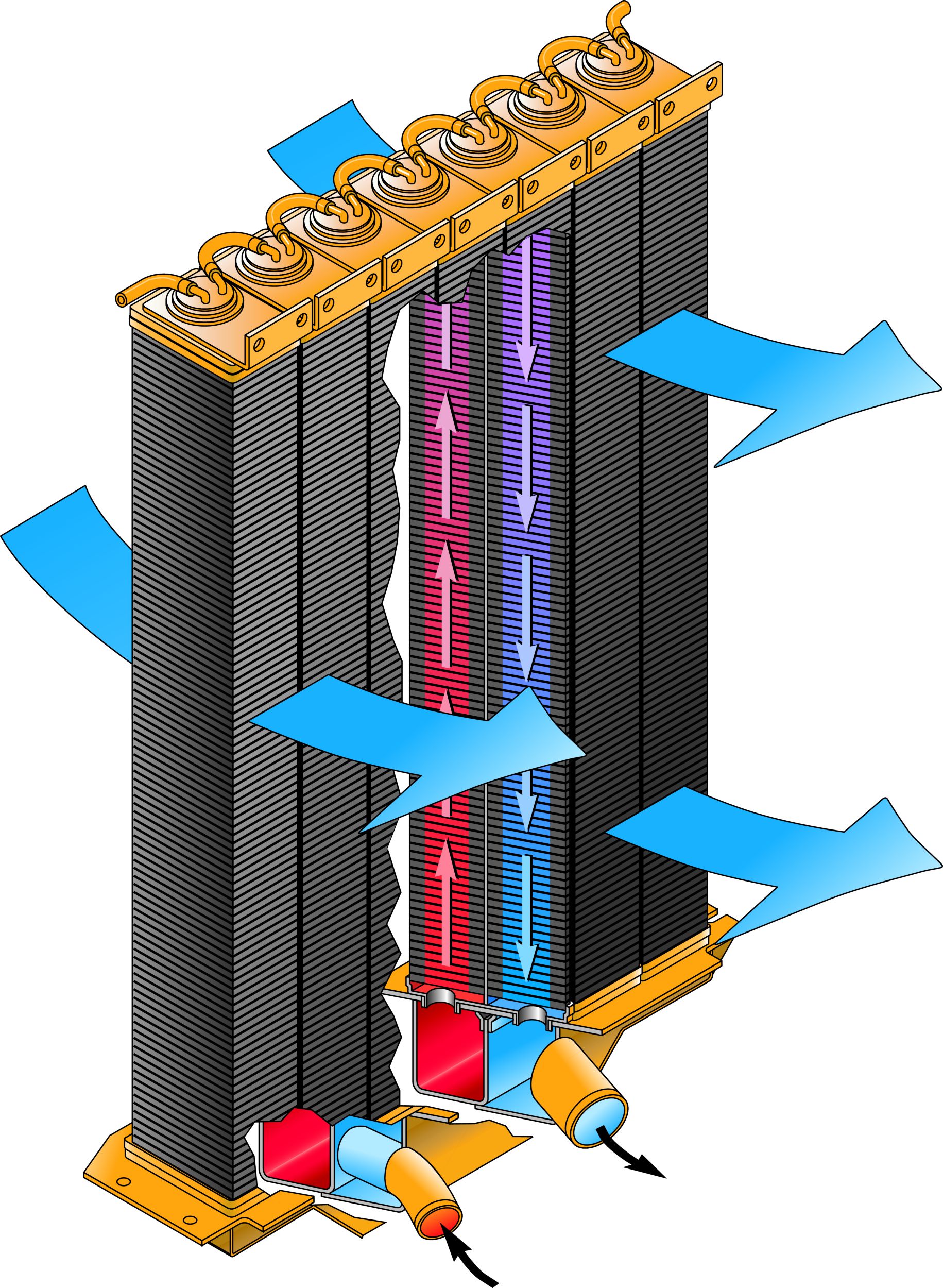

AMOCS Cooling System

Exclusive two-pass advanced modular cooling system provides high ambient cooling capacity for greater cooling efficiency.

Undercarriage

Stable Design

Proven undercarriage design and rugged structures assure outstanding durability in extreme conditions. Wide track gauge, large undercarriage and high ground clearance provide excellent stability, maneuverability and lift capacity.

Track Roller Frames

Durable Cat frames hold moving undercarriage components rigidly in place and absorb high force travel loads transmitted from carbody. Rugged design offers high resistance to shock and vibration.

Long Undercarriage

The 5110B L features a lengthened undercarriage to better tackle rough terrain on heavy construction job sites. The longer frame creates additional front and rear stability for greater lift capacity and reach capability.

Guarded Components

Travel motors, brakes and final drives are integrated within track roller frame for impact and shock protection from rocks and other hazards. Hydraulic lines are routed through guarded passages for protection and long service life.

Travel Motors

Independent, two-speed travel motors deliver smooth power to tracks and allow counter-rotation for spot turns. Two-speed travel allows fast travel on flat floor and full power on turns and slopes. Hydraulic actuation ensures smooth shifts.

Final Drives

Final drives are three-stage planetary with case-hardened gears. Two large tapered roller bearings support sprocket loads.

Rollers and Sprockets

Durable, single-flange track rollers rotate on large-diameter, solid shafts for heavy duty operation. Carrier rollers are mounted on structural supports integral to the track roller frame for exceptional durability. Sprockets are heat-treated and teeth are induction hardened for toughness.

Assembly Alignment Guides

Self-aligning grooves on track roller frames allow easy alignment of carbody to frame for quick machine assembly and disassembly.

Sealed and Greased Track

Track is sealed and greased for maintenance-free duty. Grease lubrication seals protect track links from abrasive wear for long track pin and bushing inner wear life.

Automatic Track Tensioning

Hydraulically controlled track tensioning maintains constant tension for optimum traction and adjustment-free duty.

Structures

Robust Design

The 5110B is designed with robust structural components for heavy-duty mining applications. Structures are designed and built to absorb high impact shock loads and twisting forces for superior structural durability, reliability and long life.

Heavy Duty Castings

Heat-treated castings used extensively in high load areas ensure smooth flow of stresses for long-term structural durability.

Swing Frame

I-beam construction provides outstanding resistance to fore-and-aft bending loads from front linkage and counterweight. Reinforced steel gussets and side plates provide optimum strength against torsion loads. Heat-treated castings in boom foot pedestal area provide superior structural strength and durability.

Front Structures

Durable front linkage is sturdy and strong, yet light enough for fast cycle times. Box-section design provides unsurpassed rigidity and strength. High strength steels used in critical areas insure impact and wear resistance in difficult digging conditions. Thermally stress relieved structures reduce residual stresses for longer structural life. Heat-treated castings in high load areas add exceptional strength and durability.

Carbody

Designed and built to withstand demanding digging, swing, and travel loads. Carbody structures are thermally stress relieved after fabrication for long structural life. Internal gussets add strength to H-shaped box section design to resist torsional bending. Top plates are inclined to reduce material buildup.

Swing Bearing

Mining-duty swing bearing is designed to accommodate demanding forces transmitted through the bearing between the carbody and swing frame. Unique cross roller bearing design provides greater contact area than traditional ball bearings for superior stability and long life. Efficient roller geometry results in lower frictional losses with reduced heat buildup. Swing bearing is mounted to machined surface on carbody to eliminate collar welds for exceptional structural strength and durability.

Swing Drives

Track Roller Frames

Designed and fabricated to provide structural strength and absorb stress loads transmitted from carbody to tracks. Upper structure weight and forces are distributed evenly across track roller frames for long-term durability. Box beam design with internal stiffening plates provides excellent strength and rigidity.

Sticks and Booms

All sticks and booms feature large welded box section structures with multi-plate fabrications in high-stress areas to reduce weight and enhance rigidity. Structures are thermally stress relieved to maximize fatigue life and durability. Internal baffle plate design minimizes weight for optimum performance and fast cycle times.

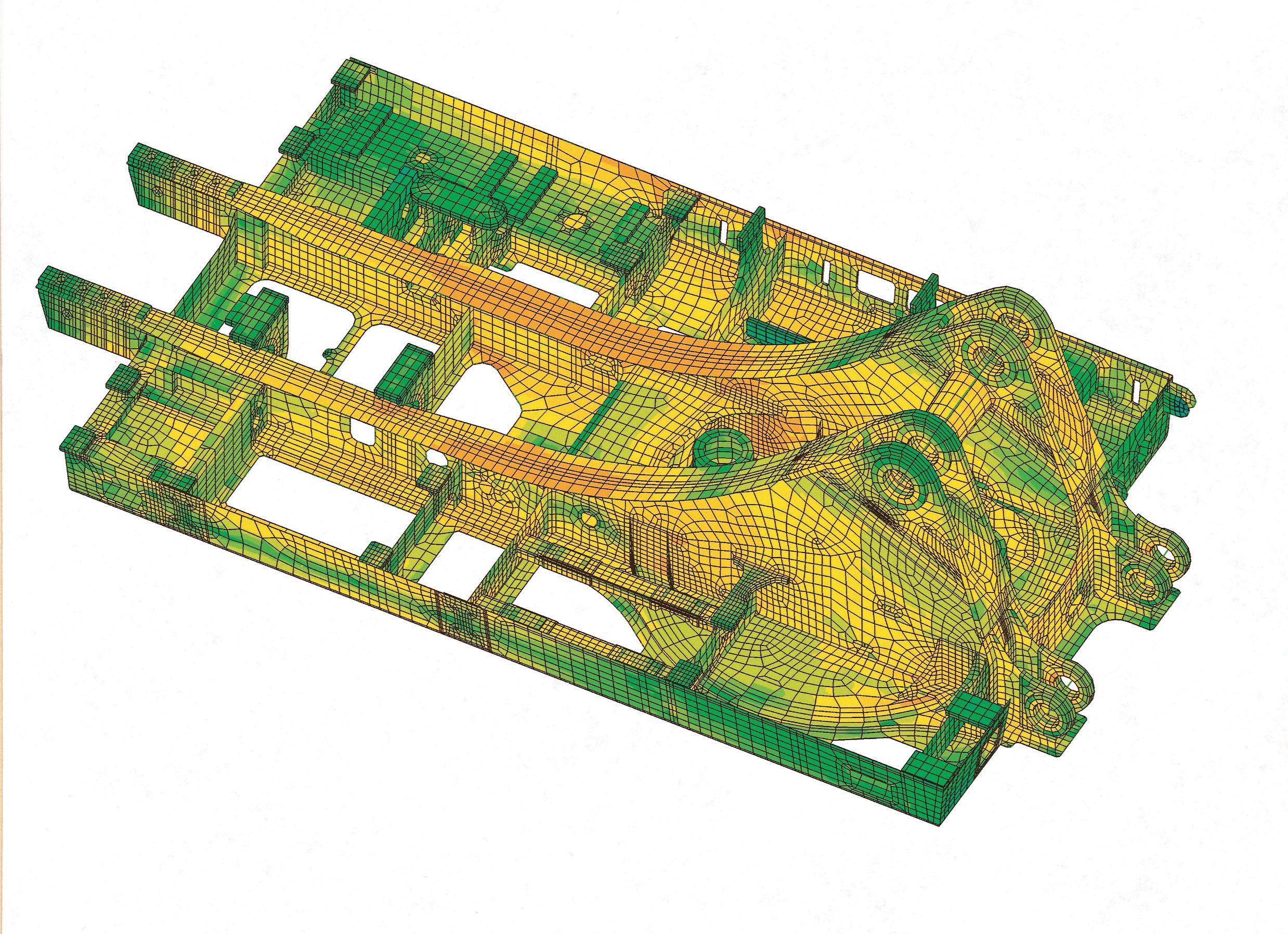

Finite Element Analysis

Finite element analysis, used in the design phase, identifies high load areas and optimizes design weight to ensure high reliability and long structural life.

Heavy Duty Access Points

Durable service platforms, crosswalk, ladders and handrails use industrial strength grating, skid plates and railings for long life in extreme conditions.

Operator's Station

Spacious Cab

Roomy cab provides comfortable working environment for hours of high productivity.

Joystick Controls

Easily accessible operator controls provide sure, precise maneuvering for high productivity and low operator fatigue. Joystick console height is adjustable independently of the seat for full operator comfort.

Travel Controls

Two rocker pedals with detachable hand levers control steering and travel functions. Foot controls allow operator to move machine while working front linkage.

Hydraulic Actuation Lever

Manually applied hydraulic actuation lever on left console cuts off pilot pressure for joysticks, travel control and electrical power to prevent accidental startup and operation when exiting the cab.

Anti-Drift Function

Optional anti-drift valve keeps the front linkage steady during delicate lifting operations.

Heavy Lift Mode

Optional feature provides increased lifting capability with excellent controllability when lifting heavy loads.

Third Pedal Straight Travel

Optional straight travel pedal allows straight, forward travel using a single pedal instead of the standard two pedal design.

Suspension Seat

Fully adjustable suspension seat provides height and weight adjustments, lumbar support, arm/wrist rests, and wide retractable seatbelt for full operator comfort and support.

Monitoring System

Cat Electronic Monitoring System III continually monitors machine conditions and alerts operator of potential problems to reduce risk of catastrophic failure. Engine performance can be monitored regularly by service technicians for diagnosis and preventative maintenance, improving machine reliability and reducing costly downtime.

Windows

Large, wide windows provide excellent all-around visibility. Retractable front windshield provides large viewing area. Lower front window provides view of the tracks. Upper left side door window slides open for excellent ventilation. Polycarbonate skylight provides an unobstructed upward view. Rear window serves as an emergency exit for operator safety.

Automatic Climate Control

Fully automatic system with air conditioner, heater and defroster maintains constant cab temperature for comfortable operation in any weather condition. Fresh air filter removes dust and particles before fresh air is circulated through cab.

Cab Riser

Optional tall cab riser enhances visibility into trucks during same level loading.

Cab Mounts

Double wall pressed cab shell is mounted to the swing frame with viscous mounts to reduce noise, vibration and operator fatigue.

FOGS

Optional Falling Object Guarding Structure (FOGS) provides protection for operator and machine. Front windshield guard swings open for glass cleaning.

Booms and Sticks

Boom and Stick Selection

Longer boom and stick arrangements are designed to maximize digging depth and reach capabilities in a variety of mining and heavy construction applications.

Boom Construction

All booms feature large welded box section structures with multi-plate fabrications in high-stress areas to reduce weight and enhance rigidity. Castings are used in high stress areas such as boom cylinder pivot and foot. Booms are thermally stress relieved to maximize fatigue life and durability while minimizing weight for optimum performance.

Stick Construction

All sticks are made of high-tensile strength steel using a large box section design with interior baffle plates and an additional bottom plate to protect against rock damage. Sticks are stress relieved for long life.

Work Tools

The 5110B L offers an assortment of work tools to perform a variety of demanding tasks. Cat designed and manufactured work tools are matched specifically for special reach and dig requirements.

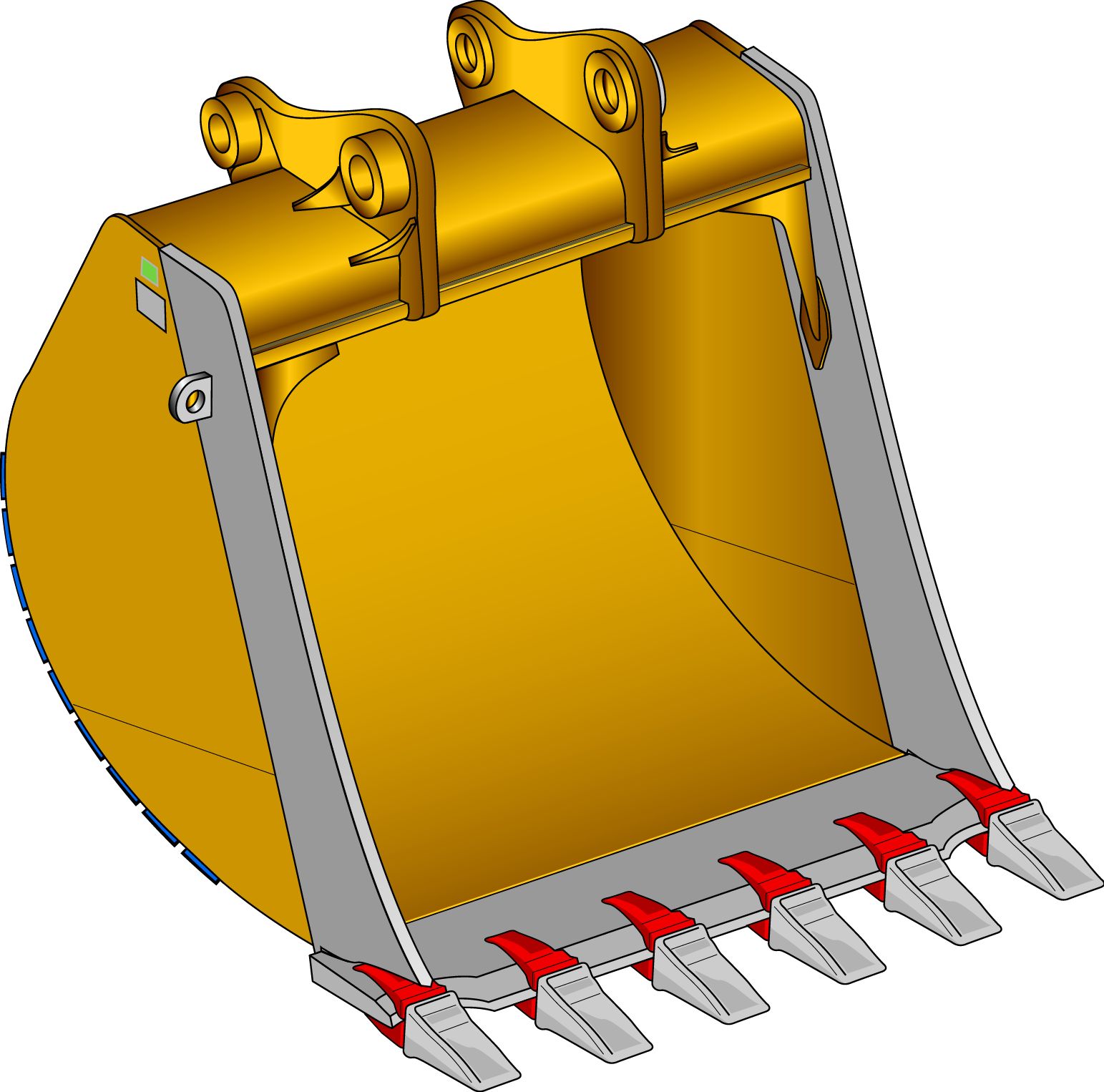

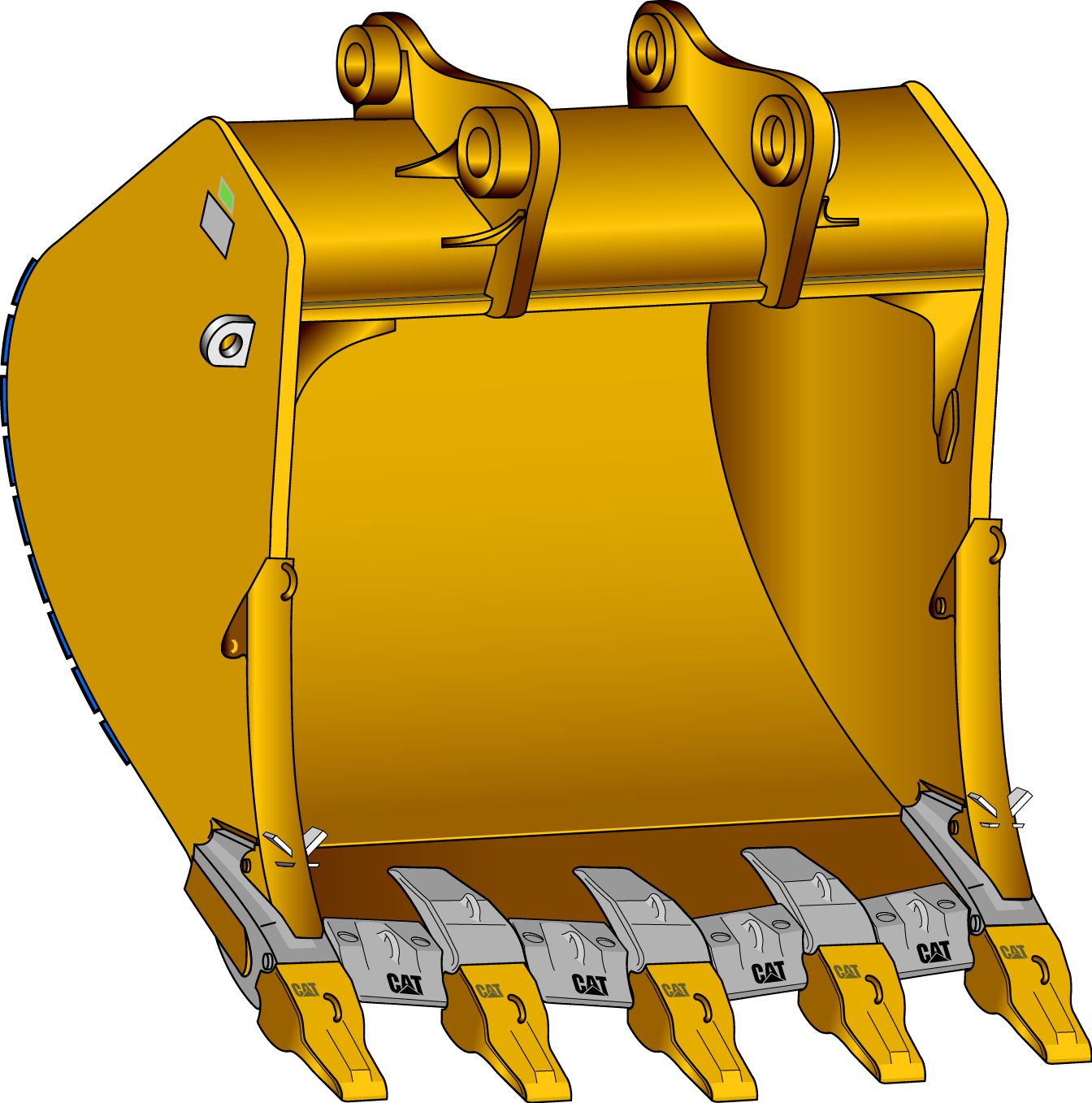

Buckets and Ground Engaging Tools

High Productivity

Aggressive Cat bucket designs deliver unmatched productivity in demanding applications. High crowd force at cutting edge improves material penetration. High breakout and stick forces combine to maximize bucket loads.

Bucket Design

Durable Cat buckets are designed for maximum operating efficiency and long service life. Unique bucket design and linkage geometry optimize bucket fill. Curved floor design promotes high breakout force and smooth material flow.

Medium Duty Buckets

Intended for mass excavation in unconsolidated materials such as top soils, clays or sands. Unique bucket design provides optimum penetration and high production fill factors when matched to required digging forces.

Heavy Duty Rock Buckets

Built rugged for mass excavation in highly abrasive materials and hard digging conditions. Thicker cutting edges with spade edge design enhance bucket performance in demanding applications.

Coal Buckets

Larger capacity buckets for digging in less abrasive, low density materials, such as coal loading.

Bucket and G.E.T. Selection

Contact your Cat dealer for a precise match to your application.

Serviceability

Servicing Ease

The 5110B layout was designed with the service technician in mind. Simplified design makes regular maintenance procedures as quick and easy as possible. Easy access to daily service points ensures maintenance will be done, increasing machine availability and service life.

Ground Level Access

Service locations are easily accessible at ground level, allowing critical, routine maintenance to get done quickly, safely and efficiently. Centralized lubrication points simplify servicing in to hard-to-reach locations.

Service Platforms

Right and left-hand service platforms with open grating provide easy access to cab, cross walkway, engine service doors and engine/pump room for safe, easy servicing.

Cross Walkway

Wide crosswalk made of extruded tread plates provides safer service access to full width of machine, including hydraulics, engine service doors and engine/pump room. Access doors open outward for easy inspection. Fluid sight gauges are visible from center of machine for daily fluid inspections.

Engine and Pump Room

Lighted, stand-up engine compartment and pump room provide easy service access to engine and pumps. Large service doors provide ample room for inspection and servicing. A bulkhead separates the pump room from the engine compartment for safer containment of hydraulic oils.

Handrails and Grab Irons

Handrails enclose all external walkways and service platforms for safe service access. Grab irons and steps provide the operator with three points of contact at all times.

Ladder Light

Ground level access switch provides lighted entry and exit for operator safety. Optional work lights provide excellent lighting after dark.

Engine Kill Switch

Ground level and engine room access to engine kill switch allows quick shutoff in emergency situations.

On-Board Diagnostic Systems

Electronic Monitoring System III continuously checks all critical machine functions and components, and helps located faults quickly for faster repair. Electronic Technician (ET) test connection is conveniently located on the console for easy access.

S·O·SSM Sampling Valves

Scheduled Oil Sampling ports provide a fast, convenient means of obtaining uncontaminated fluid samples for improved analysis and reliability.

Hydraulic Pressure Test Ports

Autolube

Optional autolube feature provides automatic lubrication at all grease fittings (except bucket linkage) at predetermined cycles for maintenance-free duty.

Grease Reel

Optional grease gun and reel allows remote lubrication of front bucket linkage from ground level. Hose has sufficient length to reach remote lubrication points near bucket.

Ecology Drains

Drain hoses connect from ground line to fuel tank, hydraulic tank, engine oil pan, engine coolant and swing drives to protect the environment from accidental spills.

Spin-on Oil Filters

Spin-on filters for fuel and oil systems reduce changing time and help assure clean, tight seals.

Fuel/Water Separator

Removes water from fuel, even when under pressure. Located at the center of the machine on the fuel tank.

AMOCS Radiator

Seven-core modular radiator features replaceable and interchangeable core modules for quick and easy servicing.

Fuel Tank

Transportability

Ease of assembly and disassembly are proven in the 5110B's modular design. Modular shipping enables quick, cost-effective hauling from site to site. The chassis is small enough to transport in one unit with the engine ready to run. All you need to do is assemble the machine modules and connect the hydraulic hoses.

Customer Support

Machine Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers can estimate component life, preventive maintenance cost, and the true cost of lost production.

Purchase

Look past initial price. Consider the financing options available, as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to lower equipment owning and operating costs over the long run.

Financing

Your dealer is an expert at arranging affordable financing options for all Caterpillar products.

Customer Support Agreements

Cat dealers offer a variety of product support agreements, and work with customers to develop a plan that meets specific needs. These plans can cover the entire machine, including attachments, to help protect your investments.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers use a worldwide computer network to find in-stock parts to minimize machine downtime. Save money with Cat Reman parts. Receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training videotapes, literature and other ideas to help you increase productivity.

Maintenance Services

Choose from your dealer's range of maintenance services when you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM and coolant sampling and technical analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

www.CAT.com

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www.CAT.com.

Safety

SAE and ISO Standards

The 5110B is designed to national and international standards, and has been tested and self certified to comply with applicable SAE and ISO safety standards.

Lighted Access

Service lighting for the engine and pump compartments provide lighted service access at night. Compartments are equipped with independently controlled switches. Ground level toggle switch at the ladder base provides lighting for operator ingress/egress.

Ladder

Wide, stationary ladder allows access to and from the machine. Handrails on both sides enable three points of contact at all times.

Engine Shut Off Switches

Located in the engine compartment and at ground level at the ladder base for safe shutdown.

Hydraulic Activation Control Lever

A lever, located on the seat console, prevents hydraulic circuits from being operated when in the locked position.

Cab Mounts

Viscous cab mounts with silicon oil absorbs vibrations and reduces interior sound levels.

Windows

The upper front window is laminated for operator protection and retracts for easy cleaning. The lower front window and side windows are made of tempered glass. The fixed position skylight is impact resistant polycarbonate. The rear window serves as an emergency exit.

Secondary Egress

Secondary egress from the cab is provided by removing the rear window and stepping out onto the fuel tank. A ladder on the right side of the machine permits secondary access or emergency egress.

Electrical System Disconnect

A disconnect switch, located outside the battery compartment, locks out the electrical system.

Bulk Head

A bulk head wall separates the pump compartment from the engine, minimizing engine heat exposure to the hydraulic system.

Minimally Pressurized Hydraulic Tank

The hydraulic tank is minimally-pressurized to improve servicing and minimize oil discharge if a leak occurs.

Travel Alarm

An exterior warning sounds when the travel circuit is activated.

Swing and Travel Brakes

The swing brake automatically engages when the operator leaves the hydraulic controls untouched for more than eight seconds, holding the upper structure securely in place. The brake releases when the operator moves either the joystick or travel controls. The final drives include a hydraulically released, spring applied, multi-plate parking brake, which applies when the machine is not moving.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, travel

- Alternator, 100-amp

- Auxiliary starting receptacle

- Batteries (2)

- Caterpillar Monitoring System (EMS III)

- Diagnostic center

- Lights, halogen (4)

- OPERATOR ENVIRONMENT

- Air conditioner/heater with auto climate control and defroster

- Ashtray/lighter

- Auxiliary power source, 5-amp, 12V, DC

- Beverage holder

- Cab, sound suppressed

- Coat hook

- Floor mat

- Hydraulic lockout lever

- Interior light

- Instrument panel, gauges:

- Joysticks, adjustable

- Radio ready

- Seat belt, retractable

- Skylight, stationary

- Storage compartment, lunchbox

- Sunshade, multiposition

- Suspension seat, adjustable, headrest/armrests

- Travel controls, pedal and lever

- Ventilation, positive filtered

- Windows:

- Windshield wiper/washer, intermittent, upper/lower

- POWERTRAIN

- AMOCS radiator

- Air cleaner, pre-cleaner

- Automatic Engine Speed Control

- Cat 3412E HEUI™ Engine

- Hydraulic oil cooler

- Proportional Priority Pressure Compensating (PPPC) System

- Starting aid, ether

- Two speed travel mode

- Water separator, fuel line

- UNDERCARRIAGE

- Automatic track tensioning, hydraulic

- Rock shoe, 700 mm (28 in)

- General purpose shoe, 900 mm (36 in) - 5110B L

- OTHER STANDARD EQUIPMENT

- Antifreeze, - 50°C (- 58°F)

- Automatic swing parking brake

- Boom, mass excavation, 7.6 m (24.9 ft)

- Boom, general purpose, 9.2 m (30.2 ft) - 5110B L

- Counterweight

- Fuel tank, fast fill

- Guard, upper frame bottom below engine, hydraulic pumps, pilot lines, cab and swivel

- Handrails/walkways, heavy-duty

- Horn, electric

- Ladder, fixed

- Lifting points, integrated assembly

- Locks, door/caps (one-key)

- Lubrication system, manual, centralized

- Mirrors, left/right

- Mufflers

- Product Link (PL201) ready

- Service access, lighted

- S·O·SSM quick sampling valves for:

- Swing gear case, drain/fill quick connects

- Provision for attachment hydraulic pump

Optional Equipment

- FRONT LINKAGE

- Stick, mass excavation, 3.4 m (11.2 ft)

- Stick, mass excavation, 4.1 m (13.5 ft)

- Stick, general purpose, 3.6 m (11.8 ft) - 5110B L

- Stick, general purpose, 4.5 m (14.7 ft) - 5110B L

- Stick, general purpose, 5.5 m (18 ft) - 5110B L

- BUCKETS

- Heavy Duty Rock - 6.2 m3 (8.1 yd3)

- Heavy Duty Rock - 7.6 m3 (9.9 yd3)

- Medium Duty - 6.8 m3 (8.9 yd3)

- Medium Duty - 7.4 m3 (9.7 yd3)

- Medium Duty - 8.0 m3 (10.5 yd3)

- Medium Duty - 8.6 m3 (11.2 yd3)

- Coal - 10.4 m3 (13.6 yd3)

- Heavy Duty Rock - 4.6 m3 (6.0 yd3) - 5110B L

- Medium Duty - 6.0 m3 (7.8 yd3) - 5110B L

- Medium Duty - 5.0 m3 (6.5 yd3) - 5110B L

- Medium Duty - 4.2 m3 (5.5 yd3) - 5110B L

- GROUND ENGAGING TOOLS

- Heavy Duty Rock, General Purpose

- Heavy Duty Rock, Penetration

- Medium Duty, General Purpose

- Medium Duty, Penetration

- Coal, General Purpose

- Coal, Penetration

- ELECTRICAL

- Lights, deluxe, boom (4), chassis (7)

- GUARDS

- FOGS (Falling Object Guard System), cab

- Track guiding, full length/center/end

- Vandalism protection, cab

- POWERTRAIN

- Engine prelube

- Fast fill, engine oil

- UNDERCARRIAGE

- General purpose shoe, 900 mm (36 in)

- Soft underfoot shoe, 1000 mm (39 in)

- AUXILIARY HYDRAULICS

- Heavy lift, anti-drift - 5110B L

- Heavy lift, load control - 5110B L

- Heavy lift, load control, shears/hammers - 5110B L (5.5 m stick only)

- OTHER ATTACHMENTS

- Autolube

- Cab riser, 1000 mm (3.2 ft)

- Cooling system, high ambient, 55°C (133°F)

- Grease reel

- Ladder, drop down

- Starting aid, cold weather

- Straight travel pedal

- Toolbox