Overview

The 5230 Mass Excavator is a high production loading tool for use in mining and large project excavation work. Its sophisticated electronics, stress resistance modular components and powerful hydraulic systems makes it a very quick, responsive excavating tool.

Specifications

| Engine Model | 3516 |

| Net Power | — |

| Operating Weight - STD | — |

Benefits & Features

Specifications

| Engine Model | 3516 |

| Net Power | — |

| Displacement | — |

| Main Implement - Pump | Variable displacement |

| Relief Valve Setting - Implement - Std. | — |

| Relief Valve Setting - Travel | — |

| Operating Weight - STD | — |

| Maximum Digging Depth | — |

| Maximum Reach - Ground Level | — |

| Maximum Dump Height | — |

| Maximum Travel Speed - High | — |

| Maximum Drawbar Pull | — |

| Shoes Per Side - Standard | 47 |

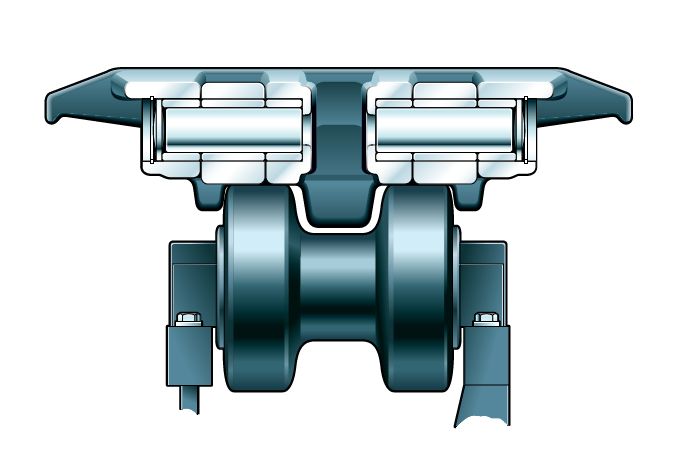

| Rollers Per Side - Standard | 8 |

| Carrier Idlers | 3 |

| Fuel Tank | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Overall Width | — |

| Tail Swing Radius | — |

| Upper Structure Width | — |

| Height - Top of Cab | — |

| Ground Clearance | — |

Benefits & Features

Hydraulics

Maximum Forces

The 5230 Front Shovel and Backhoe provide maximum forces at the bucket cutting edge for improved material penetration and bucket fill factors.

Piston Pumps

Six variable-displacement, piston pumps act together to power the front structure and travel systems. The swing function is powered by two dedicated variable-displacement piston pumps.

Modular Design

The modular design of the 5230 provides unique advantages in hydraulic system design and serviceability.

Hydraulic System Filtration

Hydraulic system filtration is provided by micron screens in the pump discharge lines and micron filters in the return lines.

Proportional Priority Pressure Compensating (PPPC)

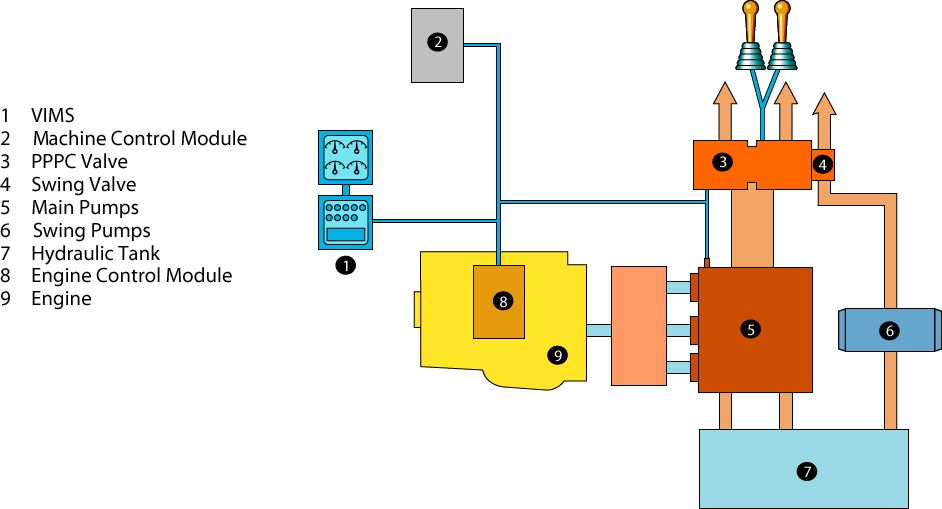

Exclusive Caterpillar Proportional Priority Pressure Compensating (PPPC) valves are used in both the front structure and travel systems.

Swing Circuit

The swing circuit is controlled by an open-center valve to assure quick, full-powered response.

Electronically Controlled Pumps

A Caterpillar designed microprocessor regulates hydraulic pump output.

Hydraulic System Cooling

Hydraulic system cooling is provided by two conventional core radiators dedicated to the hydraulic circuit.

Large-Bore Cylinders

Large-bore cylinders ensure efficient load handling.

XT Hydraulic Hose

Cat's XT hydraulic hose is exceptionally strong and flexible. Reusable couplings prolong hose assembly life.

S-O-S Sampling Valves

S-O-S sampling valves are conveniently located on the return rail on the right side of the hydraulic tank.

Engine

Electronic Control System

The Caterpillar electronic control system provides superior integration of the engine and other machine systems.

Electronic Unit Injection (EUI)

The 3516 Electronic Unit Injection (EUI) has many features.

Automatic Engine Speed Control (AESC)

Automatic Engine Speed Control (AESC) reduces fuel consumption and noise by reducing the engine speed if the hydraulic controls are not actuated for four seconds.

Engine Cooling System

The engine cooling system reduces fuel consumption using a variable-speed fan.

Cold Weather Starting

Cold weather starting can be improved with EUI's cold weather starting mode. This mode retards engine timing until the engine is warmed to the correct temperature.

Longer Service Hours

High displacement, low rpm rating and conservative hp ratings mean longer service hours with less downtime for maintenance and repair.

Piston Design

Two-piece piston design with aluminum skirt and steel crown pivot at the wrist pin provides added flexibility for reduced piston scuffing.

Structures

Castings

Heavy-duty castings are used extensively in high-stress areas for excellent, long-term structural durability.

Functions

Castings are used in: the front end of the swing frame (which is a single, massive casting); counterweight mounts; all boom and stick pin mounts; carbody; final drive mounts.

Digging Forces

High digging forces are a result of the efficient front linkage.

Box Section Construction

Rugged box section construction is used in key structures to provide unsurpassed strength while eliminating excess weight.

Floating Pins

One piece floating pins are used at swing frame to boom, boom to tick and stick to bucket joints for extra strength and life.

Front Structure Components

Front structure components are thermally stress relieved to reduce residual stresses from the welding process, increasing structure life.

Front Structure Components

Front structure components are thermally stress relieved to reduce residual stresses from the welding process, increasing structure life.

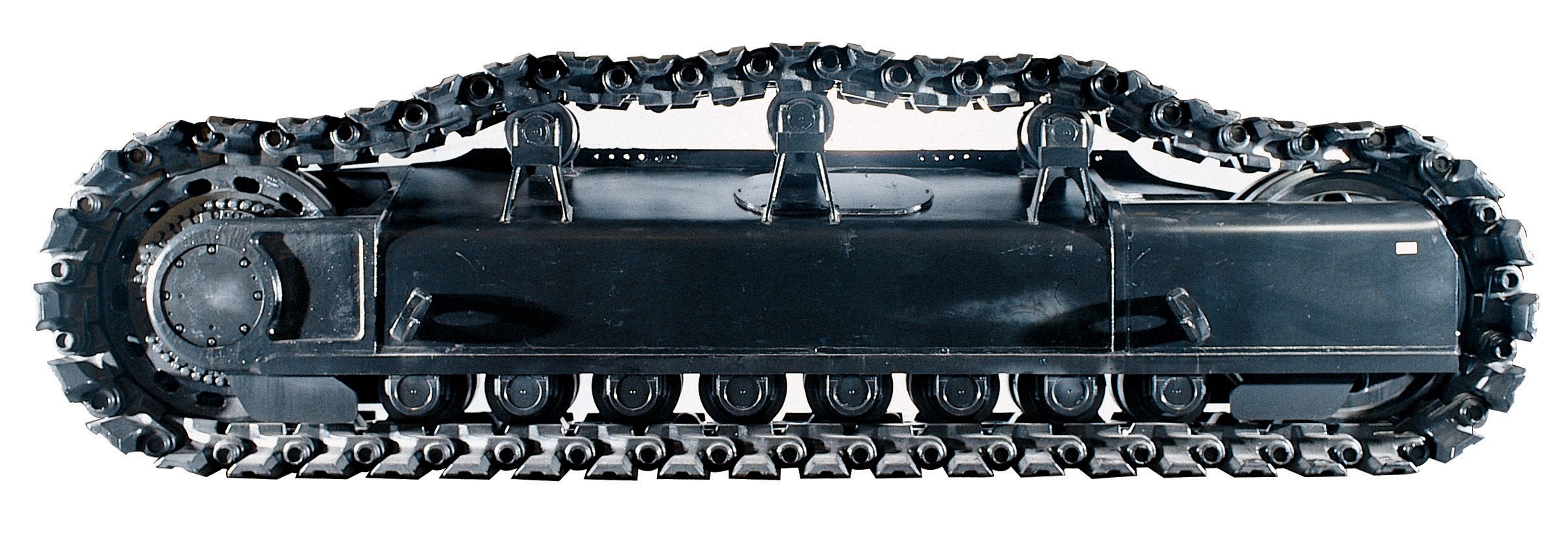

Undercarriage

Shovel Style Undercarriage

The Caterpillar shovel style undercarriage is a no-maintenance system.

Track Roller Frames

Track roller frames hold moving undercarriage components rigidly in place.

Track Tensioning

Automatic track tensioning maintains the correct track tension.

Track Gauge

A wide track gauge offers the stability needed for top production.

Shoe Widths

Three shoe widths are available to match your application: rock, general purpose and soft underfoot.

Operator's Station

Operator Compartment

The cab offers ample leg room to the front of the operator's seat. The trainee seat, with a seat belt, at the rear of the cab has cooler size storage under the seat cushion.

Cab

The cab and nearby components are isolated to dampen sound and vibration.

Comfort

Air pressurization with positive filtered ventilation keeps the cab environment comfortable and clean.

Contour Series Seat

The contour series seat is fully adjustable for shift-long comfort.

Isringhausen Seat

An Isringhausen seat is available as an option.

Vital Information Management System (VIMS)

Machine Data

The VIMS system continuously displays critical machine data.

Upper Screen Display

On its upper screen, the VIMS maintains a constant display of four critical machine functions.

Lower Screen Display

The lower screen displays operator-requested information and also contains the VIMS three-category alert system.

Lower Screen Display

The lower screen displays operator-requested information and also contains the VIMS three-category alert system.

Keypad

The VIMS keypad allows the operator to access current machine system information from VIMS display fields.

Three-Category Alert System

The three-category alert system provides advisory information to the operator when conditions in a monitored system exceed a prescribed setting for ordinary operations.

VIMS Diagnostics Program

The VIMS diagnostics program allows service personnel to download a complete record of machine data events and system diagnostics to a lap-top computer.

Buckets

Quality Design

High fill factors for the 5230 Front Shovel and Mass Excavator set this machine apart from the competition.

Box Section Construction

Box section construction is utilized in the dozer portion of front shovel buckets to provide torsional strength when the bucket is closed for digging.

Steel Castings

Steel castings are used in high-stress areas such as the dozer hinges, bowl pivots, cylinder mounts, and corner adapters.

Heat treated Steel

Heat treated steel is used to improve the service life of corner and center adapters, cutting edges and side bars which will be subjected to more abrasive conditions.

Bearings

Hardened bearings improve the durability of the pivot and cylinder mounts in mass excavator buckets.

Abrasion Resistant Material (ARM)

Standard wear plates on the back, sides and bottom reinforce front shovel bucket structures.

Coupler System

The two piece coupler system for general purpose rock tips utilizes a top-pinned coupler attached to a weld-on adapter nose.

Variety

Several front shovel and backhoe buckets are available.

Module Design

Service

The right and left side modules provide excellent service access as well as storage and working space.

Left Module

The cab riser allows stand-up access to hydraulic pilot lines and to the main junction box for electrical and electronic components.

Right Module

The right module includes walk-around, lighted access to the engine, the engine cooling system, the batteries and the hydraulic pumps.

Shipping and Assembly

The machine breaks down into eleven modules for ease of shipping.

Stability

Superior stability is achieved by creating a lower center of gravity and is a result of the modular design.

Data not available.