Specifications

| Engine Model | Caterpillar 3196 ATAAC |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Operating Weight - Long Undercarriage | — |

| Operating Weight - Standard Undercarriage | — |

| Maximum Reach - Ground Level | — |

| Maximum Digging Depth | — |

| Standard with Long Undercarriage | — |

| Optional for Long Undercarriage (1) | — |

| Optional for Long Undercarriage (2) | — |

| Number of Shoes - Each Side - Standard Undercarriage | 47 |

| Number of Shoes - Each Side - Long Undercarriage | 47 |

| Number of Track Rollers - Each Side - Standard Undercarriage | 8 |

| Number of Track Rollers - Each Side - Long Undercarriage | 8 |

| Number of Carrier Rollers - Each Side | 3 |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Travel Speed | — |

| Maximum Drawbar Pull - Standard Undercarriage | — |

| Maximum Drawbar Pull - Long Undercarriage | — |

| Main System - Maximum Flow - Total | — |

| Swing System - Maximum Flow | — |

| Maximum Pressure - Equipment - Normal | — |

| Maximum Pressure - Equipment - Heavy Lift | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| Stick Cylinder - Bore | — |

| Stick Cylinder - Stroke | — |

| VB Family Bucket Cylinder - Bore | — |

| VB Family Bucket Cylinder - Stroke | — |

| WB Family Bucket Cylinder - Bore | — |

| WB Family Bucket Cylinder - Stroke | — |

| Fuel Tank Capacity | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive - Each | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Performance | ANSI/SAE J1166 OCT98 |

| Brakes | SAE J1026 APR90 |

| Cab/FOGS | SAE J1356 FEB88 ISO10262 |

Benefits & Features

Operator Station

Operator Comfort

The work station is designed to be quiet and comfortable for the operator, assuring high productivity during a long work day. Seat and console adjustments allow for proper fitting to the operator. A positive pressure, filtered, highly efficient ventilation system is provided.

Viewing Area

Large, wide windows provide an excellent viewing area. A large skylight provides upward visibility. Both lower and upper portions of the front windshield can be easily stored in an overhead position. A sliding window on the cab door allows convenient communication between the operator and nearby workers. Upper and lower windshield wipers and washers are included as standard equipment to assure good visibility for the operator in wet or dusty conditions. The standard sunshade can be used to reduce the sunlight entering either the skylight or the upper windshield. The cab has extra height and length for increased operator space and is designed to allow direct mounting of the optional Falling Objects Guard (FOGS) recommended for applications involving overhead operation. It is mounted to the frame with rubber mounts for reduced sound and vibration transmission.

Electronic Control System

Caterpillar designed electronic control system uses Vital Information Display System (VIDS) as the interface between the machine and the operator or the service technician. VIDS includes an analog gauge section, a display screen and a keypad.

Automatic Climate Control

Automatic climate control is standard and maintains constant temperature in the cab regardless of outside conditions.

Joystick Controls

Electronic joystick controls have low lever effort and eliminate pilot lines. Control pattern can be changed electronically to suit operator preference. The operator can choose a level of gain/response from quicker and more productive to slower and more precise using a button on the console to optimize operation for different applications.

Engine Speed Dial

Engine speed dial has ten settings for simple, precise speed setting. The selected engine speed setting shows on the VIDS display screen.

Travel Controls

Electronic hand or foot actuated travel controls allow the operator to move the excavator while operating the equipment. Hand levers are easily removable.

Travel Pedal

Optional straight travel pedal provides forward or reverse straight line travel with a single pedal movement. Steering adjustments can be made by using the right or left travel pedals in combination with the straight travel pedal.

Hydraulic Activation Control Lever

Hydraulic activation control lever deactivates hydraulic functions and helps prevent operation when the operator exits the cab.

Seat

The fully adjustable Cat suspension seat includes a wide range of comfort features including fore/aft, height and weight adjustments. Also included are lumbar support, wide adjustable armrests and a retractable seat belt.

Electronic Control System

System and Components

Both system and components are Caterpillar designed and built for perfect integration to optimize machine performance.

Controllers

- Electronic control system utilizes three controllers connected by Cat Data Link to manage the engine and hydraulics for maximum productivity and efficiency:

- Advanced Diesel Engine Module (ADEM II) controller for engine.

- Pump-Valve Controller.

- Vital Information Display System (VIDS) controller.

Joysticks

- Electronic joysticks provide features not possible with hydraulic pilot valves:

- Eliminate pilot lines in cab for quieter operator environment.

- Simple pattern change through programming (consult your Caterpillar dealer).

- Operator selectable gain/response to suit application:

Analog Gauge

- The analog gauge displays information requiring frequent checking:

- Fuel level.

- Engine oil pressure.

- Hydraulic oil temperature.

- Engine coolant temperature.

Vital Information Display System

VIDS is the link between the machine and the operator or service technician.

Message Center Screen

- The message center screen displays vital information on machine conditions.

- Display shows graphic icons plus written messages in operator's choice of 16 languages.

- Displayed information includes:

Keypad

The keypad allows operator to select machine operation conditions and to set view preferences.

Service and Maintenance

Service Intervals

- Service intervals are extended to reduce maintenance costs.

- Engine oil, oil filter and fuel filters at 500 hours

- Optional fine filtration system allows hydraulic oil changes at 5000 hours

Hydraulic Capsule Filters

Hydraulic capsule filters are mounted outside the tank to prevent spills and system contamination during replacement.

Oil Sample and Pressure Ports

Oil sample and pressure ports provide easy checking of machine condition.

Service Points

Service points centrally located with easy access to facilitate routine maintenance. Engine oil filter is in pump compartment.

Hydraulic System Filter

The pilot hydraulic system filter keeps contaminants away from the pilot system.

Drain Filter

A swing and travel motor case drain filter keeps contaminants from returning to the tank.

Donaclone® Precleaner

Donaclone precleaner is standard to extend the service interval of the main air cleaner. (Donaclone is a registered trademark of Donaldson Company, Inc.)

Radial Seal Cleaner

The radial seal main air cleaner has a double layered filter element for more efficient filtration. No tools are required to change the element. Operator is alerted to clogged condition by a message on VIDS.

Electronic System Control

The electronic system control has diagnostic capabilities for Cat dealers' use. A single connection point allows Electronic Technician (ET) to communicate with all machine controllers. • Dealer service technicians can quickly and easily diagnose and adjust machine components, maximizing uptime.

Water Separator

The water separator removes water from fuel even when under pressure and is located in the battery compartment for easy access.

Remote Greasing Block

The remote greasing block on the boom and three grease points for the swing bearing deliver grease to hard to reach locations.

Hydraulics

Load Sensing System

- Load sensing Proportional Priority Pressure Compensation (PPPC) system, now with Caterpillar-developed electronic actuation, combines a proven system with state-of-the-art electronic control for high efficiency and excellent controllability.

- Cylinder speed is directly related to operator's movement of joystick from feathering to full speed.

- Flow to cylinders during multifunctional operation is directly controlled by the operator and is not dependent on loads.

- Controller reduces pump output to minimum to save power when joysticks are in neutral position.

Main Pumps

Large, heavy-duty main pumps with separate swing pump provide high speeds and full time swing priority.

Heavy Lift Feature

The heavy lift feature is standard and allows lifting of heavy objects with precision.

Auxiliary Valve

The auxiliary valve is standard for use with optional control arrangements to operate tools such as hammers and shears. Maximum flow can be set by ET (Electronic Technician).

Cylinder Snubbers

Hydraulic cylinder snubbers at rod end of boom cylinder and both ends of stick cylinder cushion shocks, reduce sound and increase cylinder life.

Cat XT-5™ and XT-6™ Hoses

Cat's XT-5 and XT-6 hoses are used in high pressure circuits to meet the critical flexibility and strength demands of today's hard working hydraulic systems.

Swing Dampening Valves

Swing dampening valves reduce swing wag and produce smooth swing stops.

Biodegradable Hydraulic Oil

Biodegradable hydraulic oil is available as an option.

Engine

Diesel Engine

The innovative Cat 3196 ATAAC diesel engine delivers large-engine performance from a compact engine design. The six-cylinder 301 kW (404 hp) engine is turbocharged and air-to-air aftercooled. With high horsepower and low displacement, this engine provides excellent fuel economy and durability that can significantly reduce operating costs.

Advanced Diesel Engine Module

The Advanced Diesel Engine Module (ADEM II) fuel system controls the engine for optimal fuel injection, increased fuel efficiency and longer component life. The engine is fully compliant with EPA Tier 2 emission regulations.

Injection Fuel System

Caterpillar state-of-the-art electronically controlled, computer-actuated unit injector fuel system, EUI, high injection pressure for complete fuel combustion, more efficient fuel use and reduced emissions. The 175 695 kPa (25,500 psi) injection pressure system provides dependable cold-starting performance. The dual-filter system reduces component wear.

Pistons

Two-piece articulated pistons with forged steel tops withstand higher cylinder pressures.

Cooling Jets

Dual cooling jets keep ring temperatures low for long ring and liner life with excellent oil control.

Cooling System

High capacity cooling system allows operation in ambient temperatures up to 47° C (117° F).

Hydrostatically Driven Fan

A separate cooling system with a hydrostatically driven fan provides quiet engine operation and reduced fuel consumption during cooler ambient conditions.

Valves

Four valves per cylinder for superior heat rejection. Valve area equals that of an engine with a 40% larger displacement. Valves and unit injection system are camshaft-actuated for precision timing.

Blocks and Heads

The blocks and heads are Caterpillar designed, cast and machined to meet Caterpillar quality standards.

Extended Life Coolant™

Extended life coolant/antifreeze offers better protection over a longer period of time, lowers operating costs, requires less maintenance and is environmentally responsible and recyclable.

Structures

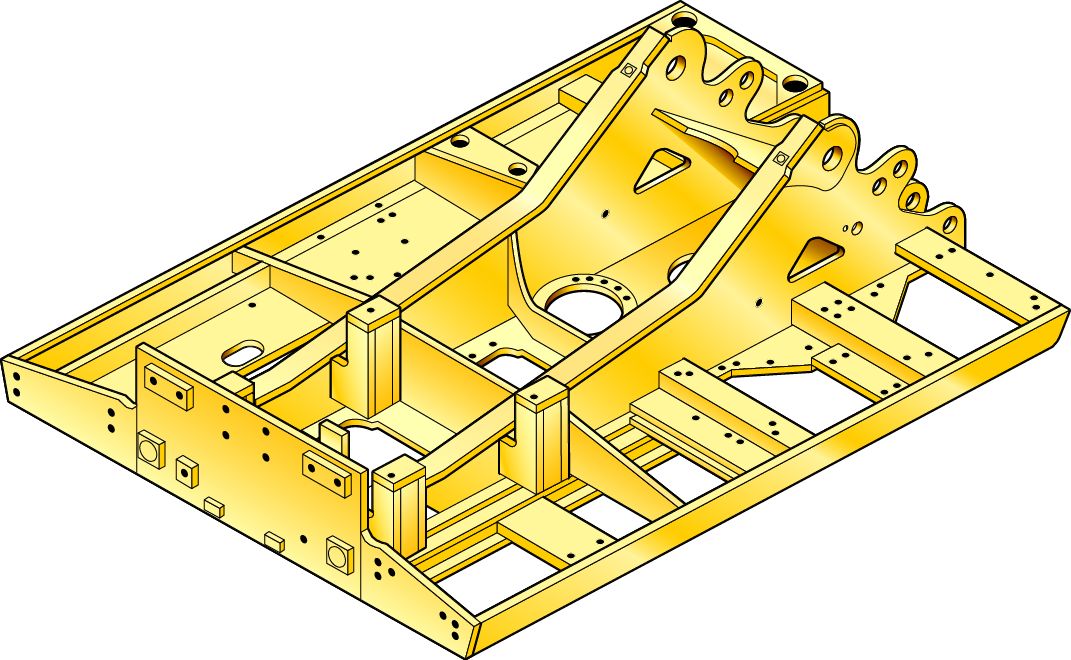

Advanced Carbody Design

- The advanced carbody design stands up to the toughest applications.

- Modified X-shaped, box-section carbody provides excellent resistance to torsional bending.

- Upper structure weight and stresses are distributed evenly across the full length of the track roller frame.

- Robot welding ensures consistent, high-quality welds throughout the manufacturing process.

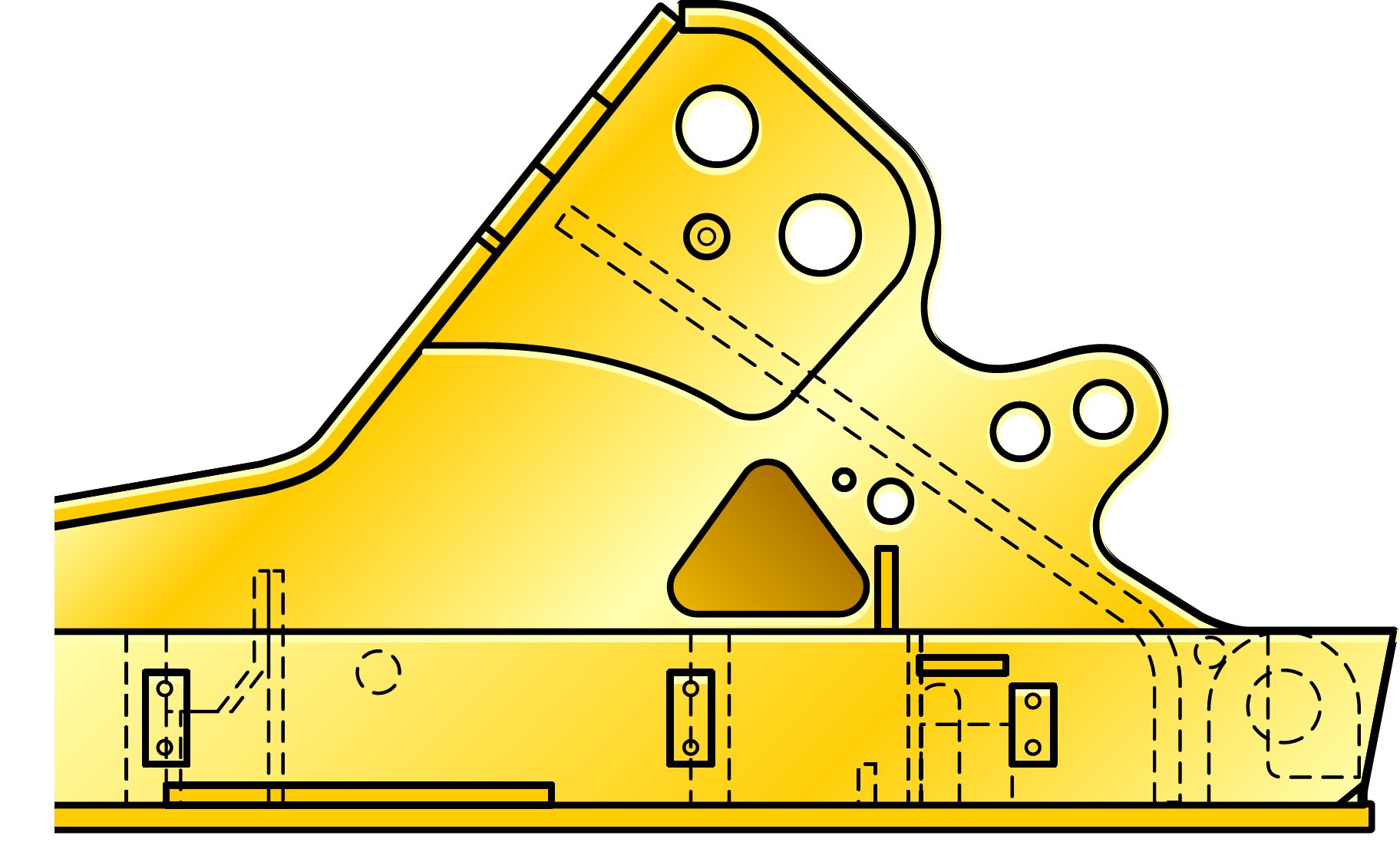

Track Roller Frames

Robot-welded track roller frames use a fabricated U-section of thick steel plates for the top portion with a flat bottom plate where the rollers mount for increased strength and stiffness.

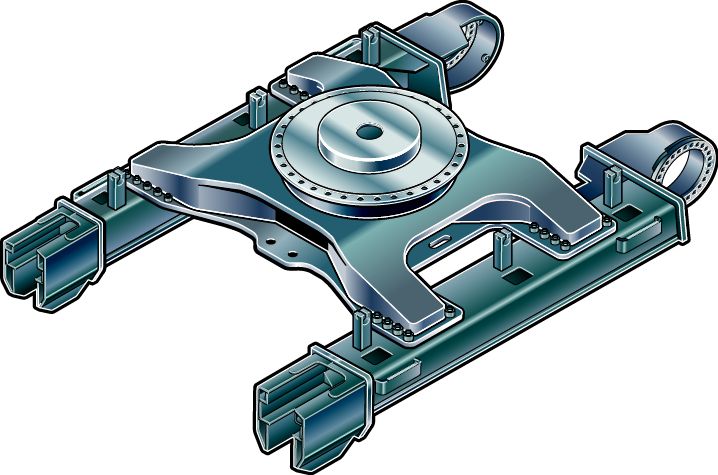

Variable Gauge Undercarriage

The Variable Gauge (VG) undercarriage is standard, providing a wide, stable base for lifting or a narrow gauge for reduced shipping width. • Roller frames are attached with 36 large bolts to assure a rigid connection.

Main Frame

- Rugged main frame is designed for maximum durability and efficient use of materials.

- Robot welding for consistent, high-quality welds.

- Outer frame utilizes curved side rails, which are die-formed, for excellent uniformity and strength throughout the length.

- Box section channels improve upper frame rigidity under the cab.

- Boom tower and one piece main rails are constructed of solid, high-tensile strength steel plates.

- New boom foot design transfers load more efficiently with less stress in critical areas.

- Reinforced lift cylinder and swing drive mounts increase structure durability in rock and quarry applications.

- A second boom mounting location provides high lifting forces for material handling fronts without the need for complicated adapters.

Undercarriage

Undercarriage Components

Caterpillar designed and built undercarriage components are purposely oversized to offer heavy-duty performance and durability.

Track Links

Strutted track links are sealed for long life. Three choices of shoe width are available to suit the application. All are heavy duty type with 20.5 mm (.81 in) thick webs.

Sealed and Lubricated Rollers

Track rollers, carrier rollers and idlers are sealed and lubricated for excellent service life.

Idler Guards and Track Guides

Standard idler guards and center track guides maintain track alignment. Optional full length track guiding guards are available for additional protection on steep side slopes.

Travel Motor

Smooth autoshifting two-speed travel motors offer top travel speeds and plenty of pull on slopes or turns. Counterbalance valves help prevent overspeeding during downhill travel. Line relief valves are shockless type for extra smooth stops.

Final Drives

Triple-reduction, planetary final drives are compact yet durable.

Heavy Guards

Heavy guards protect the travel motors against damage. Hoses are routed inside the carbody to minimize exposure.

Long Undercarriage

Long undercarriage (L) is standard to maximize stability and lifting capacity. Long, wide and sturdy undercarriage offers a stable work platform.

Booms, Sticks, and Attachments

Combination

Select the right combination for the job with your Cat dealer to help ensure top production from the start. Choose from two booms and six sticks, plus a wide selection of buckets and attachments. The 365B L Series II offers a large combination of reach and digging forces for optimum versatility.

Work Tools

Choose from a variety of work tools such as hammers, shears, rotators, grapples or crushers. Ask your Cat dealer for information on attachments or special configurations.

Booms and Sticks

- Caterpillar excavator booms and sticks are built for performance and long service life.

- Castings and forgings are used at high stress areas such as boom nose, boom foot, boom cylinder and stick foot.

- Large, welded, box-section structures with thick, multi-plate fabrications in high-stress areas.

- Internal baffle plates are incorporated to reduce stress and increase life.

- All booms and sticks are stress-relieved to maximize fatigue life and durability, while minimizing weight for improved performance.

Reach Boom

The Reach Boom (R) 7.8 m (25'7") features an optimum design that maximizes digging envelopes with three stick choices.

Mass Excavator Boom

The Mass Excavator Boom (M) 6.59 m (21'7") maximizes productivity. The M Boom, used with either of two sticks, offers significantly higher digging forces and allows the use of larger buckets.

Reach Sticks

- All reach sticks accept VB-family buckets and bucket linkage.

- Four lengths available to suit a large range of applications.

Mass Sticks

- All mass excavation sticks accept WB-family buckets and bucket linkage.

- Two lengths are available.

Buckets

Service and Performance

- Caterpillar buckets increase service life and optimize performance.

- High strength and heat treated steel are located in high wear areas.

- Dual radius design for increased heel clearance and reduced wear.

- VB-family buckets include a lift eye.

General Purpose (GP) and Excavation (E) Buckets

General Purpose (GP) and Excavation (E) buckets are for digging in soft to hard ground with low to moderate abrasive materials.

Heavy Duty (HD) and Extreme Excavation (EX) Buckets

Heavy Duty (HD) and Extreme Excavation (EX) buckets are for digging in moderate to hard abrasive materials. Differences from GP buckets are: • Thicker cutting edges and thicker bottom and side wear plates improve performance in demanding applications.

Heavy Duty Rock (HDR) and Rock (R) Buckets

- Heavy Duty Rock (HDR) and Rock (R) buckets for digging in fragmented rock, frozen ground, caliche and highly abrasive materials. Differences from HD buckets are:

- Additional, thicker wear plates extend beyond side plates for corner and rear dent protection and improved durability.

- Larger side plates provide additional dent protection.

Ground Engaging Tools

Caterpillar Ground Engaging Tools (GET) include a variety of side cutters, sidebar protectors, tip options and adapters to match operating conditions.

Complete Customer Support

Customer Support

Your Cat dealer offers a wide range of services that can be set up under a Customer Support Agreement when you purchase your equipment. To help you get the best return on your investment, the dealer will help you choose a plan that can cover everything from machine and attachment selection to replacement.

Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements? What production is needed? What is the true cost of lost production? Your Cat dealer can give you precise answers to these questions.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training videotapes, literature and other ideas to help you increase productivity.

Maintenance

What is the cost of preventive maintenance? More and more equipment buyers are planning for effective maintenance before buying the equipment. Choose from your dealer's wide range of maintenance services at the time you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured parts. You receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Data not available.

Standard Equipment

- Electrical

- Alternator - 70 ampere

- Lights

- Signal/warning horn

- Power supply in cab - 12V, 7 amp

- Guards

- Heavy duty bottom guards on upper frame

- Heavy duty swivel guard on undercarriage

- Heavy duty travel motor guards on undercarriage

- Operator Station

- Cab Glass/Glazing

- Windshield wipers and washers (upper and lower)

- Positive filtered ventilation

- Pressurized cab

- Air conditioner, heater and defroster

- Instrument panel and gauges (VIDS)

- Seat KAB524 (high back seat) with suspension and four

- Retractable seat belt (76 mm width)

- Console mounted electronic type joysticks

- Start up level check for hydraulic oil,

- Travel control pedals with removable hand levers

- Neutral lever (lock out) for all controls

- Beverage/cup holder

- Radio and speaker mounting with 12V power

- Antenna

- Storage compartment suitable for lunch box

- Coat hook

- Ashtray and 24 volt lighter

- Floor mat

- Literature compartment

- Sunshade for windshield and skylight

- Sun visor

- Engine/Powertrain

- Caterpillar 3196 ATAAC electronically

- Automatic engine speed control

- High ambient cooling, 47° C (117° F) capability

- Separate cooling system with variable speed fan

- Water separator for fuel line

- Air precleaner (Donaclone) and radial

- Two speed travel

- Automatic swing parking brake

- Automatic travel parking brakes

- Undercarriage

- Long, variable gauge

- Double grouser shoes - 900 mm (36") width

- Hydraulic track adjusters

- Idler and center section track guards

- Steps - four

- Other Standard Equipment

- Heavy lift mode

- Travel alarm with cut off switch

- Caterpillar one key security system with

- Mirrors - left hand cab mounted and right

- Cat walks - left side and right side

- Counterweight - 9800 kg (21,600 lb)

- Caterpillar XT hoses with reusable couplings

- Caterpillar high capacity batteries

- SOSSM quick sampling valves for engine

- Auxiliary hydraulic valve for hydro-mechanical tools

- Drive for auxiliary pump

- Provision for Product Link (PL201) includes

- Provision for Auto-lube includes power

- Upper frame with second boom foot mount location for

- Steel firewall between engine and hydraulic pumps

- Hydraulic oil filters

- Antifreeze protection to -29° C (-20° F)

Optional Equipment

- Front Linkage

- Booms

- Sticks

- Bucket Linkages

- Buckets - see chart

- Tips, sidecutters and edge protectors

- Track

- Double grouser 750mm (30")

- Double grouser 650mm (26")

- Guards

- FOGS (Falling Object Guard System) including

- Vandal guards for windshield

- Track guiding guards - full length

- Auxiliary Controls and Lines

- Basic control arrangements

- Auxiliary boom lines

- Auxiliary stick lines

- Miscellaneous Options

- Counterweight removal system

- Boom lowering check valves

- Stick lowering check valves

- Straight travel pedal

- Starting aid for cold weather with ether

- Fine filtration system

- Biodegradable hydraulic fluid package

- Rain protector for windshield