Specifications

| Engine Model | Caterpillar 3456 ATAAC |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Operating Weight - Long Undercarriage | — |

| Operating Weight - Standard Undercarriage | — |

| Maximum Reach - Ground Level | — |

| Maximum Digging Depth | — |

| Standard with Standard Length Undercarriage | — |

| Standard with Long Undercarriage | — |

| Optional for Standard Length Undercarriage | — |

| Optional for Long Undercarriage | — |

| Number of Shoes - Each Side - Standard Undercarriage | 47 |

| Number of Shoes - Each Side - Long Undercarriage | 51 |

| Number of Track Rollers - Each Side - Standard Undercarriage | 8 |

| Number of Track Rollers - Each Side - Long Undercarriage | 9 |

| Number of Carrier Rollers - Each Side | 3 |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Travel Speed | — |

| Maximum Drawbar Pull - Standard Undercarriage | — |

| Maximum Drawbar Pull - Long Undercarriage | — |

| Main System - Maximum Flow - Total | — |

| Swing System - Maximum Flow | — |

| Maximum Pressure - Equipment - Normal | — |

| Maximum Pressure - Equipment - Heavy Lift | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| Stick Cylinder - Bore | — |

| Stick Cylinder - Stroke | — |

| HB Family Bucket Cylinder - Bore | — |

| HB Family Bucket Cylinder - Stroke | — |

| JB Family Bucket Cylinder - Bore | — |

| JB Family Bucket Cylinder - Stroke | — |

| Fuel Tank Capacity | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive - Each | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Performance | ANSI/SAE J1166 OCT 98 |

| Brakes | SAE J1026 APR 90 |

| Cab/FOGS | SAE J1356 FEB 88 ISO 10262 |

Benefits & Features

Engine

Cylinder Block

Engine durability starts with a strong foundation - the cylinder block. The 3456 cylinder block consists of a deep-skirt, cast-iron alloy design made from 206 700 kPa (30,000 psi) minimum strength cast iron. Cylinder blocks are cast at Caterpillar's Mapleton foundry, where intensive process control programs ensure that the highest quality is maintained.

One-Piece Cylinder Head

The high strength cylinder head of the 3456 is designed for efficient breathing, which helps promote fuel efficiency. The cylinder head and intake air manifold are integrated, so no maintenance items are required such as gaskets, bolts and washers. Coolant flow throughout the cylinder head and high strength materials help deliver long cylinder head life.

Superior Fuel Economy

The 3456 features the proven Caterpillar EUI fuel system, with mechanically actuated, electronically controlled unit injectors (EUI), as well as state-of-the-art Advanced Diesel Engine Module (ADEM™ II) electronic controller, for the most precise timing and fuel metering.

Cooling System

The 385B layout puts the coolant radiator and oil cooler side by side to increase cooling efficiency and reduce the noise from the cooling system. The parallel layout of the radiator and the oil cooler improves accessibility to the cores of the cooling units, providing easy cleaning.

Emission Measures

The 3456 engine in the standard configuration meets the following emission regulations: (1) EPA Tier 2 (2) EU Stage II (3) MOC Step 2

Engine Mounts

The engine is mounted to the main frame using six rubber engine mounts. Those mounts reduce the amount of vibration that is transferred from the engine into the main frame for a smooth and quiet machine.

Overhead Camshaft and Valve Train

The overhead camshaft and valve train are key to engine efficiency through precise control of valve timing. The camshaft of the 3456 is located in the cylinder head to allow the use of higher fuel injection pressure, which is absolutely critical for performance, low fuel consumption and lower emissions.

Heavy-Duty Pistons

Two-piece articulated pistons feature a new ring package that provides excellent oil control. Cooling jets provide increased pressure and flow, which enhances piston and ring life.

Crankshaft

The 3456 crankshaft - featuring Caterpillar's exclusive total hardening process - comes from the same sturdy lineage as the 3406E and C-16 truck engine. The 3456 crankshaft delivers superb durability, long life to overhaul and lower life cycle cost.

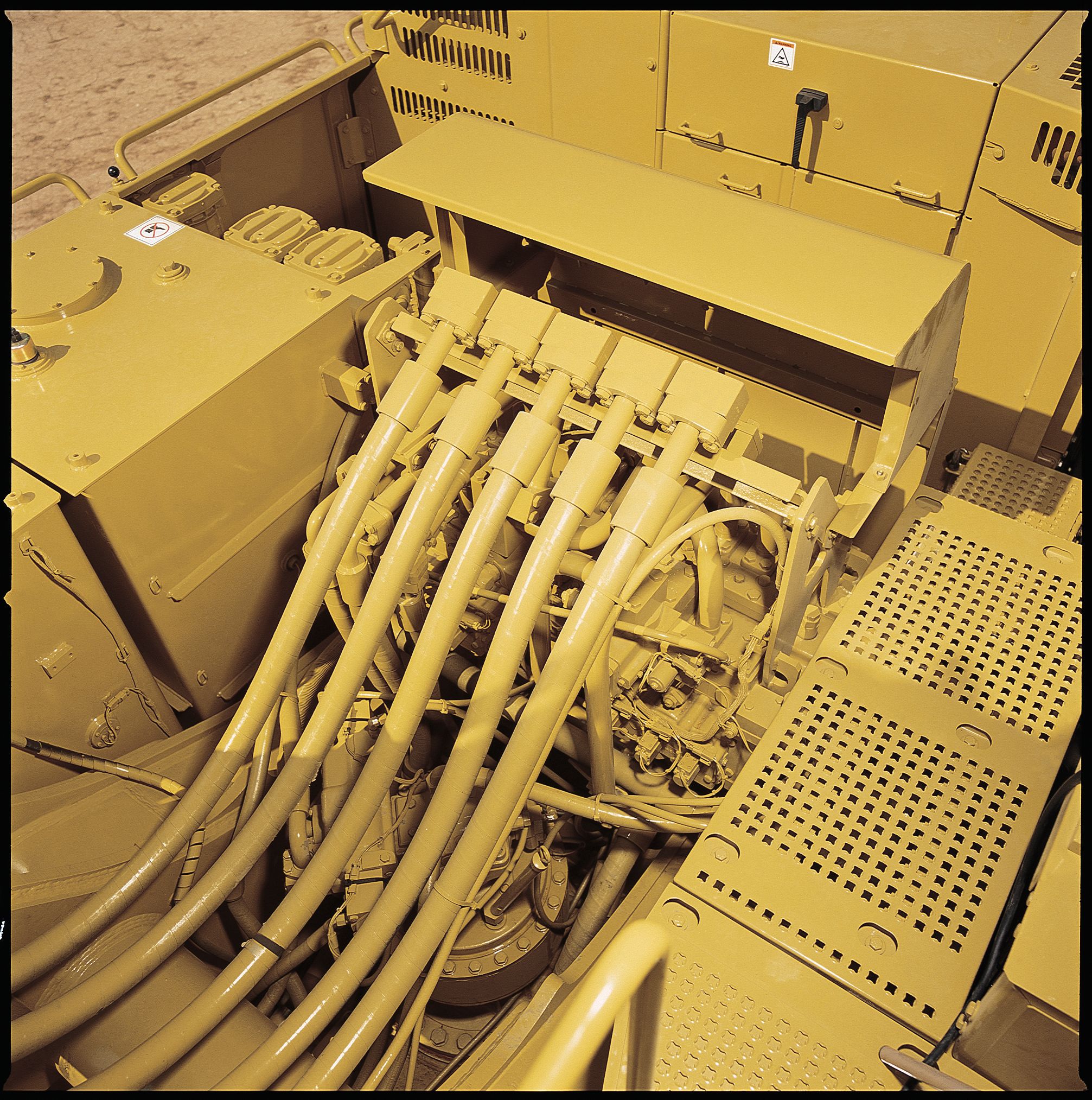

Hydraulics

Hydraulic System

The 385B hydraulic system includes a three pump system with an independent swing circuit and a hydraulic circuit utilizing the proven Proportional Priority Pressure Compensated (PPPC) system, now with Caterpillar developed electronic control and activation to ensure high hydraulic system efficiency and excellent productivity.

PPPC System

- The load sensing PPPC system provides the following features:

- Cylinder speed is directly related to operator's movement of the joystick from feathering to full speed

- Flow to cylinders during multifunctional operation is directly controlled by the operator and is not dependent on loads

- Controller reduces pump output to minimum to save power when joysticks are in neutral position

Power Management Control

The pump-valve electronic controller is central to power management control and provides highly efficient control for the pumps, valves and engine.

Component Layout

The hydraulic pumps, control valve and hydraulic tank are located close together to minimize the length of piping. The swing control valve is mounted directly on the swing motor. Main and swing pump suction and discharge lines have large diameters. These large diameters, combined with the component layout, guarantee high efficiency.

Swing Performance

The three-pump system with independent swing used on the 385B gives priority to the swing circuit for strong swing acceleration and easily controlled multi-function operation. This performance has been further enhanced by an increase in swing torque of approximately 16%.

Heavy Lift Standard

The operator can select the heavy lift mode at the push of a button to boost lifting capability and provide improved controllability.

Auxiliary Hydraulics

An auxiliary valve is standard. Control circuits are available as attachments, allowing operation of high pressure tools such as thumbs, hammers, shears and multi-processors. Flow settings for up to four tools can be programmed into VIDS™ for easy selection by the operator. A separate load sensing medium pressure circuit is also available for functions such as rotate.

Hydraulic Oil Filtration System

As standard, the 385B hydraulic system has six filters in four types. These filters improve reliability, extend the life of hydraulic equipment and hydraulic oil, boost performance and reduce running costs.

Boom and Stick Lowering Control Devices (Attachment)

A Boom Lowering Control Device and Stick Lowering Control Device are available as attachments. These valves, which are mounted on the boom or stick cylinders, help prevent the boom and stick from falling in the event of hydraulic line or tube failure.

Third Pedal for Straight Travel (Attachment)

A third pedal for straight travel is available as an attachment. This pedal allows straight machine travel using only a single pedal.

Undercarriage and Structures

Carbody

To meet transportation requirements, the 385B undercarriage is of a variable gauge type. This design allows the track roller frames to be bolted to the carbody, enabling the machine to be made narrower for ease of transport. The carbody utilizes a new columnless design which allows the swing bearing to be directly mounted on the top plate for more rigidity and strength.

Track

The track links are sealed to prevent entry of dirt and are strutted for high strength and impact resistance. Two choices of shoe width are available. Both are heavy-duty double grouser type.

Track Rollers

Track rollers are heavy-duty type with increased strength for longer life. They also use solid pins for retention of the collars for a more secure design.

Travel Motors

Two-speed axial piston hydraulic motors provide the 385B drive power. Speed selection is automatic when the high-speed position is selected. Travel motors have internal disk brakes to hold the machine when stationary. The travel motors are protected from damage by rigid covers.

Final Drives

The final drives are a new compact design with three-stage planetary reduction. They incorporate the latest seal technology to prevent entry of dirt and loss of oil.

Upper Frame

The rugged main frame is designed for maximum durability and efficient use of materials. Robot welding is used for consistent, high-quality welds. The main channels are box sections connected by a large diameter tube in the boom foot area to improve rigidity and strength. The outer frame utilizes curved side rails for rigidity against bending and torsional loads.

Buckets

All 385B Buckets Increase Service Life and Optimize Performance

- High strength and heat treated steel in high wear areas.

- Dual radius design for increased heel clearance and reduced wear.

- HB and JB buckets include a lift eye.

General Purpose (GP) Buckets

For digging in low-impact, moderately abrasive materials such as dirt, loam, gravel, and clay.

Heavy Duty Rock (HDR) Buckets

- For aggressive bucket loading in highly abrasive applications such as shot rock and granite. Differences from GP buckets:

- More robust bucket construction for improved life and durability.

- Additional, thicker bottom wear strips for improved wear and durability in highly abrasive applications.

- Side wear plates are thicker and extend further up the bucket for maximum protection in rocky materials.

- Smaller tip radius provides greater breakout force at the tips.

Caterpillar Ground Engaging Tools (GET)

The Caterpillar Ground Engaging Tools (GET) include a variety of sidecutters, sidebar protectors, tip options and adapters to match operating conditions.

Booms, Sticks and Attachments

Reach Boom - 10 m (32 ft 10 in) long

For use in deep trenching applications where long reach and depth are necessary. Two long sticks are available for this boom.

General Purpose Boom - 8.4 M (27 ft 7 in) long

The GP boom has been designed to balance the reach, digging force and the bucket capacity, and offer a wide range of applications such as digging, loading and trenching. Four sticks are available for this boom.

Mass Excavation Boom - 7.25 m (23 ft 9 in) long

This is the most suitable boom for high production loading where reach and depth are less important. It allows use of the largest buckets. Two sticks are available for this boom.

Boom Construction

All 385B booms feature large cross-sections, which are effective in reducing weight and enhancing rigidity. Also, the inside of the boom is reinforced by baffle plates to provide higher rigidity and less stress. All booms are stress relieved for extended life without added weight.

Stick

There are four lengths in six types of sticks for the 385B for maximum productivity in various applications. Each stick is used in a combination with a specific boom and bucket family.

Stick Construction

The 385B sticks are made of high-tensile strength steel using a large box section design with interior baffle plates and an additional bottom plate to protect against rock damage. All sticks are stress relieved for long life.

Bucket Linkage

Two bucket linkages are available for the 385B. The HB family is used with the longer sticks and takes HB family buckets; the JB family is used with the shorter sticks and takes JB family buckets.

Linkage Pin

All pins used in 385B front linkages have a thick chrome plating, giving them high wear and corrosion resistance. The diameter of each pin is made as large as possible to smoothly distribute the shear and bending loads associated with the digging and lifting forces.

Operator Station

Operator Environment

The work station is designed to be spacious, quiet and comfortable for the operator, assuring high productivity during a long work day. Seat and console adjustments allow for proper fitting to the operator. A positive pressure, filtered, and highly efficient ventilation system is provided. The cab has been positioned forward to provide excellent visibility into deep trenches.

Seat

This seat has a variety of adjustments to suit the operator's size and weight including fore/aft, height and weight. Also included are lumbar support, wide adjustable armrests and a retractable seat belt. It allows the operator to select the most comfortable setting.

Heating and Ventilation

Positive filtered ventilation with a pressured cab and an automatic air conditioner come standard on the 385B. Fresh air or re-circulated air can be selected with a switch on the left console.

Windows

The cab provides excellent viewing through large, wide windows. Both lower and upper portions of the front windshield can be easily stored in an overhead position. A sliding window on the cab door allows convenient communication between the operator and nearby workers. Glazing is polycarbonate for vandal protection, except for the windshield and sliding door window. Guards are included to cover these windows.

Wiper

Upper and lower windshield wipers and washers are included as standard equipment to assure good visibility for the operator in wet or dusty conditions.

Skylight

The large, fixed-type, Polycarbonate skylight delivers excellent natural lighting and upward visibility.

Console

The consoles contain the climate controls, start switch, engine speed dial, joysticks and miscellaneous switches. All items are within easy reach of the operator.

Controls

Electronic joystick controls have low lever effort and eliminate pilot lines. Control pattern can be changed electronically to suit operator preference. The operator can choose a level of gain/response from quicker and more productive to slower and more precise using a button on the console to optimize operation for different applications.

Sun Screen (optional)

A sunscreen, which can be used to cover the upper windshield or the skylight, is available as an option.

Monitor

The Caterpillar designed electronic control system uses VIDS (Vital Information Display System) as the interface between the machine and the operator or the serviceman. VIDS includes an analog gauge section, a display screen and a keypad.

Cab Exterior

Handrails are attached to both sides of the cab door to facilitate entry and exit. A filtered air ventilation port on the left side of the cab brings in fresh air. The cab is designed to allow direct mounting of the optional falling objects guard recommended for applications involving overhead operation.

Cab Mounts

The 385B uses six viscous cab mounts. They use rubber and silicon oil to absorb vibrations in two stages. They provide a higher level of vibration dampening than do rubber mounts. The mounts also help limit the sound level in the cab.

Complete Customer Support

Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements? What production is needed? What is the true cost of lost production? Your Cat dealer can give you precise answers to these questions.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training literature and other ideas to help you increase productivity.

Maintenance

Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild, or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured components.

Service and Maintenance

Service intervals

- The service intervals are extended to reduce maintenance costs.

- Engine oil, oil filter and fuel filters at 500 hours.

- Hydraulic oil at 4000 hours for normal applications (with S•O•Ssm monitoring).

Hydraulic capsule filters

Hydraulic capsule filters are mounted outside the tank to prevent spills and system contamination during replacement.

Oil sample and pressure ports

Oil sample and pressure ports provide easy checking of machine condition.

Service Points

Service points are centrally located with easy access to facilitate routine maintenance.

Pilot Hydraulic System Filter

Pilot hydraulic system filter keeps contaminants away from the pilot system.

Swing and travel motor case drain filter

A swing and travel motor case drain filter keeps contaminants from returning to the tank.

Radial seal main air cleaner

Radial seal main air cleaner with precleaner has a double-layered filter element for more efficient filtration. No tools are required to change the element. Operator is alerted to clogged condition by a message on VIDS.

Water Separator

Water separator removes water from fuel even when under pressure and is located in the battery compartment for easy access.

Remote greasing block

Remote greasing block on the boom and three grease points for the swing bearing deliver grease to hard to reach locations.

Electronic System Control

Electronic System Control has diagnostic capabilities for Cat Dealers' use. A single connection point allows Electronic Technician (Cat ET) to communicate with all machine controllers.

Data not available.

Standard Equipment

- Electrical

- Alternator - 75 ampere

- Lights

- Signal/Warning horn

- Guards

- Bottom Guards on upper frame

- Swivel Guard on Undercarriage

- Operator Station

- Cab Glass/Glazing

- Windshield wipers and washers (Upper and Lower)

- Positive filtered ventilation

- Pressurized cab

- Automatic air conditioner with defroster

- Instrument panel and gauges (VIDS)

- Seat KAB524 (high back seat) with suspension and four-way adjustment, adjustable 100 mm (4 in) armrest

- Retractable seat belt (76 mm width)

- Console mounted electronic type joysticks

- Start up level check for hydraulic oil, engine oil and engine coolant

- Travel control pedals with removable hand levers

- Beverage/cup Holder

- Radio mounting pre-wired with two stereo speakers and one 24 v to 12 v, 2.5 amp converter. DIN size mounts (radio will be supplied by dealer/user)

- Antenna

- Storage compartment suitable for lunch box

- Coat hook

- Ashtray and 24 volt lighter

- Floor mat

- Engine/Powertrain

- Caterpillar 3456 ATAAC Electronically Controlled Diesel Engine

- Automatic engine speed control

- Side-by-side separate cooling system with variable speed fans

- Water separator for fuel line

- Air precleaner and radial seal double element filter

- Two-speed travel

- Ether starting aid

- Automatic swing parking brake

- Automatic travel parking brakes

- Undercarriage

- Long length, variable gauge with 900 mm (36 in) double grouser shoes or Standard length, variable gauge with 750 mm (30 in) double grouser shoes

- Double grouser shoes - 900 mm (36 in) width

- Other Standard Equipment

- Heavy-lift mode

- Travel alarm with cut off switch

- Caterpillar one key security system with locks for doors, cab and fuel cap

- Cat walks - left side and right side

- Cast counterweight - 11,600 kg (25,600 lb)

- Caterpillar XT™ hoses with reusable couplings

- Caterpillar high-capacity batteries

- S•O•S quick sampling valves for engine oil, engine coolant, and hydraulic oil

- Auxiliary hydraulic valve for hydro-mechanical tools

- Drive for auxiliary pump

- Provision for Product Link (PL201) includes power source and mounting location

- Provision for Auto-lube includes power source and mounting location

- Steel firewall between engine and hydraulic pumps

- Hydraulic oil filters

- Antifreeze protection to -34ºC (-30ºF)

- Mirrors - left side and right side

Optional Equipment

- Front Linkage

- Booms

- Sticks

- Bucket Linkages

- Buckets - see chart

- Tips, sidecutters, and edge protectors

- Track

- Double grouser 750 mm (30 in) for long undercarriage

- Double grouser 900 mm (36 in) for standard length undercarriage

- Double grouser 1050 mm (42 in) for long undercarriage (Custom Product)

- Guards

- Wire mesh guard for front windshield

- FOGS (Falling Objects Guards System) including overhead and windshield guards

- Track guiding guards

- Aux Controls and Lines

- Basic control arrangements

- Aux boom lines

- Aux stick lines

- Miscellaneous Options

- Fast fuel fill system

- Fast engine oil fill system

- Counterweight removal system - 385B L Only

- Boom lowering check valves

- Stick lowering check valves

- On board lubricator system (hose reel) - 385B L Only

- Straight travel pedal

- Power supply - double socket 12 volt, 10 amp

- Sunscreen for windshield

- Window exit

- High ambient cooling - 52°C (125°F) capability

- Cold weather starting package

- Vandal guards for cab windows