Overview

The 385C L Series excavator has excellent control, high stick and bucket forces, impressive lift capacity, simplified service and a more comfortable operator station to increase your productivity and lower operating costs.

Specifications

| Engine Model | Cat® C18 ACERT™ |

| Net Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C18 ACERT™ |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349:2011 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Operating Weight | — |

| Operating Weight - Long Undercarriage | — |

| Operating Weight - Standard Undercarriage | — |

| Maximum Reach - Ground Level | — |

| Maximum Digging Depth | — |

| Bucket Digging Force | — |

| Stick Digging Force | — |

| Maximum Bucket Capacity | — |

| Nominal Bucket Weight | — |

| Bucket Digging Force - Normal | — |

| Standard with Long Undercarriage | — |

| Optional for Long Undercarriage | — |

| Number of Shoes - Each Side - Long Undercarriage | 51 |

| Number of Track Rollers - Each Side - Long Undercarriage | 9 |

| Number of Carrier Rollers - Each Side | 3 |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Travel Speed | — |

| Maximum Drawbar Pull - Long Undercarriage | — |

| Main System - Maximum Flow - Total | — |

| Swing System - Maximum Flow | — |

| Maximum Pressure - Equipment - Normal | — |

| Maximum Pressure - Equipment - Heavy Lift | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| Stick Cylinder - Bore | — |

| Stick Cylinder - Stroke | — |

| HB Family Bucket Cylinder - Bore | — |

| HB Family Bucket Cylinder - Stroke | — |

| JB Family Bucket Cylinder - Bore | — |

| JB Family Bucket Cylinder - Stroke | — |

| Fuel Tank Capacity | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive - Each | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Performance | ANSI/SAE J1166 OCT98 |

| Brakes | SAE J1026 APR90 |

| Cab/FOGS | SAE J1356 FEB88 ISO10262 |

| Shipping Height | — |

| Transport Width | — |

Benefits & Features

Engine

Diesel Engine

The Caterpillar C18 with ACERT Technology, is a 18.1 liter, six-cylinder, 382 kW (513 hp) engine with mechanically actuated electronic fuel injection (MEUI) and overhead camshaft. ACERT technology provides outstanding engine performance through advanced electronic control, precision fuel delivery, and refined air management.

Fuel Consumption

The ADEM™ A4 controller uses sensors throughout the engine to manage engine load and performance. The ADEM A4 controller is the muscle behind engine responsiveness, self-diagnostics, controlling emissions, and fuel economy.

Fuel System

The C18 uses a mechanically actuated electrically controlled unit injection (MEUI) system. The MEUI system combines high-pressure injection and electronic control in a single compact unit. The electronic unit injector is an integral part of the C18 fuel system. Computerized electronic control provides precise metering and timing of fuel injection.

Cooling System

High capacity, side-by-side cooling system allows operation in ambient temperatures up to 52 degree C (126 degree F). The Electric Power Control (EPC) controls the fan speed based on coolant temperature and hydraulic oil temperature for optimized cooling.

Turbocharger

The C18 uses a water-cooled, center-section waste gated turbocharger for improved performance. This turbocharger controls the air volume to the cylinders and works efficiently during low and high load conditions.

Emissions

ACERT Technology is a differentiated technology that reduces emissions at the point of combustion. The technology capitalizes on Caterpillar's proven leadership in three core engine systems: fuel, air and electronics.

Cold Weather Starting Kit

The kit consists of two additional batteries, heavy-duty harness, large capacity starting motor, and the ether starting aid. With this kit, the 385C L has the capability to start at -32 degree C (-25.6 degree F).

Hydraulics

PPPC Hydraulics

- Load sensing, Proportional Priority Pressure Compensation (PPPC) system, with Caterpillar-developed electronic actuation, provides high efficiency and excellent controllability.

- Cylinder speed is directly related to operator's movement of joystick from feathering to full speed.

- Flow to cylinders during multifunctional operation is directly controlled by the operator and is not dependent on loads.

- Controller reduces pump output to minimum to save power when joysticks are in neutral position.

Main Pumps

Large, heavy-duty main pumps and a separate swing pump provide quick cycle times during multi-function operation.

Power Management Control

The pump-valve electronic controller is central to power management and provides highly efficient control of the pumps, valves, and engine.

Reverse Swing Damping Valve

Swing dampening valves reduce swing wag and produce smooth swing stops.

Auxiliary Hydraulic Valve

The auxiliary valve is standard on the 385C L. The standard auxiliary valve is for use with optional control arrangements to operate tools such as hammers and shears. Flow settings can be programmed for up to four tools, which the operator can select through the monitor.

Heavy Lift Standard

The operator can select the heavy lift mode at the push of a button to boost lifting capability and provide improved controllability of heavy loads.

Operator Station

Cab Design

The work station has been designed to be spacious, quiet and comfortable. Operator comfort, and a high level of visibility assure productivity throughout the entire workday. The monitor and switches are conveniently located for easy access and visibility.

Seat

The 385C L seat provides a variety of adjustments, including fore/aft, height and weight to suit the operator. Also included are adjustable armrests and a retractable seat belt. For additional comfort, a new heated air suspension seat is available as an attachment.

Hydraulic Activation Control Lever

The hydraulic activation control lever deactivates hydraulic functions during engine start-up, and prevents unintentional machine operation.

Climate Control

Positive filtered ventilation with a pressurized cab comes standard on the 385C L. Fresh air or re-circulated air can be selected, and the automatic climate control maintains constant, comfortable temperature.

Windows

To maximize visibility, all glass is affixed directly to the cab eliminating the use of window frames. The upper front windshield opens, closes and stores on the roof above the operator with a one-touch action release system. The lower front windshield features a rounded design to maximize downward visibility and improves wiper coverage.

Wipers

Pillar-mounted parallelogram wiper, including a washer nozzle, increases the operator's viewing area and offers continuous and intermittent modes.

Skylight

An enlarged skylight with sunshade provides excellent visibility and good ventilation.

Consoles

Redesigned consoles feature a simple, functional design to reduce operator fatigue, ease of switch operation and excellent visibility. Both consoles have attached armrests and allow the height of the armrests to be adjusted.

Monitor

The compact, full-color, graphical display monitor is new with the 385C L. The monitor has functions to display machine, maintenance, diagnostic and prognostic information. The angle of the monitor can be adjusted to face the operator and prevent sun glare.

Cab Mounts

The cab shell is attached to the frame with viscous rubber cab mounts, which dampen vibrations and sound levels while enhancing operator comfort.

Standard Cab Equipment

To enhance operator comfort and productivity, the 385C L cab includes a lighter, drink holder, coat hook, service meter, literature holder, magazine rack and storage compartment. The cab also comes equipped with two, 12V-7 Amp electrical sockets to provide additional electrical resources.

Machine Security

An optional Machine Security System (MSS) is available from the factory on the 385C L. MSS uses a special Caterpillar key with an embedded electronic chip for controlling unauthorized machine operation.

Product Link

The 385C L is "Product Link Ready" from the factory.

Electronic Control System

Monitor Display Screen

- The monitor is a full color 400 x 234 pixels Liquid Crystal Display (LCD) graphic display. The Master Caution Lamp the action lamp blinks ON and OFF when one of the critical conditions below occurs:

- Engine oil pressure low

- Coolant temperature high

- Hydraulic oil temperature high

Operator Gain/Response

- Used to suit the operators preference or application.

- Quicker, for fast response and more production

- Slower, for more precision

- Three preset settings with 21 available

Pattern Control Changer

The standard hand control pattern changer can be accessed through the monitor, to utilize either the standard excavator control pattern (SAE) or Backhoe-loader pattern (BHL).

Electronic Joysticks

Electronic joysticks provide features not possible with hydraulic pilot valves: • Simple pattern change through the monitor

Undercarriage

Undercarriage Components

Large, Caterpillar designed and built undercarriage components offer heavy-duty performance and durability.

Track Rollers

Heavy-duty track rollers, carrier rollers and idlers are sealed and lubricated for excellent service life.

Track

The 385C L comes standard with the new grease lubricated track called GLT4. The track links are assembled and sealed with grease to decrease internal bushing wear, reduce travel noise and extend service life lowering operating costs.

Idler Guards and Track Guides

Standard idler guards and center track guides maintain track alignment. Additional sprocket and idler end guards, as well as two-piece full-length guards are optional for additional protection on steep side slopes.

Travel Motor

Two-speed axial piston hydraulic motors provide the 385C L drive power and automatic speed selection when the high-speed position is selected. This enables the machine to automatically change between computer-controlled high and low speeds depending on drawbar-pull requirements.

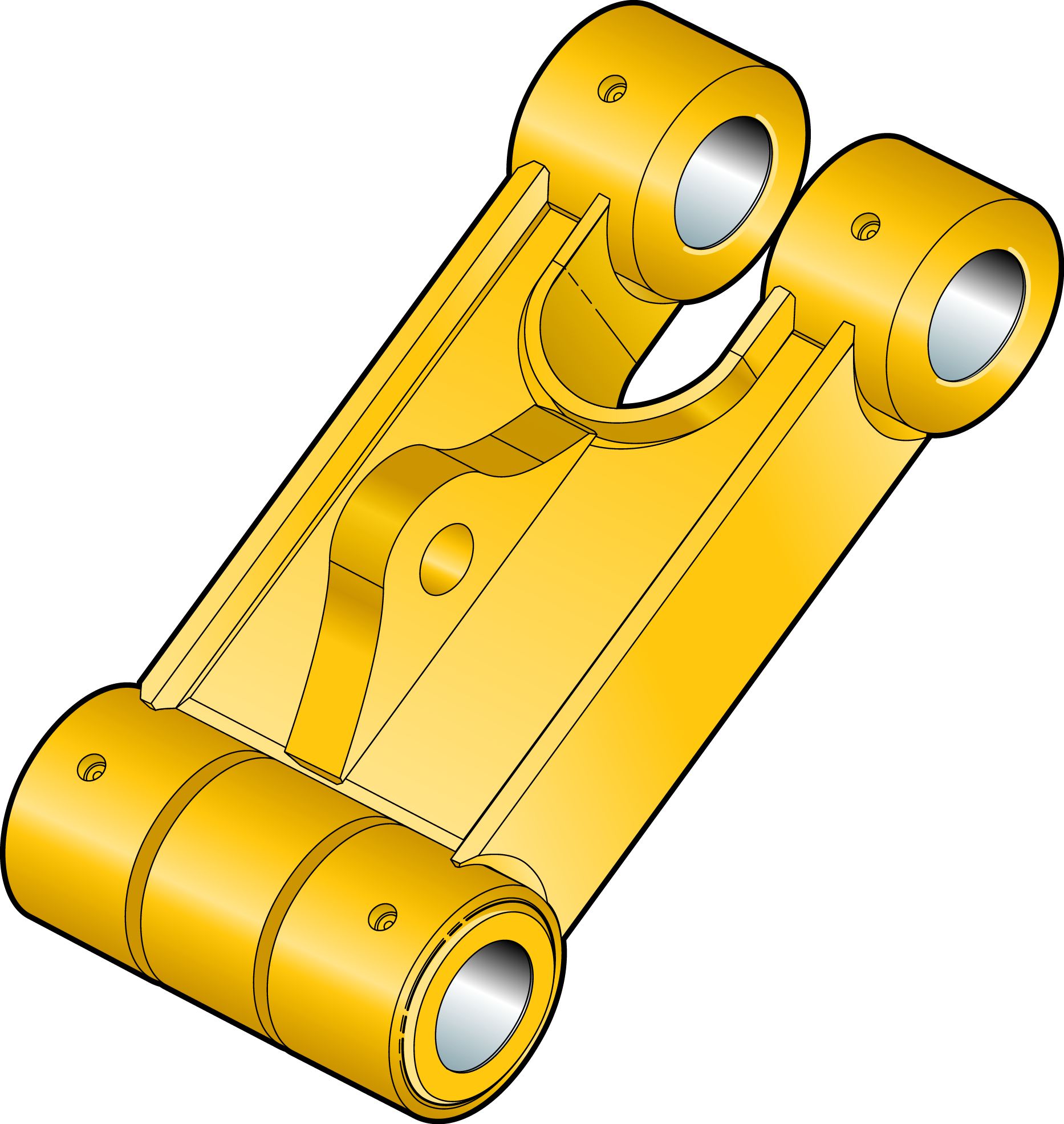

Final Drives

The final drives are the three-stage reduction planetary types. This design results in a complete drive/brake unit that is compact and delivers excellent performance and reliability.

Structures

Carbody Design

- The advanced carbody design stands up to the toughest applications.

- Modified X-shaped, box-section carbody provides excellent resistance to torsional bending.

- Upper structure weight and stresses are distributed evenly across the full length of the track roller frame.

- Robot welding ensures consistent, high-quality welds throughout the manufacturing process.

Upper Frame

- Rugged main frame is designed for maximum durability and efficient use of materials.

- Robot welding for consistent, high-quality welds.

- Outer frame utilizes curved side rails, which are die-formed, for excellent uniformity and strength throughout the length.

- The main channels are box sections connected by a large diameter tube in the boom foot area to improve rigidity and strength.

Track Roller Frames

The track roller frame is made of thick steel plate that is bent into a U-shape and welded to the bottom plate to create a box structure. The box structure design provides increased rigidity and impact resistance.

Cross-roller Bearing

The 385C L swing bearing is a cross roller type, with greater contact area than ball type bearings, for increased stability and longer life.

Variable Gauge Undercarriage

The long variable gauge undercarriage is standard. The track roller frames are bolted to the carbody, and can be placed in two positions - wide, for a stable base for operating, or a narrow gauge for reduced shipping width.

Front Linkage

Front Linkage Attachments

Select the right combination of front linkage with your Cat dealer to ensure high productivity from the very start of your job. Three types of booms and six sticks are available, offering a range of configurations suitable for a wide variety of applications. The 385C L offers a large combination of reach and digging forces for optimum versatility.

Boom Construction

All 385C L booms have large cross-sections and internal baffle plates to provide higher rigidity and less stress. All booms are stress relieved for extended life.

Reach Boom

The 10.0 m (32 ft 10 in) Reach Boom is for use in deep trenching applications where long reach and depth are necessary. Two long sticks are available for this boom.

General Purpose Boom

The 8.4 m (27 ft 7 in) GP Boom has been designed to balance the reach, digging force and bucket capacity required for a wide range of applications. Four sticks are available for use with the GP boom.

Mass Excavation Boom

The 7.25 m (23 ft 9 in) Mass Excavation Boom is most suitable for high production loading where reach and depth are less important. It allows use of the largest buckets. Two sticks are available for this boom.

Stick Construction

The 385C L sticks are made of high-tensile strength steel using a large box section design with interior baffle plates and an additional bottom guard to protect against damage. All sticks undergo a stress relieving process for greater durability.

Sticks

There are six sticks for maximum versatility in reach, digging forces, and bucket capacity requirements of various applications. Each stick is designed for use in combination with a specific boom and bucket family.

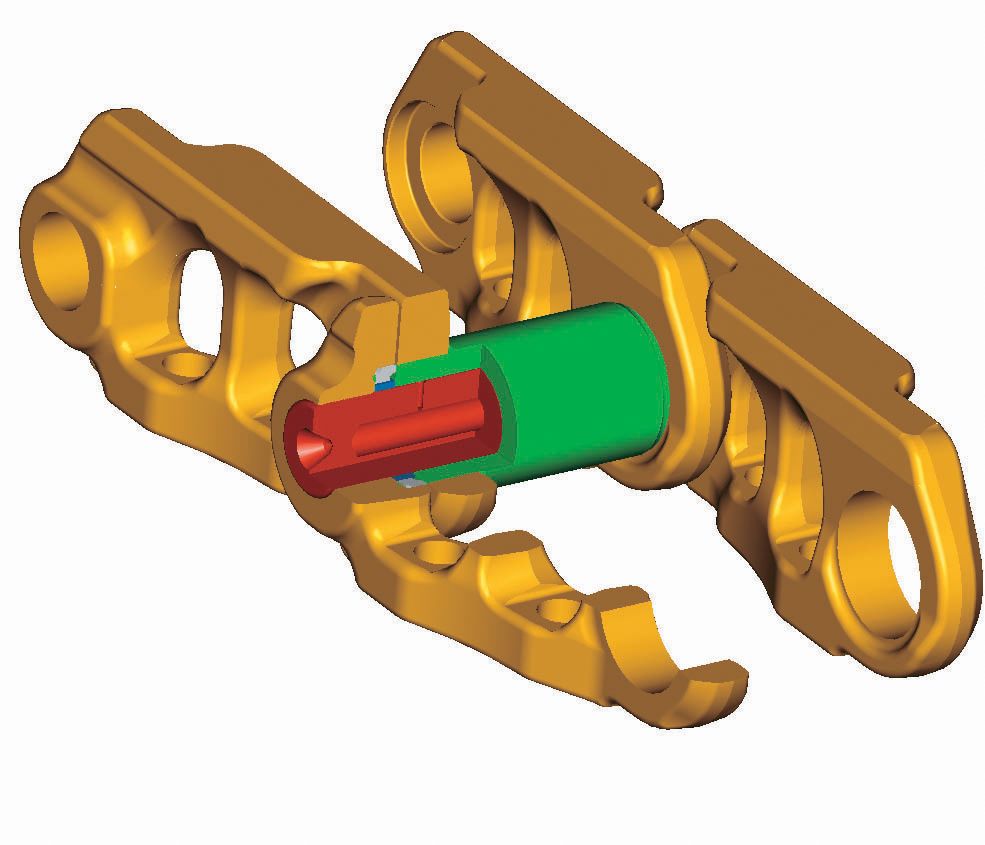

Bucket Linkage

- Two bucket linkages are available for the 385C L. Both linkages are available with or without a lifting eye on the power link.

- The HB linkage is used with the longer sticks and HB family buckets.

- The JB linkage is used with shorter sticks and JB family buckets.

Power Link

The new 385C L power link improves durability, increases machine-lifting capability in key lifting positions, and is easier to use compared to the previous lift bar design.

Linkage Pins

All pins used in 385C L front linkages have thick chrome plating, giving them high wear and corrosion resistance. The large diameter pins smoothly distribute the shear and bending loads to help ensure long pin, boom and stick life.

Buckets

Service and Performance

- Caterpillar buckets increase service life and optimize performance.

- High strength and heat treated steel are located in high wear areas.

- Dual radius design for increased heel clearance and reduced wear.

- HB and JB-family buckets include a lift eye.

- A variety of exclusive hydraulic dedicated coupler buckets are also available.

General Purpose (GP)

General Purpose (GP) buckets are for digging in soft to hard ground with low to moderate abrasive materials.

Heavy Duty Rock (HDR)

- Heavy Duty Rock (HDR) buckets are for aggressive bucket loading in highly abrasive applications such as shot rock and granite. Differences from GP buckets are:

- More robust construction for improved life and durability

- Additional, thicker bottom wear strips for improved wear in abrasive applications

- Larger, thicker side plates for maximum protection in rocky materials

- Smaller tip radius for greater breakout force

Ground Engaging Tools

Caterpillar Ground Engaging Tools (GET) include a variety of side cutters, sidebar protectors, and tip options to match operating conditions.

Service and Maintenance

Service Intervals

Service intervals are extended to reduce maintenance costs. • Engine oil, oil filter and fuel filters at 500 hours

Oil Sample and Pressure Ports

Oil sample and pressure ports provide easy checking of machine condition and are standard on every machine.

Hydraulic Capsule Filters

The return filters or capsule filters for the hydraulic system are located beside the hydraulic tank. The filter elements are removable without spilling hydraulic oil.

Service Points

Service points are centrally located with easy access to facilitate routine maintenance.

Pilot Hydraulic System Filter

Pilot hydraulic system filter keeps contaminants from the pilot system and is located in the pump compartment.

Greasing Points

A concentrated remote greasing block on the boom delivers grease to hard-to-reach locations.

Radial Seal Cleaner

Radial seal main air cleaner with precleaner has a double-layered filter element for more efficient filtration. No tools are required to change the element.

Fuel-Water Separator

The water separator removes water from fuel, even when under pressure, and water level can be monitored in the cab.

Complete Customer Support

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. You can save money with Cat remanufactured components.

Machine Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements, machine attachments and operating hours? What production is needed? Your Cat dealer can provide recommendations.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Customer Support Agreements

Cat dealers offer a variety of product support agreements, and work with customers to develop a plan the best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Operation

Improving operating techniques can boost your profits. Your cat dealer has videotapes, literature and other ideas to help you increase productivity, and Caterpillar offers certified operator training classes to help maximize the return on your investment.

Maintenance Services

Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling, Coolant Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.

Standard Equipment

- Electrical

- Alternator - 75 ampere

- Lights

- Power supply in cab - 12V, 7 amp

- Signal/warning horn

- Engine/Powertrain

- Automatic engine speed control

- Automatic swing parking brake

- Automatic travel parking brakes

- Cat C18 with ACERT® Technology

- High ambient cooling, 52° C (126° F) capability

- Side-by-side cooling system with separately mounted AC condenser and variable speed fan

- Two speed travel

- Water separator, with level indicator, for fuel line

- Guards

- Heavy duty bottom guards on upper frame

- Heavy duty swivel guard on undercarriage

- Heavy duty travel motor guards on undercarriage

- Operator Station

- Air conditioner, heater and defroster with automatic climate control

- Ashtray and 24 volt lighter

- AM/FM radio with antenna and two speakers

- Beverage/cup holder

- Cab Glass/Glazing

- Coat hook

- Console mounted electronic type joysticks with adjustable gain and response

- Floor mat

- Instrument panel and gauges with full color graphical display

- Literature compartment

- Lunch box storage with lid

- Neutral lever (lock out) for all controls

- Positive filtered ventilation

- Pressurized cab

- Retractable seat belt 76 mm width (3")

- Sunshade for windshield and skylight

- Travel control pedals with removable hand levers

- Windshield wipers and washers (upper and lower)

- Undercarriage

- Double grouser shoes - 900 mm (36") width

- Grease lubricated track

- Hydraulic track adjusters

- Idler and center section track guards

- Long, variable gauge

- Steps - four

- Other Standard Equipment

- Auxiliary hydraulic valve for hydro-mechanical tools

- Caterpillar one key security system with locks for doors, cab and fuel cap

- Cat walks - left side and right side

- Cross-roller type swing bearing

- Drive for auxiliary pump

- Hand control pattern changer

- Heavy lift mode

- Mirrors - left and right

- S•O•SSM quick sampling valves for engine oil and hydraulic oil

- Steel firewall between engine and hydraulic pumps

- Travel alarm with cut off switch

- Wiring provisions for Product Link, Auto-lube System and lighted beacon

Optional Equipment

- Front Linkage

- Booms

- Sticks

- Bucket Linkages

- Buckets - see chart

- Tips, sidecutters and edge protectors

- Track

- Double grouser 650 mm (26")

- Double grouser 750 mm (30")

- Guards

- FOGS (Falling Object Guard System) including overhead and windshield guards

- Track guiding guards - full length

- Vandal guards for windshield

- Wire mesh screen for windshield

- Auxiliary Controls and Lines

- Basic control arrangements

- Auxiliary boom lines

- Auxiliary stick lines

- Miscellaneous Options

- Adjustable high-back heated seat with mechanical suspension

- Adjustable high-back seat with air suspension and heat

- Boom lowering control device

- Counterweight removal system

- Electric lubricator with hose reel

- Machine security system with programmable keys

- Starting aid for cold weather with ether

- Stick lowering control device

- Straight travel pedal