Overview

The new 815F Soil Compactor gives you greater power, productivity and compaction. Combine this with the finest customer support system in the world - the Caterpillar dealer network of service and parts - and you get the lowest operating cost with the best up-time in the industry!

Benefits & Features

Specifications

Benefits & Features

Power Train

Caterpillar 3176C Diesel Engine

Delivers, at a rated speed of 2,100 rpm, flywheel power of 179 kW (240 hp) and meets the U.S. Environmental Protection Agency Tier 2 emissions regulations and Stage II EU Emissions Directive 97/68/EC. With high horsepower and low displacement, this innovative engine provides excellent fuel economy and durability which can significantly reduce operating costs.

Torque Rise

Is increased as a result of the electronically controlled, computer actuated unit injection fuel system that provides high injection pressure and more precisely controlled fuel delivery as the engine lugs back from rated speed.

Advanced Diesel Engine Module (ADEM III) Fuel System

Is a Caterpillar electronic control module which provides improved engine response, performance, fuel efficiency, troubleshooting diagnostics and reduced emissions. It allows integration with the electronic transmission control for maximum power train efficiency.

Turbocharger

Packs more dense air into the cylinders for more complete combustion and lower emissions, improving performance and engine efficiency. These benefits are especially useful at high altitudes.

Air-to-Air Aftercooler

Reduces smoke and emissions by providing cooler inlet air for more efficient combustion. This also extends the life of the piston rings and bore.

Dual Cooling Jets

In the block spray oil on the piston skirt and cylinder bores keep ring temperatures low for long ring and liner life with excellent oil control.

Pistons

Are two piece articulated with forged steel crowns for excellent strength and aluminum skirts for reduced weight. Pistons are oil cooled for increased heat dissipation and longer life.

Valves

Four per cylinder allow for good air flow, enhancing fuel efficiency and heat rejection. Valves and unit injection system are camshaft-actuated for precise timing.

Crankshaft

Is steel-forged, carburized and induction-hardened for long-term durability. It is dynamically balanced for smooth operation. The crankshaft is completely regrindable, and the connecting rods can be removed through the tops of the cylinders for easy servicing.

Caterpillar Engine Oil

Is formulated to optimize engine life and performance and is strongly recommended for use in Cat diesel engines. Engine oil change interval is increased to 500 hours.

Cat Remanufactured Parts

Are available, along with dealer proposed repair options, which increase machine availability and reduce total repair costs.

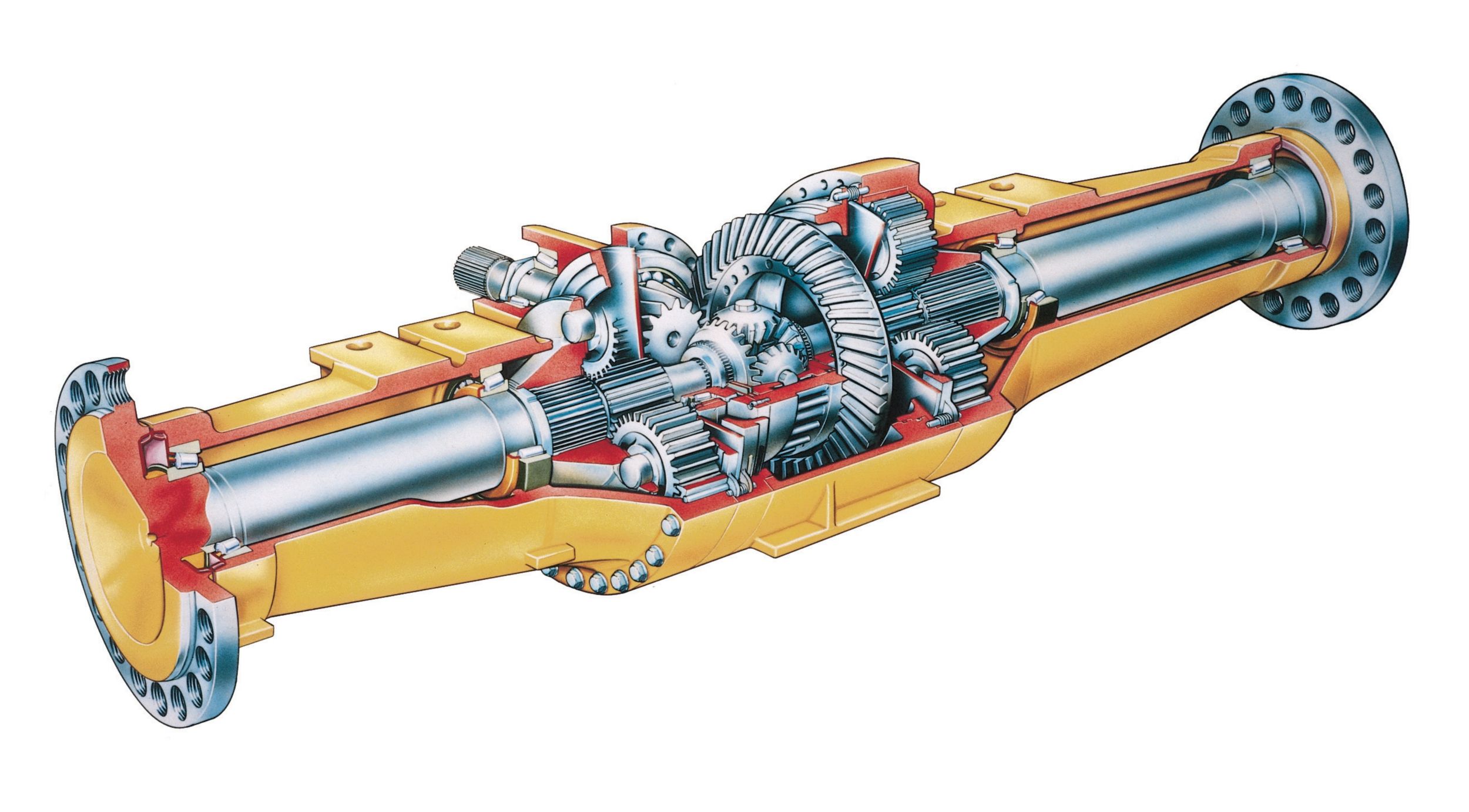

Caterpillar Planetary Powershift Transmission

Features heavy-duty components to handle tough jobs. The 345.4 mm (13.6 in) planet drives operate in all gears, forward and reverse. The addition of Electronic Clutch Pressure Control 9ECPC) contributes to improved shift quality, reduced torque spikes and overall transmission durability.

Heavy-Duty Axles and Brakes

Are designed to last in all kinds of operating conditions. Two front axle disc brakes provide improved braking capability and better heat dissipation. Planetary final drives use free-floating, bronze sleeve bearings in the planet gears.• Oil disc brakes are adjustment free and fully enclosed to lock out contaminants.

Front Axle

Is rigidly mounted to the frame to support the weight of the compactor, internal torque loads and external loads applied during compacting and dozing operations.

Rear Axle

Includes a trunnion, two trunnion supports and associated bearings, allowing it to oscillate plus or minus 12 degrees.

Four Piece Axle

Contains two axle shaft housings - the center housing and the intermediate housing. Features and benefits of this design include:• Inboard brakes on the front axle only are positioned immediately adjacent to the differential and operate on the low torque side of the final drive, requiring less braking to stop the machine.

Operator Station and Controls

1 Exceptional All-Around Viewing Area

Reduces strain and fatigue, making operators more productive.

2 Caterpillar Monitoring System

With electronic analog gauges is a highly effective and reliable warning and diagnostic system.As a warning system, it constantly checks machine functions and tells the operator when there is a problem. Easy-to-read gauges display fuel level, temperatures for engine coolant, transmission and hydraulic oil, engine rpm and gear range. Hour meter, odometer and analog tachometer readings are also displayed.As a diagnostic system, it identifies conditions, shows current readings and plays back maximum or highest readings registered during recent operations.The right side panel contains a three level warning system, providing full-time monitoring of key functions. The system alerts the operator of immediate or impending problems with air inlet temperature, brake oil pressure, electrical system, low voltage, engine oil pressure, engine over-speed, fuel filter status, parking brake status, steering oil pressure and transmission filter status.

3 Quick Gear Kick Up/Down Button

Lets the operator easily downshift or upshift to a different gear. It is a convenient way to shift that saves time and effort.

4 Ignition Key Start/Stop Switch

Is positioned for easy machine starting and stopping.

5 12-Volt Power Supply and Electronic Technician (ET) Diagnostics

Is provided inside the cab for powering radios, telephones or a laptop computer. This is particularly useful for powering a laptop running ET to access the enhanced engine and transmission control system diagnostics.

6 Steering Column

Adjusts to multiple positions. The leather-like steering wheel and transmission control provide a sure grip and comfortable feel. The horn is conveniently located in the center of the steering wheel.

7 Pilot-Operated Blade Controls

Are conveniently located and allow for precise blade movement.

8 Contour Seat

Is designed for comfort and support. Seat cushions reduce pressure on the lower back and thighs while allowing unrestricted arm and leg movement.• A fully adjustable air suspension seat with self-contained compressor is available as an option.

9 Built-In Storage Space

Is designed to hold cups, lunch box, insulated bottle and personal items.

10 Repositioned Vents

Throughout the cab keep fresh air flowing while improving the cab's heating, cooling, defrost and defog capability.

11 Throttle Lock

Allows and operator to set the engine speed and remove his foot from the governor (accelerator) pedal much like cruise control on an automobile. Using this feature increases productivity, fuel efficiency and improves operator comfort.

12 Decelerator Pedal

On the left acts as both an engine decelerator and a brake that overrides the engine speed selected by the throttle lock. This enables the operator to slow down when throttle lock is engaged and to return to throttle lock without pressing a button. It aids in maneuvering around scrapers, haul trucks, tractors or any other obstacle.

13 Windshield Washers/Wipers

With in-the-blade washer delivery system are standard features on front and rear windows. The front wiper has intermittent speed capability.

Tamping Wheels and Tips

Wheel Design

Gives the operator four-wheel width coverage in just two passes with front and rear wheel tracking that eliminates gaps and overlaps.

Chevron Tamping Wheel Tip Design

Is used for equal compaction in forward or reverse. Tips are full perimeter and are replaceable. The tip is welded to a base assembly, which is then welded directly to the drum. There are 12 tips per row and 60 tips per wheel for excellent compaction.

Symmetrical Tamping Wheel Tip Pattern

The modified chevron tamping wheel tip design provides greater ground pressure, more compaction, a smooth ride and excellent traction. Tip height is 190 mm (7.5 in) and width is 168 mm (6.6 in).

Cleaner Bars

Help keep the drums free of carry-over dirt regardless of rolling direction. A new pass-through bolt design allows for easier serviceability.

Adjustable Cleaner Bar Tip

Are constructed from cutting edge steel that is heat treated and direct hardened, which increases the wear life and translates into lower operating costs.

Compaction

Is achieved from the bottom of the lift to the top. The tapered pads walk out of the lift without "fluffing" the soil. The top of the lift is compacted and the surface is relatively smooth and sealed so hauling units are able to maintain a high speed when traveling over the fill. 815F travel speed allows for four forces of compaction: pressure, manipulation, impact and vibration. Since it can also spread fill, the number of spreader tractors may be able to be reduced.

Blade

Blade Package

Consists of the blade, push-arms, trunnion mounting, dozer-length skid plate with replaceable wear plates, reversible cutting edges, self-sharpening end bits, hydraulic lines guard and hydraulic lift cylinders.

Outside Mounted S-Blade

With multiple box section construction including heat treated moldboard and DH-2 steel cutting edges and end bits for long life. The outside mounting is a stronger design because stresses are put on the frame rather than the blade so blade flexing is reduced. It also allows for higher lift and a wider blade can be used than with an inside mounted design.

Operator Controls

Lift and tilt are both standard options, and the controls are seat-mounted and located in a convenient location to the right of the operator.

Applications

The 815F excels at production dozing, spreading fill, backfilling, stockpiling, boosting scrapers and compacting. With the ability to work at higher speeds over other types of soil compactors, the 815F can keep up with a fast-moving scraper fleet or an articulated truck hauling operation. When speed and dozing capability are required job duties for a soil compactor, the 815F has no equal.

Optional Features

Air Suspension Seat

Provides added comfort for the operator so productivity stays high.

Air Conditioner

Uses blended air and R134a refrigerant for immediate temperature changes.

Rear No-SPIN Differential

Replaces the rear standard differential. It delivers maximum traction in low traction or inconsistent ground conditions.

Fast Fill Adapter

Used during peak periods when high production is needed and little down time can be afforded for fueling. Fuel is pumped into the tank through a filling nozzle at rates up to 378.5 liters (100 gallons) per minute. As fuel enters the tank, air is forced out through an open vent. When the tank is full, the vent closes and the filling nozzle automatically shuts off.

Attachment Cleaner Bar Tip

Improves performance and increases wear life in sticky, abrasive soil applications. Constructed from cutting edge steel used for blades and buckets, this high alloy steel is heat treated and direct hardened, which increases the wear life of the tip by up to 240 percent over other designs.

Heavy Duty Cleaner Bar Tips

The shape of these tips enables them to penetrate the wheel more efficiently than the standard cleaner bar tips, thereby reducing wheel drag and improving machine performance. Constructed from cutting edge steel used for blades and buckets, this high alloy steel is heat treated and direct hardened, which increases tip wear life by up to 240 percent over other designs in sticky, abrasive soil applications.

Serviceability

Engine Access

All metal engine enclosure and hinged access doors allow for easy daily maintenance and inspection.

Left Side Service Access

Provides convenient entry to the engine oil filter, grease points (lower), air filter (front), power train oil dipstick (top), coolant sight gauge (top), power train oil fill (below cab), power train oil filter and high speed engine oil fill.

Right Side Service Access

Features that are easily reached under the hood include fuel filter and water separator, fuel primer and engine oil dipstick.

500 Hour Oil Change Interval

Increases uptime and production by doubling the time between oil and filter changes without requiring increased oil sump capacity.

Hinged Hydraulic Oil Cooler

Can be swung open 70 degrees without special tools.

Hinged Air Conditioning Condenser

Swings open 120 degrees and coupled with the swing out oil cooler, allows the cooling system to be cleaned quickly and easily.

Operator Station

Can be removed or replaced in about 45 minutes without having to disconnect hydraulic lines. Quick disconnect couplings allow fast disconnect of the air conditioning unit without releasing refrigerant.

Engine Shutdown Switch

Is located inside the left engine enclosure panel for simple access and extended switch life.

Battery Box

Is located in the right side bumper for convenient access to the maintenance-free batteries.

Tool Box

Is located in the left side bumper for additional protection against harsh work environments.

Complete Customer Support

Machine Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers can estimate component life, preventative maintenance cost and the true cost of lost production.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. Look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Customer Support Agreements

Cat dealers offer a variety of product support agreements and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers use a worldwide computer network to find in-stock parts to minimize downtime. Save money with genuine Cat Reman parts. You receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training video tapes, literature, application and equipment training courses and other ideas to help you increase productivity.

Maintenance Services

More equipment buyers are planning for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM and Coolant Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, backup

- Alternator (70 amp)

- Batteries, maintenance-free

- Diagnostic connectors

- Lighting system, halogen (front, rear and cab-mounted)

- Starting and charging system (24-volt)

- Starting receptacle for emergency starts

- OPERATOR ENVIRONMENT

- Blade control system locks

- Cab, pressurized and sound suppressed (ROPS/FOPS)

- Coat hook

- Cigar lighter and ashtray

- Caterpillar Monitoring System

- Dome light (cab)

- Heater and defroster

- Horn, electric (steering wheel mounted)

- Hydraulic steering

- Lunchbox and beverage holders

- Mirrors, rearview (interior mounted)

- Seat, KAB mechanical suspension

- Seatbelt, retractable, 76 mm (3 in) wide

- Steering column, adjustable

- Wet-arm wipers/washers (front and rear)

- POWER TRAIN

- Brakes, fully hydraulic, enclosed, wet-disc

- Engine, Cat 3176C with ATAAC

- Fuel priming pump

- Muffler

- Radiator, Advanced Modular Cooling System (AMOCS)

- Starting aid (ether)

- Torque converter

- Transmission, planetary (3 forward/3 reverse speeds)

- OTHER STANDARD EQUIPMENT

- Caterpillar O-ring face seals/couplings

- XT hoses

- Cleaner bars

- Guards

- Hood, metallic with lockable service doors

- Hitch, drawbar with pin

- Hydraulic oil cooler

- Oil sampling valves

- Trunnion

- Tamper wheels

- Vandalism protection caplocks

- BULLDOZERS

- Bulldozer blade, hydraulics and linkage are not included in standard equipment.

- ANTIFREEZE

- Premixed 50 percent concentration of Extended Life Coolant with freeze protection to -34°C (-29°F)