Overview

The Power of One... One manufacturer... One dealer... One source for all your warranty, parts and service needs. The 826G Series II landfill compactor was conceived and designed to surpass any competitor with exciting innovations that exceed customer expectations for performance, reliability and operator comfort.

Specifications

| Operating Weight | — |

| Gross Power | — |

| Engine Model | Cat® 3406E ATAAC Diesel |

Benefits & Features

Specifications

| Gross Power | — |

| Engine Model | Cat® 3406E ATAAC Diesel |

| Flywheel Power | — |

| Net Power ISO 3046-2 | — |

| Net Power - ISO 9249 | — |

| SAE J1349 | — |

| EEC 80/1269 | — |

| DIN 70020 | 327 PS |

| Peak Torque - 1,200 rpm - Net | — |

| Torque Rise | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Vane Pump Output at 2,000 rpm and 6900 kPa (1,000 psi) | — |

| Relief Valve Setting | — |

| Lift Cylinder Bore x Stroke | 114.3 mm x 576 mm 4.49 in x 22.68 in |

| Front | Planetary - Fixed |

| Oscillating Rear | Planetary - Oscillating ±5° |

| Standards | Meet OSHA, SAE J1473 Dec 84, ISO 3450-1985 standards. |

| Drum Width | — |

| Drum Diameter | — |

| Diameter - With Tips | — |

| Tips per Wheel | 25 |

| Drum Width | — |

| Drum Diameter | — |

| Diameter - With Tips | — |

| Tips per Wheel | 45 |

| Drum Width | — |

| Drum Diameter | — |

| Diameter - With Blades | — |

| Blades per Wheel | 25 |

| Width - Over End Bits | — |

| Moldboard - Length | — |

| Height | — |

| Lift Speed at Rated RPM | — |

| Cutting Edges (2), Reversible, End Section Length (Each) | — |

| Cutting Edges (2), Reversible, Width x Thickness | 254 mm x 25 mm 10 in x 1 in |

| End Bits (2), Self-sharpening, Length - Each | — |

| End Bits (2), Self-sharpening, Width x Thickness | 254 mm x 25 mm 10 in x 1 in |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic Tank | — |

| Operating Weight | — |

| ROPS/FOPS | Meets SAE and ISO standards. |

| Standards | Meets ANSI/SAE and ISO standards. |

| Height - Top of Cab with A/C | — |

| Height - Top of Exhaust Pipe | — |

| Height - Top of Hood | — |

| Ground Clearance - Counterweight | — |

| Height - Bottom of Ladder | — |

| Centerline of Rear Axle to Edge of Counterweight | — |

| Centerline of Rear Axle to Hitch | — |

| Wheel Base | — |

| Length - With Blade on Ground | — |

| Width - Over Wheels | — |

| Width - Over End Bits - Blade | — |

| Turning Radius - Inside | — |

| Turning Radius - Outside | — |

Benefits & Features

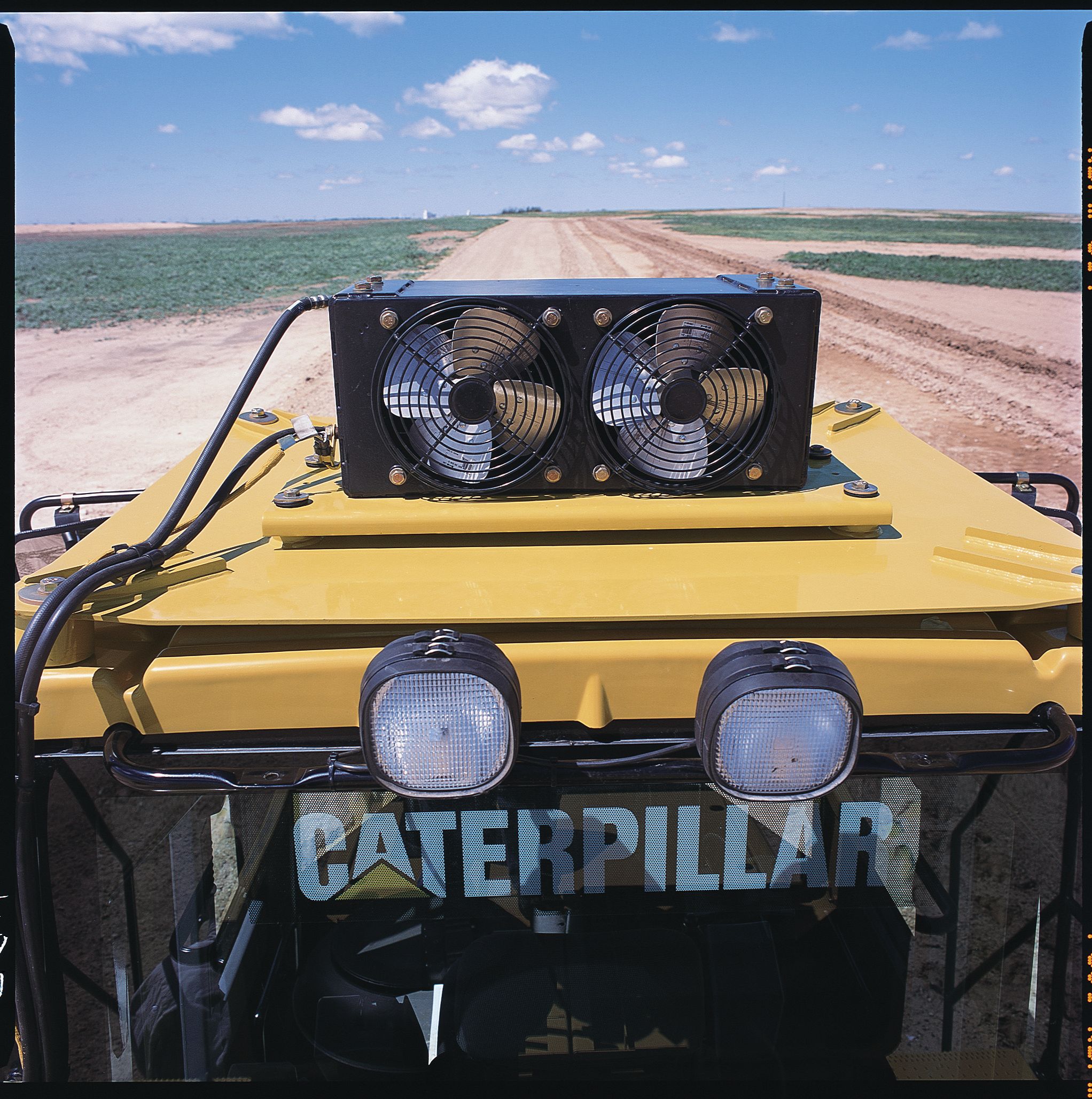

Trash Protection and Cooling System

Cooling System

The 826G Series II is designed specifically for landfill compactors operating at 100 percent engine load. At these conditions, the ambient capability is above the benchmark of 43 degrees C (110 degrees F), demonstrating the machine's purpose-built cooling system.

Roof-Mounted Air Conditioner

Makes the rear cooling package easier to clean because the A/C core is removed from the rear. It also reduces the frequency of cleaning for the condenser core, providing better cooling to the cab for longer periods of time.

Hinged Oil Cooler Core

Swings out 30 degrees from the radiator for easier cleaning.

(1) Air Inlet Screen

Is vertically-corrugated, fine mesh to help reduce trash from entering the radiator area and allow debris to fall off.

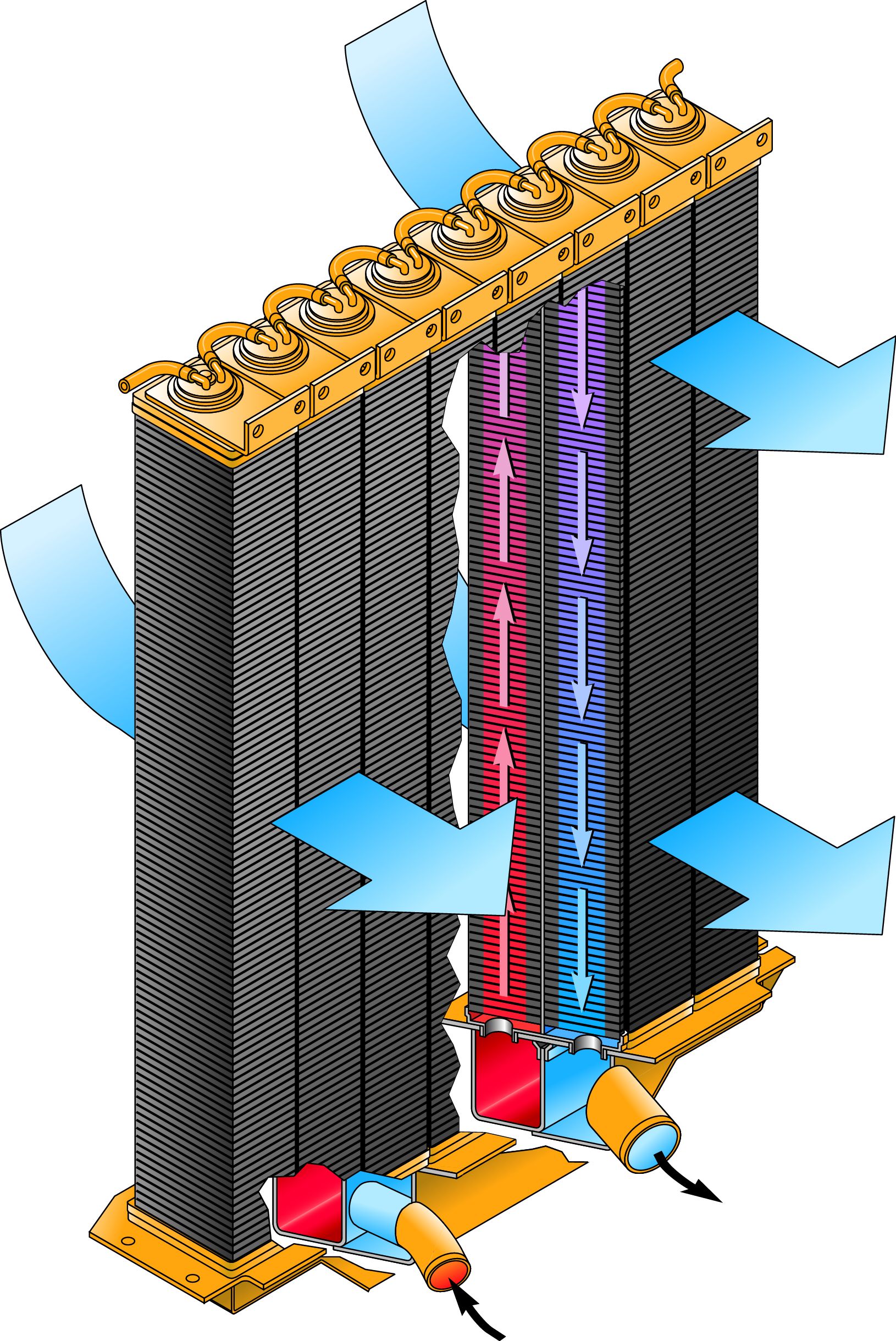

Advanced Modular Cooling System (AMOCS)

The G-Series II cooling system has been upgraded to the Advanced Modular Cooling System (AMOCS). It is a Caterpillar exclusive technology that improves serviceability. The brass tubes on the AMOCS are straight and in-line, along with six fins per inch, making the radiator easy to keep clean. The tubes are welded to a large, thick header, providing the strength of the tube-header joint, reducing the possibility of coolant leaks.

(2) Auto-Reversing, Hydraulically-Driven Fan

Is an electronically controlled, hydraulically driven, on-demand fan system that reduces sound levels and increases fuel economy while providing maximum cooling efficiency by directing power through the system as needed. With electronic control of the continuously variable-speed, on-demand fan, temperature levels of the engine coolant, transmission oil, hydraulic oil and air inlet manifold are constantly monitored. This information is used to control and maintain fan speed at the level necessary to maintain normal system temperatures. It also reverses direction for 20 seconds every 30 minutes or manually from the cab, to purge the intake screens of debris.

(3) Swing-Out Radiator Fan

The fan can swing out 65 degrees to provide access to the cooling cores from the side opposite the direction of airflow. This is the ideal side from which to clean the radiator and enables the system to be accessed wrench-free and cleaned in 15 minutes or less.

Electrically Actuated Engine and Power Train Guards

Guards help prevent trash build-up and shield components from demolition debris, trash, wire, rebar and chemicals while allowing access for the cleaning and maintenance.

(1) Cab Bottom Guard

Protects hoses and wires beneath the cab from damage due to flying debris and waste.

(2) Striker Bars

Located in front of and behind the rear wheels and behind the front wheels provide protection from trash that can be thrown or carried by the wheels.

(3) Hydraulic Tank and Steering Cylinders

Are guarded to resist damage. The oil sight gauge is visible for easy checking.

Cleaner Fingers (Optional)

Provide maximum capability to maintain clean Plus Tip wheels when working in very cohesive materials and the most severe packing conditions.

Hitch Pin Retainer Guard

Extends from the front belly toward the hitch to protect the hitch pin retaining plate from wear and sudden impact.

Rear Access Walkover Stairway

Provides easy access to the operator's station. Optional swing-out stairway provides for unparalleled access for wheel inspection and cleanout, engine service and preventative maintenance.

Hydraulic Tank and Steering Cylinders

Are guarded to resist damage. The oil sight gauge is visible for easy checking.

Front Frame Guards

Prevent trash build-up inside the frame that could harm hydraulic lines. The lift lines are in a higher location where damage from debris is less likely.

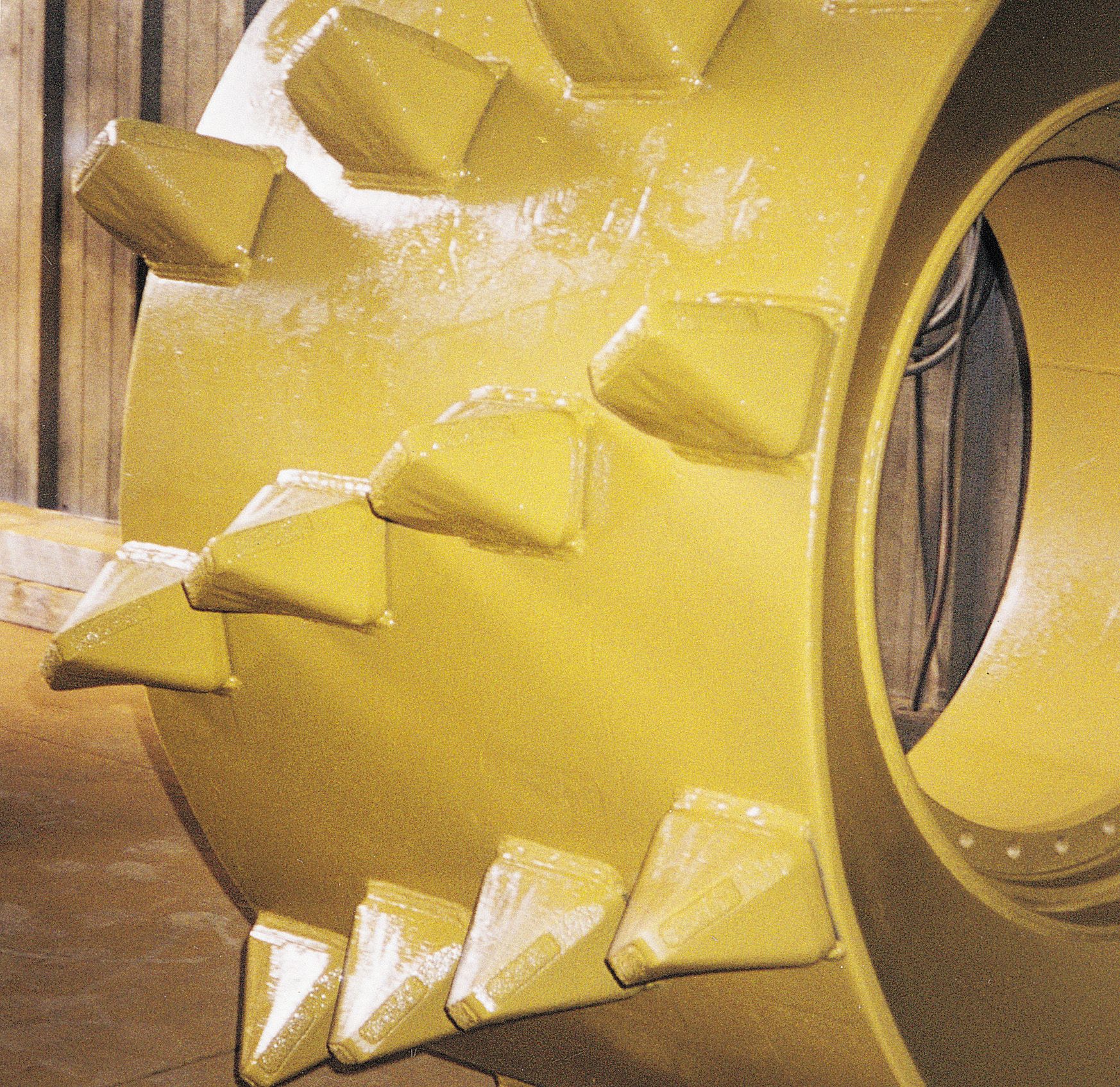

Wheels and Tips

Standard Equipment

The standard machine offering is the long-life Plus Tip that provides excellent traction and side-hill stability with a self-cleaning layout that resists plugging or the self-cleaning chopper blades for shredding material, the special application traction tip. All choices are specifically designed for our Caterpillar steel wheels.

Plus Tips

With Abrasion-Resistance Material (ARM) have an exclusive plus-shaped design for superior compaction and sidehill stability on sloped material. A widely spaced tip pattern require fewer tips than competitors and results in less plugging, lower replacement cost and maximum compaction. Plus Tips are guaranteed for 10,000 hours or four years of wear life. They offer the lowest cost per hour of any compactor tips in the industry.

Self Cleaning Chopper Wheels

Are designed to deliver maximum compaction and traction. Aggressive chopping action is provided by 24 blades per wheel. Heat-treated DH-2, Abrasion Resistant Material steel blades provide longer wear. The staggered chevron blade arrangement evenly distributes chopping coverage. Blade center gussets help assure maximum refuse demolition. Blades are mounted differently on the front and rear wheels to maximize chopping and compaction in both forward and reverse.

Weld-On Traction Tips

Are designed for landfill applications where maximum traction is required. These tips perform best in frozen or other difficult to penetrate applications. Designed and built to Caterpillar standards, these tips are forged for maximum strength and Abrasion Resistant Material is applied to critical wear areas.

Smooth Wheel Option

If our tip selection does not meet your needs, consider our Caterpillar smooth steel wheel. We test and build a Caterpillar system. Engineers who work together with our power train, structures and manufacturing engineers design and manufacture our wheels in the same facility in which the machines are designed and built. This ensures the entire system is complemented by each component. If you alter components, you could compromise a system that was designed and tested for peak performance. If a wheel is produced that does not meet our exact design specifications and does not balance the load over our final drives, it could reduce the life of the bearing substantially and wear out other components creating unnecessary downtime. This also allows our standard axle guard system to work with the components for which it was designed.

Hydraulics

Hydraulic System

Provides low-effort blade control. Seat-mounted levers send electrical signals to a pilot valve mounted on the front frame. This moves the sound, heat and effort caused by a hydraulic valve out of the operator's station.

Command Control Steering

A mechanical feedback system combines with valve ratio to provide quarter-turn, side-to-side steering. Unlike systems that rely on steering wheel velocity to activate steering cylinders, this system directly links steering wheel position to articulation. The speed the machine turns is proportional to the steering wheel position. The benefit is precise control, quicker response and dramatically reduced operator motion and effort.

Hydraulic Power Steering

Features center-point frame articulation that permits the front and rear wheels to track. Hydraulic power is a flow-amplified system, with full-flow filtering. The steering wheel operated pilot valve controls flow to the steering cylinders. The steering angle is ±42°.

Load Sensing Steering

Maximizes machine performance by directing power to the steering system only when the operator steers the machine. This allows more power to be applied to the ground when the machine is not being steered. It also helps decrease fuel consumption because the steering system does not constantly draw on the engine.

Positive-Displacement Hydraulic Pumps

Perform with high efficiency and great reliability. For improved serviceability, all hydraulic pumps are mounted on a single pump drive.

Lift Lines

Are located in a high location above the cylinder yoke where damage from debris is less likely.

XT-3 and XT-5 Hose

Along with O-ring face seals and a large capacity lift cylinder top off the hydraulic system, delivering the performance and durability owners expect. Reliable components reduce the risk of leaks and blown lines, helping protect the environment and reducing operating costs.

Power Train

Caterpillar 3406E Engine

- Is a six-cylinder, turbocharged, air-to-air aftercooled (ATAAC), Electronic Unit Injection (EUI) engine and one of the most developed and proven engines offered by Caterpillar. It has a strong reputation for realibility, durability and performance.

- The 3406E delivers a full-rated net power of 283 kW (380 hp). High torque rise delivers performance you can feel, resulting in more rimpull, greater lift force and faster cycle times.

- The four stroke engine delivers fuel economy, durability and reliability in the most demanding conditions. Improved intake and combustion chamber designs help meet the latest emission standards.

- Resilient engine mounts dampen vibration for lower sound levels.

- Meets U.S. Enviromental Protection Agency Tier 2 emissions regulations and Stage II EU Emissions Directive 97/68/EC.

Engine Lubrication

Engine lubricating oil is both filtered and cooled and supplied by a gear-type pump.

Electronic Unit Injector (EUI)

Is a high-pressure, direct injection fuel system that is virtually adjustment-free. It electronically monitors operator and sensor inputs to optimize engine performance.

ADEM™ III Electronic Control Module

Along with the Caterpillar Monitoring System controls all major engine functions and regulates the timing, duration and pressure of the injected fuel. ADEM III also offers automatic altitude compensation, a cold mode start-up strategy and oil pressure and coolant warnings which result in precise engine speed control, superior cold start capability, low smoke and emissions in all operating conditions.

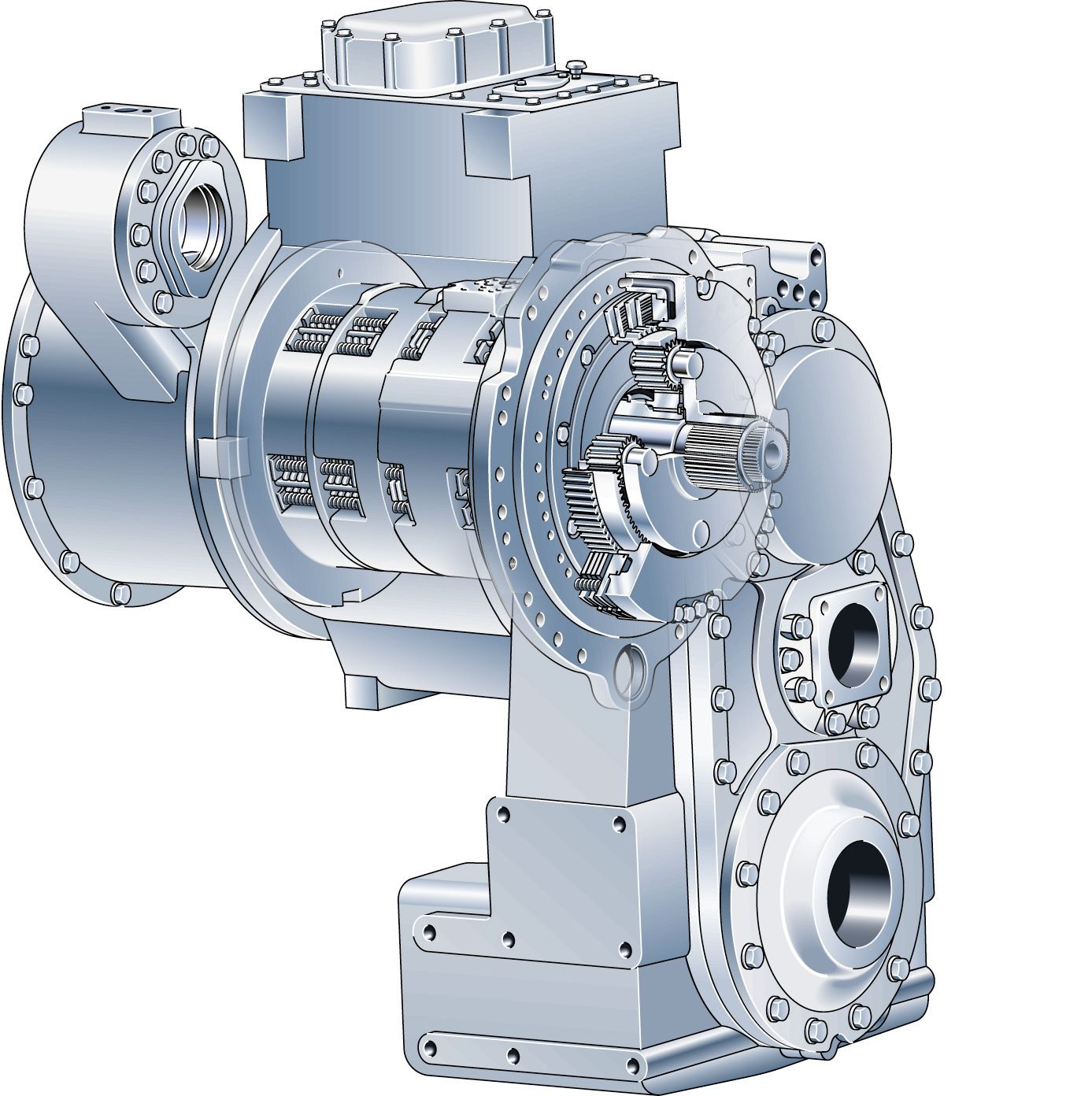

Transmission

The Caterpillar planetary, powershift transmission features heavy-duty components to handle the toughest jobs. Electronic controls provide features to enhance productivity, durability and serviceability. The addition of the Electronic Clutch Pressure Control (ECPC) contributes to improved shift quality, reduced torque spikes and overall transmission durability.

Torque Converter

The torque converter uses a high-capacity impeller to handle the engine's increased torque rise (28 percent) and power.

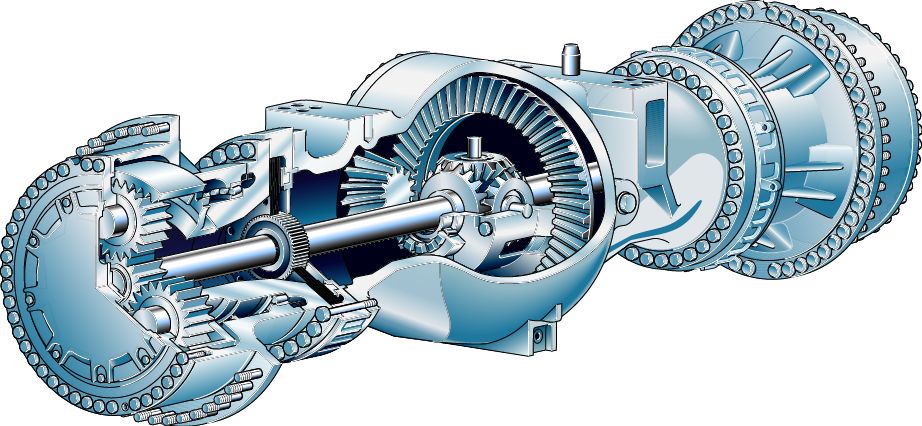

(1) Heavy-Duty Axles

Are fixed on the front and oscillating ±5 degrees on the rear. They feature strong gears and bearings in both the differentials and heavy-duty final drives for increased durability. Permanently lubricated, maintenance-free U-joints result in fewer parts and improved serviceability. Free-floating axle shafts can be removed independently from the wheels and planetary final drives.

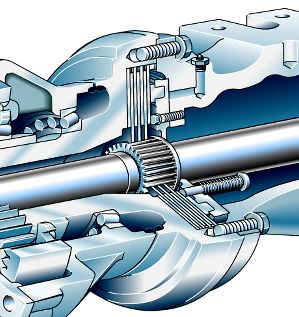

Gears and (2) Shafts

Large, shot-peened gears and increased bolt capacity improve the durability of the standard differentials. Axle shafts are stronger and feature more splines to help spread the load.

Spindles and (3) Final Drives

Reduce the number of parts and greatly improve serviceability, allowing easier access to the duo-cone seals without removing the center housing from the machine. Planetary units can be removed independently from the wheels and brakes. The final drives feature planetary reduction at each wheel, and with torque developed at the wheel, less stress is placed on the axle shafts.

(4) Differentials

Are conventional in the front and No-SPIN on the rear to deliver maximum traction in low traction or inconsistent ground conditions.

(5) Oil-Enclosed, Multiple Disc Brakes

- Feature fewer parts, better heat rejection and improved serviceability. Fully hydraulic actuator circuits improve performance and reliability.

- Brakes operate on the low torque side of the final drive, requiring less force, resulting in less heat buildup.

- Improved axle oil circulation (6) provides additional cooling to the (7) brake discs. A combination of thicker reaction plates and improved cooling improve durability.

- Fewer parts and brake disc location improve serviceability by allowing technicians to remove the spindle, final drive and brake pack as one unit without disturbing the wheel bearings.

- Internal brake lines increase reliability and performance.

(8) Service Brakes

Are completely enclosed and located on the two front wheels. The service brakes are also self-adjusting with modulated engagement and are designed for easy servicing. With two brake pedals, the right pedal controls standard braking while engine deceleration and braking occurs with the left pedal.

Parking Brake

Is a spring-applied, oil-released, dry drum design. It is mounted on the transmission output shaft driveline for manual operation. The Caterpillar Monitoring System alerts the operator if the transmission is engaged while the parking brake is applied.

Secondary Brake

Can be applied manually by the operator. In addition, the Caterpillar Monitoring System alerts the operator if pressure drops and will automatically apply the parking brake.

Operator Station and Controls

STIC Control System (Optional)

- Is a revolutionary system that integrates steering and transmission into a single controller. Simple side-to-side motions of the operator's left arm turn the machine right or left.

- Transmission shifting forward, neutral or reverse is controlled by the operator's fingers, and gear selection is controlled by the operator's thumb.

- Produces a fluid motion that reduces effort and allows the operator to work the machine for long periods with little or no fatigue.

Two Types of Mounted Windows

Standard bonded glass in the front window (left) improves the viewing area or the optional rubber mounted glass cab (above) facilitates quick window replacement when broken glass is a problem.

Radio-Ready

Includes 12-volt converter, speakers, antenna, all wiring and brackets for communications or entertainment radio installation.

Right and Left Front-Hinged Doors

Provide a walk-though operator's station. Both doors can be opened. The addition of the stairways and improved platforms also makes entry and exit easier.

Sound Levels

A thick, non-metallic floor, along with outside the cab hydraulics and a separated cooling system contribute to a quiet work environment.

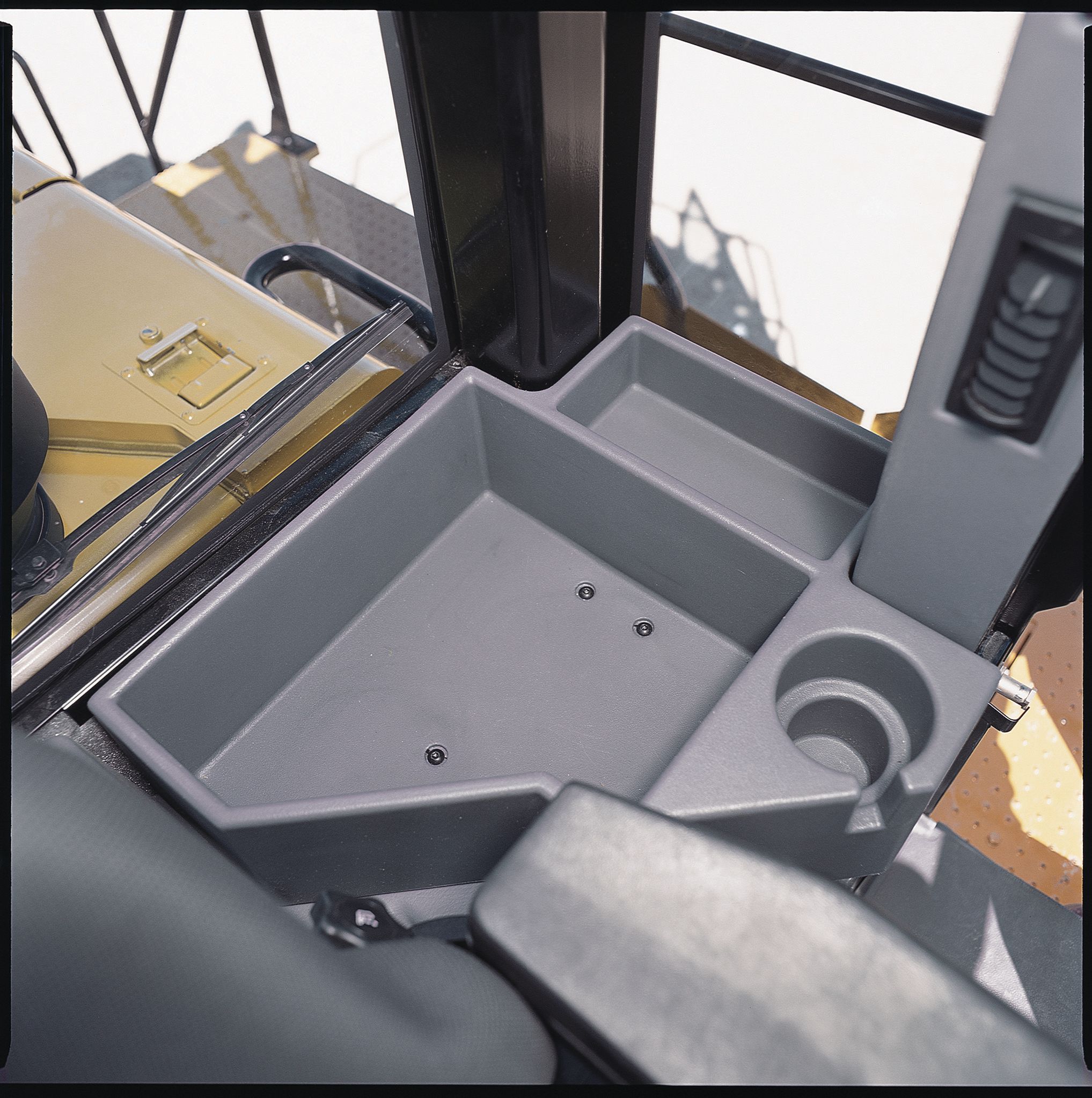

Storage Space

With room for a lunch cooler, thermal bottle, cup and other personal items. There is also a coathook.

Caterpillar Comfort Series Seat

Provides comfort and support with six-way adjustment. The seat cushions reduce the pressure on the lower back and thighs, while offering unrestricted arm and leg movement. Air suspension adds to the overall comfort level by smoothing the ride over rough terrain.

Caterpillar Monitoring System

Provides four gauges on the left side of the dash monitoring fuel level; engine coolant, hydraulic oil and transmission oil temperatures. The center panel contains the tachometer/speedometer. The right side panel contains a three-level warning system, providing full-time monitoring of key functions. The system alerts the operator of immediate or impending problems with air inlet temperature, brake oil pressure, electrical system low voltage, engine oil pressure, engine overspeed, fuel filter status, parking brake status, steering oil pressure and transmission filter status.

Ventilation Ducts and Vents

Provide more air flow to the operator and windows. Post-mounted vents direct air to the rear window.

Air Conditioning

Uses blended air for immediate temperature changes, clears windows with ease and improves operator comfort. The system is located behind the operator's seat and uses environmentally-friendly R134a refrigerant.

Dual Pedal Braking

Is available by using the right pedal for standard braking or the left pedal for engine deceleration for the first 50 percent of travel then the brake engages.

Throttle Lock

Allows the operator to preset the engine speed for operator and machine efficiency (similar to cruise control on an automobile).

Reversing Fan Selection Switch

Allows the operator to reverse the radiator fan if conditions necessitate reversals more frequently than automatically timed reversals.

Landfill Features

Cat Axle Guard System

- Protects final drives, planetaries and seals from damage caused by wire, cable plastics or other materials that can wrap or become packed around axle components.

- Guarding increases axle circumference to avert stringy materials from wrapping and encircling the axle.

- Extended rim wheels further help to seal out materials that cling to wheel or axle surfaces.

- Recessed bolt heads reduce snagging of stringy or stranded materials.

- System reduces the need for periodic cleaning of axle assemblies.

Axle Guard System Design

- The Axle Guard System is comprised of three basic components:

- Frame bosses welded to the frame.

- Bolt-on guarding assemblies mounted onto the frame bosses and frame.

- Rim extensions welded directly to the wheel rims.

New Metal Engine Enclosure

Completely redesigned metal engine enclosure, framing and service doors provide the durability and serviceability required for the abusive landfill application.

Straight Blade

- Ideal for most waste management applications.

- Built to withstand the rigors of heavy-duty dozing.

- Versatile blade for most applications.

- Trash rack design provides excellent visibility and load-carrying capability.

- Design incorporates Cat cutting edges.

Optional Front Window Guard

An all new, tubular steel guard across the bottom of the front cab glass prevents large debris from damaging the lower portion of the front windows.

Optional Sound Suppression

Engine enclosure padding added for reduced exterior noise levels.

See your Caterpillar dealer for these and other specialty attachments.

Serviceability

Daily Maintenance

Lockable ground level service doors give quick access to engine oil fill and dipstick, coolant sight gauge, rear frame grease fittings, relay panel and electrical breakers. The transmission oil fill tube is located beneath the platform area and the transmission oil dipstick has a sight gauge next to the fill tube. All four maintenance-free batteries are secure in a built-in battery box in the right rear frame. U-joints are lifetime lubricated, leaving the slip joint as the only driveline component needing grease.

Engine Access

All metal engine enclosure and hinged access doors allow for easy daily maintenance and inspection.

Service Access

Scheduled maintenance points are well within reach. An air filter service indicator is visible from the cab or platform, with the air filter accessible from the left platform and the engine oil filter from the right platform. A remote grease fitting is provided to lubricate the lift cylinder yoke. Removable treadplates in the platform give access to less commonly serviced components.

Transmission Oil Fill Tube

Is located, along with the sight gauge, under the platform area for easy maintenance.

Separated Cooling System

Isolates the fan and radiator away from the engine for a quieter running machine. The oil cooler and reversible fan swing away for easy cleaning. AMOCS reduces radiator repair time.

Swing-Out Stairs (optional)

Located on both sides of the 826G Series II offer easy access for wheel inspection and cleanout, engine service and preventative maintenance.

Caterpillar Monitoring System

Provides diagnostics that allow technicians to review a machine's operation and quickly troubleshoot problems. Operating parameters, diagnostic codes and out-of-range gauge readings are displayed through the diagnostic connector. There are also pressure taps for easy hydraulic system checks.

Operator Station

Can be removed or replaced in about 45 minutes without having to disconnect hydraulic lines. Quick disconnect couplings allow fast disconnect of the air conditioning unit without releasing refrigerant.

Complete Customer Support

Machine Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers can estimate component life, preventative maintenance cost and the true cost of lost production.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. Look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Customer Support Agreements

Cat dealers offer a variety of product support agreements and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers use a worldwide computer network to find in-stock parts to minimize downtime. Save money with genuie Cat Reman parts. You receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training video tapes, literature, application and equipment training courses and other ideas to help you increase productivity.

Maintenance Services

More equipment buyers are planning for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S•O•SSM and Coolant Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.

Standard Equipment

- Electrical

- Alarm, back-up

- Alternator (75 amp)

- Batteries, maintenance-free (heavy-duty)

- Diagnostic connector

- Starting and charging system

- Electrical system (24-volt)

- Lighting system, halogen (front and rear)

- Lockable master disconnect switch

- Starter, electric (heavy-duty)

- Starting receptacle for emergency starting

- Guards

- Axle guards (front and rear)

- Guards, powered (crankcase and power train)

- Operator Environment

- Air conditioner, roof mounted

- Blade control system locks

- Cab, pressurized and sound suppressed

- Cigar lighter and ashtray

- Coat hook

- Command Control steering

- Electro-hydraulic blade controls

- Gear selection display

- Heater and defroster

- Horn, electric

- Hour meter display

- Light, dome (two in cab)

- Lunchbox and beverage holders

- Mirrors, rearview (externally mounted)

- Monitoring system

- Seat belt, retractable, 76 mm (3 in) wide

- Wet-arm wipers/washer (front and rear)

- Power Train

- Brakes, fully hydraulic, enclosed, wet multiple disc

- Cat axles (outboard final drives and No-SPIN differential [rear] standard)

- Engine, Cat 3406E with ATAAC diesel

- Fan, radiator, hydraulically-driven (automatically reversible)

- Fuel priming aid

- Muffler, sound suppressed

- Precleaner, engine air intake

- Radiator, Advanced Modular Cooling System (AMOCS), six fins per inch

- Starting aid (ether)

- Switch, transmission neutralizer lockout

- Torque converter

- Transmission, planetary with (2F/2R) electronic clutch pressure control

- Other Standard Equipment

- Bumper, extended full width for radiator protection

- Caterpillar O-ring face seal couplings

- Coolers

- Hitch, drawbar with pin

- Hood, metallic with lockable service doors

- Oil sampling valves

- Rear egress, left and right side

- Striker bars, full coverage

- Wheels, 1219 mm (48 in) with long-life weld-on Plus Tips with rim extensions

- XT hoses

- Bulldozers

- Bulldozer blade, hydraulics and linkage are not included in standard equipment.

- Antifreeze

- Premixed 50 percent concentration of Extended Life Coolant with freeze protection to -34C (-29F)

Optional Equipment

- Fast fill system

- Fuel - 4 kg (9 lb)

- Oil - 1 kg (3 lb)

- Wheels (four combined)

- Chopper blade - 530 kg (1168 lb)

- Traction tip - 308 kg (680 lb)

- Various wheels, see price list

- Field Installed Attachments

- Axle guards

- Cleaner fingers - 1001 kg (2207 lb)