Overview

The Cat 826G Landfill Compactor combines power, mobility and operator comfort for high landfill compacting productivity. Rugged construction and easy maintenance provide long life with low operating cost.

Specifications

| Operating Weight | — |

| Gross Power | — |

| Engine Model | Cat® 3406C TA |

Benefits & Features

Specifications

| Gross Power | — |

| Engine Model | Cat® 3406C TA |

| Flywheel Power | — |

| Displacement | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Front | Fixed |

| Oscillating Rear | Oscillating |

| Moldboard - Length | — |

| Height | — |

| Lift Speed at Rated RPM | — |

| Cutting Edges (2), Reversible, End Section Length (Each) | — |

| End Bits (2), Self-sharpening, Length - Each | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic Tank | — |

| Operating Weight | — |

| Travel Speed Forward | — |

| Travel Speed Reverse | — |

| Ground Clearance | — |

| Wheel Base | — |

| Length - With Blade on Ground | — |

| Width - Over Wheels | — |

| Width - Over End Bits - Blade | — |

| Blade Width - Straight | — |

| Drum Width | — |

Benefits & Features

Trash Protection

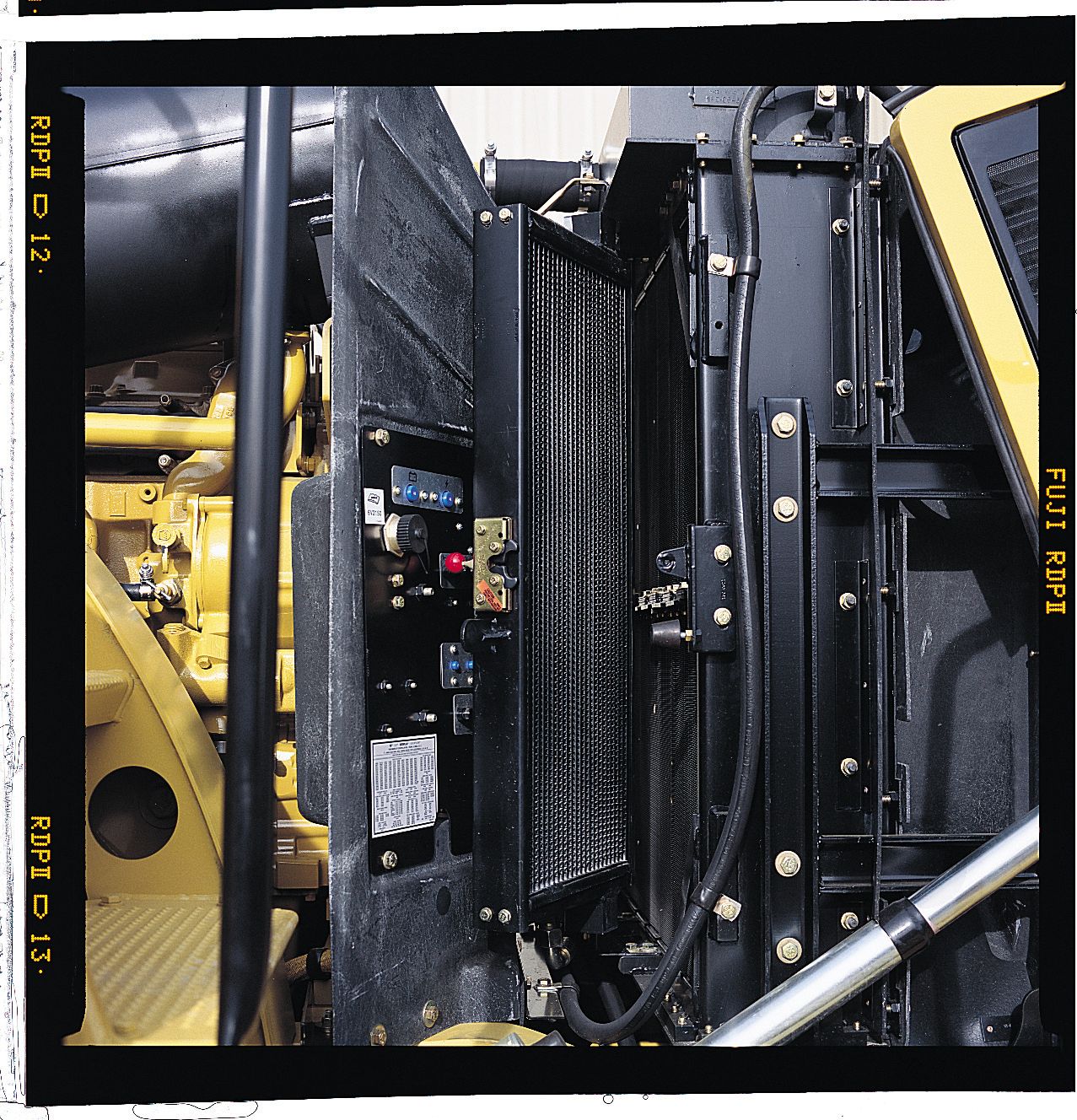

Radiator and cooling system

Radiator and cooling system on the 826G incorporate many trash resistant features.

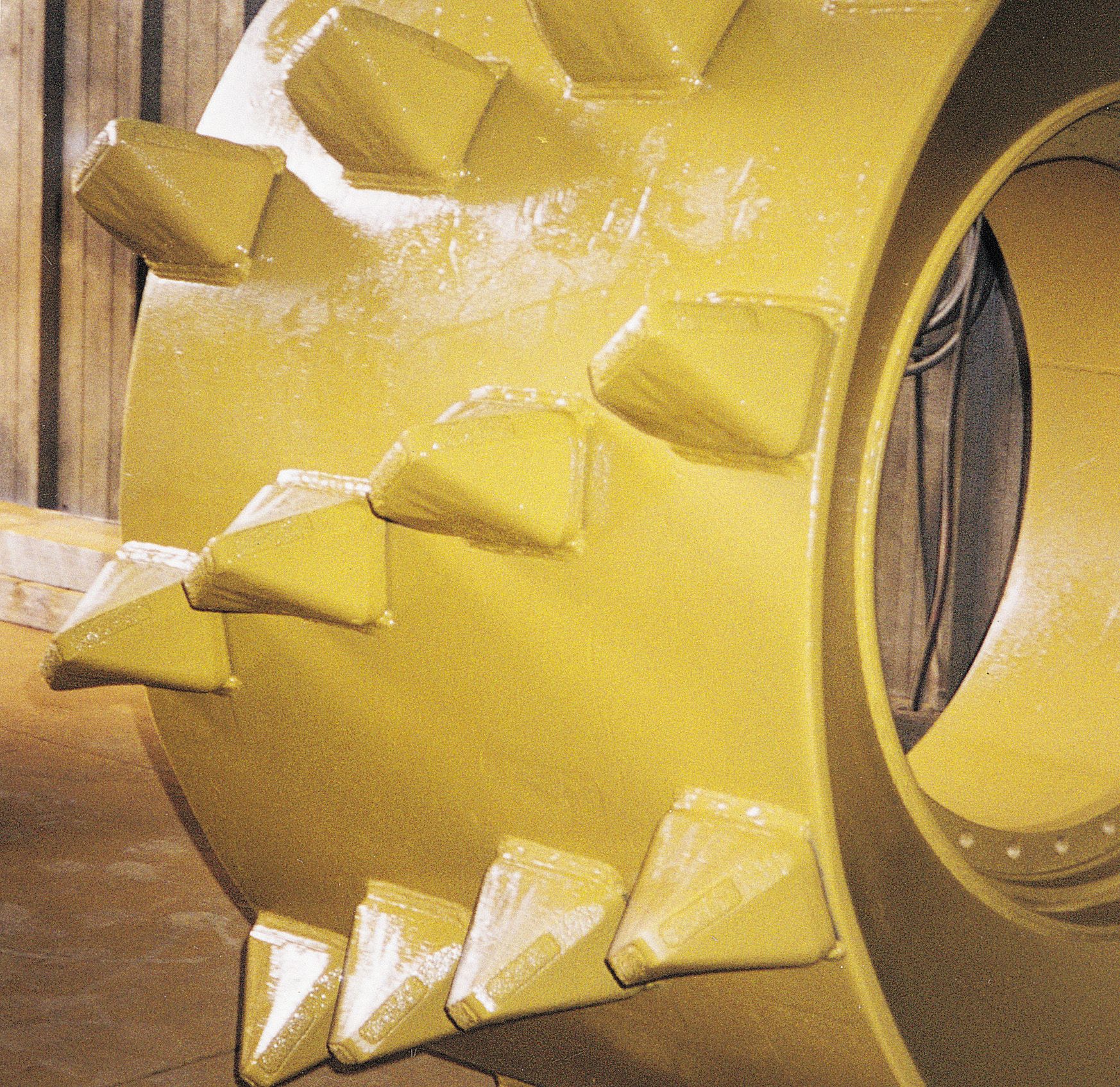

Tips and Wheels

Cost-Effective

Extending the life of your current site through increased compaction can be a cost-effective alternative to new site development.

Weld-on Plus Tips with Abrasion Resistant Material

Exclusive Plus-shaped design provides superior compaction densities.

Self-cleaning Chopper Wheels

Self-cleaning Chopper Wheels are designed to deliver maximum compaction and traction in landfill work.

Weld-on Tips

Weld-on traction tips are designed for those landfill applications where maximum traction is required. These tips perform best in frozen or other difficult to penetrate applications.

Landfill Features

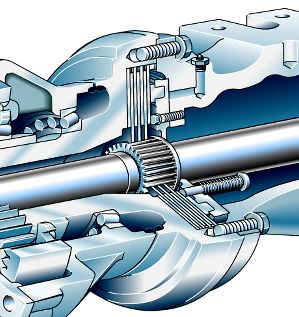

Cat Anti-Wrap Axle Guard System (optional)

Protects final drives, planetaries and seals from damage caused by wire, cable, plastics or other materials.

Anti-Wrap Axle Components

The Anti-Wrap Axle Guard System is comprised of three basic components.

Guards

A cab bottom guard protects hoses and wires beneath the cab from damage due to flying debris and waste.

Straight Blade

The straight blade is ideal for most waste management applications. The straight blade is built to withstand the rigors of heavy-duty dozing and is a versatile blade for most applications.

Power Train Components

Engine

The six-cylinder, turbocharged and aftercooled 3406C engine is one of the most developed and proven engines offered by Caterpillar.

Transmission

The Caterpillar planetary, power shift transmission features heavy-duty components to handle the toughest jobs.

Axles

Heavy-duty axles feature stronger gears and bearings in both the differentials and final drives for increased durability.

Brakes

Oil-enclosed, multiple-disc brakes feature fewer parts, better heat rejection and improved serviceability.

Hydraulics

Hydraulic System

A revolutionary hydraulic system provides low-effort implement control. Armrest-mounted levers send electrical signals to a pilot valve mounted on the front frame.

Command Control Steering

Low-effort, Command Control steering is another result of innovative design. A new mechanical feedback system and redesigned valve ratio provide quarter-turn side-to-side steering.

Load Sensing Steering

Load Sensing steering maximizes machine performance by directing power to steering system only when the operator steers the machine.

Hydraulic Pumps

Positive-displacement hydraulic pumps perform with high efficiency and great reliability. For improved serviceability, all hydraulic pumps are mounted on a single pump drive.

Caterpillar's XT-3 and XT-5 Hose

Caterpillar's XT-3 and XT-5 hose, O-ring face seals and large capacity lift cylinder top off the hydraulic system, delivering the performance and durability owners expect.

Operator Controls

Operator Control Benefits

One of the most exciting benefits of the 826G is the dramatic reduction in operator motion effort provided by Command Control steering, integrated transmission controls and fully hydraulic brakes.

Command Control Steering

Command Control steering allows one hand operation of steering and transmission controls.

Implement Control Lever

Low-effort implement control lever requires very low operator effort and reduced travel.

Integrated Transmission Controls

Integrated transmission controls are part of the steering control design, providing one hand operation.

Dual-Pedal Braking

Dual-pedal braking lets the left pedal function as a brake. The right pedal functions as a regular brake.

Operator Control Options

Operator Station

Setting Industry Standards

The 826G sets a new industry standard for operator station comfort and efficiency. It offers easier entry and exit, 65 percent more volume, improved visibility and reduced sound levels.

Internal ROPS

Internal ROPS improves visibility and styling, giving the 824G a sleek new look.

Windows

Larger windows improve visibility in all directions.

Downsloped Hood

Downsloped hood also contribute to improved rearward visibility by allowing the operator to see objects on the ground closer to the machine.

Radio Ready

Radio ready means this cab includes 12-volt converter, speakers, antenna, all wiring and brackets for entertainment or communications radio installation.

Right and Left Rear-Hinged Doors

Right and left rear-hinged doors provide a walk-through operator's station.

Non-Metallic Floor

Non-metallic floor is rustproof and slopes to assist water drainage and clean-out.

Sound Level

Reduced sound level is the result of several new designs.

Storage

Increased storage space provides room for a lunch cooler, a thermos, a cup, coat hook and other personal items.

Seat

Caterpillar Contour Series seat is 6-way adjustable, providing comfort and support.

Monitoring System

826G Monitoring System provides gauges, tachometer/speedometer and 3-level warning to provide full-time monitoring of key functions.

Ventilation

Improved ventilation ducts and vents, in better locations, provide more air flow to the operator and the windows. Post-mounted vents provide air to the rear window.

Air-Conditioning

Standard air-conditioning uses blended air for immediate temperature changes, clears windows with ease and improves operator comfort.

Reversing Fan Selection Switch

Reversing fan selection switch allows operator to reverse the radiator fan if conditions necessitate reversals more frequently than the automatically timed reversals.

Operator Station Options

Customer Support

Service

Your Cat dealer offers a wide range of services that can be set up under a customer support agreement when you purchase your equipment.

Selection

Make detailed comparisons of the machines you are considering before you buy.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs.

Operation

Improving operating techniques can boost your profits.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time.

Serviceability

Daily Maintenance

Daily maintenance has never been more accessible than on the 826G. Lockable, ground level service doors give quick access to engine oil fill and dipstick, coolant sight gauge, grease fittings for the rear frame, relay panel and electrical breakers.

Sloped Hood

Sloped hood tilts for complete access to the engine, cooling system and other major components. An electric screwjack tilts the hood up to 75 degrees.

Scheduled Maintenance Points

Scheduled maintenance points are well within reach. An air filter service indicator is visible from the cab or platform, with the air filter reachable from the left platform and the engine oil filter form the rear platform.

Separated Cooling System

Separated cooling system isolates the fan and radiator away from the engine for a quieter running machine.

Monitoring System

826G Monitoring System provides diagnostics, allowing technicians to review a machine's operation and quickly troubleshoot problems.

Operator Station

Operator's station may be removed or replaced in about 45 minutes without having to disconnect hydraulic lines.

Data not available.