740 EjectorNon-Current

740 Ejector - 2008 - GlobalOverview

Cat 740 Ejector with 42 ton rated payload offers proven reliability and durability, high productivity, superior operator comfort and lower operating costs.Spacious two-person cab with forward facing trainer/passenger seat and off road oil/nitrogen front suspension cylinders keep the operator comfortable through out the working day.True "on-the-go" differential locks with simple operation improve cycle times and productivity.Strong, durable Cat ACERT engines and electronically controlled transmissions deliver high productivity with low fuel consumption.

Specifications

| Engine Model | Cat® C15 ACERT™ |

| Gross Power - SAE J1995 | — |

| Net Power - SAE J1349 | — |

Benefits & Features

Specifications

| Engine Model | Cat® C15 ACERT™ |

| Gross Power - SAE J1995 | — |

| Net Power - SAE J1349 | — |

| Net Power - ISO 9249 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Rated Payload | — |

| Heaped (SAE 2:1) | — |

| Struck | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Forward - 4 | — |

| Forward - 5 | — |

| Forward - 6 | — |

| Forward - 7 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Interior Cab | — |

| Front Axle - Empty | — |

| Center Axle - Empty | — |

| Rear Axle - Empty | — |

| Total - Empty | — |

| Front Axle - Rated Load | — |

| Center Axle - Rated Load | — |

| Rear Axle - Rated Load | — |

| Total - Rated Load | — |

| Front Axle - Loaded | — |

| Center Axle - Loaded | — |

| Rear Axle - Loaded | — |

| Total - Loaded | — |

| Front | — |

| Side | — |

| Base | — |

| Fuel Tank | — |

| Cooling System | — |

| Hydraulic System | — |

| Engine Crankcase | — |

| Transmission | — |

| Final Drives/Differential | — |

| Output Transfer Gear Box | — |

| Eject Time | — |

| Retract Time | — |

| Brakes | ISO 3450 – 1996 |

| Cab - FOPS | ISO 3449 Level II – 2005 |

| Cab - ROPS | ISO 3471 – 2008 |

| Steering | ISO 5010 – 2007 |

Benefits & Features

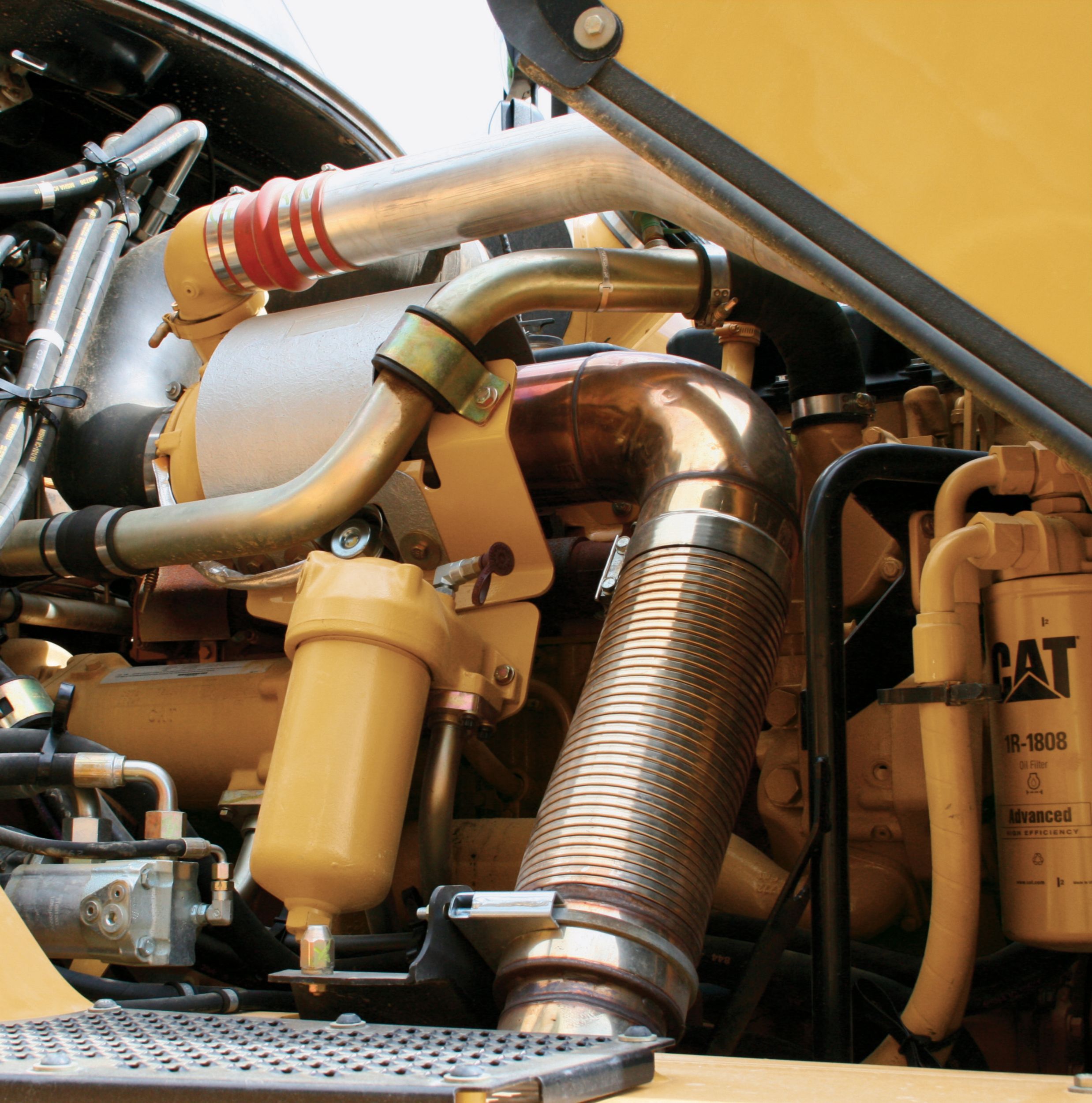

Engine with ACERT™ Technology

ACERT Technology

The Cat C15 ACERT engine introduces a series of evolutionary, incremental improvements that provide breakthrough engine technology built on systems and components developed by Caterpillar with proven reliability.

Advanced Diesel Engine Management (ADEM) A4 Engine Controller

The ADEM A4 electronic control module manages fuel delivery and provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs.

Fuel Delivery

Multiple injection fuel delivery involves a high degree of precision. Precisely shaping the combustion cycle lowers combustion chamber temperatures, generating fewer emissions and optimizing fuel combustion. This translates into more work output for your fuel cost.

Noise Reduction Technologies

Noise reduction has been achieved through design changes to the isolated top cover, oil pan, multiple injection strategy, insulated timing case cover, sculpted crankcase and gear train refinements.

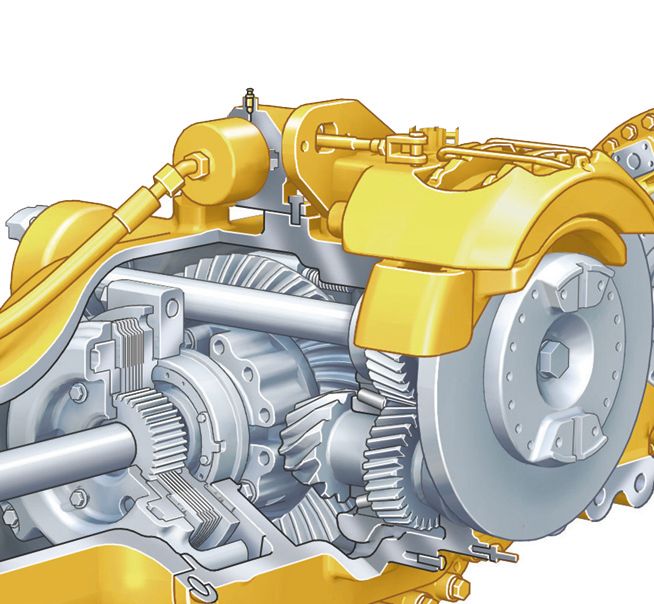

Transmission

Electronic Transmission

The Caterpillar seven-speed electronically controlled transmission features anti-hunt shift strategy for speed continuity, and Individual Clutch Modulation (ICM) to ensure constant shift times.

Controlled Throttle Shifting (CTS)

Significantly reduces power train stress and clutch wear by controlling engine speed, torque converter lock-up and transmission clutch engagements.

Two Reverse Gears

The transmission arrangement provides a second reverse gear for improved performance when operating in longer rear hauling applications.

Suspension and Traction Control

Front Suspension

The three-point front suspension oscillate ±6°to provide a smooth ride, allowing the operator to travel at speed over rough terrain and softening impact loads on structures and components. Large bore, low pressure cylinders are purpose designed for tough applications and offer a soft, smooth ride.

Enclosed, Oil-Cooled Brakes

Multi-plate, oil-immersed, oil-cooled brakes are fitted to both front and center axles. These brakes provide outstanding stopping capability, while maintaining maximum durability and low wear characteristics.

Rear Suspension

Features a walking beam geometry with Caterpillar designed rear suspension mounts which provide a reliable and stable ride for excellent load retention.

Traction Control

The traction control system is comprised of a wet clutched inter-axle differential and wet clutched cross-axle differentials. All differentials can be engaged and disengaged "on-the-go" for maximum versatility. When used together, the differentials provide 100 percent driveline locking.

Inter-Axle Differential Lock

Locks all three axles in unison and modifies torque distribution for excellent traction in poor underfoot conditions and on grades. It is operated by a switch located at the footrest.

Cross-Axle Differential Locks

Provides full driveline locking – all three axles and all six wheels – for maximum performance in the most adverse conditions. Acts in unison with the inter-axle differential lock when the footswitch is actuated and the dash-mounted switch is selected.

Operator Comfort

Ride Comfort

The three-point front suspension with its oscillating axle and low-pressure ride struts, combined with the center-mounted cab, offers unrivaled levels of ride comfort for the operator in all driving conditions. The operator remains comfortable and productive throughout the day.

Spacious Two-Person Cab

The 740 Ejector features a large two-person cab, offering comfortable working space for both the operator and trainer or trainee. All 700 Family articulated trucks use the same spacious cab design.

Air Suspension Seat

The air suspension seat enhances operator comfort with a cushioned upper high back, adjustable damping with three settings, ride zone indicator and adjustable lumbar settings. It is fully adjustable to provide the optimal driving position.

Trainer Seat

Full-size trainer seat features a fully padded seat with a backrest and a wide seatbelt for a secure and comfortable ride. The trainer seat is positioned next to the operator seat, giving both the operator and trainer a clear view of the instrument panel, controls and the road.

Steering Column

A comfortable driving position is provided by a telescopic and tilt steering column.

Ease of Operation

Ergonomic Layout

The controls and layout of the cab are designed to make it as easy to operate as your car. Quick, easy to read and simple to operate, the controls and gauges allow the operator to concentrate on production.

Dash

The Generation II wrap-around dash puts all controls within easy reach of the operator. Featuring LED illuminated rocker switches, large LCD display and a rear wash wipe rocker switch. It provides an automotive feel with the industrial strength you would expect from Caterpillar.

Viewing Area

The low sloping hood and placement of the cooling package behind the cab give the operator excellent all-around visibility. The large glass area and central operator position also provide excellent visibility.

Wipers

The wet arm wiper system cleans more glass area and is bottom-mounted to keep it out of the operator's line of sight. Windows are tinted to reduce glare.

Differential Lock Controls

The inter-axle differential lock is engaged/disengaged "on-the go" by using a raised switch incorporated into the drivers foot rest, for ease of operation. For 100% lock up, all three cross-axle differential locks act in unison with the inter-axle differential lock when the foot switch is activated and a dash mounted switch is selected. Disengaging the foot switch opens all differential locks immediately.

Transmission and Ejector Levers

Finger tip controls allow easy operation and low effort. The ejector and transmission levers are positioned for easy, comfortable operation, along with the control for top gear limit, transmission hold and neutral lock.

Blade Retraction Sequence

The ejector blade returns to the loading position as soon as the blade retract sequence is initiated. The transmission is held in the gear selected for the ejecting cycle until this sequence is completed and the ejector control lever is returned to the float position.

Suspended Pedals

Easy to operate and reach with plenty of leg and foot room. They also make for easier cleaning of the cab floor by keeping the pedals out of the dirt.

Durability and Reliability

Front Frame

The front frame design features a large box section and wide, stiff frame beams to handle torque loads. The divergent frame design decreases stress in the hitch area and optimizes suspension geometry. The frame design makes maximum use of robotic welding for increased durability.

Rear Frame

Twin-box construction minimizes stress concentrations and provides low weight with long life.

Suspension

The three-point oscillating axle front suspension provides unparalleled ride quality. It also protects the truck from adverse road conditions by absorbing shock loads that would reach the frame.

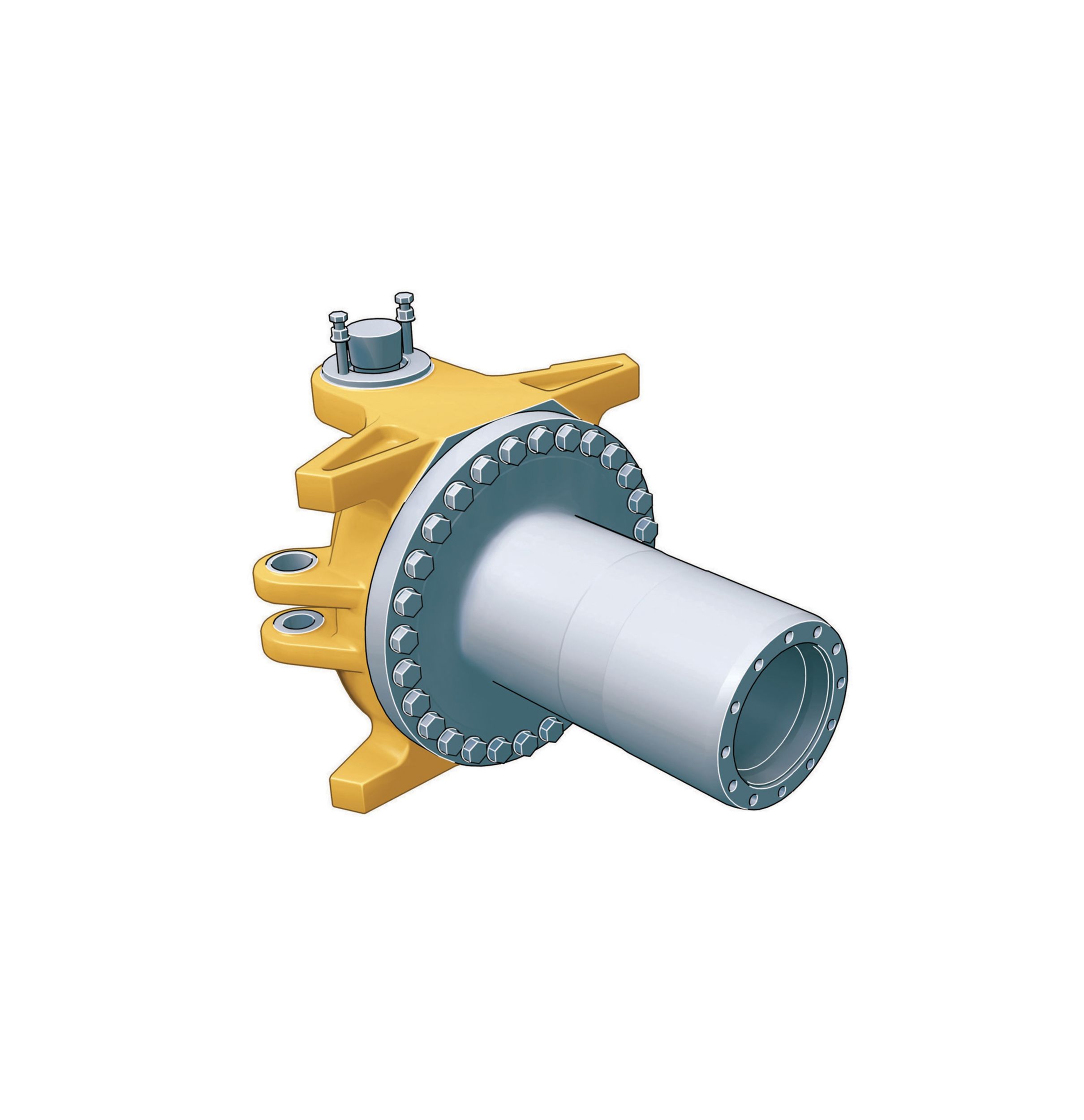

Articulating/Oscillating Hitch

The articulating hitch provides the truck with steering articulation, and the oscillation ensures all-wheel ground contact in rough terrain.

Hitch Construction

Two-piece construction features a durable cast steel head bolted to a hard-wearing forged steel tube.

Service Brakes

Oil-cooled, multiple disc brakes are continuously cooled for exceptional non-fading braking. They are designed and built for reliable, adjustment-free operation.

Parking Brake

Located on the center axle in an elevated position and designed to deliver higher heat capacity and abuse resistance.

Ejector Body

Ejector

The ejector body offers clean load ejection on-the-go and the capability to work in areas with restricted overhead clearance and soft underfoot conditions.

Versatility

The 740 Ejector shares the versatility of the Standard 740 Articulated Truck, operating in the same conditions, but offering unique capabilities that stretch the operation envelope.

Spreading

The truck can eject and spread the material while moving, reducing additional spreading and dozing equipment. "On-the go" ejecting results in faster cycle times and reduced power train loads.

Stability

Ejecting the load without raising the body increases stability, allowing load dispersal on inclines, side slopes and in very soft underfoot conditions especially on landfill sites.

Overhead Clearance

The truck can eject in areas with reduced overhead clearance, such as around overhead lines or in tunneling and underground operations.

Carry-Back

The body design eliminates material sticking to the body, which increases productivity, improves fuel efficiency and lowers cost per ton.

Body

Reinforced body is made from thick high-yield, heat-treated Brinell hardened steel (Brinell 400 on the base and sides) that provides exceptional durability. Ejector top rails are made from high-strength alloy steel. For optimum durability and wear life, the ejector body is designed to work in applications where the material consists of rocks smaller than 152 mm (6 in.) in diameter.

Blade

The ejector blade is made from high-strength steel and uses technology similar to that proven in Cat wheel tractor-scrapers.

Cylinder

A four-stage, high-speed, double-acting cylinder is specifically designed for horizontal mounting and smooth load ejection.

Product Link

Equipment Manager - a better way to manage your fleet

- Equipment Manager allows transmitted data to be searched and sorted by alert level, group, equipment identification, make and model. Each new machine comes with Asset Watch. However, you can subscribe to a higher level of service for any machine, at any time, through your Cat dealer. Depending on your information needs, Equipment Manager will:

- Report current equipment parameters (machine hours, location, fuel consumption, etc)

- Track all elements of machine maintenance and keep history

- Predict when a service is needed

- Facilitate maintenance scheduling and parts ordering

- Alert you to potential and immediate issues

Asset Watch

Asset Watch manages your assets – enabling you to find your machine quickly, and to control its movement and work schedule.

Maintenance Watch

Maintenance Watch includes all the features of Asset Watch and will also help you plan, coordinate and track your repairs and maintenance, allowing you to align maintenance with machine usage.

Health Watch

Health Watch includes all the features of Asset Watch and will track machine operational conditions to help address potential issues before they become serious. You can also identify abuse, efficiency and training issues with individual operators.

Complete Customer Support

Selection

Make comparisons of the machines you are considering before you buy. Your Cat dealer can help.

Operation

For the best operating techniques to increase productivity and your profit, turn to your Cat dealer for the latest training literature and trained staff.

Maintenance

Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair or rebuild? Cat articulated trucks are designed for longer life with rebuildable components. Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

Your local Cat dealership will be with you every step of the way with its unsurpassed worldwide parts support, trained technicians and customer support agreements.

cat.com

For more complete information on Cat products, dealer services and industry solutions, visit us on the Web at www.cat.com.

Safety

Product Safety

Caterpillar has been and continues to be proactive in developing machines that meet or exceed safety standards. Safety is an integral part of all machines and system designs.

Safety Features

- Cab integral ROPS (Roll Over Protection System) and FOPS (Falling Object Protection System)

- Rear view camera system provides a continuous panoramic rear view or when reverse gear is selected

- The secondary and parking brake functions are spring applied and hydraulic released

- Electro-hydraulic secondary steering system, automatically activates in forward/reverse or when stationary if low pressure is sensed. Can be manually selected for machine recovery purposes

- External engine fuel cut off switch for easy access from outside of the machine

- External electrical system disconnect switch for easy access from outside of the machine

- Slip resistant surfaces – punched steel plate

- 75 mm (3 in) wide seat belts for operator/trainer and passenger

- Wide angled mirrors for excellent rear visibility

- Sweeping hood design for panoramic forward visibility

- Extensive hand rails

- Ejector blade active alarm

- Heated mirrors (optional)

- Xenon flashing beacon (optional)

Serviceability

Long Service Intervals

Long engine oil change and hydraulic oil change intervals lower maintenance costs and downtime. Wheel bearing adjustment is completely eliminated.

Lube Points

Lube points are grouped at the rear of the front frame and the front of the rear frame. Universal joints are lubed for life, eliminating servicing. Autolube is optional.

Service Points

Engine and transmission dipstick and fill caps, air and fuel filters and the fuel-priming pump are all mounted on the left side of the engine under the electrically raised hood. Coolant level indicator and fill cap are outside the cab.

Radiator

The radiator package is located behind the cab, which provides protection from frontal impacts and offers easy access to both inlet and outlet sides of the radiator. The ATAAC radiator is located at the front of the truck.

Extended Life Coolant

Extends the change interval and improves component life by reducing aluminum corrosion.

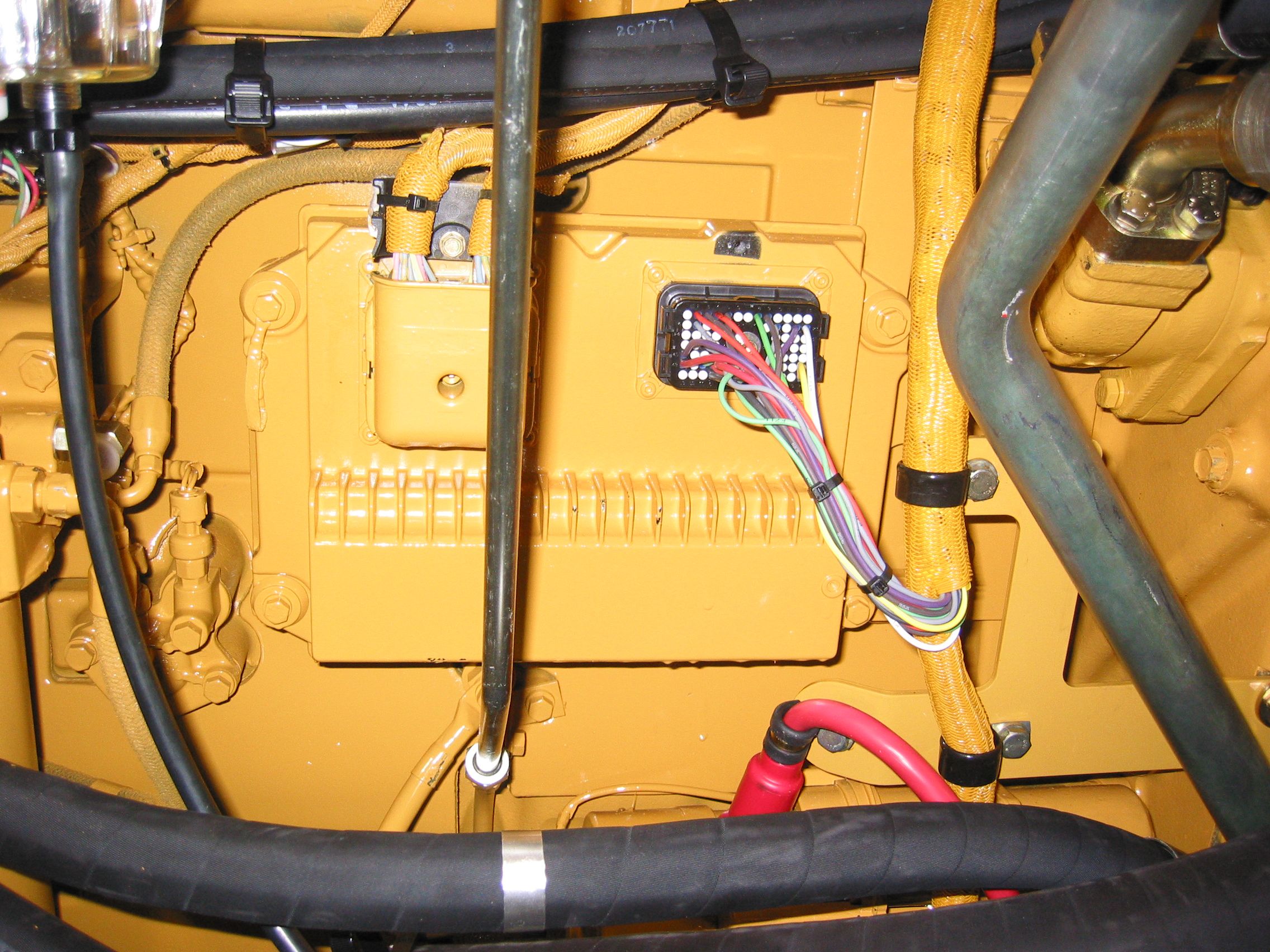

Electrical Service Center

Located inside the cab, this service center provides a power port, diagnostic connector and Cat Data Link connector.

Cat Data Link Connector

The Cat Data Link connector provides a plug-in using a laptop computer with Electronic Technician (ET) software.

Service Access

The cab tilts to the side to provide easy access underneath, which simplifies servicing of the transmission, drive shafts and hydraulic pumps. Machine electrical and hydraulic interfaces are located on the right side of the cab, behind a removable cab body panel for easy access.

Truck Transport

The suspension system eliminates the need to lower the suspension when transporting the truck, reducing maintenance and downtime.

Output Transfer Gear

Provides lubrication of all bearings and clutches using a distributed-pressure lubricated and filtered system.

Data not available.

Standard Equipment

- ROPS/FOPS cab, with full instrumentation, including:

- - Instrument cluster display module

- - Indicator lamps: left turn, secondary steering, primary steering loss, front and rear brake temp (735/740 and 740 Ejector only), brake oil pressure, action lamp, transmission fault, park brake, charging system status, differential lock, body not in float, right turn, high beam, transmission hold, machine filter warning, retarder, retarder up shift warning

- - Gauges: engine oil pressure, engine coolant temperature, torque converter oil temperature, fuel level, and fuel tank level gauge

- - Meters: service hour meter, speedometer, tachometer