Overview

The Cat 420D IT takes the integrated toolcarrier to a new level with pilot operated joystick controls. Operator comfort is enhanced which contributes to less operator fatigue and increased productivity. With best-in-class bucket rotation, digging forces and overall backhoe lift, the 420D IT is everything you expect from a Cat machine and more!

Benefits & Features

Specifications

Benefits & Features

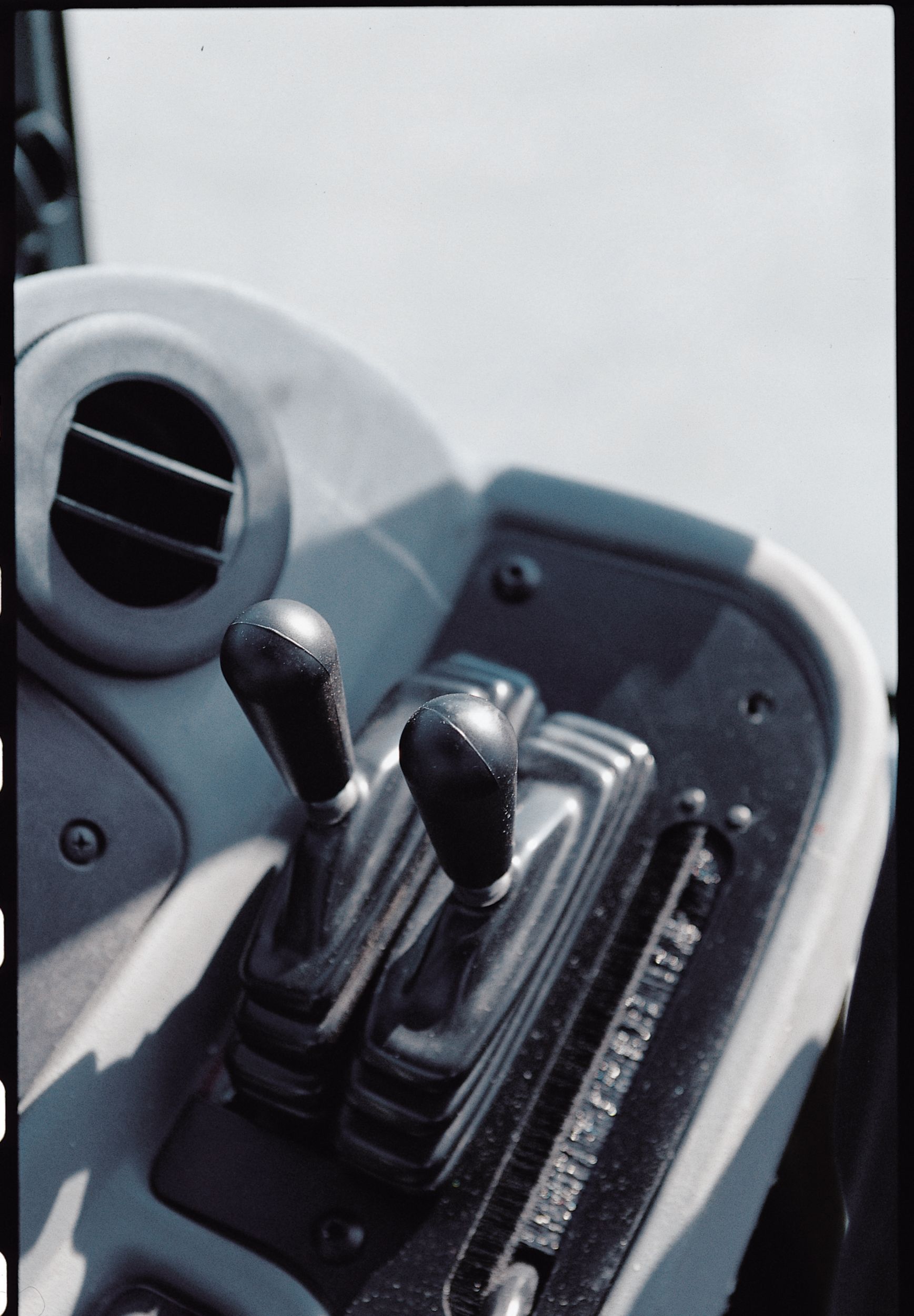

Pilot Operated Joystick Controls

Joystick Controls

Standard excavator-style, joysticks provide smooth modulation and are ergonomically designed for low effort control and operator comfort. As a result of this control design, legroom is increased and the rearward viewing area is greater.

Pattern Changer Valve

The hydraulic excavator control pattern is standard. An optional pattern changer makes switching between backhoe and excavator control patterns as easy as loosening and moving a bolt on the side of the machine.

Pilot Operated Stabilizer Controls

These provide low effort and fine modulation control. The stabilizer controls are within easy reach of the operator's side when operating the backhoe.

Pilot Control Pods

Located on the left and right sides, the controls can move fore and aft and three stops are available for ergonomically correct positioning.

Loader Performance

Loader Linkage

The standard single-tilt loader features increased lift and breakout forces. The optional integrated toolcarrier loader provides even higher forces, as well as parallel lift for efficient loading and material handling. A return-to-dig system makes operation easy and improves cycle times.

Quick Coupler

Provides versatility and allows quick connection to selected work tools for the Cat family of integrated toolcarriers. Most work tools can be changed in less than 30 seconds, from the comfort of the operator station.

Disconnects

New flat face, hydraulic hose quick disconnect fittings with a connect-under-pressure feature improve the connection of hydraulic work tools.

IT Loader Controls

The 420D IT has a standard single lever, pilot-operated loader control for proportional control and fine modulation of the hydraulic work tools. A thumb control on top operates auxiliary hydraulic functions such as the clam bucket and two buttons control hydraulic broom angle.

Reverse Signal System

Pump control changes improve power management between the loader hydraulic system and machine rimpull for faster truck loading. The new reverse signal system provides priority to backhoe hydraulics to maximize hydraulic horsepower.

Backhoe Performance

High Rotation Backhoe Linkage

Single pin bucket linkage contributes to best-in-class rotation of 205 degrees for all applications, eliminating the need to change pin position when moving from loading trucks to vertical wall trenching.

Backhoe Boom

The excavator-style boom features box section fabrication with internal stiffeners for better balance and weight distribution. The curved design provides additional clearance over obstacles while digging a trench or truck loading. The narrow boom enhances the viewing area to the bucket and trench throughout the entire operating range.

Dig Forces

The 420D IT boom, stick and bucket dig forces increased ten percent over the 416C.

Extendible Stick

This optional backhoe attachment replaces the standard stick and increases reach and dig depth by approximately 1.2 meters (4 feet). The extendible stick uses eight self-lubricated, non-metallic wear pads which can be shimmed or replaced. Improved wear pad materials increase wear life in all conditions.

Buckets and Couplers

Bucket Line

Expansion of the bucket line includes rock and coral bucket designs. All D-Series buckets are painted black and carry the Cat logo.

Bucket Improvements

D-Series buckets have an excavator profile with improved fill characteristics. The scalloped bucket sides also provide improved material clamping.

Diagonal Retention System

Bucket teeth are attached with diagonal pins rather than horizontal pins for easy exchange of bucket teeth. The adapters are stronger as a result of this diagonal pinning and additional wear material on the bucket teeth increases durability.

Quick Couplers

Allow for quick attachment of buckets and other work tools. The D-Series High Rotation pin grabber design and a C-Series compatible pin grabber allow buckets to be changed without removing the bucket pins. Other manufacturers' buckets can be coupled with a pin puller coupler, one for Case and D-Series buckets or one for John Deere and D-Series buckets. D-Series quick couplers are painted black for easy identification.

Lift Eye

An integral lifting eye is a standard feature of the bucket linkage.

Work Tools

420D IT Work Tools

Caterpillar Work Tools for backhoe loaders extend the versatility of the machine. Built for performance and durability, these tools deliver high productivity, long service life and excellent value:Backhoe Work Tools· Standard Duty Bucket· Heavy Duty Bucket· Heavy Duty Rock Bucket· High Capacity Bucket· Coral Bucket· Ditch Cleaning Bucket· Hydraulic Hammer· Vibratory Plate Compactor· RipperLoader Work Tools· General Purpose Bucket· Multi Purpose Bucket· Side Dump Bucket· Light Material Bucket· Penetration Bucket· Loader Forks· Material Handling Arm· Angle Blade· Broom· Rake· Asphalt Cutter· Bale Spear

Operator Station

Operator Comfort

The 420D operator station incorporates years of cab design innovations to maximize operator productivity. The pilot operated controls allow for more legroom and a spacious work environment.

Open Canopy

Includes air suspension vinyl seat, tilt steering wheel, 12-volt power supply, phone clip, left side storage space with a lockable compartment, drink holders and floor mats.

Standard Cab

Features an air suspension fabric seat, tilt steering wheel, 12-volt power adapter, left-side storage console with drink holders and a lockable compartment, phone clip, two doors and rear windows with opening glass and eight working lights. The cab is radio-ready.

Deluxe Cab

Includes all standard cab benefits plus a deluxe, nine-way adjustable air suspension seat; pilot operated stabilizer controls with individual auto-up feature; additional system monitoring including a voltmeter and service indicators for fuel water separator, engine air cleaner and hydraulic filters.

HVAC System

The heating, ventilation and air conditioning system main components are located near the floor and significant improvements have been made to air circulation and increased defrost capabilities.

Tilt Wheel

The standard tilt steering wheel on every 420D allows more room when entering and exiting the cab and allows the operator to choose the most comfortable steering position.

Air Suspension Seat

Utilizes an air adjustment mechanism for a greater operating range and more comfortable ride. By pressing a button, the seat can be tailored to support differing body weights. Adjustable seat height accomodates all operators. The Deluxe cab seat also has an adjustable back support, lumbar support, seat cushion extension, seat cushion tilt, as well as vertical and angle adjusting armrests.

Operator Controls

The controls of the 420D have been carefully laid out to create a user-friendly environment. Switches, boom lock and pilot operated stabilizer controls are located in the side console, within easy reach of the operator. New white-faced gauges are easy to read. The low effort pilot controls reduce operator fatigue and help boost overall productivity.

Ride Control System

Provides a smoother ride in all applications, reduces machine loping while roading and provides better material retention during load and carry operations while increasing operator comfort. A nitrogen accumulator added to the loader lift circuit cushions the system and engages with the flip of a switch.

Rear Window

The redesigned rear window features a heavier hinge structure and positive latch mechanism to hold the window in the open position.

Power Train

3054T Diesel Engine

Turbocharged, with a gear driven water pump, the Cat 3054T delivers reliable power with low emissions, while providing excellent fuel economy with a new fuel system and traditional Caterpillar durability.

Direct Injection Fuel System

Individual unit fuel injectors deliver efficient and accurate fuel metering, reduced emissions, reliable power, high torque rise and responsive performance.

Air Cleaner

Dry-type, radial seal, two-stage filter incorporates air cleaner and precleaner functions into a single unit.

Starting Aid

Standard thermal starting aid system for efficient cold weather starting down to -28° C (-20° F).

Transmission

The Caterpillar Power Shuttle transmission provides four speeds forward and reverse. Full synchromesh gears and hydraulically shifted forward and reverse shuttle clutches allow direction and travel speed to be changed on-the-go. A neutral start provision prevents starting while the shuttle is engaged.

Automatic Shift Transmission

The optional Auto-Shift transmission automatically matches gears with grade and load conditions. Manual mode gives full gear selection to the operator for operation as a Power Shift transmission.

Kick-down Switch/Transmission Neutralizer

Located on the loader lever, the kick-down switch on Auto-Shift machines allows the operator to downshift through the gears to first. When this switch is depressed for more than one second, it serves as the transmission neutralizer to maintain engine and hydraulic speed when dumping into trucks.

Transmission Neutralizer

Standard on Power Shuttle machines, the hand-operated power disconnect provides easy, on-the-go shifting and full engine rpm for faster cycle times.

Two Wheel Drive

Heavy-duty rear axle with self-adjusting inboard brakes, differential lock and final drives.

All Wheel Drive (AWD) Option

Heavy-duty front drive axle can be engaged at any time by activating the switch on the front console. The switch can be activated while the machine is stopped or moving, with or without load. AWD features outboard planetary gear final drives and improves mobility and loader performance in poor traction conditions.

Brake Mode Selector

The brake mode selector switch has three positions: two wheel drive, two wheel drive with all wheel braking and all wheel drive. Center position provides two wheel drive for better tire life while roading and engages the front axle when brakes are applied for improved braking performance.

Hydraulics

Hydraulic System

The load-sensing, variable flow hydraulic system senses work demand and adjusts flow and pressure to match. This allows full hydraulic forces at any engine speed for delicate jobs in tight areas.

Hydraulic Pump

Closed centered implement valves, with pressure compensation for reduced lever effort, signal hydraulic system requirements to a control valve located on the pump. This valve controls the pump to deliver the flow and pressure necessary to fulfill the implement demands.

Dual Setting Torque Limiter

The variable displacement pump provides better performance in both backhoe and loader operations through a dual setting torque limiter. It automatically optimizes power to the hydraulic system during backhoe operations and manages the power balance between the loader hydraulic circuit and the drive train during front loader operations.

XT Hoses

Made of four overlapping, insulated wire spiral wraps bonded together for durability, XT-3 hoses exceed SAE certification standards. The hose routing protects them from work damage, and hose failure downtime is substantially reduced. XT-3 hoses combined with Caterpillar couplings and O-ring face seal fittings provide a leak-free system.

Clamps and Bushings

Metal clamps with rubber busings are used at hose attachment points to eliminate metal-to-metal contact and increase wear life.

Customer Support

Machine Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers can estimate component life, preventative maintenance cost and the true cost of lost production.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. Look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Customer Support Agreements

Cat dealers offer a variety of product support agreements and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including work tools, to help protect the customer's investment.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers use a worldwide computer network to find in-stock parts to minimize machine downtime. Save money with genuine Cat Reman parts. You receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training videotapes, literature and other ideas to help you increase productivity.

Maintenance Services

Choose from your dealer's range of maintenance services when you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM and Coolant Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.

Standard Equipment

- Filters, spin-on

- fuel, engine oil, transmission oil, water separator, hydraulic fluid

- Gauges

- coolant temperature, fuel level, tachometer, hour meter, torque converter oil temperature

- Indicators

- air cleaner service, brake on, engine coolant, hydraulic oil level, sight gauge, oil pressure

- Joystick controls

- pilot operated, excavator-style (excavator pattern)

- Loader

- self-leveling, return-to-dig and transmission disconnect switch

Optional Equipment

- Attachments, front loader

- General-purpose buckets:

- Multi-purpose bucket:

- Forks:

- Carriage, fork

- Material-handling arm

- Attachments, backhoe

- Mechanical Quick Coupler:

- Axle, front:

- All-wheel drive

- Backhoe controls:

- Excavator pattern with pattern changer

- Counterweights:

- Base

- Stackable:

- Cutting edge, bolt-on:

- Two piece

- Guards:

- AWD driveshaft

- Stabilizer, rock

- Hydraulic valves, loader:

- 3rd valve for GP, MP or Quick Coupler

- Hydraulic valves, backhoe:

- Auxiliary valve (standard stick)

- Auxiliary valve (extendible stick)

- Hydraulic lines:

- Auxiliary, 2-way lines (to boom)

- Universal, 1-way lines (to stick)

- Rotating beacon

- Fixed mounted

- Magnetic mounted

- Stabilizers:

- Street pads, rubber (set of 4)

- Reversible pads

- Vandalism protection:

- Gauge cover

- Padlocks

- Hood lock