Overview

The TH210 Telehandler is a highly versatile, compact machine, designed to deliver maximum performance with traditional Cat reliability, durability and productivity in the toughest working conditions.

Specifications

| Rated Load Capacity | — |

| Maximum Lift Height | — |

| Engine Model | Cat® 3054B |

Benefits & Features

Specifications

| Engine Model | Cat® 3054B |

| Gross Power | — |

| Net Power | — |

| Maximum Torque | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Operating Weight | — |

| Rated Load Capacity | — |

| Maximum Lift Height | — |

| Maximum Forward Reach | — |

| Load at Maximum Reach - No Stabilizers | — |

| Top Travel Speed | — |

| Load at Maximum Height | — |

| Load at Maximum Reach | — |

| Height | — |

| Width | — |

| Wheel Base | — |

| Length - Fork Face | — |

| Ground Clearance | — |

| Turning Radius - Over Tires | — |

| Rear - Overhang | — |

| Length - Front of Tire | — |

| Height - Top of Hood | — |

| Standard | 10.5-20 MPT Goodyear |

| Maximum System Pressure | — |

| Maximum Pump Flow | — |

| Maximum Pressure | — |

| Auxiliary Hydraulic Supply (1) | — |

| Auxiliary Hydraulic Supply (2) | — |

| Pump Type | Gear |

| Maximum Auxiliary Pressure | — |

| Auxiliary Flow at Boom Head | — |

| Fuel Tank | — |

| Hydraulic Tank | — |

| Hydraulic System | — |

| Number of Speed Ranges - Forward/Reverse | 2 |

| Range 1 | — |

| Range 2 | — |

| Number of Power Modes | 2 |

| Boom Up | — |

| Boom Down | — |

| Tele In | — |

| Tele Out | — |

| Crowd Forward - Dump | — |

| Crowd Backward | — |

| Combined - Up and Out | — |

| Combined - Down and In | — |

| Foot Brake | Servo front axle |

| Parking Brake | Front axle |

Benefits & Features

Operator Efficiency

Enclosed Cab

The TH210 is equipped with an enclosed cab allowing the operator to work comfortably, with air conditioning available as an option. The cab structure has been designed and certified to provide falling object and rollover protection (FOPS/ROPS).

Seat

The standard suspension seat is adjustable to provide a comfortable ride and an air suspension seat is available as an option. The operator can adjust the angle and the height of the steering column for maximum comfort.

Control Layout

The cab layout has been ergonomically designed to make the operator's job as easy as possible. The controls are logical, highly responsive and easy to reach. The instrument panel is comprehensive and clear. The gauge cluster includes a tachometer, hour meter, fuel gauge and engine coolant temperature indicator to monitor the machine's systems.

Single Joystick

The joystick is located within easy reach of the operator. Diagonal movement of the joystick allows a combination of boom and tool functions to be achieved simultaneously. To raise or lower the boom, move the joystick backward or forward respectively. Move the joystick to the right to dump and the left to rack back. The colored buttons on the joystick control the boom and auxiliary hydraulic functions.

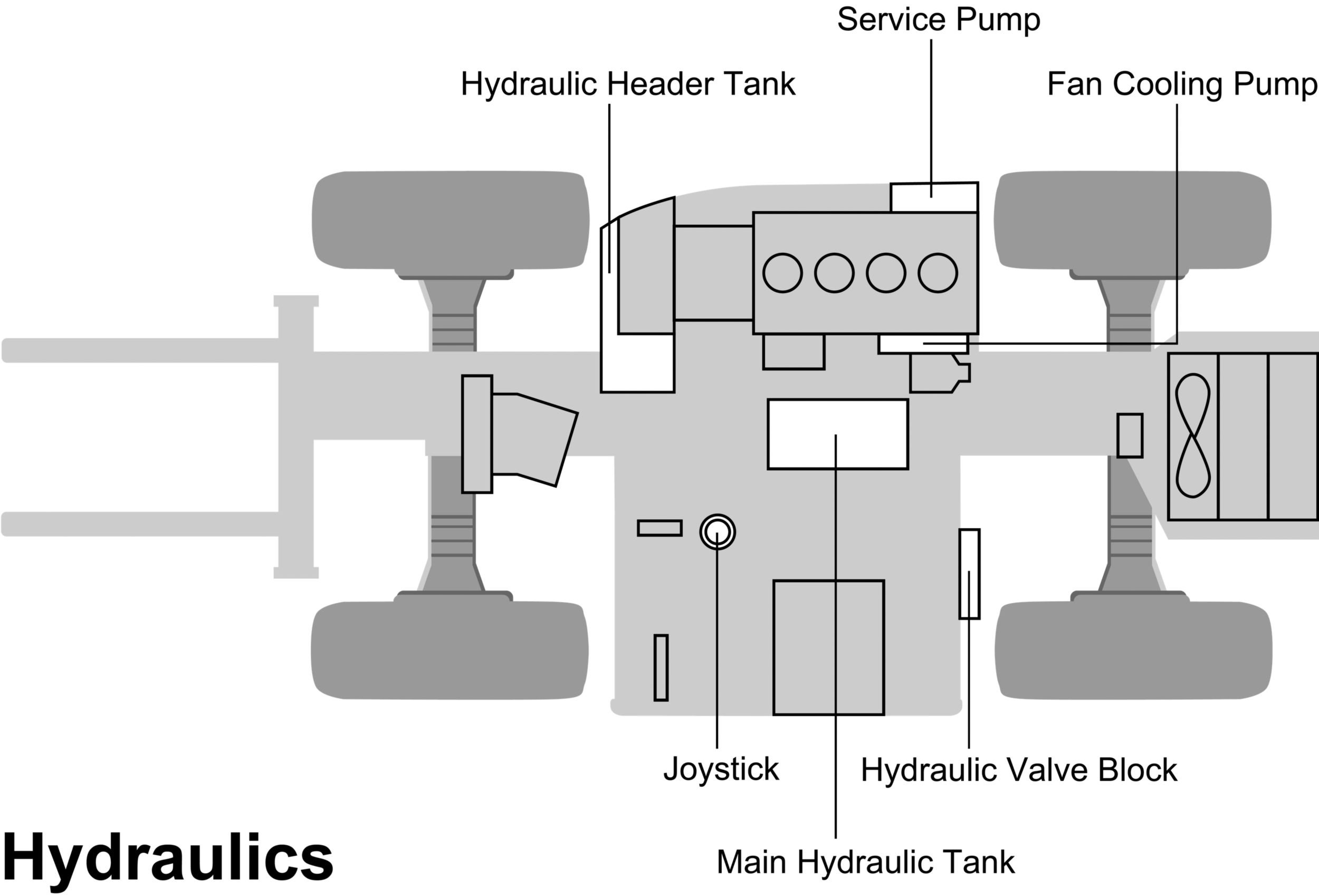

Hydraulics

A hydraulic header tank is located in the engine compartment for easy fill access. The hydrostatic circuit is supplied by the hystat gear pump, which provides 80 L/min (21 gal/min) of flow at the boom head.

Ease of Operation

Visibility

The machine's low profile design, side mounted engine, and low boom pivot point allow the operator to carry loads in a low position without obstructing visibility to the right of the machine. The mid-mounted cab also improves visibility to the rear. The front windshield is a rounded single sheet of glass stretching from just above the dashboard, over the operator's head for excellent visibility. The upper portion of the cab door is independently hinged so that it can be opened and secured for ventilation and ease of communication.

Maneuverability

The compact dimensions of the TH210 offer excellent maneuverability. With its low profile and 3 m (9 ft 10 in) outside turning radius, it can work productively in confined areas.

Steering Modes

Three steering modes (circle, two wheel and crab steer) allow the operator to easily position the machine in small, confined areas. Steering modes are selected by using the steering mode switch in the operator's compartment. An indicator light in the cab illuminates when the wheels are properly aligned.

Fenders

The fenders are mounted to the axle and turn with the wheels allowing the operator to easily determine the wheel orientation while protecting them from mud, rocks and water spray.

Performance and Power Train

Engine

The TH210 is powered by the well-proven Caterpillar 3054B-DI naturally aspirated diesel engine. The engine is U.S. EPA Tier II emissions compliant. It provides high fuel efficiency and excellent reliability, developing full torque at lower revolutions compared to other engines.

Power Mode

A power mode switch located on the right side of the operator console allows an operator to select between two different modes of operation - progressive and aggressive - to match application.

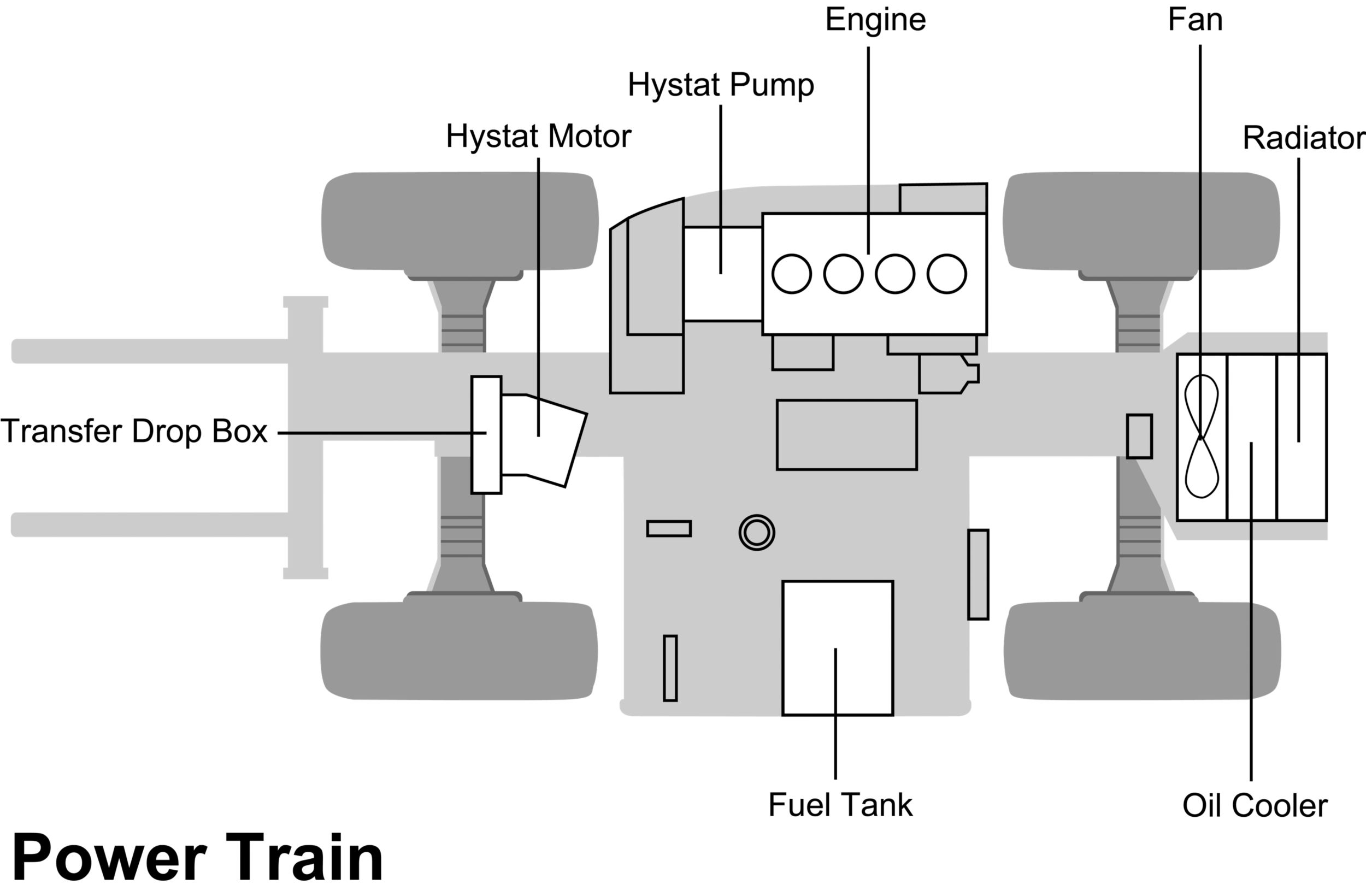

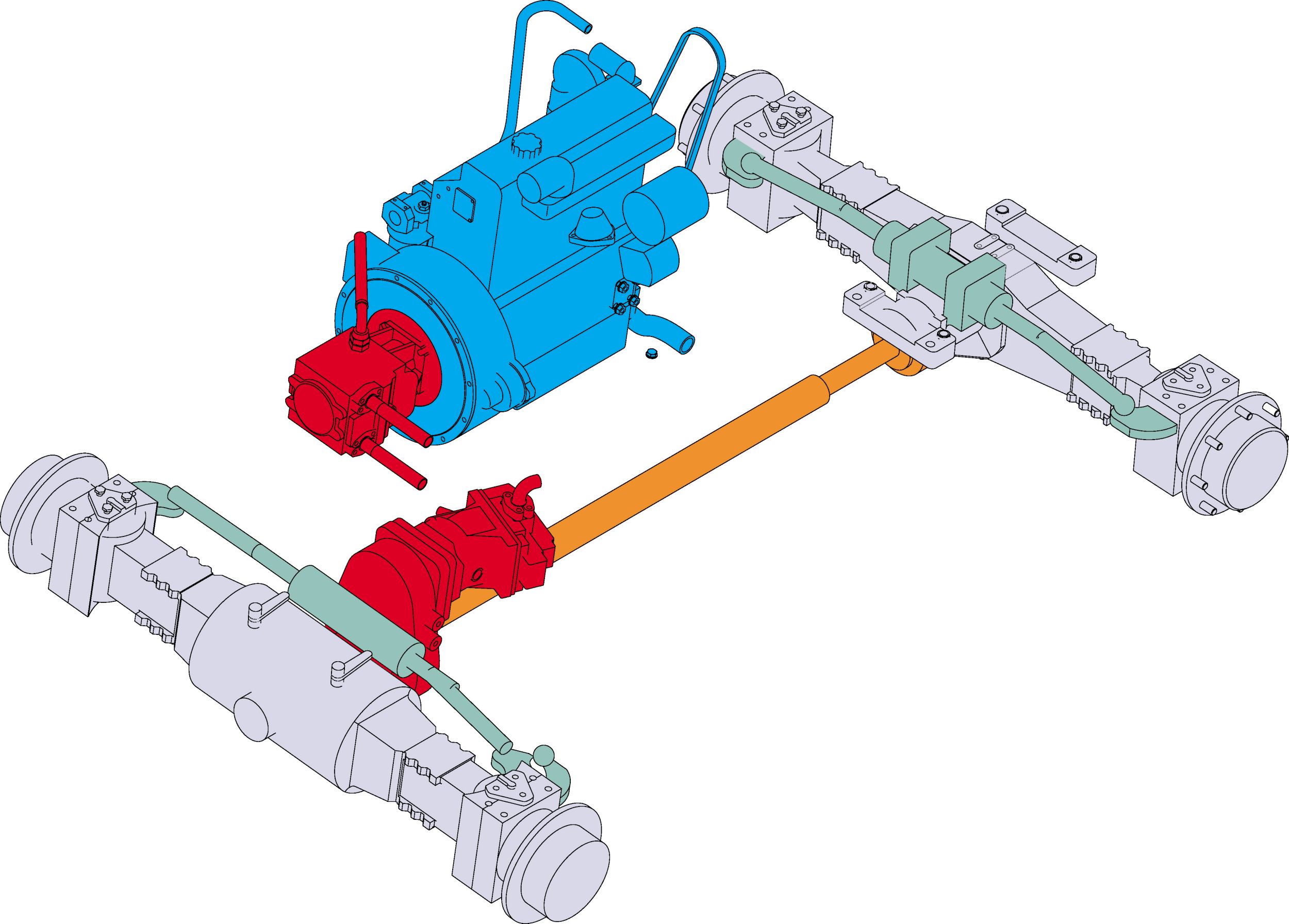

Hydrostatic Drive

The TH210 features a high pressure, closed circuit hydrostatic drive to deliver powerful but smooth acceleration while providing continuous torque through the two speed ranges. The low speed band is 8 km/h (5 mph) and the high speed band is 32 km/h (20 mph).

Hystat Pump

The hystat pump is an axial piston, variable displacement pump with a cradle swashplate design.

Axles

Both axles steer and utilize planetary reduction hubs. The rear axle is center trunnion mounted, allowing 5 degrees of total oscillation. The front axle is fixed.

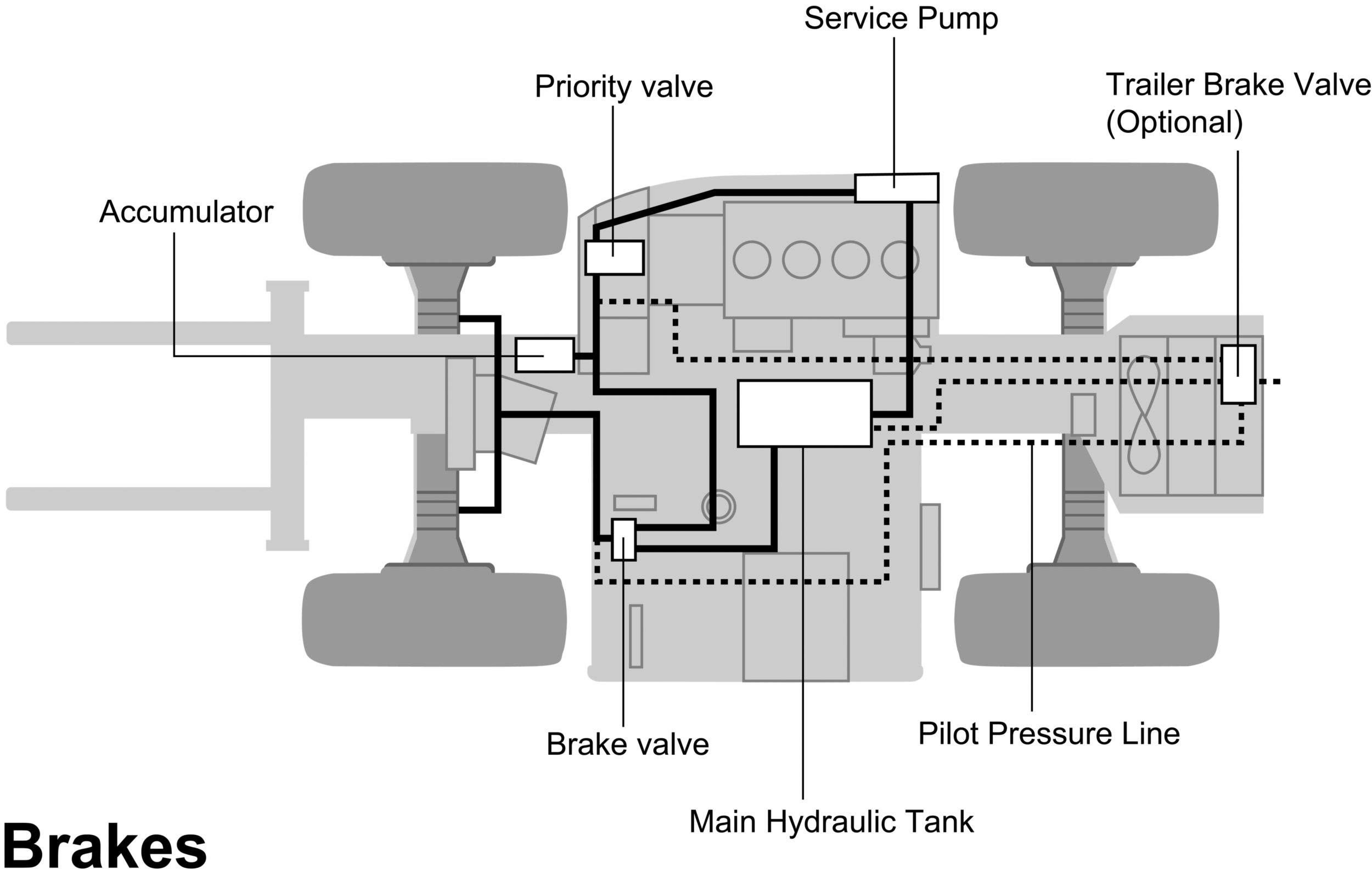

Brakes

The brake system is filled with hydraulic oil from the main hydraulic system. The parking brake is hand activated. The brake system has an accumulator that provides reserved brake pressure in the event of a hydraulic failure.

Tires

Versatility

Compact Size

The small size and maneuverability of these machines make them capable of providing a solution to a customer who may not have used a telehandler before or to those customers who need compact size combined with low cab height.

Applications

- The TH210 is a very versatile machine that can be used in a wide variety of applications. With the correct work tool for the job, the machine's size and capability can provide an advantage in many of the applications listed: GENERAL CONSTRUCTION

- Parking Deck Refurbishment

- Material Handling

- Site Maintenance and Clean-up

- Specialized Material Placement

- Material Loading/Unloading

- Landscaping

- Pallet Handling

- Snow Removal AGRICULTURE

- Manure Handling

- General Bucket Work

- Bulk Material Handling

- Feed Passage

- Alley Clean-Up

- Bale Handling/Stacking

- Poultry Farming

- Trailer Towing

- Truck Loading/Unloading INDUSTRIAL

- Material Rehandling

- Container Loading/Unloading

- Transfer Station Rehandling

- Material Loading/Unloading

- Recycling

- Waste Management

- Warehousing Activities

- Lumber Yard Work

Manual Coupler

The TH210 utilizes a manual quick coupler using the same interface as the Caterpillar Skid Steer Loader.

Work Tools

- Work tools greatly enhance the versatility of the TH210 and increase its ability to perform multiple tasks. The following work tools are available:

- General Purpose Bucket

- Light Material Bucket

- Multi Purpose Bucket (available 2005)

- Grapple Bucket (available 2005)

- Pallet Forks

- Grapple Forks (available 2005)

- Carriage

- Auger*

- Material Handling Arm*

Serviceability

Ease of Access

The TH210 utilizes a side mounted engine design, which provides easy access to major service points. Regular maintenance is important in ensuring a long, productive machine life and helping minimize downtime on the job. The complete service schedule can be found in the Operation and Maintenance Manual that accompanies the machine.

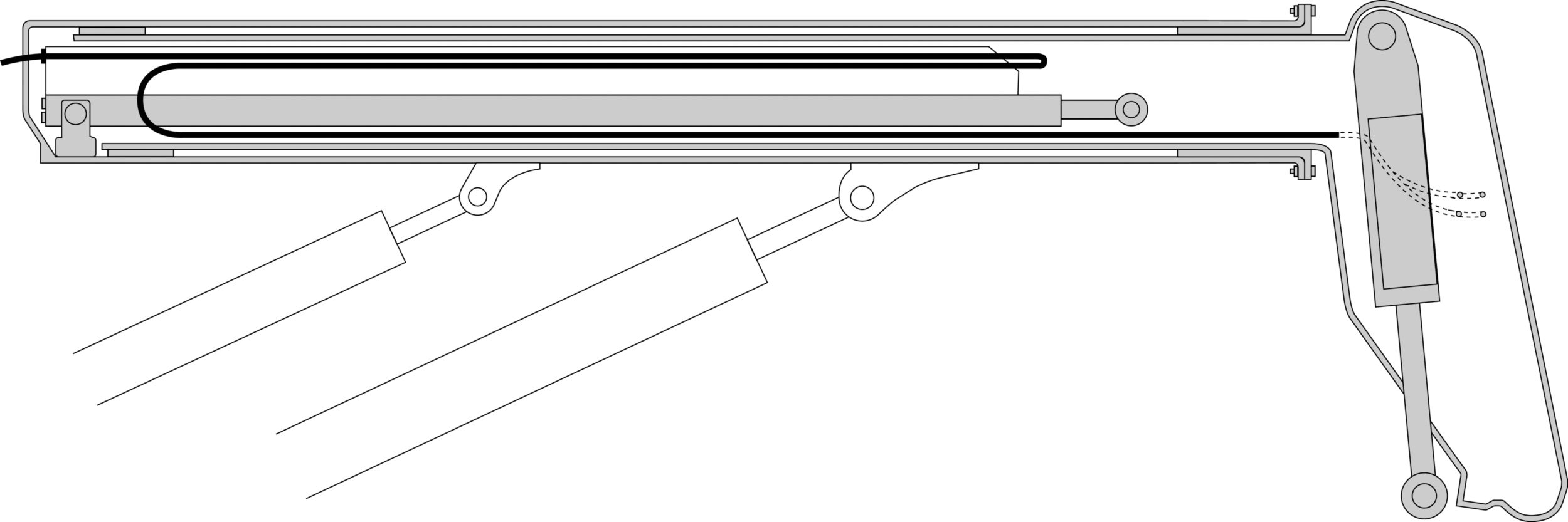

Boom

The TH210 has a two-section, box-formed boom constructed from a continuously welded, high-strength, heavy-duty pressed steel plate with generous boom section overlaps to reduce pad loads and increase pad life.

Reinforced Cooling Package

The hydraulic oil is cooled upon exit from the hystat drive motor by an oil-to-air heat exchanger before returning to the main hydraulic tank. The TH210 is equipped with a blower fan that pushes air out through the rear-mounted radiator and an oil cooler that tilts out for cleaning purposes. This directs the hot air away from the operator providing a more comfortable work environment. An optional reversing fan is available for more effective cooling when working in hot or rugged environments.

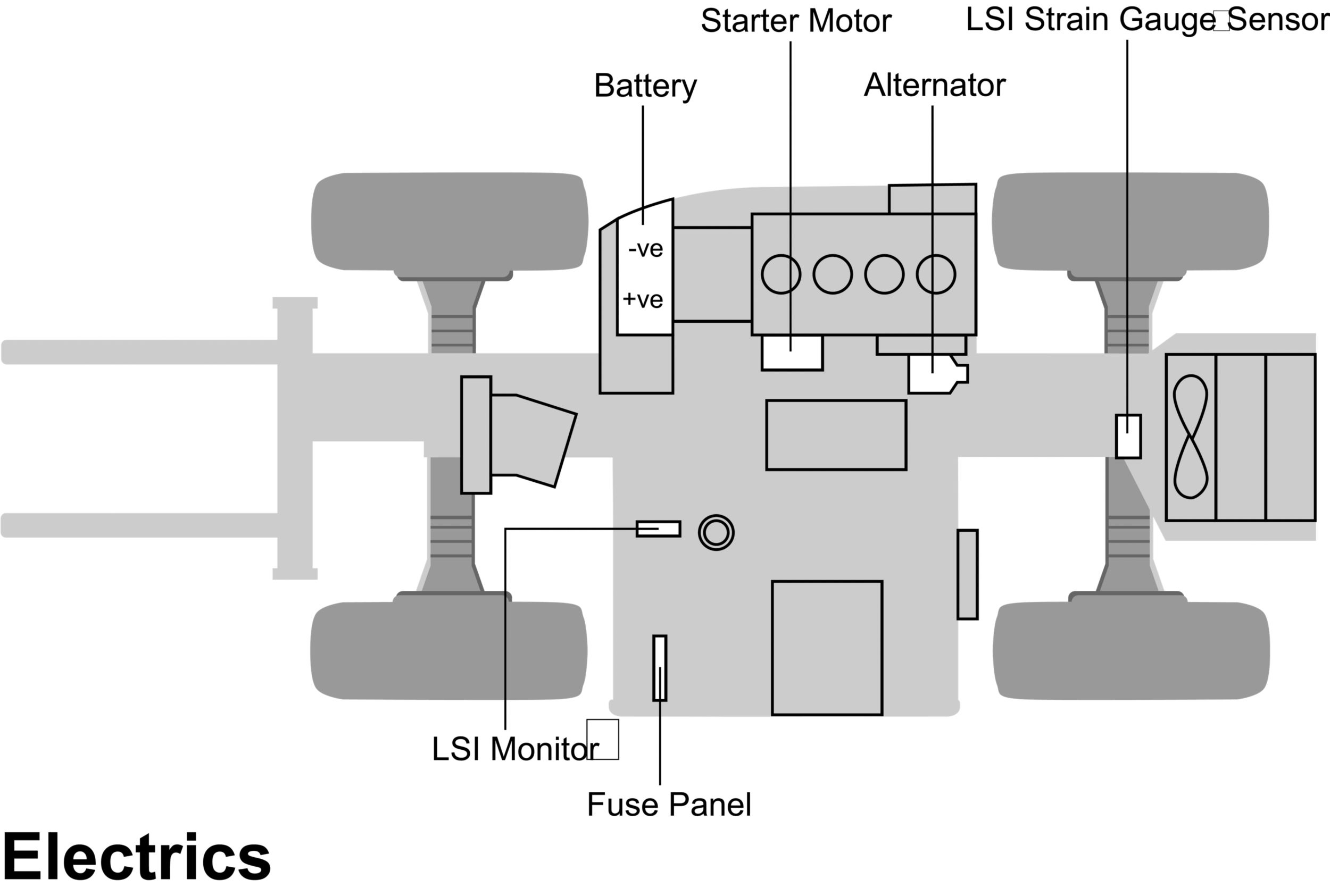

Electrical System

A battery disconnect switch is standard to help prevent theft and to minimize drain on the battery. The fuse panel is located within the cab console and is well protected by a removable plastic cover.

Customer Support

Selection

Make detailed comparisons before you buy. Your Cat dealer can give you precise answers to your questions.

Purchase

Look at the value that the TH210 Telehandler will offer you. Consider all the flexible financing options your Cat dealer offers as well as day to day operating costs.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training literature and other ideas to help increase your productivity.

Maintenance

Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

Cat Dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime.

Easy Financing

Your Cat Dealer can provide a financing package to meet your needs.

Data not available.

Standard Equipment

- TELESCOPIC BOOM

- 2 section boom with non-metallic wear pads

- Lock valves on hydraulic cylinders

- Manual coupler

- Coupler tilt angle maintained automatically throughout boom range

- ELECTRICAL

- 12 volt electrical start

- 65 ampere alternator

- 750 CCA maintenance-free battery with battery disconnect switch

- Anti-restart key switch

- Horn

- OPERATOR ENVIRONMENT

- FOPS/ROPS certified cab

- Low step and grab bars for easy entry

- 2 piece entry door

- Cab isolated on rubber mounts

- Power steering

- Illuminated gauges for engine temperature, transmission oil temperature and fuel level

- Warning light for alternator output and engine oil pressure

- Tachometer

- Rear window wiper

- Cab worklights

- Right-side rear view mirror

- Service hour meter

- Floor mat

- Hand operated parking brake

- Single Caterpillar key

- POWER TRAIN

- Cat 3054B-DI diesel engine (U.S. EPA Tier II compliant)

- Dual element air cleaner with filter condition indicator

- Thermal starting aid

- Water separator

- Hydrostatic transmission

- Column mounted control for transmission direction

- Spin-on engine and transmission oil filters

- Planetary drive axles with full-time mechanical four wheel drive

- Limited slip differential in front axle

- Steer cylinder protected above axles

- Three steering modes: circle, crab and two-wheel front steer

- Enclosed oil disc brakes on front axle

- Power assisted, hydraulic brake system

- HYDRAULICS

- Joystick boom control

- 5 micron spin-on hydraulic filter

- O-ring seal fittings

- Front auxiliary hydraulic supply

- ANTIFREEZE

- Extended life antifreeze -37°C (-34°F)

- OTHER STANDARD EQUIPMENT

- Integral lift and tie-down points

- Fenders on all tires

- Reinforced radiator dust screen

- Pin on retrieval hitch

Optional Equipment

- OPERATOR ENVIRONMENT

- Additional left hand mirror

- Guard, front screen

- ANTIFREEZE

- Antifreeze, -50°C (-58°F)

- WORK TOOLS

- Carriage, Fixed

- Pallet Fork, 1067 mm (42") Class II

- Pallet Fork, 1120 mm (44") Class II

- Pallet Fork, 1220 mm (48") Class II

- Bucket, Light Material 2.0 m3 (2.6 yd3)

- Bucket, General Purpose 0.75 m3 (0.98 yd3)

- TIRES, RIMS AND WHEELS

- Goodyear 12.5/20 construction tread

- Michelin 10.5/80R20 agricultural tread

- Michelin 12.5/80R20 agricultural tread

- AIR INTAKE

- Cap, pre-cleaner

- ELECTRICAL

- Boom lights

- Roading lights, includes: single beam headlights, front and rear running lights and turn signal, stop and tail lights, reversing light, rear fog light.

- Beacon, magnetic mount

- OTHER ATTACHMENTS

- Air conditioning

- Reversing fan

- Rear hydraulic services

- French and Spanish service instructions