Overview

Cat Telescopic Handlers give you reliability, maneuverability and versatility, even in challenging operating conditions. Their features and options are specifically designed to meet the needs of both construction and agricultural industries.

Specifications

| Rated Load Capacity | — |

| Maximum Lift Height | — |

| Engine Model | Cat 3054T |

Benefits & Features

Specifications

| Engine Model | Cat 3054T |

| Gross Power | — |

| Net Power | — |

| Maximum Torque | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Operating Weight | — |

| Rated Load Capacity | — |

| Maximum Lift Height | — |

| Load at Maximum Height - No Stabilizers | — |

| Maximum Forward Reach | — |

| Load at Maximum Reach - No Stabilizers | — |

| Top Travel Speed | — |

| Height | — |

| Width | — |

| Wheel Base | — |

| Length - Fork Face | — |

| Ground Clearance | — |

| Turning Radius - Over Tires | — |

| Turning Radius - Over Forks | — |

| Maximum System Pressure | — |

| Maximum Pump Flow | — |

| Maximum Pressure | — |

| Pump Standby Pressure | — |

| Steering Relief Pressure | — |

| Auxiliary Hydraulic Supply (1) | — |

| Auxiliary Hydraulic Supply (2) | — |

| Pump Type | Axial piston |

| Fuel Tank | — |

| Hydraulic Tank | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Forward - 4 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Coupler - Fore/Aft Tilt | — |

| Foot Brake | Power assisted, foot-operated |

| Parking Brake | Hand-operated, modulating |

Benefits & Features

Proven Power Train

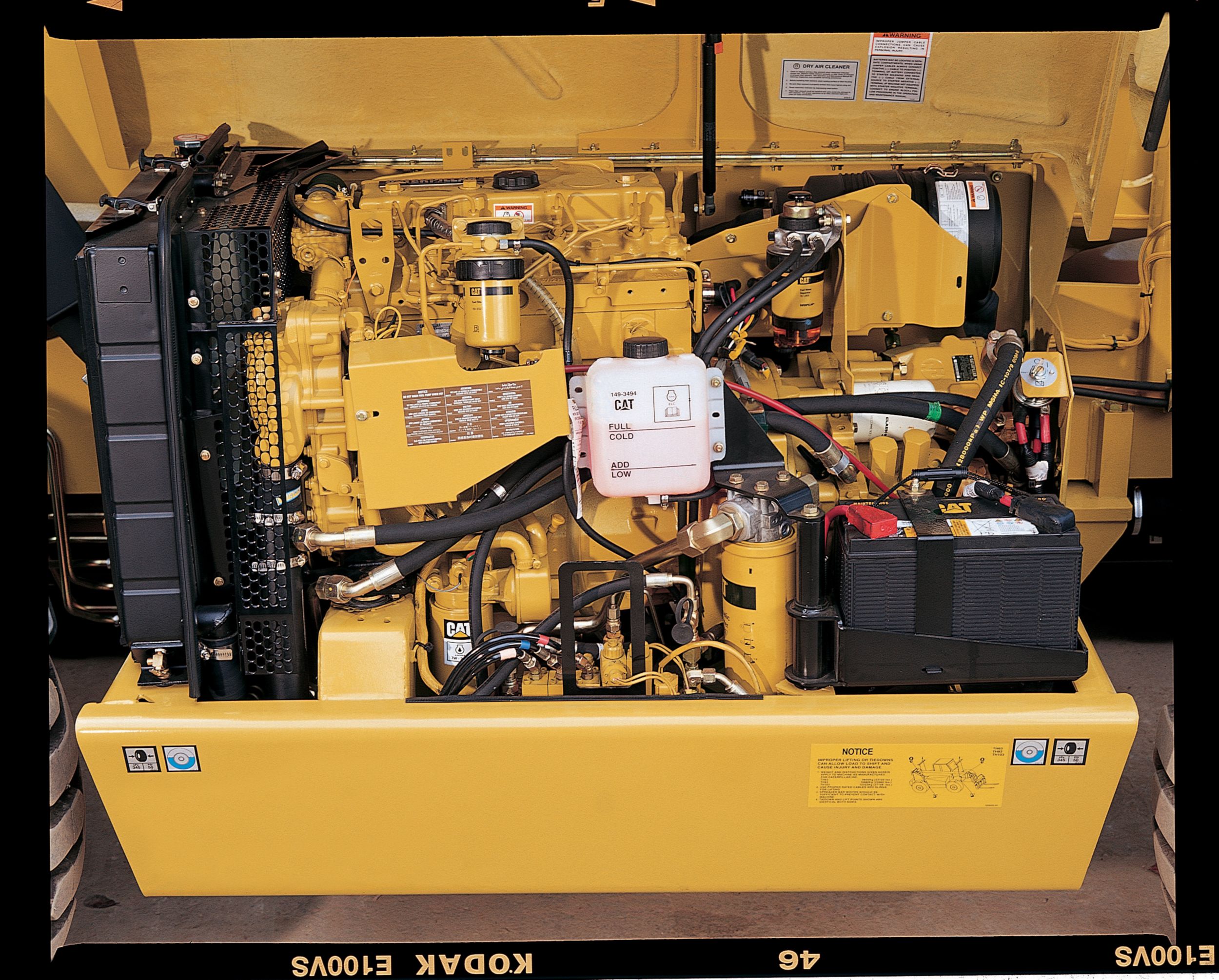

Engine

Cat Telehandlers are powered by the reliable Cat 3054T side mounted engine. This 4 liter engine provides high fuel efficiency and excellent reliability. It is quiet in operation, developing full power at low revs. The module has a lockable cover and a one-stop service and maintenance point.

Axles

Combined with the Cat Telehandler's unique chassis design, these axles permit greater steering lock angles and allow tight turning circles. A long wheelbase improves overall stability and reduces the weight factor.

Brakes

Low effort, highly efficient fade-free, oil-discs operate on all four wheels. Hand operated mechanical park-brake operates on front axle and incorporates transmission disconnect with override. Trouble-free totally enclosed design reduces the chance for contamination resulting in longer component life.

Transmission

Full power shift transmission allows clutch shifting at any engine speed. The gears are permanently in mesh and revolve freely on their shafts when the transmission is in neutral.

Visibility

Low Boom Design

The machine's low profile design allows for loads to be carried with the boom in a low position. Carrying loads low improves visibility to the front and right side of the machine. Low boom design provides unobstructed visibility when in the load carry position. For maximum visibility, load must be carried as low as possible.

Close Fitting Fenders

Flexible, close-fitting fenders resist damage, while protecting operator and machine components from jobsite debris. Fenders move with the wheels, allowing the operator to easily determine wheel direction. The carefully profiled engine hood, aside from providing excellent visibility, allows for easy access to the engine compartment.

Panoramic View

The ergonomically designed operator station provides excellent all-around visibility. The adjustable suspension seat accommodates a wide range of operators, allowing optimal adjustment in the settings.

Operator Station

Ergonomically Designed Cab

The cab layout is ergonomically designed with controls that are logical, highly responsive and within easy reach. Instrumentation is comprehensive and clear. The operator compartment is a separate module resiliently mounted to the frame on four rubber mounts. This reduces vibrations and noise for greater operator comfort. The overhead guard is an integral part of the operator module. The cab structure has been designed and certified to provide falling object and rollover protection (FOPS/ROPS).

Load Charts

Conveniently located in front of the operator, load charts define the operating range and weight in which a load can be lifted and placed.

Instrument Cluster

Gauges are designed to help operators monitor machine operating conditions. The gauge cluster includes an Hour meter, Transmission and Coolant temperature gauges, and Fuel Level indicator.

Operation and Maintenance Manual

This manual, along with other machine information, is located behind the seat in a weather resistant storage case.

Joystick Control

All boom functions, including auxiliary hydraulic supply, are controlled with a smooth operating ergonomic joystick.

Frame Leveling

The three position, frame leveling switch is used to level the machine when on uneven surfaces. The machine allows a maximum tilt of 10 degrees to either side.

Suspension Seat

Ergonomically designed for comfort in hardworking environments. The fully adjustable suspension seat is also designed to accommodate various operator requirements.

Maneuverability

Maneuverability

Full time four-wheel drive and four-wheel steer enhance maneuverability and productivity. Circle steer and crab steer help the operator maneuver in tight spaces, while a third steering mode, two-wheel steer, is ideal when roading the machine. A differential lock on the front axle and enclosed, oil-immersed brakes enable Caterpillar Telehandlers to work in tough underfoot conditions.

Steering

Three steering modes are available: two wheel steer, circle steer and crab steer. A three-position switch on the dash allows the operator to easily select the desired steering mode.

Tires

Cat Telehandlers offer a variety of tire options to fit specific application needs. Appraisal of underfoot conditions and application severities are criteria that will provide proper tire selection. Proper tire selection and tire pressure setting will ensure optimum machine performance, stability and maneuverability.

Versatility

Versatility

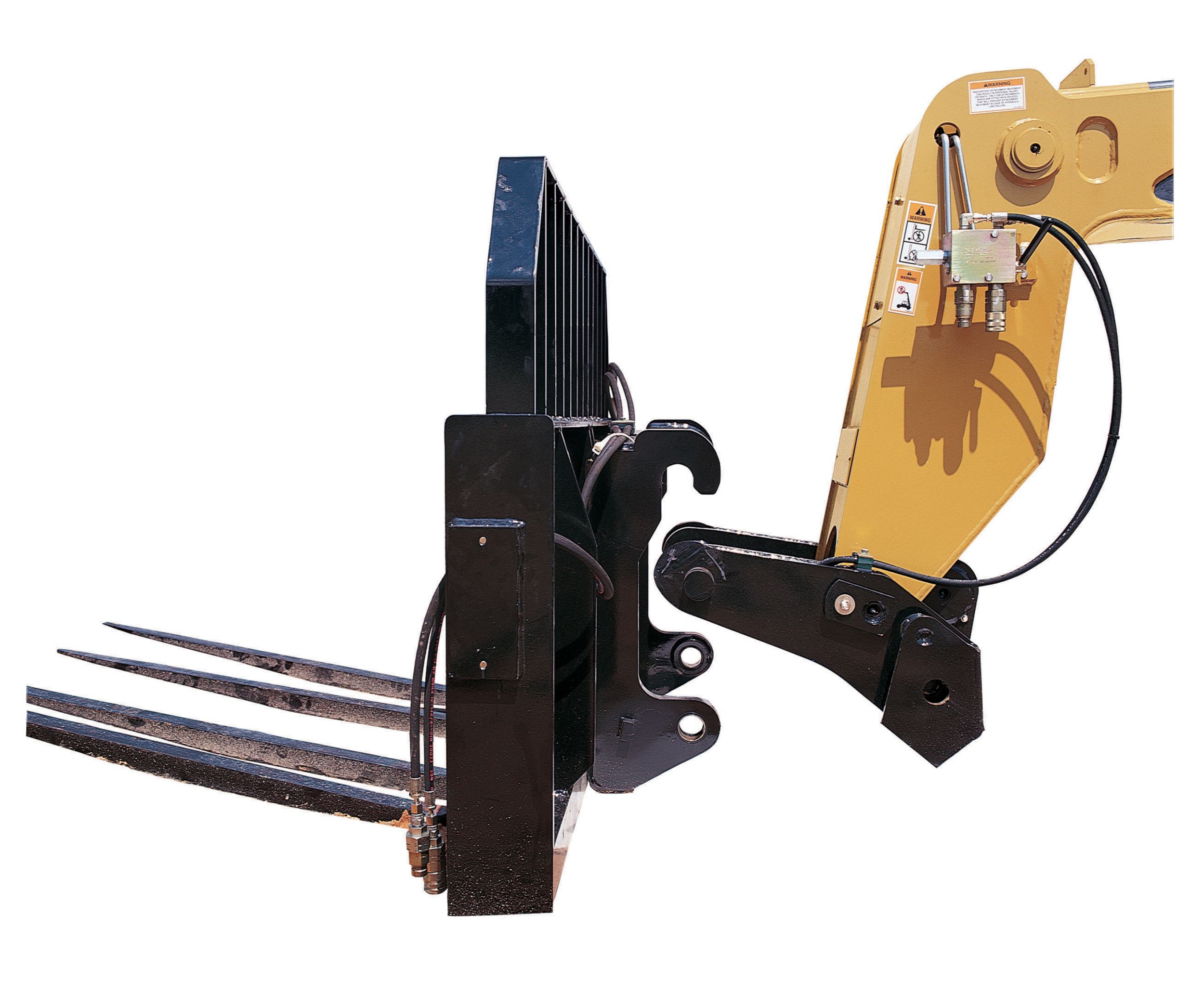

Cat Telehandlers are designed to perform in a wide range of applications. Features such as a hydraulic quick coupler, low boom profile and ample work tool rotation make it an extremely versatile machine. The standard hydraulic quick coupler allows the operator to effortlessly couple the right work tool for the job at hand. The machine's ample work tool rotation enables the machine to shine in bucket applications.

Applications

With a wide range of work tools available, Cat Telehandlers can be used in a variety of applications: - General Construction - Agriculture - Forestry - Warehouse Depots and Waste Disposal

Work Tools

Work Tools

A wide range of Work Tools are available to meet most job site applications. Lift and place operations are easily accomplished with a wide variety of carriages and forks. An assortment of buckets and hydraulically assisted Work Tools are also available. Caterpillar Telehandler Work Tools extend the versatility of the machine.

Quick Coupler

The Caterpillar TH82 Telehandler uses a Hydraulic Quick Coupler for fastening work tools to the front of the boom. This easy-to-use attachment point allows the use of a wide range of work tools, taking advantage of the standard auxiliary hydraulic supply and the ample boom head rotation.

Available Work Tools

Built for performance and durability, these work tools deliver high productivity, long life and excellent value: - General Purpose Bucket - Grapple Bucket - Light Material Bucket - Material Handling Bucket - Multi Purpose Bucket - Fixed Carriages - Rotate Carriages - Block Forks - Pallet Forks - Lifting Hook - Self Tipping Hopper - Truss Boom

Advanced Hydraulic System

Outstanding Load Control

The Cat Telehandler's load sensing hydraulic system provides smooth power on demand, allowing the operator to efficiently place loads.

Axial-Piston Hydraulic Pump

The hydraulic pump automatically adjusts to meet the constantly changing requirements for optimum performance and fuel efficiency. The pump has been sized for maximum productivity. The piston pump allows for simultaneous functions to take place, giving the operator precise control while maintaining fuel efficiency. This also reduces the amount of heat generated on internal components, extending component life.

Compensated Control Valve

The pressure and flow compensated control valve provides load independent flow distribution for exceptional control, modulation and multi-function capability.

Single, Multi-function Joystick

All boom and auxiliary functions are controlled with a single, smooth operating ergonomic joystick. The pilot-operated joystick allows remote location of the main hydraulic control valve and other hydraulic components. This reduces operator fatigue, exposure to noise, vibration and excess heat. Caterpillar offers two joystick arrangements: fork and bucket configuration.

Serviceability and Customer Support

Serviceability

All Cat Telehandler service points are readily accessible and major components are easy to reach due to overall machine design.

Customer Support

Your Cat dealer offers a wide range of services that can be set up under a customer-support agreement when you purchase equipment. Your dealer can help choose a plan that can cover everything from machine and work tool selection to replacement to help you get the best return on your investment.

Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements? What production is needed? What is the true cost of lost production? Your Cat dealer can give you precise answers to these questions.

Purchase

Look past initial price. Consider the financing options available through Cat Financial, as well as day-to-day operating costs.

Operation

Improving operating techniques can boost profits. Caterpillar dealers have training materials and other ideas to help you increase productivity.

Maintenance

More and more equipment users are planning for effective maintenance before purchasing equipment. Choose from your dealer's wide range of maintenance services at the time you receive your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

Most parts are in stock at Caterpillar dealers. Cat dealers utilize a worldwide computer network to find in-stock parts, minimizing machine downtime.

Data not available.