Overview

The TL1055 is precision engineered to handle any task, offering stability, maneuverability, speed and power in any application.

Specifications

| Rated Load Capacity | — |

| Maximum Lift Height | — |

| Engine Model | Cat® C3.6L* |

Benefits & Features

Specifications

| Engine Model | Cat® C3.6L* |

| Gross Power - Basic | — |

| Note | *Meets U.S. EPA Tier 4 Final emission standards. |

| Rated Load Capacity | — |

| Maximum Lift Height | — |

| Maximum Forward Reach | — |

| Top Travel Speed | — |

| Capacity at Maximum Reach (o/r Down) | — |

| Drawbar Pull - Loaded | — |

| Capacity at Maximum Height (o/r Down) | — |

| Frame Leveling | 10° |

| Maximum Lift Height (o/r Down) | — |

| Turning Radius - Over Tires | — |

| Maximum Rated Load Capacity | — |

| Operating Weight | — |

| Pump Type | Variable displacement load sensing axial piston pump |

| Auxiliary Hydraulic Pressure | — |

| Auxiliary Hydraulic Flow | — |

| Fuel Tank | — |

| Diesel Exhaust Fluid (DEF) Tank | — |

| Hydraulic System | — |

| Types (1) | Trunnion mounted planetary 55-degree steer axles |

| Types (2) | High bias limited slip differential on front axle |

| Service Brakes | Inboard wet disc brakes on front and rear axles |

| Parking Brakes | Wet disc, spring applied hydraulic release on front axle |

| Forward | 4 Speeds |

| Reverse | 3 Speeds |

| Standard | 400/75-28 Duraforce Air |

| Optional | 400/75-28 Duraforce Foam; 360/85-28 Telemaster Solid; 14.00-24 16PR Air; 14.00-24 12PR Foam; 400/75-28 Non-Marking Air; 400/75-28 Non-Marking Foam |

| Boom Up | — |

| Boom Down | — |

| Tele In | — |

| Tele Out | — |

| Carriages: Standard Tilt - Option 3 | — |

| Fork Mounted - Work Platform | 1220 mm × 2438 mm (4 ft × 8 ft) |

| Carriages: Standard Tilt - Option 1 | — |

| Forks: Pallet - Option 2 | — |

| Carriages: Side Tilt - Option 1 | — |

| Truss with Winch - Option 1 | — |

| Truss with Winch - Option 2 | — |

| Carriages: Dual Hydraulic Fork Positioner - Option 1 | — |

| Buckets: Multi Purpose | — |

| Carriages: Dual Hydraulic Fork Positioner - Option 2 | — |

| Forks: Pallet - Option 3 | — |

| Material Handling Arm | Adjustable 2-4 m (Adjustable 6.7-13.2 ft) |

| Forks: Lumber | — |

| Forks: Pallet - Option 1 | — |

| Carriages: Swing, 100° | — |

| Fork Extensions* | — |

| Buckets: General Purpose - Option 2 | — |

| Buckets: Grapple | — |

| Carriages: Standard Tilt - Option 2 | — |

| Fork Mounted - Hook | Lifting Hook |

| Carriages: Side Tilt - Option 2 | — |

| Truss Booms - Option 2 | — |

| Forks: Block/Cubing | — |

| Buckets: General Purpose - Option 1 | — |

| Note | *For use with 1525 mm (60 in) forks or larger |

| Truss Booms - Option 1 | — |

| Carriages: Side Shift | — |

| Fork Mounted - Truss Boom | Adjustable 2.1-3.6 m (Adjustable 7-12 ft) |

| Coupler | Hydraulic IT Coupler (Includes Auxiliary Electronics) |

| Fork Mounted - Hopper | Trash Hopper |

| Operating Weight | — |

Benefits & Features

Operator Station

Intuitive Control Layout

All day operator comfort and efficiency is ensured through our simple, logical control layout.

Easier Access

Cab entry and exit is both easier and more convenient due to the well placed handholds.

Operator Protection

The machine provides full operator security with OROPS or EROPS protection.

Enhanced Visibility

The TL-Series cab has improved visibility due to the use of advanced virtual design techniques.

Ease of Operation

Joystick Control

The joystick allows three simultaneous boom functions and operates the auxiliary hydraulic function. It allows the option of a second auxiliary service for the use of work tools that require more than one hydraulic service.

Flow Sharing

Three simultaneous hydraulic functions are achieved using a full flow sharing hydraulic valve. A load sensing variable displacement pump allows full hydraulic power even at low revs.

Performance

Lift Height

The TL1055 can effectively pick and place materials to a maximum height of 54.9 ft. (16.7 m).

Reach

Job site obstacles present challenges demanding a machine to place loads at greater distances - the TL1055 delivers.

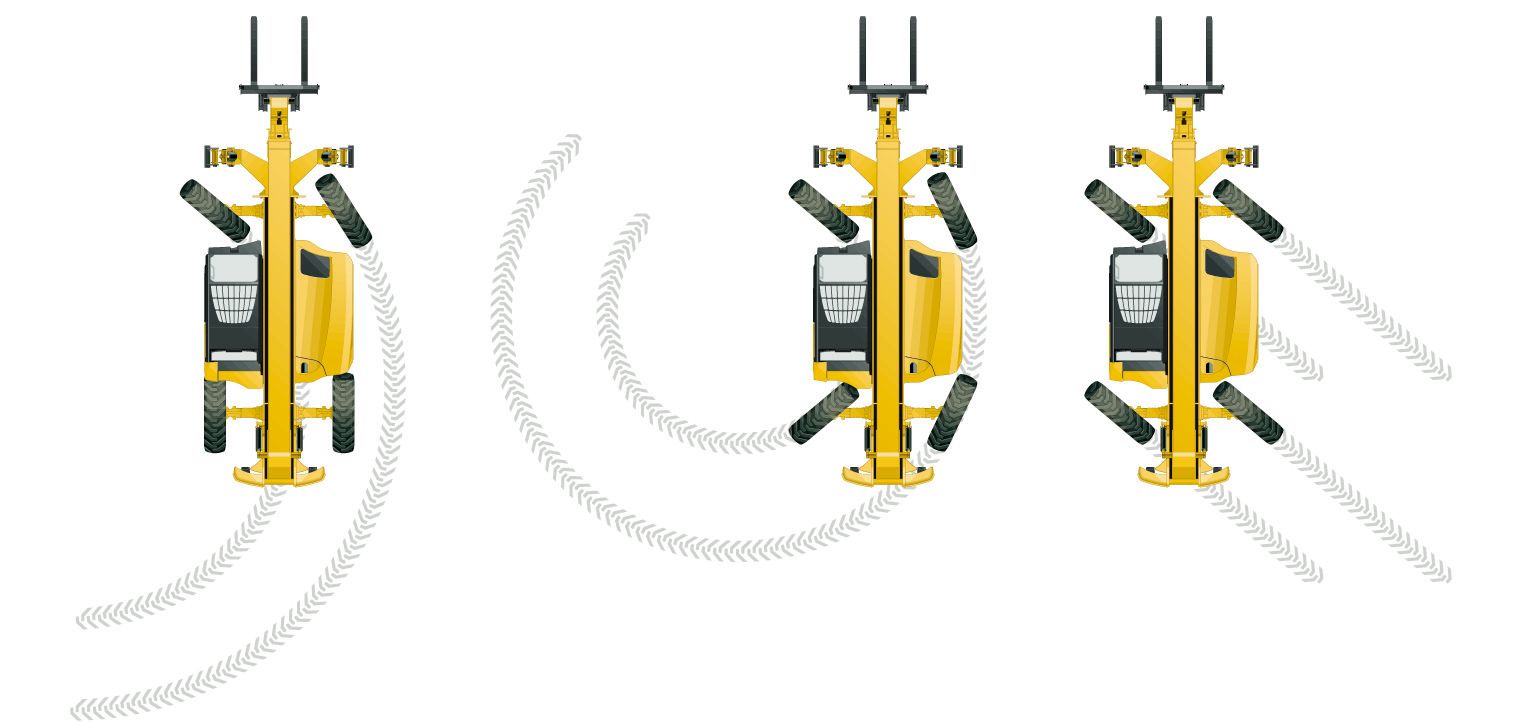

Maneuverability

The TL1055 offers improved maneuverability, allowing it to work productively in confined areas.

Steering Modes

The TL1055 offers three steering modes (two wheel, crab and circle steer) to allow an operator to more easily position the machine. Steering modes are selected by a single three-position rocker switch. Steering position sensors are fitted as standard to all steering modes to be changed while moving.

Power Train

Transmission

The TL1055 features a Cat PG145 power-shift transmission.

Versatility

Quick Coupler

A manual IT quick coupler is standard on the TL-Series machines. For optimum versatility, an optional hydraulic quick coupler is available, allowing the operator to more easily change non-hydraulic work tools without leaving the cab.

Work Tools

- A wide range of work tools are available to meet most job site applications. Caterpillar Telehandler Work Tools extend the versatility of the machine. Built for performance and durability, these work tools deliver high productivity, long life and excellent value.

- General Purpose Bucket (1.0 m3/1.3 yd3)

- Light Materials Bucket (2.0 m3/2.6 yd3, 2.5 m3/3.25 yd3, 3.0 m3/3.90 yd3)

- Material Handling Bucket (1.5 m3/1.95 yd3)

- Multi Purpose Bucket (1.0 m3/1.3 yd3)

- Grapple Bucket (0.85 m3/1.1 yd3)

- Fixed Carriage

- Rotate Carriage

- Sideshift Carriage

- Pallet Forks

- Block Forks

- Lift Hook

- Truss Boom

- Self-tipping Hopper

- Material Handling Arm

Tires

A wide range of tire options enables the machine to be configured to achieve optimum job site performance, including foam-filled and non-marking tires.

Cost of Ownership

Ease of Access

Cost of ownership starts with ease of service. All Cat Telehandler service points are accessible and major components are at ground level due to overall machine design.

Daily Maintenance

Routine daily maintenance is now reduced to checking fluid levels and a walkaround inspection.

Service Intervals

Engine oil, filter changes and routine lubrication are now only required every 500 hours.

Reduced Componentry

With the reduction in the number of filters and extended service intervals, operating costs are the lowest in the industry.

Equipment Protection Plan

Designed to enhance your telehandler ownership experience with comprehensive coverage and peace of mind.

Serviceability and Customer Support

Access

All Cat Telehandler service points, including the combined transmission/hydraulic oil filter, are accessible and major components are at ground level due to the overall machine design. A cab mounted service point allows access to the fuel fill, hydraulic oil fill, washer bottle, fuse box and cab air filter for routine checks.

Selection

Make detailed comparisons before you buy. Your Cat Dealer can give you precise answers to your questions.

Purchase

Look at the value that the TL1055 telehandler will offer you. Consider all the flexible financing options your Cat Dealer offers as well as day to day operating costs.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has literature and other tools to help increase your productivity.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find high availability of parts at our Dealer parts counter. Cat Dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. Additionally, Caterpillar offers a line of genuine remanufactured components which can help lower repair costs.

Easy Financing

Your Cat Dealer can provide a financing package to meet your needs.

Data not available.

Standard Equipment

- TELESCOPIC BOOM

- Boom angle indicator

- ELECTRICAL

- Alternator, 60 amp, 12 volt

- Battery, 12 volt, 1000 CCA

- Horn

- Alarm, backup

- OPERATOR STATION

- Canopy, ROPS/FOPS

- Joystick, single electronic

- Adjustable joystick wristrest

- Grab bars for easy entry

- Seat - vinyl, suspension with Cat logo

- Steering wheel spinner knob

- Floor mat - heavy duty

- Left side rear view mirror

- Service door, cab air intake filter, fuel fill, hydraulic fill, level indicator, fuse panel and washer fill

- Instruments - volt meter, hourmeter, engine oil pressure gauge, water temperature gauge. All gauges protected by clear acrylic cover.

- Park Brake with indicator light

- Steering Wheel with Cat logo

- Cat keys and locks

- Brakes - wet disc service

- Belt, seat - 3" wide

- POWER TRAIN

- Engine, Cat C3.6L - 100 kW (134 hp) gross horsepower

- Thermal starting aid

- Transmission, Cat PG145 6 speed Power-shift, 4-speed forward, 3-speed reverse

- Cat filters, hoses and couplings

- Axles - Dana

- Steering - 4 wheel

- Drive - 4 wheel

- STRUCTURE

- Chassis, frame level up to 10 degrees when operating in rough, uneven terrain

- Cat IT Coupler

- ANTI-FREEZE

- Coolant - Anti-freeze, 50/50 Mix

- TIRES

- Tires - 370/75-28 Duraforce Air

- OTHER EQUIPMENT

- Integrated lift and tie down points

- Standard Cat color paint

- Auxillary hydraulics for auxillary attachments (one function)

Optional Equipment

- TELESCOPIC BOOM

- Hydraulic IT Coupler (includes Auxiliary Electrics)

- ELECTRICAL

- Work Light Group: 3 Cab mounted Lights -- 2 forward, 1 rearward; 1 reversing light; 2 Boom mounted Lights, 1 rotating beacon

- Engine heater block

- Heater - open cab

- Road Light Group -- Headlights, Brake Lights, Turn Signals

- OPERATOR STATION

- Air conditioning

- Single Joystick - with Rocker Switch

- EROPS - Cab Enclosure (Door, Safety Glass Windows, Front Windshield Wiper, Heater & Defroster Fan)

- Skylight Wiper

- Brick guard - Front and top.

- TIRES

- Tires - 370/75-28 Duraforce Foam Fill

- Tires - 315/95-28 Telemaster Solid

- Tire - 14.00-24 16PR Air

- Tire - 14.00-24 12 PR Foam

- Tires - 370/75-28 Non-Marking Air

- OTHER EQUIPMENT

- Fenders

- Tow Hook - Pintle Type

- Artic package - Package includes: 2400 AMP starter, 1000 watt hydraulic reservoir heater, 500 watt engine oil-pan heater, Dual maintenance free, 1375 CCA gel cell batteries, 160 watt battery heating blanket, 1000 watt engine block heater

- WORK TOOLS

- Carriage - side shift, 50 in. (available from factory)

- Lifting Hook - fork mounted (available from factory)

- Truss Broom

- Carriage - standard tilt, 50 in. (available from factory)

- Carriage - standard rotate, 50 in. (available from factory)

- Carriage - swing, 72 in., 100 degrees, 9,000 lb. capacity, 5,000 lb. swung (available from factory)

- Pallet Forks - two 60 in, 2 in x 6 in, 9,000 lb. capacity per pair (available from factory)

- Pallet Forks - two 48 in, 2.36 in x 4 in, 9,000 lb. capacity per pair (available from factory)

- Cubing Forks - two 48 in, 2 in x 2 in, 3,800 lb. capacity per pair (available from factory)

- Bucket - General Purpose 1.3 Cu. Yd.

- Bucket - Material Handling 1.95 Cu. Yd.

- Bucket - Multi-Purpose, 1.3 Cu. Yd.

- Work Platform -- 8 ft x 4 ft with maximum capacity of 1,000 lbs. Includes enclosed fork pockets, side entry/exit gate, removable front rail and wire mesh floor