Overview

The Cat 924H Wheel Loader leads the industry in operator comfort, performance and versatility. Size, power, performance and work tool interchangeability make this machine ideal for a wide range of jobs. Fast cycle times help you move more material. Large spacious cab with joystick control keeps you comfortable throughout the work day, allowing you to get more done. Loader design delivers strength and durability with superior control and unmatched versatility. Discover how much more you can get done with the 924H.

Specifications

| Rated Net Power | — |

| Operating Weight | — |

| Bucket Capacities | 1.7 m3 - 2.8 m3 2.2 yd3 - 3.6 yd3 |

Benefits & Features

Specifications

| Rated Net Power | — |

| Model | Cat® C6.6 |

| SAE J1349 (1) | — |

| ISO 9249 (1997) (1) | — |

| EEC 80/1269 (1) | — |

| SAE J1349 (2) | — |

| Maximum Net Power - 1800 rpm | — |

| ISO 9249 (1997) (2) | — |

| EEC 80/1269 (2) | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Torque | — |

| Peak Torque | — |

| Bucket Capacities | 1.7 m3 - 2.8 m3 2.2 yd3 - 3.6 yd3 |

| Operating Weight | — |

| Steering Articulation | — |

| Minimum Turning Radius - Over Tires | — |

| Steering Angle - Each Direction | — |

| Steering Cylinder, Two, Bore | — |

| Hydraulic output at 2300 engine rpm and 6900 kPa (1000 psi) | — |

| Maximum Working Pressure | — |

| Output at 2,300 Engine rpm and 6900 kPa (1000 psi) with SAE 10W Oil at 65°C (150°F) | — |

| Hydraulic Cycle Time | — |

| Pump Flow - Implement Pump | — |

| Maximum Working Pressure | — |

| Hydraulic Cycle Time | 8.9 Seconds |

| Raise | — |

| Dump | — |

| Lower, Empty, Float Down | — |

| Total | — |

| Bore (1) | — |

| Stroke (1) | — |

| Bore (2) | — |

| Stroke (2) | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Front | — |

| Rear | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Standard Transmission Maximum Travel Speeds | — |

| Forward - 1 (1) | — |

| 2 (1) | — |

| 3 (1) | — |

| 4 (1) | — |

| Reverse - 1 (1) | — |

| Forward - 1 (2) | — |

| Optional Low Speed Transmission Maximum Travel Speeds | — |

| 2 (2) | — |

| 3 (2) | — |

| 4 (2) | — |

| Reverse - 1 (2) | — |

| 2 (3) | — |

| 3 (3) | — |

| Size | 20.5 R25 Radial (L-3) |

| Tread Width | — |

| ROPS | SAE J1040 MAY94, ISO 3471-1994 |

| FOPS | SAE J/ISO 3449 APR98 Level II, ISO 3449 1992 Level II |

| Wheel Base | — |

| Width - Over Tires | — |

| Height - Top of ROPS/FOPS | — |

| Height - Top of Exhaust Stack | — |

| Height - Top of Hood | — |

| Height - Center of Axle | — |

| Ground Clearance | — |

| Overall Length | — |

| Length - Rear Axle to Bumper | — |

| Centerline of Front Axle to Hitch | — |

| Dump Clearance at Maximum Lift - 45° | — |

| Bucket Clearance-Maximum Lift/Carry | — |

| Bucket Pin Height - Maximum Lift | — |

| Overall Height - Bucket Raised | — |

| Reach at Maximum Lift and 45° Dump | — |

| Rack Back Angle - Maximum Lift | — |

| Dump Angle at Maximum Lift | — |

| Rack Back Angle - Ground | — |

| Rack Back Angle - Carry | — |

| Carry Height | — |

| Digging Depth | — |

| Static Tipping Load - Full Turn | — |

| Reach - Full Lift and 45° Dump | — |

| Dump Clearance at Full Lift and 45° Dump Angle | — |

| Articulation Angle | — |

Benefits & Features

VersaLink™ Loader Linkage

Linkage Design

- The Cat exclusive VersaLink design provides toolcarrier controllability, versatility and parallel lift with the strength, durability and speed of Z-Bar linkage. The 924H can be configured in several ways:

- Equipped with a Quick Coupler for quick and easy work tool changes providing optimum utility and versatility.

- Equipped with the High Lift VersaLink loader linkage option for special applications that require more reach and lift height.

Loader Performance

- The VersaLink Loader linkage is designed for exceptional loader performance in a wide range of applications, offering:

- Simultaneous tilt, lift and auxiliary hydraulics function for precise control of the work tool.

- Increased breakout force to shorten cycle times and increase bucket fill factors.

- Higher dump clearance for working in "high target" situations that ordinary loaders cannot.

- More dig depth for better excavation performance, even when equipped with larger tires.

- Greater dozing angle for improved control of material when fine grading.

Parallel Lift

Parallel lift simplifies working with palletized or stacked material. Operators can concentrate on material placement while the load automatically remains parallel throughout the lift range. And, like an integrated toolcarrier, the 924H can easily manipulate loads at all heights.

High Lift Version

Special applications call for special equipment. The optional High Lift VersaLink loader linkage provides an additional clearance of 483 mm (19 in) and is ideal for jobs that require high lift of lighter materials. The high lift VersaLink is available in both pin-on and quick coupler versions.

Power Train

Cat Engine

The Cat C6.6 engine provides cleaner, quieter operation while delivering superior performance and durability. The 96 kW (128 hp) rated net power engine meets all worldwide emissions standards and features: flatter power curve for outstanding response in the working RPM range (1,900 to 2,300), noise reduction technologies for up to 5dB reduction, and patented ACERT™ Technology combined with common rail fuel system, smart waste gate turbocharger and crossflow head design for reduced emissions.

Cat Axles

Heavy-duty axles feature hardened gears and bearings for durable performance. Rear axle oscillates up to 12 degrees to help assure four-wheel ground contact for optimum traction and stability. Optional front and rear Limited Slip Differentials enable outstanding traction in poor underfoot conditions.

Cat Transmission

Rugged Cat transmission uses heavy-duty components for durable and reliable operation. The operator can choose between manual shift and two autoshift modes, Performance or Economy. Performance mode provides maximum acceleration while the economy mode increases fuel economy and improves operator comfort.

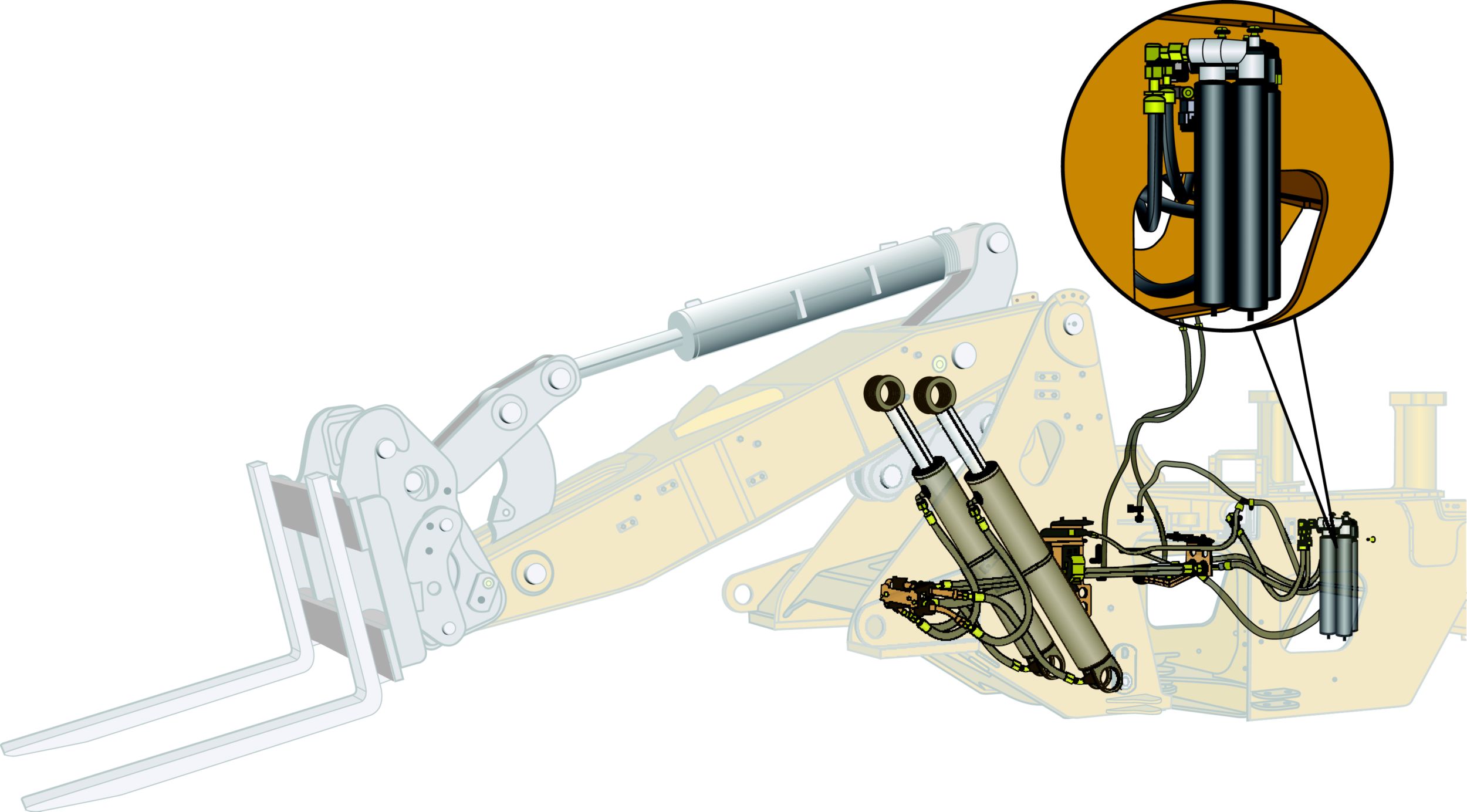

Hydraulics

Load-Sensing Hydraulics

Modular hydraulic system delivers precise control with low effort operation. This load-sensing, variable flow system senses work demand and adjusts flow and pressure to match. This allows full hydraulic forces at any engine speed for delicate jobs in tight areas. Combined with the VersaLink linkage, the hydraulic system allows simultaneous lift, tilt and auxiliary hydraulic function.

Auxiliary Hydraulics

Auxiliary hydraulics provide unparalleled versatility allowing you to select the configuration that best suits your applications. Third function only or packaged with fourth enables the use of almost all work tools.

Optional Joystick with Integrated Third Function Controls

An optional joystick combines lift and tilt functions with transmission controls and third function auxiliary hydraulic controls in one ergonomic joystick. This allows the operator to maintain control of the load linkage while operating hydromechanical tools. The system can operate in two modes: the Work Tool and Continuous Flow mode, which allows bi-directional flow to be controlled with a thumbwheel, and the Continuous Flow mode, which provides infinitely variable flow to tools with hydraulic motors.

Ride Control System

The optional Ride Control System provides a comfortable ride and excellent material retention. Four nitrogen charged accumulators set to different pressures enable optimum cushioning over uneven terrain for all loads and speeds. The system operates in Automatic; as the loader ground speed exceeds 5 kph (3 mph) the system will activate, below 5 kph (3 mph) the system is off, providing maximum lift power.

Operator Station

Cab

Experience comfort and convenience in the H-Series cab. The spacious interior and ergonomic controls keep you comfortable throughout the work day. Choose the seat that meets your needs - the standard, fully adjustable seat or the optional Cat Contour seat for added adjustment and air suspension. The two-door design lets you enter and exit from either side of the machine and wide, serrated steps provide stable footing. Both doors lock open 180 degrees and feature sliding glass windows for better communication with workers on the ground. Large flat glass windows provide excellent visibility all around the machine. The rear window features a standard electric defroster.

Controls

Low effort, ergonomic joystick controls provide easy operation of lift and tilt functions. The standard joystick features an integrated directional control switch for added convenience. The operator programmable transmission neutralizer can be set in seconds optimizing brake effort for all applications.

Instrument Panel

The sealed instrument panel with easy to read white faced gauges and indicators keeps the operator informed of system conditions. The large LED readout provides ground speed and other critical information.

Optional Rear View Camera

This work area visual enhancement system uses a closed circuit video monitoring system. Up to three cameras can be mounted on the machine frame. Objects can be viewed on a color LCD monitor in the cab.

Work Tools

The Right Tool for the Job

The wide variety of work tools offered by Caterpillar makes the 924H one of the most versatile machines on the jobsite. Work tools can be changed quickly and easily with the machine's quick coupler system. A switch in the cab activates a hydraulic cylinder for positive tool engagement and disengagement.

Bucket Work

- With exceptional rimpull and high breakout and lift forces, the 924H delivers strong performance as a bucket loading machine. A wide range of Cat buckets are available including:

- General purpose - 1.8 m3 (2.4 yd3) and 2.1 m3 (2.75 yd3)

- Penetration

- Light Material

- Multi purpose

- Side dump

- High dump

- Wood chip

- Top clamp

Material Handling

- The exceptional visibility and heavy-lift capabilities of the 924H let you work quickly and efficiently in material handling applications. A wide range of tools are available:

- Standard width carriage with pallet forks--1220 mm (48 in), 1370 mm (53 in) and 1524 mm (60 in)

- 2440 mm (96 in) wide carriage with 1830 mm (72 in) or 1524 mm (60 in) tines

- Offset forks for improved tip visibility

- Material handling arm

- Log and lumber forks with avariety of top clamp choices

Special Applications

- Caterpillar also offers other work tools designed to meet specific job requirements:

- Dozer blades

- Snow plows

- Hydraulic brooms

- Asphalt cutter

- Loader rakes

Serviceability

Convenient Service Features

- All service points are accessible from ground level on the right side of the engine. Gull-wing doors with gas struts lift for exceptional access to filters and service points. Extended service intervals reduce service time and increase machine availability.

- Sight gauges let you easily check radiator coolant, hydraulic oil and transmission oil levels as well as engine air filter restriction without opening the air cleaner.

- Standard pressure taps allow quick diagnosis of the entire hydraulic system.

- SOSSM ports make oil sampling quicker, cleaner and provide the best oil sample for analysis.

- Spin-on filters for engine oil, transmission oil and hydraulic oil are vertically mounted for easier servicing.

- 924H features a standard electronic fuel prime pump.

- Sequentially placed radiator and oil coolers are easy to access.

- Optional reversing fan cleans screens without interrupting machine operation.

Customer Support

Your Cat dealer is ready to assist you with your purchase decision and everything after.

- Make comparisons of machines, with estimates of component life, preventative maintenance and cost of production.

- Financing packages are flexible to meet your needs.

- Your Cat dealer can evaluate the cost to repair, rebuild and replace your machine, so you can make the right choice.

- For more information on Cat products, dealer services and industry solutions, visit us at www.cat.com.

Data not available.

Standard Equipment

- ELECTRICAL

- Alternator, 95-amp brushless

- Alarm, back-up

- Batteries, maintenance-free, 950 CCA, (2)

- Directional signals (front & rear)

- Starting and charging system, 24V

- Halogen work lights (front & rear)

- Ignition key start/stop switch

- Roading lights

- Starting aid, thermal

- Switch, battery disconnect

- OPERATOR ENVIRONMENT

- Standard two door cab includes all of the following items:

- Air conditioner, heater/defroster

- Sliding glass door windows

- Radio ready

- 12 volt electrical accessory outlet

- Sealed Instrument Gauge: - Engine RPM - Hydraulic oil temperature - Engine coolant temperature - Torque converter oil temperature - Fuel level - Digital LED speedometer, hour meter/odometer

- Indicator Lights: - Turn signal - Primary steering malfunction - Hydraulic oil bypass - Parking brake applied - Brake charge pressure low - Transmission oil temperature - General warning - Electrical system voltage low - Fuel water separator - Engine oil temperature - Bright lights activated

- Adjustable tilt steering column

- Coat hook

- Ground level door release

- Horn, steering wheel mounted (electric)

- Hydraulic control lever lockout

- Interior light

- Lighter

- Lunch box storage with cup holder

- Pilot hydraulic implement controls

- Rear window defroster, electric

- Rear view mirrors (2 inside)

- Seat, adjustable suspension, armrest (fabric or vinyl)

- Seat belt, 75 mm (3 in), retractable

- Tinted safety glass, front

- Tool box

- Wet arm wiper/washer (front & rear), front intermittent

- POWER TRAIN

- Engine, Cat C6.6 ACERT - Low emission diesel engine - Noise reduction technology - Smart waste gate turbocharged - After cooled - Closed Circuit Breather - Electronically controlled

- Air cleaner, dry type

- Axle seal guards, integrated

- Brakes, enclosed wet-disc full hydraulic

- Differentials, conventional (front/rear)

- Driveshaft, lubed for life

- Electric fuel prime pump

- Engine speed control

- Fuel/water separator

- Muffler

- Radiator, unit serviceable

- S•O•S oil sampling port, engine oil

- S•O•S oil sampling port, transmission oil

- Torque converter

- Transmission, 4F/3R, autoshift, single lever control with F/N/R and kickdown button

- Transmission neutralizer; operator programmable

- HYDRAULICS

- Hydraulic diagnostic connectors

- Heavy duty hydraulic oil cooler

- Hydraulic control, 3-valve, 2-lever with F/N/R

- Hydraulics, third function

- Load-sensing hydraulic system

- Load-sensing steering system

- S•O•Ssm oil sampling port, hydraulic oil

- OTHER STANDARD EQUIPMENT

- Antifreeze/coolant, extended-life protects to -36°C (-33°F)

- Automatic bucket positioner/fork positioner

- Brakes, secondary and parking

- Counterweight

- Coupler controls and lines

- Engine enclosure, lockable

- Fenders, front

- Hitch, recovery

- Loader linkage, VersaLink

- Lift kickout, automatic

- Machine Security System ready

- Product Link ready

- Remote grease lines

- Steering stops, cushioned

- Swing-out, hydraulically driven demand fan

- Vandalism protection, lockable service points

- Visual indicators: - air cleaner service - coolant level - hydraulic oil - transmission oil

Optional Equipment

- Radio packages:

- • Radio, AM/FM

- • Radio, AM/FM with CD player