Overview

The 930G is one of the most versatile wheel loaders in the world. Size, power, performance and work tool interchangeability make this machine ideal for a wide range of jobs.

Specifications

| Rated Net Power | — |

| Operating Weight | — |

| Bucket Capacities | 2.1 m3 - 5.0 m3 2.6 yd3 - 6.5 yd3 |

Benefits & Features

Specifications

| Rated Net Power | — |

| Model | Cat® 3056E DIT ATAAC |

| SAE J1349 (1) | — |

| ISO 9249 (1997) (1) | — |

| EEC 80/1269 (1) | — |

| Maximum Net Power - 2000 rpm | — |

| SAE J1349 (2) | — |

| ISO 9249 (1997) (2) | — |

| EEC 80/1269 (2) | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Bucket Capacities | 2.1 m3 - 5.0 m3 2.6 yd3 - 6.5 yd3 |

| Bucket Width | — |

| Operating Weight | — |

| Maximum Weight | — |

| Optional Counterweight | — |

| Steering Articulation | — |

| Minimum Turning Radius - Over Tires | — |

| Steering Angle - Each Direction | — |

| Steering Cylinder, Two, Bore | — |

| Hydraulic output at 2300 engine rpm and 6900 kPa (1000 psi) | — |

| Maximum Working Pressure | — |

| Output at 2,300 Engine rpm and 6900 kPa (1000 psi) with SAE 10W Oil at 65°C (150°F) | — |

| Hydraulic Cycle Time | — |

| Pump Flow - Implement Pump | — |

| Relief Pressure - Implement pump | — |

| Maximum Working Pressure | — |

| Hydraulic Cycle Time | 9.5sec |

| Raise | — |

| Dump | — |

| Lower, Empty, Float Down | — |

| Total | — |

| Bore (1) | — |

| Stroke (1) | — |

| Bore (2) | — |

| Stroke (2) | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Front | — |

| Rear | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Forward - 1 | — |

| 2 | — |

| 3 | — |

| 4 | — |

| Reverse - 1 | — |

| Axle Oscillation | — |

| Size | 17.5-25 12PR L-2 |

| Tread Width | — |

| ROPS | SAE J1040 MAY94, ISO 3471-1994 |

| FOPS | SAE J/ISO 3449 APR98 Level II, ISO 3449 1992 Level II |

| Overall Height | — |

| Wheel Base | — |

| Width - Over Tires | — |

| Height - Top of ROPS/FOPS | — |

| Height - Top of Exhaust Stack | — |

| Height - Top of Hood | — |

| Height - Center of Axle | — |

| Ground Clearance | — |

| Overall Length | — |

| Length - Rear Axle to Bumper | — |

| Centerline of Front Axle to Hitch | — |

| Wheel Base Length | — |

| Dump Clearance at Maximum Lift - 45° | — |

| Bucket Clearance-Maximum Lift/Carry | — |

| Bucket Pin Height - Maximum Lift | — |

| Overall Height - Bucket Raised | — |

| Reach at Maximum Lift and 45° Dump | — |

| Rack Back Angle - Maximum Lift | — |

| Dump Angle at Maximum Lift | — |

| Rack Back Angle - Ground | — |

| Rack Back Angle - Carry | — |

| Carry Height | — |

| Digging Depth | — |

| Static Tipping Load - Full Turn | — |

| Reach - Full Lift and 45° Dump | — |

| Dump Clearance at Full Lift and 45° Dump Angle | — |

| Articulation Angle | — |

| Dump Clearance | — |

Benefits & Features

VersaLink™ Loader Linkage

Linkage Design

- Versatility is the key benefit of the VersaLink loader linkage. The 930G can be configured in many ways:

- with a Quick Coupler, work tool changes are quick and easy. In this configuration, the versatility of an integrated toolcarrier and the performance of a wheel loader are combined;

- equipped with pin-on tools, like a bucket, you get a dedicated wheel loader, with exceptional breakout force, tipping load and dump height;

- equipped with the High Lift VersaLink loader linkage option, the 930G is ideal for special applications that require more reach and lift height.

Reconfiguration

The VersaLink loader linkage can be reconfigured from pin-on to Quick Coupler or from standard linkage to high lift linkage with a minimum of new parts required.

Outstanding Performance

- The VersaLink loader linkage is designed for exceptional loader performance in a wide range of applications, offering:

- increased breakout force to shorten cycle times and increase bucket fill factors;

- higher dump clearance for working in "high target" situations that ordinary loaders cannot;

- more dig depth for better excavation performance, even when equipped with larger 20.5 x 25 tires;

- greater rackback angle for improved material retention, resulting in higher productivity;

- greater dozing angle for improved control of material when fine grading.

Visibility

Visibility to critical areas such as bucket corners and fork tips is optimized for more productive material and pallet handling. The VersaLink loader linkage geometry maximizes visibility throughout the entire production cycle.

Parallel Lift

Parallel lift simplifies working with palletized or stacked material. Operators can concentrate on material placement while the load automatically remains parallel throughout the lift range. And, like an integrated toolcarrier, the 930G can easily manipulate loads.

Exceptional Strength and Durability

The one-piece fabricated box-section design of the VersaLink loader linkage delivers unprecedented torsional loading strength. The result is high rigidity and fewer stress paths for exceptional durability.

High Lift Version

- Special applications call for special equipment. The optional High Lift VersaLink loader linkage provides an additional clearance of 19 in (483 mm) and is ideal for jobs that require higher lift of lighter materials such as:

- feedlots

- dairies

- waste transfer stations

- fertilizer producers

- miscellaneous material handling

Performance

Productivity

Balanced structural design and exceptional rimpull tuned to powerful implement hydraulics allow fast cycle times and higher productivity.

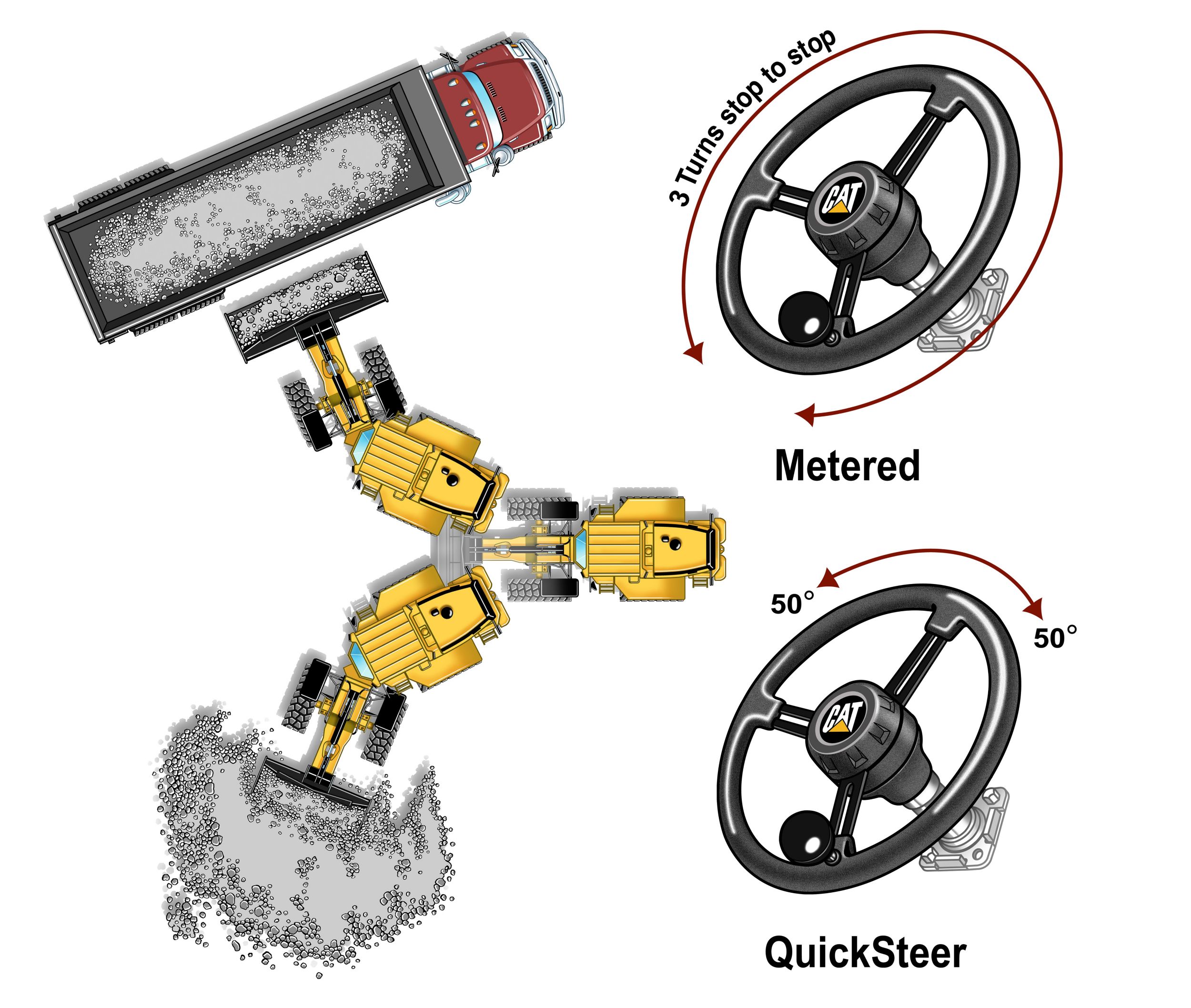

Optional Dual Mode Steering

The operator can choose traditional steering or select QuickSteer mode with a switch in the cab for faster, extremely low effort truck loading. This mode provides higher productivity and efficiency with less operator fatigue.

Versatility

The hydraulic quick coupler and wide range of Cat Work Tools enable one machine to accomplish the tasks of many. Auxiliary hydraulics allow unparalleled versatility and interchangeability. Adjustable flow third function hydraulics provide proportional control and allow you to efficiently match power to the application. Broom performance demands are optimized to machine ground speed for minimal debris. Packaged third and fourth, as well as fifth and sixth function hydraulics expand work tool and machine capability.

Auxiliary Hydraulics

Application Specific

Industrial and Waste Handling guarding packages and multiple tire options increase machine durability and are available to meet your specific job needs.

Operator Station

Cab

The ergonomic cab provides a comfortable work environment with large windows, spacious interior room, generous storage areas and low interior sound levels.

Access/Egress

The two-door design makes access and egress easy. Both doors open fully and lock flush against the cab for efficiency and safety. Steps leading up to the cab are wide, serrated and angled out for secure footing. Large grab handles allow safe positioning while climbing.

Windows

Large windows improve visibility in all directions. The rear window features a standard electric defroster. Sliding glass is available as an option on the doors.

Visibility

Visibility to critical areas such as the bucket have been optimized. The VersaLink loader linkage geometry maximizes visibility throughout the production cycle.

Optional Rear View Camera System

Work area visual enhancement system utilizes a closed circuit video monitoring system. One, two or three cameras can be mounted on the machine frame. Objects can be viewed in a 7 inch color LCD monitor located in place of the right cab rear view mirror. Rear view system is compatible with heavy duty radiator guarding and waste handling packages.

Instrument Panel

The 930G instrument panel is conveniently located with easy-to-read gauges and expanded warning/indicator and diagnostic functions.

Electronic Engine Speed Control

A specific engine RPM can be set and maintained with a switch in the cab.

Steering System

The load-sensing, closed-center steering system with flow amplification matches steering response to a wide variety of applications. The adjustable steering console lifts easily out of the way. Dual suspended brake pedals function as a brake and a transmission neutralizer so the operator can maintain high engine RPM for full hydraulic flow and fast cycle times.

Low Effort Operation

Hydraulic joystick controls provide ease of lift and tilt functions. A single joystick is standard. An integrated directional control switch on the joystick provides easy operation and enhanced productivity. A two lever control is optional.

Storage

Generous storage space includes a lockable compartment, coat hook and special molded compartments designed to hold a lunchbox/cooler, cup or can. A tool box is also provided.

Standard Operator Programmable Transmission Neutralizer

Operator can select any brake pressure setting depending on the application to neutralize the transmission or select off for no neutralization. In less than 15 seconds, this system enables any operator to set up the machine exactly the way that best fits the application, greater pressure for applications up ramps and hills, lighter pressure for flat work areas like truck loading or material handling for underground utility sites.

Seat

- The standard seat is available in cloth or vinyl with fully adjustable fore/aft position, seatback angle, bottom cushion height, armrest angle and suspension stiffness. Other seat options include:

- Cat Contour Seat, fabric, with adjustable backrest and lumbar support.

- Cat Contour Seat, fabric, electrically adjustable with air suspension.

Customize the Cab

- The cab can be customized with various options such as:

- 12V converter for powering electronics such as cellular phones, two-way radios and music systems

- Optional rear view camera

- Radio installation package

- Sun visor for windshield

- Roll-down sun screen for rear window

- External mirror package

- Auxiliary lighting packages

Hydraulic System

Precise Control

Designed by Caterpillar, the modular hydraulic system provides low effort operation and superior control.

Load-Sensing Hydraulics

The load-sensing, variable flow hydraulic system senses work demand and adjusts flow and pressure to match. This allows full hydraulic forces at any engine speed for delicate jobs in tight areas.

Auxiliary Hydraulics

The 930G auxiliary hydraulics provide unparalleled versatility. Select the configuration that best suits the application. Third function only or third and fourth package together enable the use of almost all work tools. Fifth and sixth function hydraulics are also available for responsive independent positioning of work tools with multiple hydraulic cylinders, such as snow plows with hydraulically movable snow wings.

Optional Ride Control System

The optional Ride Control System provides a comfortable ride at all speeds and improves hard bank digging. Three modes are available: auto, on and off. Auto mode is factory set to engage above 6 mph but can be adjusted to any speed. On mode should be used in load and carry applications for ride control at all speeds.

Optional Joystick with Integrated Third Function Controls

- Low effort pilot hydraulics operated lift and tilt functions are combined with electrohydraulic transmission forward-neutral-reverse, transmission kick down and integrated third function auxiliary hydraulic controls. Enables operator to maintain control of loader linkage while manipulating hydromechanical tools such as top clamp buckets and forks, side dump buckets and hydraulic brooms. Two modes of operation include:

- Standard Work Tool Mode - Provides intermittent flow to the work tool. Rolling the roller switch upward pressurizes the left side of the auxiliary system, downward activation of the roller switch pressurizes the right side. This system is ideal for top clamps or side dump buckets.

- Continuous Flow Mode - Gradually increases auxiliary hydraulic flow to the work tool when the roller switch is held upward. A momentary downward activation of the roller switch stops the flow.

Variable Displacement Axial Pump

Variable displacement axial pump provides intuitive hydraulic flow. Closed-centered implement valves, with pressure compensation for reduced lever effort, signal hydraulic system requirements to a control valve located on the pump. This valve controls the pump to deliver the flow and pressure necessary to fulfill the implement demands.

Load-Sensing Steering

Load-sensing steering provides low effort operator control, making more power available for rimpull, breakout and lift forces.

Joystick Control

Low effort, joystick implement control improves efficiency with simultaneous lift and tilt functions.

Modular Hydraulic Control Valves

Modular hydraulic control valves add a new dimension of versatility that greatly simplifies and lowers overall cost of reconfiguring the machine for additional functions.

Tilt Cylinder

A large tilt cylinder delivers exceptional backdrag performance.

Hoses

Caterpillar XT™ hoses and couplings provide rugged, reliable performance with significantly reduced risk.

Caterpillar Power Train

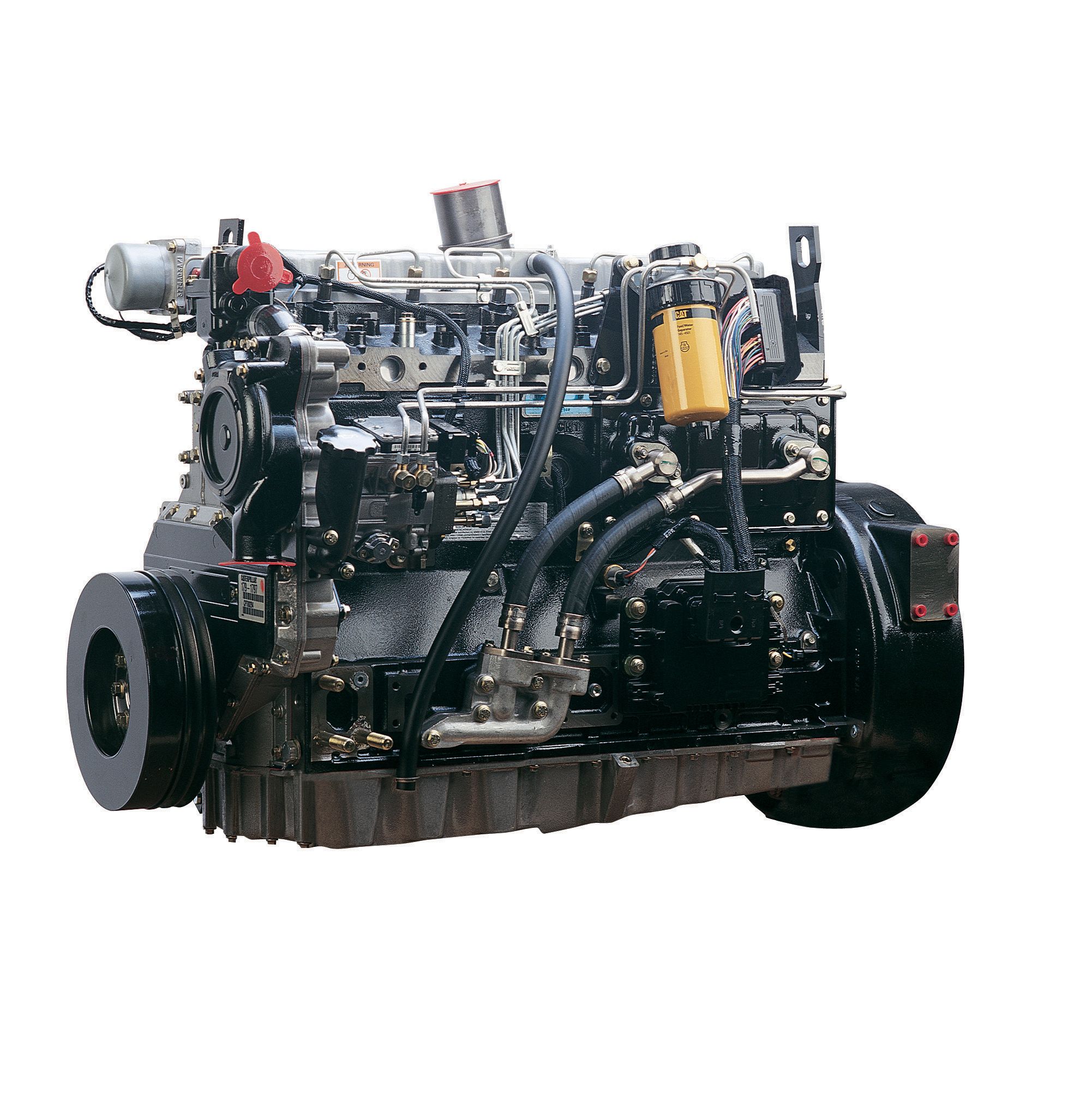

Caterpillar Engine

The six-cylinder 3056E Direct Injection Turbocharged (DIT) engine with Air-to-Air After Cooler (ATAAC) meets worldwide emissions standards and has a proven reputation for reliability, durability and performance. Fuel injection is electronically controlled for precise timing.

Air-to-Air After Cooling

Air-to-air after cooling reduces engine emissions.

Torque Rise

The engine features a 37% torque rise for increased power during heavy-duty use.

Cylinders

Low cylinder pressure rise and low peak pressure provide outstanding reliability and durability.

Cooling System

Engine and cooling system are in separate compartments for clean, quiet operation and easy service.

Electronic Control Module

The Caterpillar engine control module not only controls the timing needs of the engine but also monitors critical systems to maintain optimum performance and provide engine protection.

Service Intervals

The recommended engine oil change requirement is every 500 hours of operation.

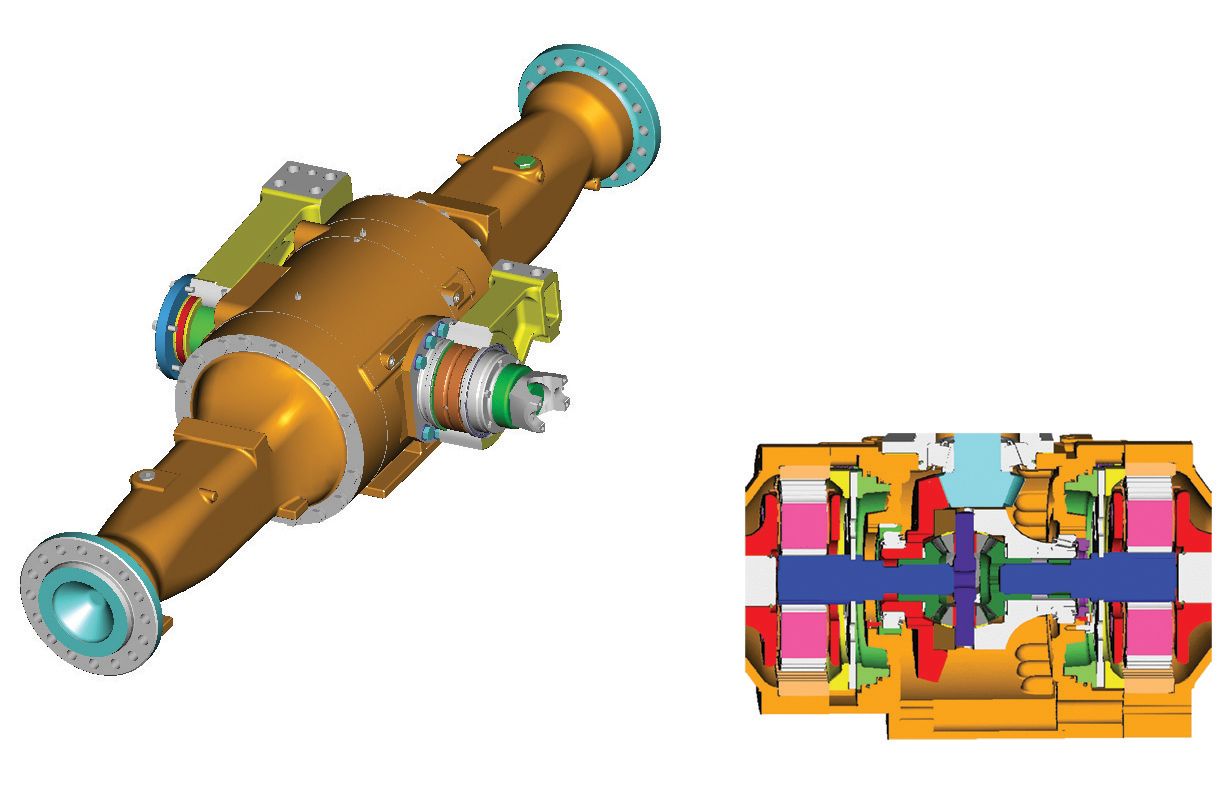

Axles

Heavy-duty design features strong gears and bearings for durable performance. Oscillating rear axle helps assure four-wheel ground contact for optimum traction and stability.

Brakes

Oil-disc brakes are adjustment-free and fully enclosed.

Optional Heavy-Duty Brakes

Optional heavy-duty brakes provide additional brake discs and axle oil cooler for severe applications.

Duo-Cone® Seals

Duo-Cone Seals keep oil in and contaminants out.

Limited Slip Differentials

Optional front and rear Limited Slip Differentials provide improved traction in poor or uneven underfoot conditions.

Transmission

Rugged, field-proven Caterpillar 4F/3R transmission uses heavy-duty components for durable and reliable operation. High-energy friction materials allow for better heat tolerance while thick reaction plates allow for better heat dissipation. The transmission is also designed for easy service and rebuild.

Electronic Clutch Pressure Control

The Electronic Clutch Pressure Control (ECPC) manages shift torque providing exceptional smoothness.

Gears

High-contact ratio spur gears are precision ground and heat treated for quiet, durable operation.

Shifting Options

Operator can choose manual shift or two autoshift modes (full throttle or variable shift control). Full throttle selection provides maximum acceleration while variable selection increases fuel economy and improves operator comfort.

Work Tools

Versatility

With a variety of work tools offered by Caterpillar, the 930G is ideal for a wide range of applications.

Quick Coupler

Work tools can be changed quickly and easily with the machine's integral quick coupler system. A switch in the operator compartment activates a hydraulic cylinder for positive tool engagement or disengagement.

Buckets

- With exceptional rimpull and high breakout and lift forces, the 930G demonstrates strong performance as a bucket loading machine. A wide range of Caterpillar buckets are available including:

- general purpose

- penetration

- light material

- multi purpose

- side dump

- high dump

- wood chip

- ejector

- top-clamp

Material Handling

- Exceptional visibility and heavy-lift capabilities enable you to work quickly and efficiently as a material handler. A wide range of tools are available such as:

- pallet forks

- offset forks

- log and lumber forks

- material handling arm

- tire loaders

Auxiliary Hydraulics

Optional third and fourth function hydraulics are available for use with work tools that require hydraulic power, such as rotary brooms, high dump and side dump buckets. Optional 5th and 6th function hydraulics are also available for snow plow and snow wing jobs.

Special Applications

- Some of the numerous specialty tools available include:

- dozer blades

- snow plows

- hydraulic brooms

- asphalt cutter

- loader rakes

Serviceability

Easy Access

Gull-wing engine enclosure doors with gas struts lift for exceptional access to filters and service points. Radiator and oil coolers are easily accessible for cleaning.

Simplified Routine Service

All service points are accessible from the ground level. Easily check radiator coolant, hydraulic oil and transmission oil levels with sight gauges.

Swing-out Cooling Fan

A swing-out cooling fan allows quick, easy cleaning and service of the radiator. The fan is hydraulically driven and separate from the engine compartment for exceptional low noise operation.

Optional Reversing Fan

Optional reversing capability of the fan cleans screens without interrupting machine operation.

Pressure Taps

Standard pressure taps allow quick diagnosis of the entire hydraulic system.

S•O•SSM Ports

Scheduled Oil Sampling ports are factory installed for improved access to engine, transmission and hydraulic oils. S•O•S ports make oil sampling quicker, cleaner and provide the best oil sample for analysis.

Oil Filters

Spin-on filters for engine oil, transmission oil and hydraulic oil are vertically mounted for easier servicing.

Clamps and Bushings

Metal clamps with rubber bushings are used at hose attachment points to eliminate metal-to-metal contact and increase wear life.

Self-Diagnostics

Self-diagnostic transmission and data link allows quick and easy troubleshooting by service personnel. Service codes are easily accessed through the gauge console.

Ground Level Access

The control valves feature convenient ground level access for easy modifications to the system.

Extended Life Coolant/Antifreeze

Cat Extended Life Coolant/Antifreeze allows extended operation (up to 6,000 hours) between changes.

Other Service Features

- Other service features include:

- Maintenance-free driveshaft

- Stationary radiator and coolant hoses

- Standard hydraulic oil cooler

- Adjustment-free brakes

- Adjustment-free engine fuel system

- Grouped grease fittings

- Positive torque hose clamps

- Braided, color coded and numbered wiring consistent throughout Caterpillar machines

Owning & Operating Costs

Low Fuel Consumption

The 3056E DIT ATAAC engine features low fuel consumption for more economical operation and meets all worldwide emissions standards. Load sensing hydraulics matches power and speed to your specific job application for high efficiency.

Heavy-Duty Power, Fast Cycle Times

High horsepower provides rugged, dependable power and faster cycle times, allowing the operator to get more work done in a day.

Extended Service Intervals

- Service intervals have been extended to reduce machine service time and increase machine availability:

- 4,000 hour hydraulic oil change (S•O•S sampling required)

- 1,000 hour hydraulic filter change

- 500 hour engine oil change

Smoother Transmission for Increased Productivity

A smoother shifting transmission provides a more comfortable work environment, allowing the operator to be more productive throughout the entire work shift.

Demand Fan

Demand fan changes speed to meet cooling requirements and save fuel.

Engine Derate Feature

Auto Derate monitors vital engine systems and will reduce the engine horsepower up to 50% to protect the engine.

Optional Axle Cooler

Protection for severe applications.

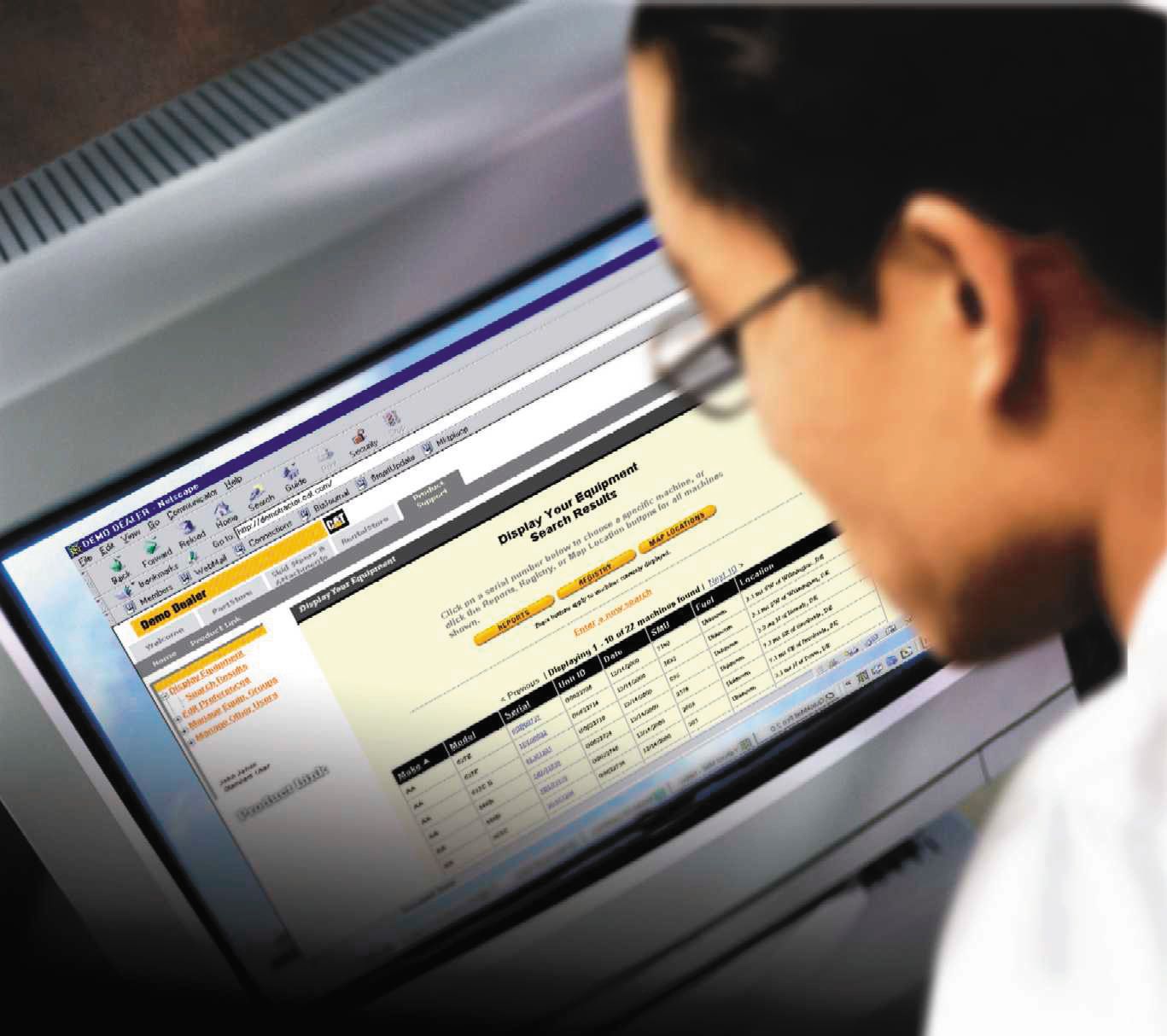

Equipment Management Option

Caterpillar's asset management or equipment management system called Product Link-World View, enables dealers and their customers to track equipment for hours and location, and in some cases monitor machine health. This easy-to-use system provides information flow between a machine and the user through the internet based Dealer Storefront. This information helps lower operating costs through timely service/repairs and optimized machine use.

Machine Security System Option

The Machine Security System (MSS) inhibits unauthorized machine use by immobilizing vital electrical circuits. Critical machine circuits are inhibited unless a valid key is used to start the machine.

Environmentally Responsible Design

Low Fuel Consumption

As the top performer in its size class, the 930G gets more work done in less time and provides low fuel consumption with minimal impact on the environment.

Low Exhaust Emissions

The Cat 3056E DIT ATAAC is a low emission engine designed to meet current worldwide emission regulations and is Tier 2 compliant.

Quiet Operation

The engine cooling system allows the engine to be fully enclosed, allowing less engine noise to escape. With the optional sound suppression package, the 930G is even quieter.

Ozone Protection

To help protect the earth's ozone layer, the air conditioning unit uses only R-134a refrigerant which does not contain harmful chlorofluorocarbons (CFC's).

Fewer Leaks and Spills

Engine oil, transmission and hydraulic filters are positioned vertically and are easily removed without spillage. The Cat 3056E is fitted with a Closed Circuit Breather to eliminate valve cover drips. Cat O-ring face seals, XT hose and hydraulic cylinders are all designed to help prevent fluid leaks that can weaken the machine's performance and cause harm to the environment.

Rebuildable Components

All major components are designed for rebuildability.

Biodegradable Hydraulic Oil

Caterpillar biodegradable hydraulic oil can be used, providing an environmentally-sound alternative to mineral-based oils.

Complete Customer Support

Selection

Make detailed comparisons of machines before purchasing. What are the job requirements? What production is needed? What is the true cost of lost production? Your Cat dealer can give you precise answers to these questions. You can also build the machine that is right for you. Go online anytime to review the full range of features and options available using the Build & Quote application on your Cat dealer's website or www.cat.com.

Purchase

Look at the total package. Consider the financing options available through your Cat dealer as well as day-to-day operating costs. Dealer support services can be included in the cost of the machine to yield lower equipment owning and operating costs over the life of the machine.

Operation

For the best operating techniques to increase productivity and your profit, turn to your Cat dealer for the latest training literature and knowledgeable staff.

Maintenance

Choose from a wide range of maintenance services at the time of machine purchase. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S•O•S Oil Analysis and Technical Analysis help avoid unscheduled repairs that can cost unnecessary time and money.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved to make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. Additionally, Caterpillar offers a line of genuine remanufactured components which can help lower repair costs.

www.cat.com

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www.cat.com. Specializing in fast, accurate and up-to-date information, the Cat web site delivers the information you need to operate your business, 24-hours a day.

Data not available.

Standard Equipment

- ELECTRICAL

- Alternator, 80-amp

- Alarm, back-up

- Batteries, maintenance-free, 950 CCA, (2)

- Directional signals (front & rear)

- Starting and charging system, 24V

- Halogen work lights (front & rear)

- Ignition key start/stop switch

- Roading lights

- Starting aid, thermal

- Switch, battery disconnect

- OPERATOR ENVIRONMENT

- Cab, ROPS (sound suppressed and pressurized)

- Gauges: - Engine coolant temperature - Hydraulic oil temperature - Torque converter oil temperature - Fuel level gauge - Speedometer - Digital tachometer - Digital hour meter/odometer - Transmission oil

- Warning indicators: - Primary steering malfunction - Electrical system voltage low - Coolant temperature - Engine oil pressure low - Parking brake applied - Brake charge pressure low - Transmission oil temperature - Transmission oil filter bypass - Hydraulic oil filter bypass

- Adjustable tilt steering column

- Coat hook

- Ground level door release

- Heater/defroster

- Horn, steering wheel mounted (electric)

- Hydraulic control lever lockout

- Interior light

- Interior and exterior auxiliary power sockets

- Lighter

- Lunch box storage with cup holder

- Pilot hydraulic implement controls

- Rear window defroster, electric

- Rear view mirrors (2 inside)

- Seat, adjustable suspension, armrest (fabric or vinyl)

- Seat belt, 75 mm (3 in), retractable

- Tinted safety glass, front

- Tool box

- Two door cab, fixed glass

- Wet arm wiper/washer (front & rear), front intermittent

- POWER TRAIN

- Engine, Caterpillar 3056E DIT ATAAC - Low emission diesel engine - Turbocharged - After cooled - Closed Circuit Breather (CCB) - Electronically controlled engine

- Air cleaner, dry type

- Axle seal guards

- Brakes, enclosed wet-disc full hydraulic

- Differentials, conventional (front/rear)

- Driveshaft, lubed for life

- Engine fuel priming pump

- Engine speed control

- Fuel/water separator

- Muffler

- Radiator, unit serviceable

- S•O•S oil sampling port, engine oil

- S•O•S oil sampling port, transmission oil

- Torque converter

- Transmission, 4F/3R, autoshift, single lever control with F/N/R and kickdown button

- Transmission neutralizer; operator programmable

- HYDRAULICS

- Hydraulic diagnostic connectors

- Hydraulic oil cooler

- Hydraulic control, 2-valve, 1-lever with F/N/R

- Load-sensing steering system

- S•O•Ssm oil sampling port, hydraulic oil

- OTHER STANDARD EQUIPMENT

- Antenna, for radio

- Antifreeze/coolant, extended-life protects to -36°C (-33°F)

- Automatic bucket positioner/fork positioner

- Brakes, secondary and parking

- Counterweight

- Engine enclosure, lockable

- Fenders, front

- Hitch, recovery

- Loader linkage, VersaLink

- Lift kickout, automatic

- Machine Security System ready

- Product Link- World View ready

- Remote grease lines

- Steering stops, cushioned

- Swing-out, hydraulically driven demand fan

- Vandalism protection, lockable service points

- Visual indicators: - air cleaner service - coolant level - hydraulic oil - transmission oil

Optional Equipment

- Radio packages:

- Radio prep installation, 12V, includes speakers, cable, mounting bracket, hardware, converter and accessory plug. Radio not included.

- Radio, AM/FM

- Radio, AM/FM with CD player