Engineered Class Conveyor PulleysNon-Current

Engineered Class Conveyor Pulleys - 2014 - GlobalOverview

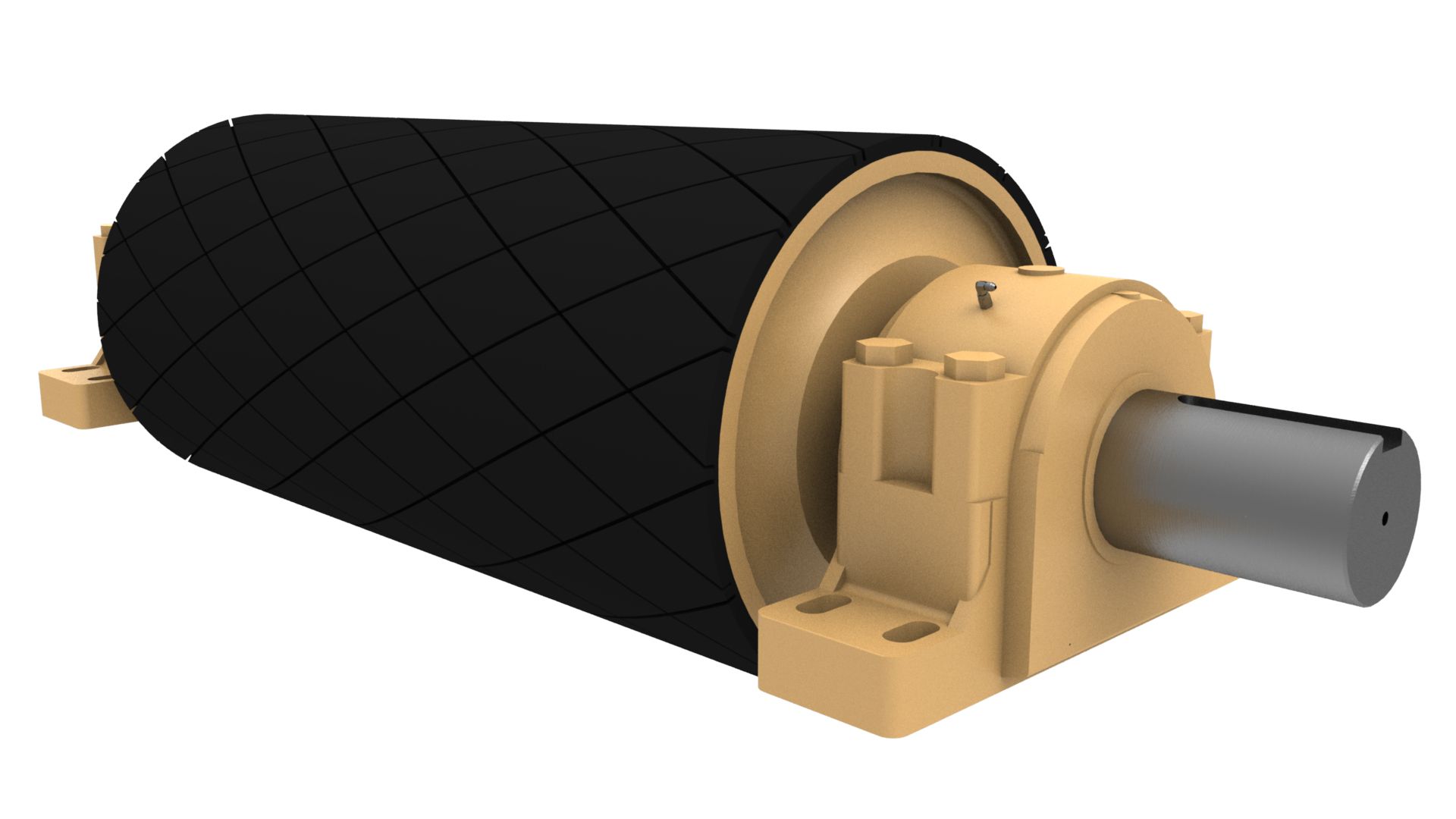

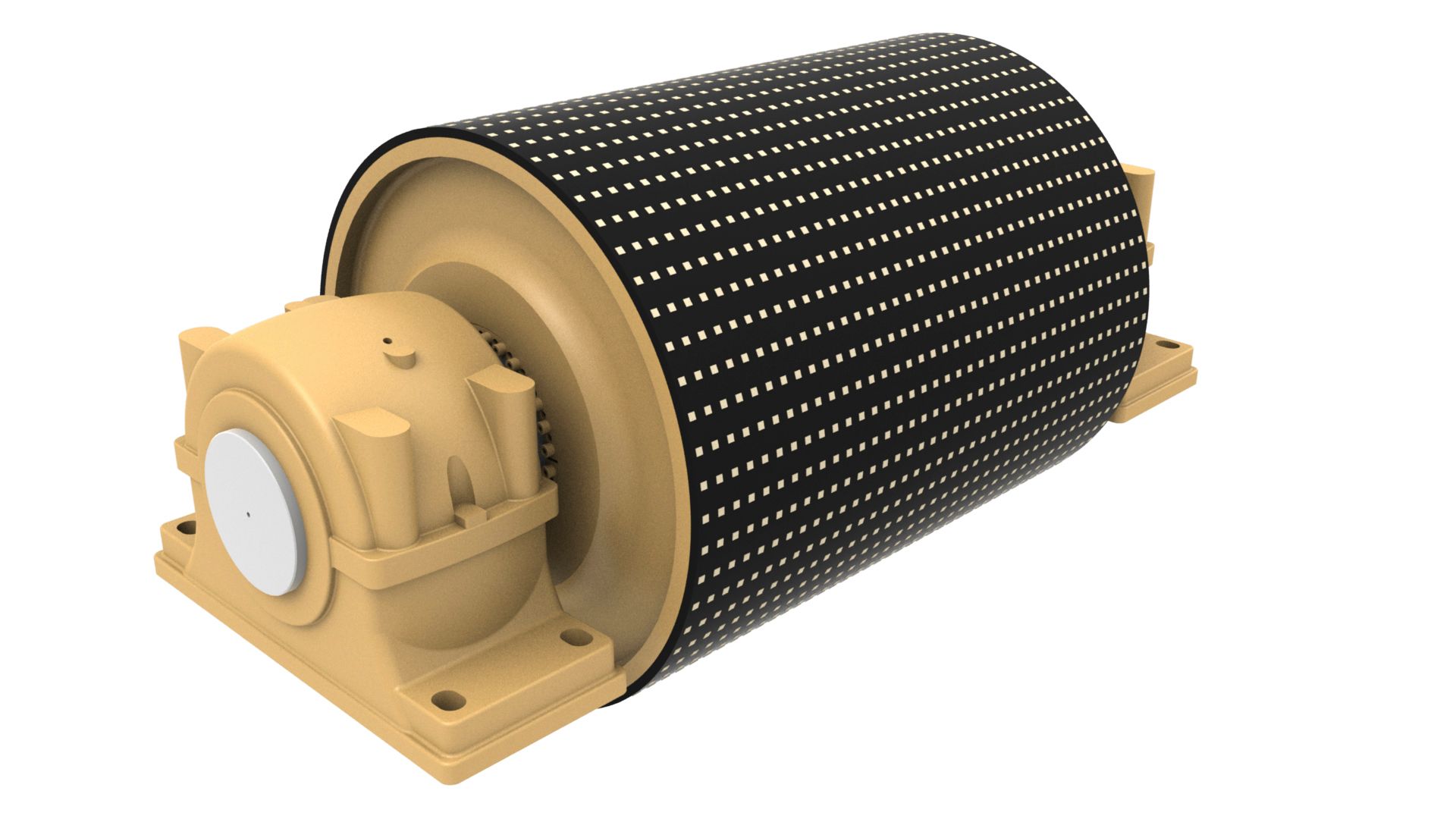

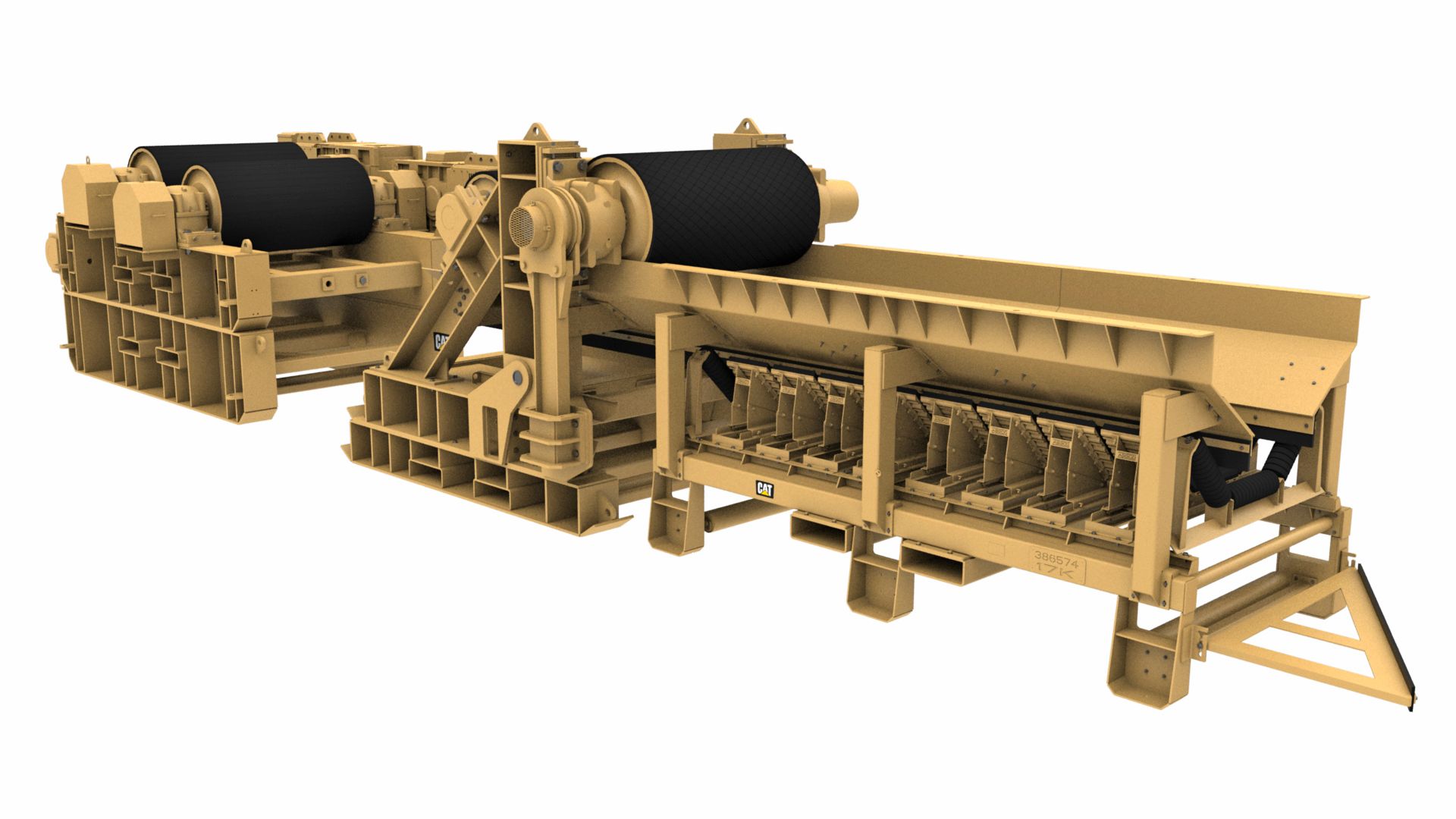

Cat® pulleys are engineered and machined to provide fewer areas of failure and maximum stability. These pulleys have proven their legendary strength and reliability under some of the most severe conditions imaginable. They perform reliably, driving conveyors with installed power in excess of 3728 kW (5,000 hp).

Specifications

Units:

| Belt Width | Up to 2400 mm (96 in) |

| Pulley Specifications | Designed to meet specific tension requirements for any conveyor system |

| Lagging Type | Plain, Diamond Grooved, Ceramic, Spiral |

Benefits & Features

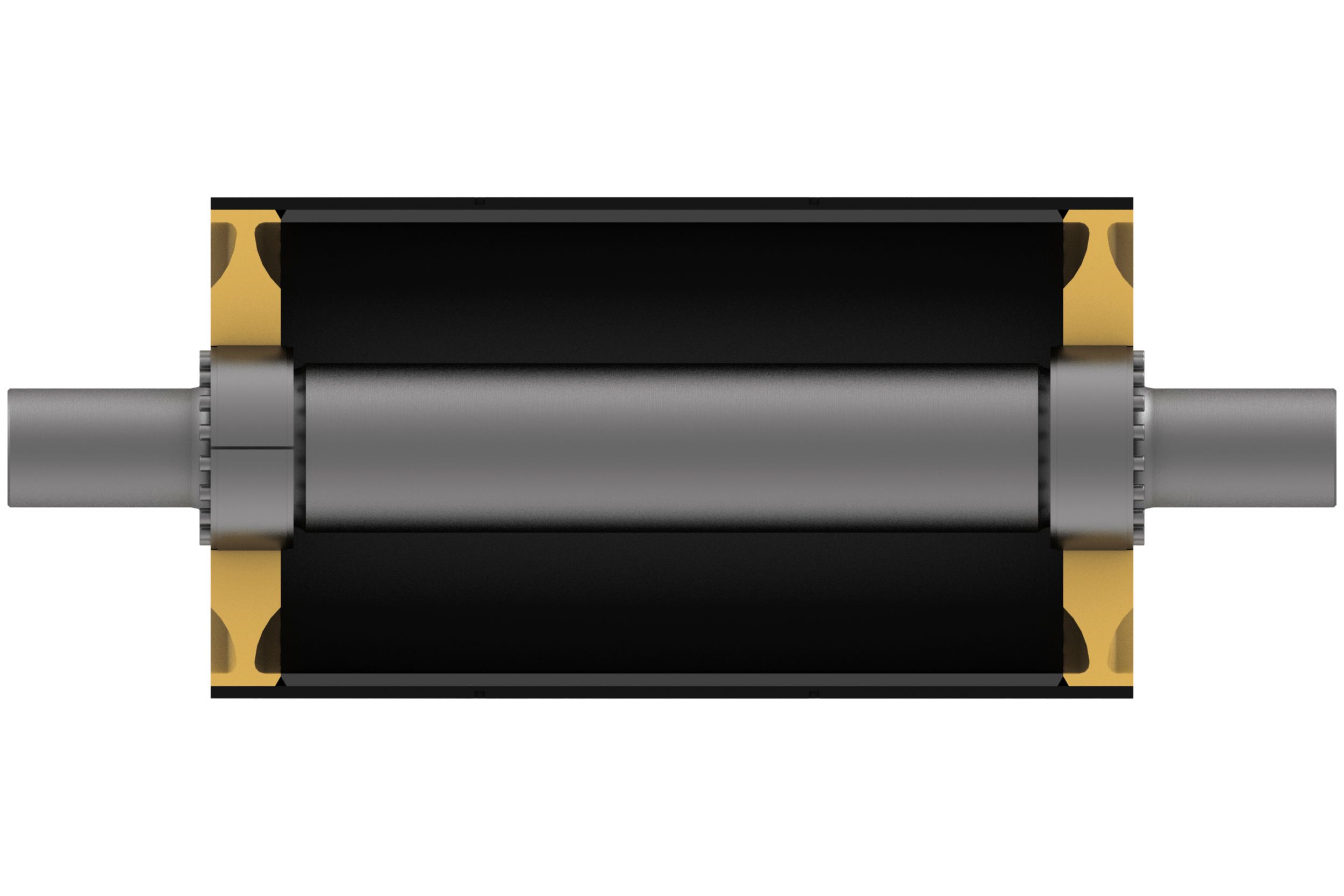

Two Standard Designs: T-Bottom and Turbo-Disc

- For conveyor pulleys, the area most prone to failure is the end-disc, especially where circumferential welds are located.

- By machining the end-disc from solid steel plate and making the hub integral to the end-disc, high stress-concentration welds are minimized.

- In both designs, the end-discs are shaped to ensure optimum distribution of stresses throughout the end-disc and the pulley.

- T-Bottom for T1 Tensions > 53.4 kN (12,000 lbf)

- Turbo-Disc for T1 Tensions < 53.4 kN (12,000 lbf)

Surface and Underground

- Strength and reliability to handle your most severe conditions. Ideal for use in both surface and underground mining applications, Cat Pulleys are designed for high reliability and long life.

- Machined end-discs require fewer welds to provide fewer areas for failure.

- Utilization of keyless locking elements in conjunction with T-Bottom or Turbo-Disc Designs removes ‘Bellows Stress' from each pulley end disc at the shaft.

Specifications

- Surface and Underground Applications

- Designed for each customer's Tension Requirements

- T-Bottom and Turbo-Disc Designs

- Diameters to 1800 mm (72 in)

- Belt Widths to 2400 mm (96 in)

- Installed power to 3728 kW (5,000 hp)

- Rubber Lagging (Plain or Diamond Grooved)

- Ceramic Lagging

- Spiral Lagging

- Mounted Bearings

- Bearings sized for 100,000 hours L10 Life

- Balanced to ISO 194Ø-1 Q4Ø

April 22, 2025

Specifications

Units:

| Belt Width | Up to 2400 mm (96 in) |

| Pulley Specifications | Designed to meet specific tension requirements for any conveyor system |

| Lagging Type | Plain, Diamond Grooved, Ceramic, Spiral |

| Application | Surface and Underground |

| Design Type | T-Bottom and Turbo-Disc |

Benefits & Features

Two Standard Designs: T-Bottom and Turbo-Disc

- For conveyor pulleys, the area most prone to failure is the end-disc, especially where circumferential welds are located.

- By machining the end-disc from solid steel plate and making the hub integral to the end-disc, high stress-concentration welds are minimized.

- In both designs, the end-discs are shaped to ensure optimum distribution of stresses throughout the end-disc and the pulley.

- T-Bottom for T1 Tensions > 53.4 kN (12,000 lbf)

- Turbo-Disc for T1 Tensions < 53.4 kN (12,000 lbf)

Surface and Underground

- Strength and reliability to handle your most severe conditions. Ideal for use in both surface and underground mining applications, Cat Pulleys are designed for high reliability and long life.

- Machined end-discs require fewer welds to provide fewer areas for failure.

- Utilization of keyless locking elements in conjunction with T-Bottom or Turbo-Disc Designs removes ‘Bellows Stress' from each pulley end disc at the shaft.

Specifications

- Surface and Underground Applications

- Designed for each customer's Tension Requirements

- T-Bottom and Turbo-Disc Designs

- Diameters to 1800 mm (72 in)

- Belt Widths to 2400 mm (96 in)

- Installed power to 3728 kW (5,000 hp)

- Rubber Lagging (Plain or Diamond Grooved)

- Ceramic Lagging

- Spiral Lagging

- Mounted Bearings

- Bearings sized for 100,000 hours L10 Life

- Balanced to ISO 194Ø-1 Q4Ø

Data not available.