Engineered Belt Terminal GroupsNon-Current

Engineered Belt Terminal Groups - 2014 - GlobalOverview

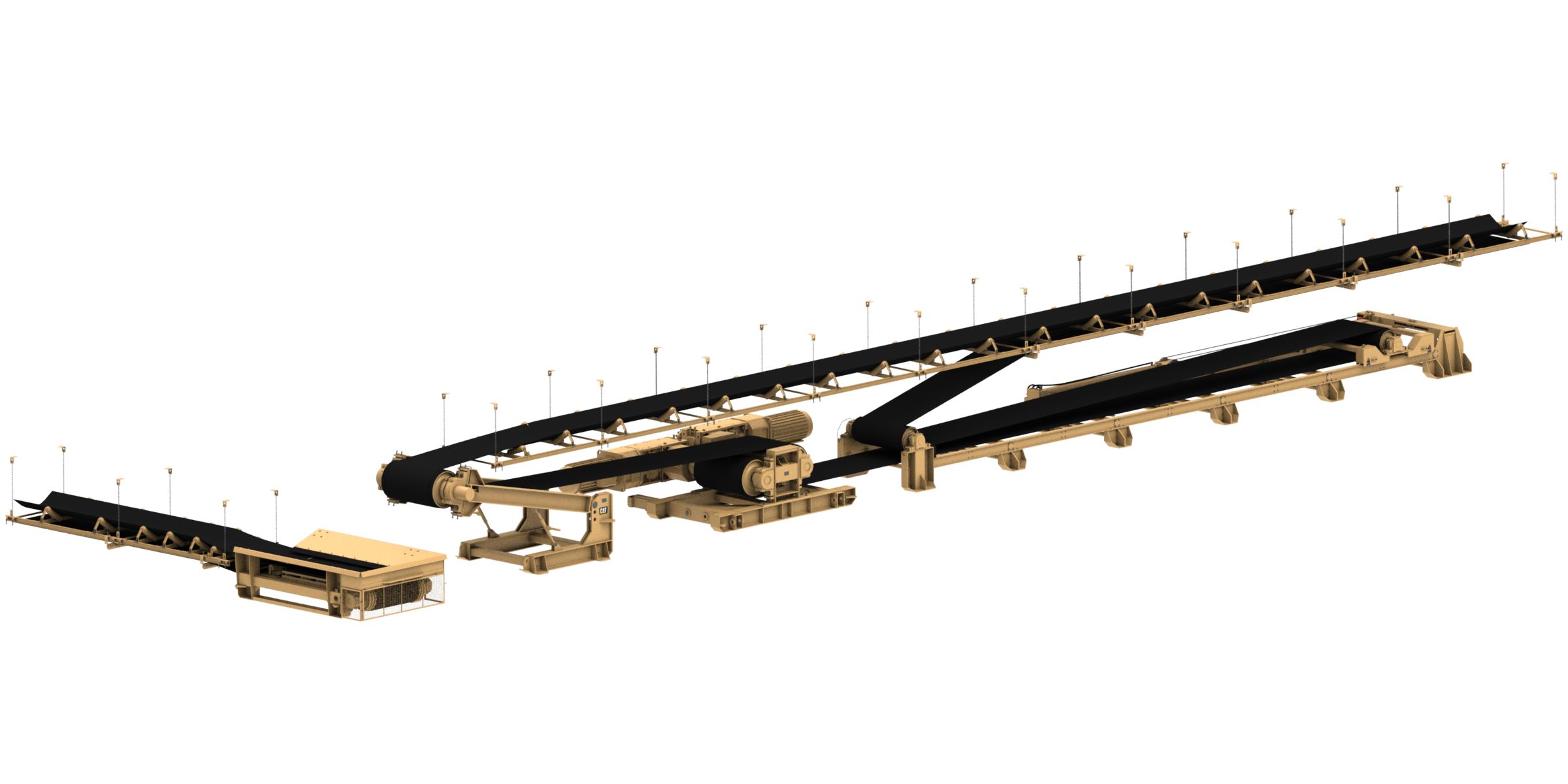

Caterpillar offers custom-designed, heavy-duty engineered conveyor systems solutions and conveyor products to handle the most demanding bulk-material handling requirements in both underground and surface applications. Cat® belt terminal groups are precision engineered to meet each customer's requirements, and experienced technicians are available to supervise the installation and ensure a smooth startup.

Specifications

| Drive Technology | VFD, Fluid Coupling Drives |

| Installed Power - Maximum | — |

| Belt Speed - Maximum | 5.08 m/sec (1,000 ft/min) |

Benefits & Features

Specifications

| Drive Technology | VFD, Fluid Coupling Drives |

| Installed Power - Maximum | — |

| Belt Speed - Maximum | 5.08 m/sec (1,000 ft/min) |

| Belt Width - Maximum | — |

| Capacity - Maximum | 9072 tonne/hr (10,000 ton/hr) |

| Configuration | Right Angle Alignment-free, Parallel Shaft |

| Design | Hydraulic Cylinder, Electric Constant Tension Winch, Gravity |

| Belt Width - Maximum | — |

| Carriage Travel - Maximum | — |

| Belt Width - Maximum | — |

| Design | Remote A-frame, Remote Adjustable Boom |

| Belt Plow | V-plow, Diagonal |

| Design | Tail, Intermediate |

| Belt Width - Maximum | — |

| Belt Width - Maximum | — |

| Design | Electric Constant Tension Winch |

| Belt Storage - Maximum | — |

Benefits & Features

Conveyor Drives

- Alignment free or parallel shaft design options

- Alignment-free design gives the following benefits - Ease of setup and installation - Ease of transportation in and around site - Narrower overall drive width - Universal mounting - left-hand or right-hand mounting - Reduced operating maintenance - Up to 447 kW (600 hp) per motor

- Parallel shaft benefit: accommodates larger motor sizes

- Supports both mechanical and electrical technologies (Fluid Couplings or Variable Frequency Drive [VFD], etc.)

- Engineered class pulleys

Remote Discharges

- Floor-mounted or roof-hung configurations

- Remote A-frame design

- Adjustable boom design

- Designed for multiple transfer points

- Includes engineered class pulley(s)

- Can be used with backstop for uphill applications

- Can incorporate driven discharge pulley

- Can be used with uni-directional transfer chute

Belt Take-Ups/Storage Units

- Cat take-ups/storage units apply accurate and very responsive belt tension

- Various designs available to meet customer needs - Electric winch design - Hydraulic cylinder design - Active travel length/belt storage per design requirements

- Each take-up pulley is a tension-specific, engineered class pulley

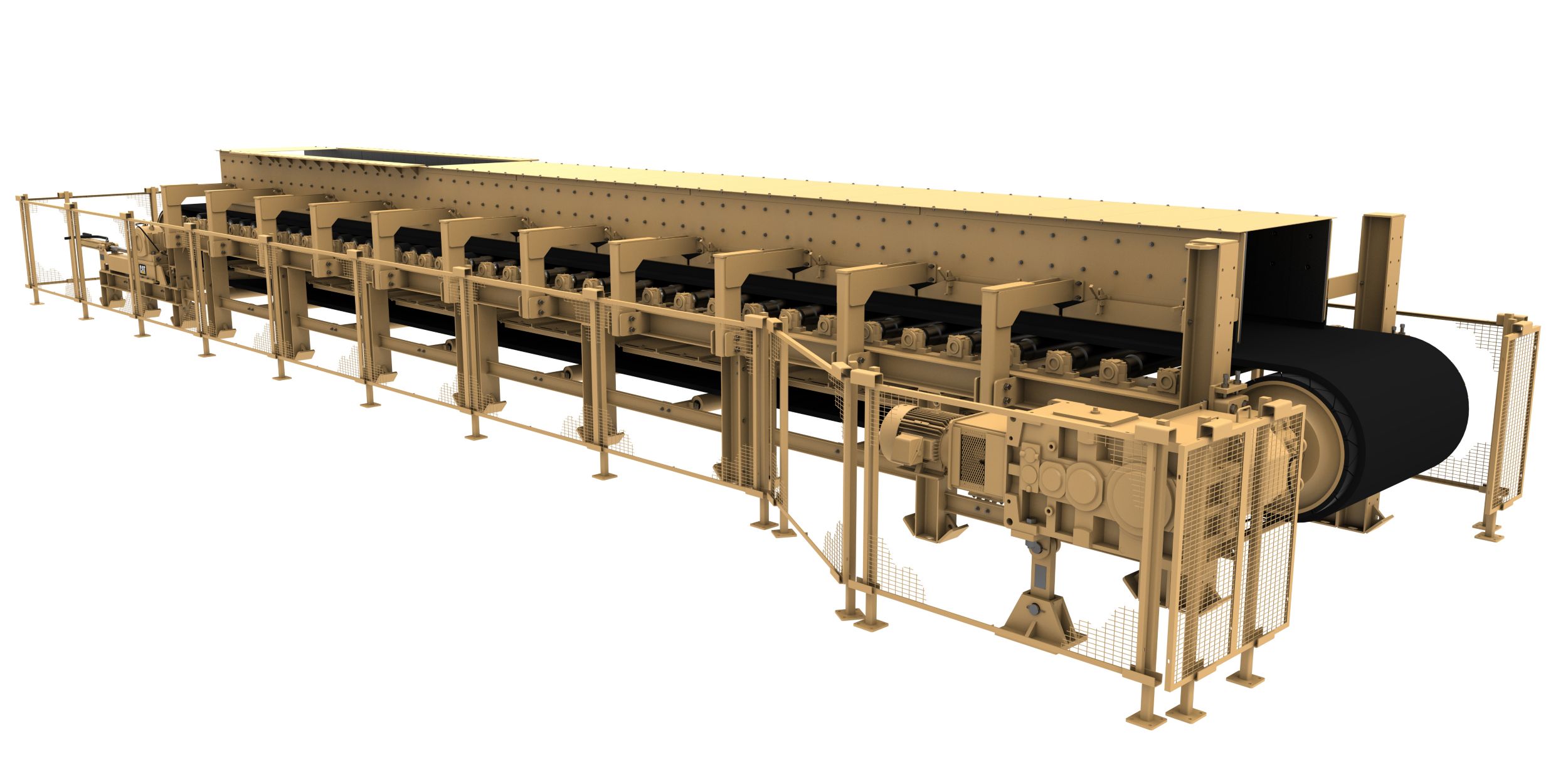

Loading Sections

- Cat loading sections are designed and built for efficient transfer of extracted materials

- Two impact idler designs: in-line and off-set

- Intermediate and tail loading sections offer either impact idlers or impact slider beds

- Rigid, heavy-duty engineered loading frame

Engineered Class Pulleys

- Cat engineered class pulleys are each designed to meet the specific power and tension needs of the conveyor system

- Two design options: Turbo-Disc and T-Bottom

- Design features:

Custom Designed Equipment

Working closely with our customers and dealer teams, Caterpillar engineers are able to provide solutions for whatever your material transportation needs may be. Caterpillar engineering excellence allows for the accommodation of many unique applications. We offer a low cost per ton material transportation solution for various industries, including surface and underground mining, tunneling, construction aggregates, and more.

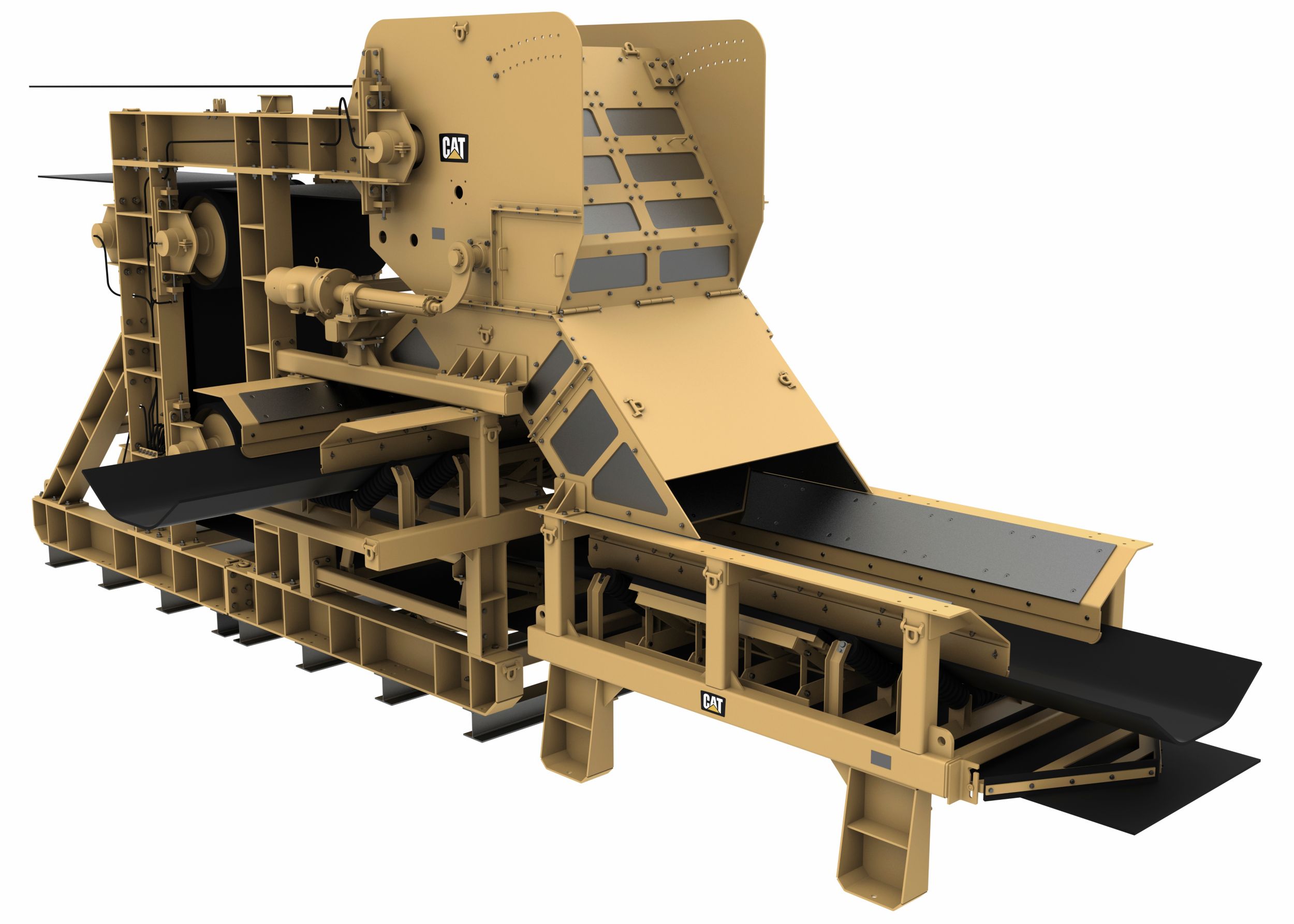

Advanced Tailpiece for TBM (Tunnel Boring Machine) Tunnel System

- Accommodates multiple belt widths and tonnage rates

- Integrated directly to customer or tunnel TBM

Bi-Directional Material Handling Tripper Transfer

- Allows for bi-directional material flow

- PLC controlled for smooth operation with electric, pneumatic, or hydraulic operation

- Can accommodate multiple belt widths and tonnage rates

Material Handling Feeder

- PLC driven allowing for metering and control of belt speed and tonnage rate onto the main belt

- Modular for customer shoot integration

- Can accommodate multiple belt widths and tonnage rates

Data not available.