Surface Rolls, Idlers, and StructureNon-Current

Surface Rolls, Idlers, and Structure - 2012Overview

Caterpillar has a full range of rugged and reliable belt systems and belt products unsurpassed in performance and service life—custom-designed solutions to handle the most demanding bulk material-handling applications.

Benefits & Features

Steel Rolls

Electronic Quality Tracking: An Industry First

Surface Belt Structure Configurations

Specifications

Benefits & Features

Steel Rolls

Our end cap is designed for increased strength and a close fit to the deflector cap. Every roll is equipped with a self-lubricating system. Our automated assembly process includes three separate, metered grease inputs to ensure every roll has plenty of grease for a lifetime of trouble-free operation. The Idler PAL™ bearing cavity design allows for extra lubricant capacity, which is unmatched in the industry and assures that the grease stays in the bearing.

Electronic Quality Tracking: An Industry First

Each roll is test run, ensuring complete grease distribution throughout the bearings and seals. Each shaft end is coded at the time of assembly with the day of the year, production year, and an individual serial number. In addition, automatic data recording of rotational torque, TIR (Total Indicated Runout) and the bearing play of each individual roll is tied to the serial number.

Surface Belt Structure Configurations

The intelligent design and manufacturing technology provide long life, high reliability and superior performance.

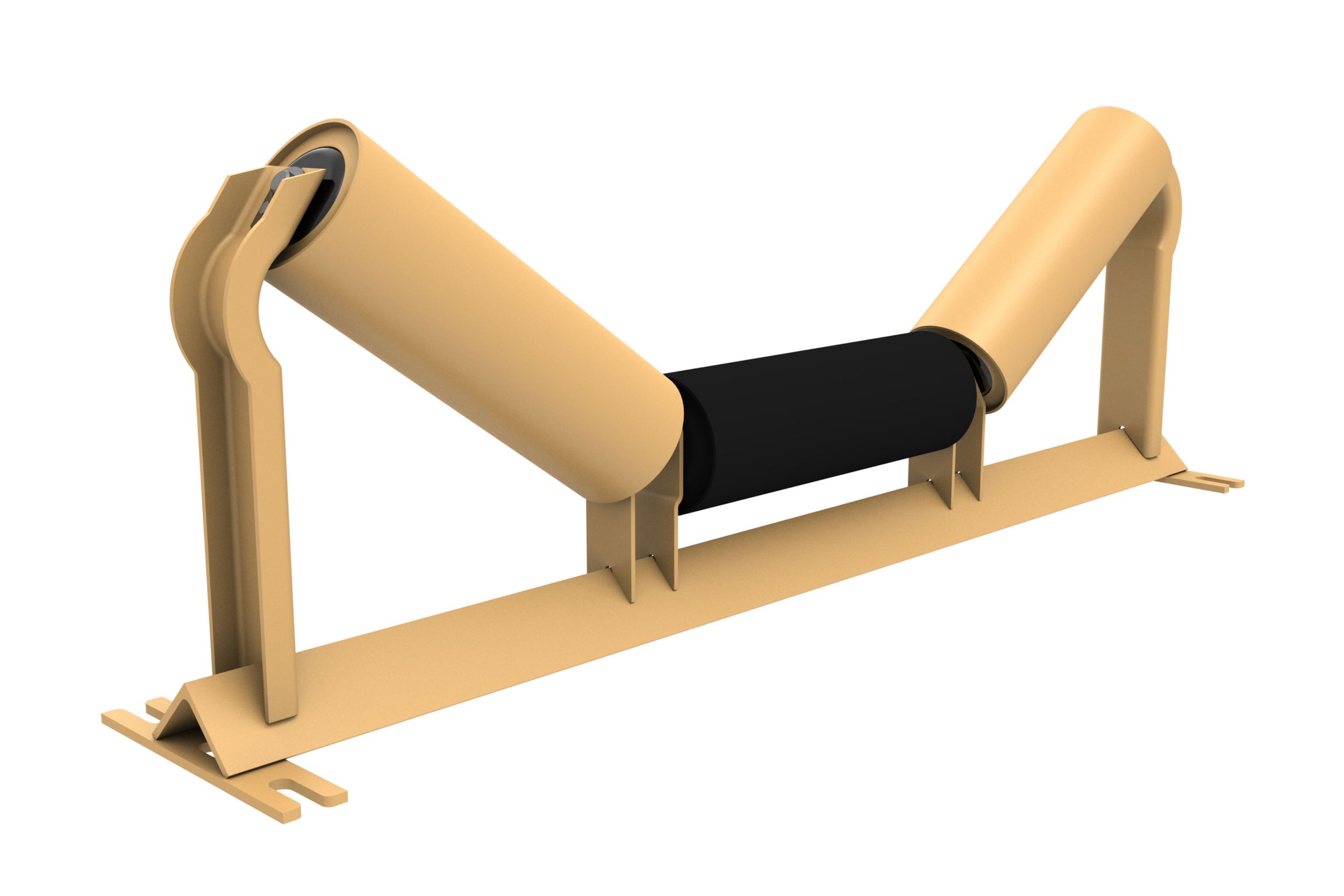

Carrying Idlers

Multiple configurations and roll material options provide maximum flexibility for all surface mining belt conveyors.

Impact Idlers

Roll technology utilizing two-piece tapered roller bearings and a reliable sealing system provides excellent performance in dirty and adverse mining conditions.

Return Idlers

Multiple configurations and roll material options provide maximum flexibility for all surface mining belt conveyors.

Rubber Disc Return Idlers

The utilization of rubber discs provides additional wear capacity to the idler and also protects the conveyor belting in any mining conditions.

Steel Rolls - Surface Applications

- Shell Thicknesses:

- 0.1793"

- 0.25"

- Carrying Assembly Idler Styles:

- In-line

- Single tube cross member

- Belt Widths:

- 24"

- 30"

- 36"

- 42"

- 48"

- 54"

- 60"

- 72"

EXALON® Rolls

Applications with environments that are highly corrosive, abrasive, wet and have a tendency for material buildup are ideal for EXALON® rolls. This roll offers balanced, vibration-free running. Cat EXALON® rolls are tube-based, with higher concentricity further enhanced by final machining (poly-body) for reduced belt wear. These fully conductive rolls are MSHA-certified as safe for underground use. They have two certifications: IC-56/1 - flame-resistant and IC-56/2 - flame-resistant and static dissipating. EXALON® rolls can also be retrofitted into virtually any frame and come in custom sizes.

Data not available.