Belt CleanersNon-Current

Belt Cleaners - 2014 - NACDOverview

Caterpillar can supply virtually any type of Belt Cleaning System to clean a wide range of materials from your belting. Cat Belt Cleaners help extend the life of your conveyor system, comply with local laws and regulations, and keep your operations up and running.

Benefits & Features

Specifications

Benefits & Features

Primary and Secondary Belt Cleaners

Primary and Secondary Belt Cleaners

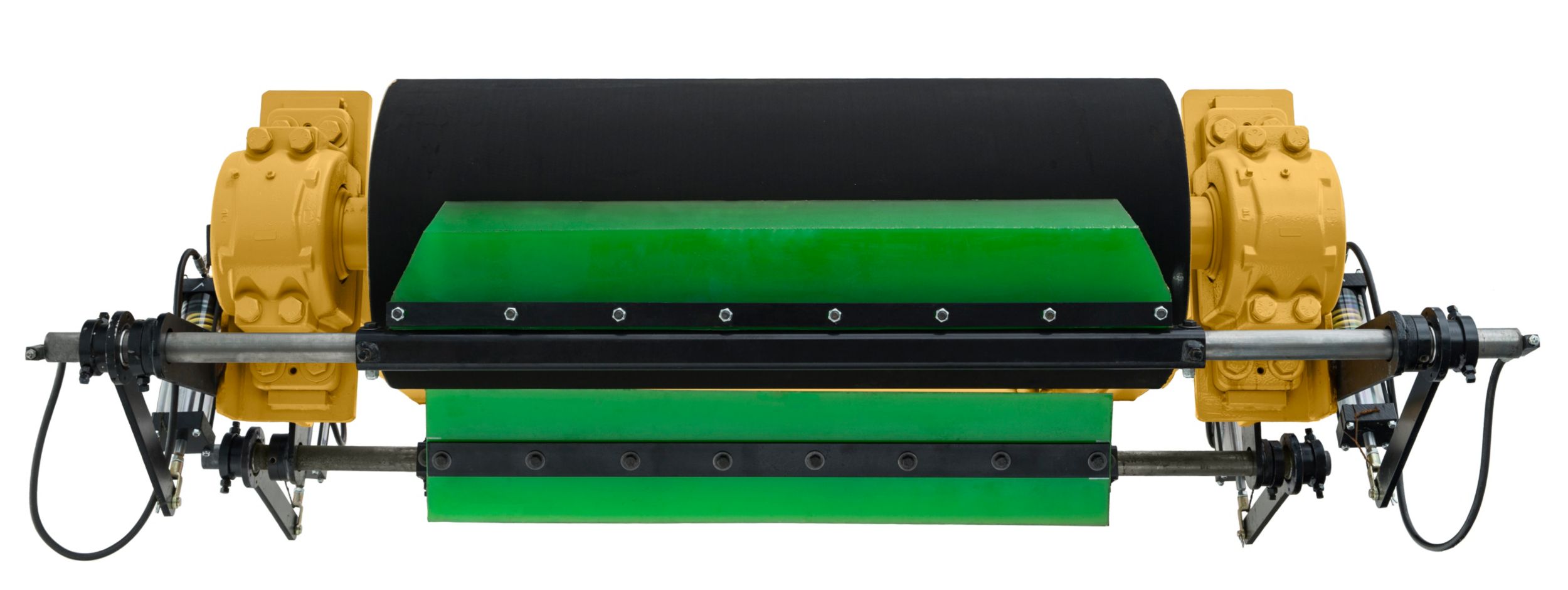

Cat Primary and Secondary Belt Cleaning Systems can be used on any conveyor belt. They work with a variety of applications carrying products such as coal, sand, gravel, junk yard or seaport material. Cat Belt Cleaners come in multiple widths ranging from 457 mm (18 in) through 2133 mm (84 in) to fit a wide range of belt conveyor system applications. Combined, these cleaners will keep your belt free of debris, reduce damage to your belting, and keep your belt running in a safer capacity. Primary Belt Cleaners – Primary Belt Cleaners are installed on the discharge point of your conveyor system. The purpose of the Primary Belt Cleaner is to remove the majority of material that is transferred onto the discharge area. Secondary Cleaners – Secondary Belt Cleaners are installed on the return side of the belt, and are deigned to free the belt from any leftover material that the Primary Belt Cleaner does not remove.

Manufacturing

Caterpillar manufactures Belt Cleaners using urethane materials, which come in a variety of durometers – or hardness. This allows for flexibility by providing the type of material best suited for our customer's applications. Harder applications are manufactured using a tungsten carbine insert which are typically used on vulcanized belting. Cleaners for less abrasive applications are comprised of a softer material, which is common for mechanical spliced belts and wet applications.

Return Plows

V-Plows

Cat V-Plows will move materials to both sides of the belt, allowing unwanted material to be removed from the conveyor. This provides easier and safer access for maintenance teams to clean or remove material which has landed on either side of the conveyor belt. Cat V-Plows are designed so that both sides of the urethane cleaner can be utilized, increasing longevity and decreasing maintenance.

Angle Side Plow

Side Plows will clean and remove material off of the return belt to one side of the conveyor system. Side Plows are ideal for locations with very tight space restrictions, moving material to one side of the belt for clean up.

Impact Beds

Cat Impact Beds absorb pressure from material falling off of the conveyor belt, reducing or even eliminating damage to the belt. Impact beds are used in an area with heavier and larger materials. The impact bed itself is comprised of a soft durometer urethane which is used to cushion impact with 38 mm or 76 mm (1.5 in or 3 in) of Ultra High Molecular Weight (UHMW) for wearing surface.

Moon Sliders

Cat Moon Sliders are available in any transition degree and are designed using an easy three bolt Ultra High Molecular Weight (UHMW) replacement system. With a tubular steel construction and up to 2.5 in (63 mm) of wear surface, the Moon Sliders are typically used for smaller materials being conveyed with a lower density.

Data not available.