6060/6060 FSNon-Current

60606060 FS - 2012Overview

We understand the challenges you face, the importance of reliability, and the relationship between uptime and productivity. That's why we continually strive to produce the safest, most reliable and productive hydraulic mining shovels possible. Offering the widest payload range of any manufacturer in the industry, the ability to optimally pair with our popular line of mining trucks, and the support of our world-class Cat dealer network, we are uniquely positioned to partner with you to help achieve your productivity targets. We understand what matters to you. Our hydraulic mining shovels are built with you in mind. Because in mining, every day matters and every load counts.

Specifications

| Engine Output - SAE J1995 | — |

| Bucket Payload | — |

| Operating Weight | — |

Benefits & Features

Drive System – Balanced Combination of Power and Efficiency

Twin-engine Concept – Stay Up and Running More Consistently

Structures – Designed for the Toughest Conditions

Specifications

| Engine Output - SAE J1995 | — |

| Bucket Payload | — |

| Operating Weight | — |

| Note | Specifications shown above apply to Face Shovel configuration. Backhoe and Frontless configurations are also available. |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing Pumps | — |

| Maximum Pressure - Attachment | — |

| Maximum Oil Flow - Swing Pumps | 4 × 352 L/min (4 × 93 gal/min) |

| Maximum Oil Flow - Main Pumps | 4 × 1300 L/min (4 × 343 gal/min) |

| Swing Pumps | 4 × reversible swash plate pumps |

| Hydraulic Tank Capacity - Approximately | — |

| Total Volume of Hydraulic Oil - Approximately | — |

| Features (1) | Pressure cut-off for main pumps |

| Main Pumps | 4 × swash plate double pumps |

| Filters | – Full-flow high-pressure filters (100 μm) for the main pumps, installed directly behind each pump<br>– High pressure filters (200 μm) for the closed swing circuit<br>– Full-flow filters (10 μm) for the complete return circuit<br>– Pressure filters (40 μm and 6 μm) for servo circuit<br>– Pressure filters (40 μm) for the feed pumps of the closed swing circuit<br>– Transmission oil filters (40 μm) |

| Pump Managing System contains: | – Electronic load limit control<br>– Flow on demand from main pumps depending on joystick position<br>– Automatic regulation of main pumps to zero flow without demand<br>– Automatic rpm reduction of engine speed during working breaks<br>– Reduced oil flow of main pumps at high hydraulic oil temperature or engine temperature |

| Features (2) | Cooling of pump transmission gear oil |

| Features (1) | Cooling system fully independent of all main circuits, i.e. controlled cooling capacity is available whenever engine is running |

| Features (3) | Extremely high cooling efficiency to ensure optimum oil temperature |

| Oil Flow of Cooling Pumps | 4 × 488 L/min (4 × 129 gal/min) |

| Diameter - Fan | 4 × 1170 mm (4 × 46 in) |

| Components | Gear-type cooling pumps supplying high-volume, low-pressure oil to fans and aluminum coolers |

| Features (2) | Fan speed and flow of oil to the coolers are thermostatically controlled |

| Components (11) | Sliding emergency ladder (kick-down type) with ladder cage |

| Components (2) | Under roof mounted heating ventilating and air conditioning system |

| Internal Dimensions of Cab - Width | — |

| Operator's Eye Level - Approximately | — |

| Components (3) | Windshield with parallel intermittent wiper/washer |

| Internal Dimensions of Cab - Length | — |

| Components (6) | Fold-away auxiliary seat with safety belt |

| Components (13) | Roller blinds at all windows |

| Components (1) | Pneumatically cushioned and multi-adjustable comfort seat with lumbar support, safety belt, head and armrests |

| Components (9) | Joystick controls integrated in independently adjustable seat consoles |

| Components (8) | Switch in seat cushion to automatically neutralize the hydraulic controls when operator leaves the seat |

| Components (12) | Machine access via retractable access stairway, stairway angle approximately 45°, hydraulically operated |

| Components (4) | All-round safety glass, armored windshield and sliding side window |

| Internal Dimensions of Cab - Height | — |

| Components (7) | External sun shields at side and rear windows |

| Components (5) | Operator Protective Guard (Top Guard approved according to ISO 10262:1998) |

| Board Control System (BCS III) | Electronic monitoring, data logging and diagnostic system for vital signs and service data of engines, hydraulic system and lubrication system, featuring:<br>– Robust instrument panel including large (12 in) colored touch screen for intuitive handling<br>– On-screen PDF documentation (e.g. operating instructions, technical handbook, spare parts catalog, electric circuit diagram)<br>– On-screen troubleshooting assistance<br>– Graphic charts of logged data<br>– Fault memory with storage of related conditions<br>– USB, Lan (TCP/IP) and CAN BUS interfaces for data export |

| Features (4) | All raceways and the internal gearing of swing ring, supplied by automatic central lubrication system |

| Swing Drive | 4 compact planetary transmissions with axial piston motors |

| Features (2) | Closed-loop swing circuit with torque control |

| Parking Brakes | Wet multiple disc brake, spring loaded/hydraulically released |

| Features (1) | Dirt wipers at swing ring to prevent build-up of debris between swing ring and carbody |

| Swing Ring | Triple-race roller bearing with sealed internal gearing |

| Maximum Swing Speed | — |

| Features (3) | Hydraulic braking of the swing motion by counteracting control |

| Bottom Rollers - Each Side | 7 |

| Maximum Tractive Force | — |

| Gradeability - Travel Drives - Maximum | — |

| Travel Speed - 2nd Stage - Maximum | — |

| Components (1) | All running surfaces of sprockets, idlers, rollers & pad links, as well as teeth contact areas of sprocket & pad links, are hardened |

| Travel Drives - Each Side | 1 planetary transmission with 2 two-stage axial piston motors |

| Track Pads - Each Side | 42 |

| Components (3) | Cast double-grouser combined pad links with bushings connected by hardened full floating pins |

| Support Rollers - Each Side | 2 plus a skid plate in between |

| Components (2) | Acoustic travel alarm |

| Parking Brakes | Wet multiple-disc brake, spring applied/hydraulically released |

| Components (6) | Automatic hydraulic retarder valve to prevent over-speed on downhill travel |

| Travel Speed - 1st Stage - Maximum | — |

| Components (4) | Bottom rollers are connected to the automatic lubrication system |

| Components (5) | Fully hydraulic, self-adjusting track tensioning system with piston accumulator |

| Capacity - Grease Container | — |

| Type (3) | Grease filters (200 μm) between service station and container as well as directly behind grease pump |

| Type (4) | Connected to main lube system are:<br>– pivot points of attachment, bucket and cylinders<br>– bottom rollers of undercarriage |

| Type (5) | Connected to main lube system are:<br>– raceways of swing roller bearing<br>– 2 greasing pinions for the internal gearing of swing ring |

| Type (1) | Dual-circuit system with hydraulically driven heavy-duty pumps and electronic time relay control to adjust the pause/lube times |

| Type (2) | System failures displayed by Board Control System |

| 6060 - Operating Weight | — |

| 6060 FS - Operating Weight | — |

| 6060 FS - Standard Track Pads | — |

| 6060 - Standard Track Pads | — |

| Note | Other track pads available on request. |

| 6060 FS - Ground Pressure | 26.4 N/cm² (38.3 psi) |

| 6060 - Ground Pressure | 26.3 N/cm² (38.1 psi) |

| Installation | Retractable service station installed underneath the engine module and easily accessible from ground. |

| Equipped With (2) | Cat jump-start socket |

| Equipped With (1) | Quick couplings for:<br>– Diesel fuel<br>– Engine coolant – left/right<br>– Pump transmission gear oil – left/right<br>– Engine oil – left/right<br>– Hydraulic oil tank<br>– Grease container |

| Equipped With (3) | Indicator lights for fuel tanks left/right full and grease container full |

| All buckets (FS and BH) are equipped with a wear package consisting of: (2) | – Wing shrouds on side walls<br>– Heel shrouds at bottom edges |

| Type (8) | Special wear packages for highly abrasive materials on request |

| All buckets (FS and BH) are equipped with a wear package consisting of: (1) | – Special liner material covering main wear areas inside and outside of bucket<br>– Lip shrouds between teeth |

| Type (5) | Welding procedures allow for internal counter-welding (double prep weld) wherever possible |

| Type (1) | Catwalks with rails at booms |

| Type (3) | Pressure-free lowering of boom (FS and BH) and stick (FS) by means of a float valve |

| Type (7) | Booms and sticks are torsion-resistant, welded box design of high-tensile steel with massive steel castings at pivot areas |

| Type (6) | Booms and sticks are stress-relieved after welding |

| Shovel attachment with unique TriPower kinematics ensuring the following main features: (3) | – Constant boom momentum throughout the entire lift arc<br>– Crowd force assistance |

| Type (4) | Inspection holes in booms (FS and BH) and stick (FS) |

| Shovel attachment with unique TriPower kinematics ensuring the following main features: (1) | – Automatic roll-back limiter to prevent material spillage<br>– Kinematic assistance to hydraulic forces |

| Type (2) | Guards for shovel cylinders (FS) |

| Shovel attachment with unique TriPower kinematics ensuring the following main features: (2) | – Horizontal Automatic constant-angle bucket guidance<br>– Vertical Automatic constant-angle bucket guidance |

| Displacement | — |

| Emissions | Emit equivalent to U.S. EPA Tier 2 |

| Fuel Tank Capacity | — |

| Components (5) | Hydraulically driven radiator fan with electronically controlled fan speed |

| Components (3) | Heavy-duty air filters |

| Make/Model | 2 × Cat 3512C |

| Stroke | — |

| Components (2) | Two-stage fuel filter including water separator |

| Number of Cylinders - Each Engine | 12 |

| Bore | — |

| Alternators | 2 × 150 A |

| Components (1) | Additional high-capacity water separator |

| Components (4) | Microprocessed engine management |

| Aspiration | Turbocharged and charge air-cooled |

| Rated Speed | 1,800 min-1 (1,800 rpm) |

| Maximum Altitude without Deration | 3500 m (11,500 ft) – above sea level |

| Net Power - ISO 9249 | — |

| Gross Power - SAE J1995 | — |

| Net Power - SAE J1349 | — |

| Engine Model | 2 × Cat® 3512C |

| Gross Power - SAE J1995:2014 | — |

| Net Power - SAE J1349:2011 | — |

| Bucket Capacity - Face Shovel (heaped 2:1) | — |

| Bucket Capacity - Backhoe (heaped 1:1) | — |

| Operating Weight - Face Shovel | — |

| Operating Weight - Backhoe | — |

| Bucket Payload | — |

| Batteries in Series/Parallel Installation | 6 × 210 Ah – 12V each; 630 Ah – 24V in total |

| Components (1) | Battery isolation relays and switches |

| Components (2) | Emergency stop switches accessible from ground level and in engine module |

| Components (4) | 2 LED high-brightness access flood lights |

| System Voltage | 24V |

| Components (5) | 16 LED service lights |

| Components (3) | 12 LED high-brightness working flood lights<br>– 10 for working area<br>– 2 for rear end |

| Feature (8) | Torque control in closed-loop swing circuit |

| Feature (4) | 5-circuit hydraulic system |

| Feature (9) | Automatic central lubrication system |

| Feature (6) | Board Control System (BCS) |

| Feature (1) | TriPower shovel attachment |

| Feature (10) | LED working lights |

| Feature (5) | On-board electronics system: Control and Monitoring Platform (CAMP) |

| Feature (2) | Independent oil-cooling system |

| Feature (7) | Operator Assist (OA) |

| Feature (3) | Spacious walk-through machine house |

Benefits & Features

Drive System – Balanced Combination of Power and Efficiency

Meeting Your Site Specific Needs

Durable and Proven Cat 3512C Engines – Offering unsurpassed performance and durability, Cat 3512C engines have been proven to withstand the challenging conditions found at mine sites across the globe. Delivering high power output, proven reliability, and excellent fuel efficiency, 3512C engines keep your primary loading tool producing, while maintaining a low cost of operation, to keep you profitable.

Twin-engine Concept – Stay Up and Running More Consistently

Keep Producing and Ensure the Safety of Your Operators, Even During Single Engine Loss

You will realize enhanced safety, greater uptime, more productivity, and better serviceability as a result of our twin engine concept.

Enhanced Safety

The ability to move your shovel to a safe area for repair, away from high walls, blast zones, or other safety hazards, is still possible with the use of a single engine.

Greater Uptime and More Productivity

65% of full production can still be achieved with the use of a single engine. This is due to the shovel's continued ability to exert maximum digging forces, to lower the front attachment without requiring engine power (i.e., pressure-free), and to recuperate energy via its closed-loop swing circuit.

Better Serviceability

Troubleshooting is greatly simplified and expedited with the ability to compare one engine versus the other.

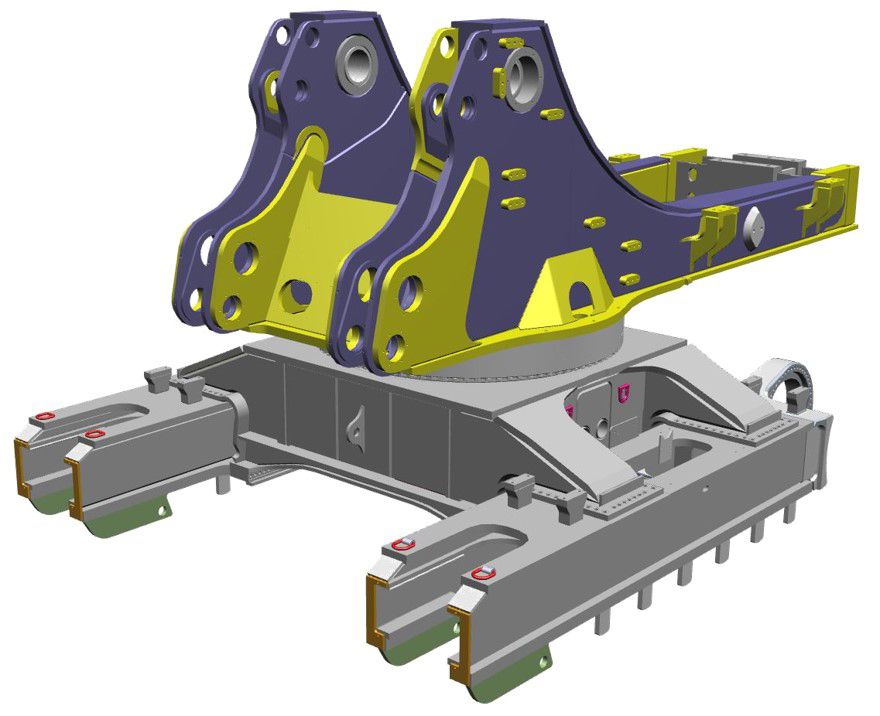

Structures – Designed for the Toughest Conditions

Durable Structures

Based upon state of the art engineering and extensive field testing, redesigned structures translate into maximum life expectancy, durability, and reliability.

Highly durable structures reduce your cost per ton by maximizing uptime and productivity – even in the toughest mining conditions.

Redesigned superstructure frame disperses loads better, especially around the boom foot support area and power module mounts. Increased plate thicknesses contribute to improved performance.

Strengthened undercarriage center frame offers higher structural durability through thicker base plates, carrying the enlarged swing roller bearing.

Front Shovel stick is redesigned in key locations to improve the transition of forces through the structure resulting in longer lifetime, improving your bottom line.

Operator Assist – Attachment Control – Protect Your Largest Asset

Operate your Equipment with Confidence

Cat Operator Assist helps your operator to efficiently utilize the loading tool by improving machine controllability and actively reducing linkage and cylinder mechanical contact, thereby reducing maintenance costs and TCO.

These enhancements allow the operator to confidently load material reducing operator fatigue, improving durability and reliability, all while maximizing the usable linkage range.

System Details

The new calibration procedure will enhance the controllability of the linkage through improved joystick and implement valve calibration.

Furthermore, the Operator Assist (OA) control system will reduce impacts by calculating the linkage position and decelerating the linkage to avoid mechanical contact.

- Contacts reduced by OA:

- Mechanical contacts with linkage stops

- Bucket cylinder end-stroking

- Stick cylinder end-stroking

- Boom cylinder end-stroking

TriPower System – Superior Digging Capability and Bucket Fill Factors

Dig More Effectively with Our Unique TriPower Front Shovel Design

You will experience safer, easier and faster front shovel operation with TriPower, a system proven on over a thousand Cat hydraulic mining shovels worldwide. Generating superior mechanical leverage and control, our FS configured hydraulic mining shovels utilize a unique boom design that employs rotatable triangular rockers. This design facilitates quicker cycle times, increased effective lifting force, constant boom momentum, automatic constant bucket angle, and automatic roll-back limiter.

Quicker Cycle Times

– Faster lifting speeds are achieved, because the design enables the use of smaller-diameter boom cylinders.

Increased Effective Lifting Force

– Design transfers digging forces into the superstructure, creating supporting boom momentum in addition to momentum that is generated hydraulically.

Constant Boom Momentum

– Allows smaller boom cylinders for higher lifting speed.

– Keeps lifting speed constant.

– Enables the shovel to lift a single load along the entire digging distance.

– No retracting of stick cylinders is required, ensuring that all hydraulic pumps are supplying the boom-up function.

Automatic Constant Bucket Angle

– Material spillage is avoided during boom lifting, because the filled bucket automatically maintains a constant bucket angle.

– On conventional kinematics the operator has to control manually the bucket position during lifting which cut in half the available oil flow for the boom cylinders.

Automatic Roll-back Limiter

– Preventing material spillage back on to the operator’s cab and machine superstructure, our system ensures that the bucket is always in a safe position, without operator control/manipulation, when it is at maximum height.

– The boom cylinder continues to receive maximum oil flow, because the operator does not need to activate the bucket cylinder.

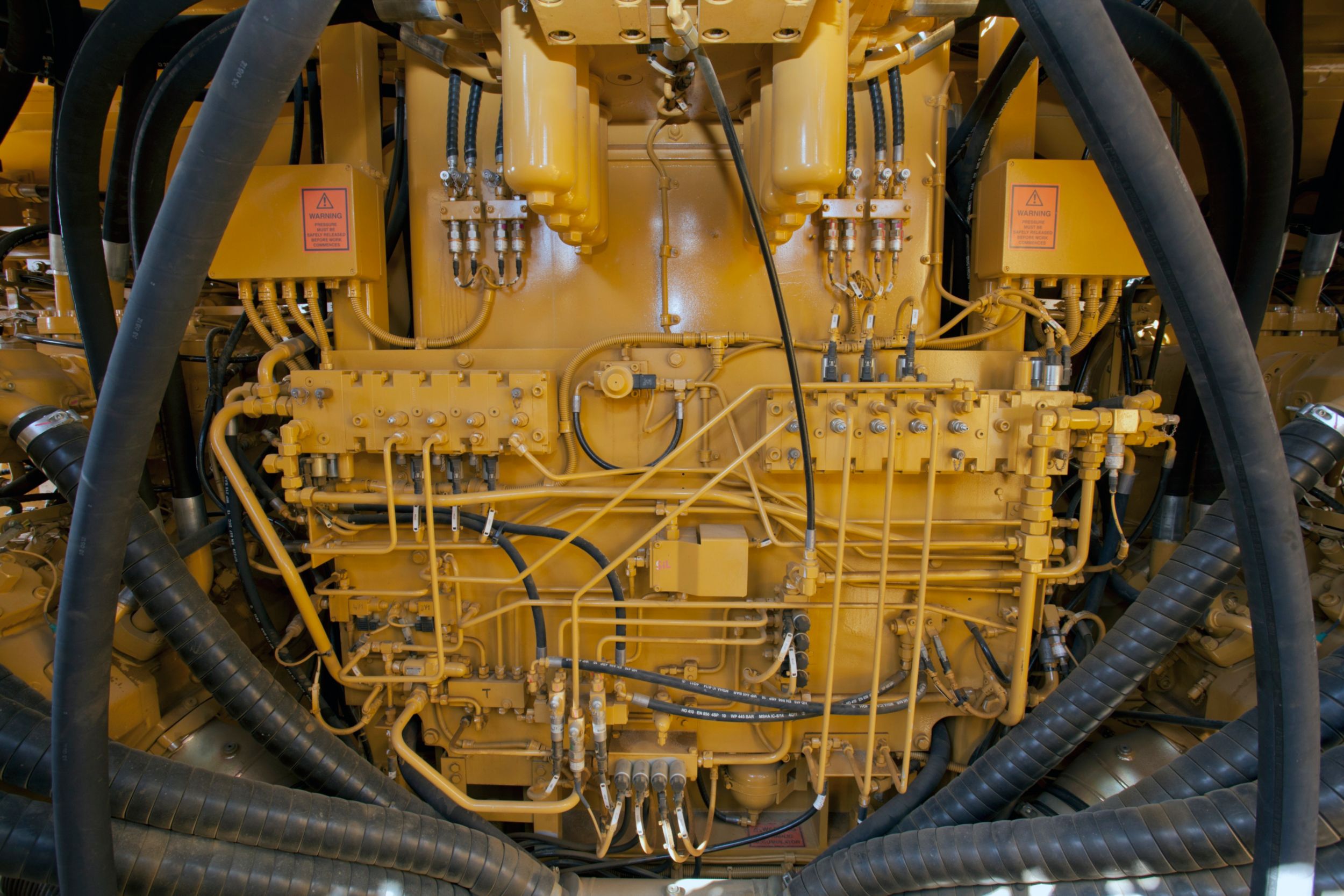

Hydraulic System – Easy Serviceability and Greater Productivity

Straightforward, Safe System Maintenance

Ensuring neat organization for safe operation, easy inspection, and fast service, and reducing the number of hoses needed, the main valve block is located on top of the boom.

Faster Cycle Times

Faster cycle times are realized, because float valves are used to lower the boom instead of engaging pumps. This facilitates faster boom movements and allows other operating functions to occur simultaneously, such as bucket curl and stick in/out.

Greater Control

Your operators will experience greater control with our five circuit hydraulics, allowing for two cylinder motions, two travel motions, and swing to be controlled simultaneously.

Independent Oil Cooling System – More Effective Oil Cooling for Extended Component Life

Protect and Extend the Life of Your Hydraulic Components and Seals

Providing a more efficient means of cooling, particularly in demanding applications, our unique independent oil cooling system will extend the life of your hydraulic mining shovel’s components.

More Efficient Oil Cooling

Our system is independent of return oil, achieving efficiency through the utilization of dedicated pumps that provide cooling capacity as needed, whether the engine is idling or under load. That means optimum oil temperature is being maintained, even while your operator waits for the next truck to load. Competitive hydraulic mining shovels only provide cooling when the machine is working and the engine is under load.

Additional efficiency is achieved via our thermostatically controlled radiator fan speed. The fans do not run until oil temperature exceeds a temperature of 50° C (122° F), saving energy.

Optimal Oil Temperature Maintained

The highly efficient oil cooling system ensures that the oil temperature is only 25° C to 30° C (45° F to 54° F) higher than the ambient temperature. Thus the hydraulic oil working temperature remains within the optimal operating viscosity range of 50° C to 70° C (122° F to 158° F).

Pump Managing System – Enhanced Efficiency, Component Life, and Control Response

Experience Improved Machine Control and Component Life, while Reducing Fuel Consumption and Noise Emission, with Our Intelligent Pump Managing System

Delivering optimal performance, our pump managing system continuously evaluates actual engine and hydraulic operating values against set values, and adjusts pump output accordingly. This results in efficient use of the engine for greater productivity.

- Pump managing system advantages include:

- Best possible utilization of engine output and engine overload avoidance via electronic load limit regulation

- Less energy consumption and less thermal load on hydraulic oil with zero oil flow regulation for main pumps

- Less fuel consumption and lower noise emission via automatic RPM reduction

- Reduced component wear and lower noise emission with automatic oil flow reduction for closing/opening of bucket clam

- Protection of components with automatic oil flow reduction if hydraulic and/or engine coolant temperature exceed set maximum

- Improved operator control response via on-demand pump flow

Closed-loop Swing Circuit – More Efficient Energy Use and Faster Boom Lift Motion During Swing

Load More Material, at Lower Cost, with the Energy Recovery Capability of our Closed-loop Swing System

Delivering faster cycle times and improved energy efficiency, while also generating less heat, our closed-loop swing circuit provides distinct advantages over competitive machines utilizing open-circuit swing systems.

Greater Efficiency Via Energy Recovery

Kinetic energy captured during the swing motion is fed back into the system during deceleration, providing more power to drive the main and auxiliary pumps. Energy is saved during deceleration, because braking occurs via counteracting controls, as opposed to throttles used in open circuit swing systems.

Energy Savings During Acceleration

Energy is saved during acceleration via torque control, providing a pressure balance valve that controls the swing pump against pressure in the closed-loop swing circuit, ensuring that only the minimum necessary oil flow is utilized at any given time.

Faster Cycle Times

Faster boom lift motion during swing is achieved with our closed-loop swing system, increasing overall productivity.

Operator’s Cab – Ensuring the Safety and Comfort of Your Operators

Get Peak Operator Performance with Our Safe and Comfortable Operator's Cab

We understand that the most important factor in your hydraulic shovel's effectiveness is the performance of its operator. To help make their workday as productive as possible, we've incorporated safety and comfort features into the 6060/6060 FS operator's cab.

Protection for Your Operator; Every Day, Every Shift

- Safety glass is used for all cab windows, and armored glass for the windshield.

- Operator’s seat is equipped with integrated safety switch that automatically neutralizes the hydraulic controls when the operator leaves the seat.

- Position of cab module, approximately 7.6 m (24 ft 11 in) high, provides excellent visibility of the digging and loading areas.

- Cab meets Operator Protective Guard standard ISO 10262:1998 (Top Guard).

Supporting Peak Operator Performance with Comfort Features

- Pneumatically cushioned, multi-adjustable operator's seat.

- Large, transflective color touch-screen display (BCS III) provides vital machine monitoring and diagnostic data for convenient troubleshooting and service assistance.

- Enhanced control response and servo adjustment capability via electro-hydraulic servo control.

Electronic Control System – Operate with Confidence

Enhanced Control Response and Optimized Hydraulic Engine Load Management

Help your team meet productivity and performance standards with our intuitive, informative on-board electronics.

Electro-Hydraulic Servo Control – Enhanced Control Response

The system relays actuating signals from the joysticks, delivering fast and precise machine reactions that reduce operator fatigue.

Electro-Hydraulic Servo Control – Increased Uptime

Uptime is increased as a result of simplified troubleshooting and advanced diagnostic capabilities.

Electro-Hydraulic Servo Control – Greater Operator Comfort

Easier setting of servo control characteristics allow operators to adjust to their preference.

Electro-Hydraulic Servo Control – Clean and Quiet Cab Environment

No hydraulic lines are present in the cab or the cab module, ensuring a clean arrangement with less noise emission.

Control and Monitoring Platform (CAMP) – Reduced Control System Inventory

Streamlined system requires only one type of controller for each function (i.e., left side drive train, right side drive train, servo, and auxiliary) reducing the number of required controllers in the system and associated replacement stock.

Control and Monitoring Platform (CAMP) – Less Fuel Consumption

Engine works in optimal range of performance during the entire digging cycle, reducing fuel burn.

Control and Monitoring Platform (CAMP) – Increased Component Life

Reduced hydraulic pulsation lessens stress imposed on the engine and hydraulic components.

Control and Monitoring Platform (CAMP) – Enhanced Operator Comfort

Less vibration and more even machine movement via reduced pressure peaks.

Control and Monitoring Platform (CAMP) – On-screen Documentation

The Parts book, Technical handbook, and Operating handbook, as well as hydraulic and electric schematics, are available in electronic format.

Cat® MineStar™ System and Technology Solutions – Evolving Your Mine for Greater Safety and Productivity

Helping You Enhance Safety and Productivity through Technology

Aimed at enhancing the productivity and profitability of your hydraulic mining shovel, we currently offer a combination of Cat MineStar System offerings and Cat hydraulic mining shovel technology solutions.

Cat MineStar System

Helping you achieve your goals for enhanced mine site safety, improved efficiency, reduced operating costs, and greater profitability, the Cat MineStar System provides the most comprehensive suite of mining technology products in the industry. It consists of a number of configurable capability sets – Fleet, Terrain, Detect, Health, and Command – that allow you to scale the system to your mine site needs. Cat MineStar System helps you manage everything from material tracking to sophisticated real-time fleet management, machine health systems, autonomous equipment, and more.

- The Cat 6060/6060 FS is able to utilize the following Cat MineStar System capability sets:

- Fleet – Fleet provides real-time machine tracking, assignment and productivity management, providing a comprehensive overview of all your asset operations from anywhere in the world.

- Terrain – Terrain enables high-precision management of drilling, dragline, grading and loading operations through the use of guidance technology. It increases machine productivity and provides you real-time feedback for improved efficiency.

- Detect – Detect helps increase operator awareness, enhancing safety at your operation. It includes a range of capabilities designed to assist the operator, including blind spot and proximity detection of fixed and mobile equipment.

- Health – Health delivers critical event-based machine condition and operating data for your entire fleet. It includes comprehensive equipment health and asset monitoring capabilities, with a wide range of diagnostic, analytic and reporting tools.

Hydraulic Mining Shovel Technology Solutions – Monitoring and Diagnostic System

Enhancing diagnostic capabilities and providing detailed troubleshooting functions, our Board Control System uses sensors throughout the machine to monitor operating data, record faults, and notify the operator audibly and visually. This promotes the earliest possible detection of faults and allows for timely maintenance planning and assistance for speedy repair.

Loading/Hauling Efficiency – Move More Material with Optimal Pass Match Pairings

Achieve Targeted Loading/Hauling Production with Perfectly Paired Cat Hydraulic Mining Shovels and Mining Trucks

For full truck payloads with minimum loading time, an efficient loading/hauling system begins with an optimized equipment match. Cat hydraulic mining shovels are matched with Cat mining trucks to maximize volume of material moved at the lowest operating cost per ton.

Front Attachment – Bolstering Your Investment with Robust and Durable Structures

Rugged Front Attachment Options Designed and Fabricated to Withstand Your Extreme Mining Conditions

To extend service life and ensure that your shovel keeps producing, our front shovel attachment structures are designed for durability and dependability. Extended performance in the harsh mining conditions you face daily is accomplished through selection of high-strength steels and rugged castings, joined and thermally stress-relieved, to help you achieve your productivity targets.

Front Attachment Structures Include:

- Heavy castings at all pivot points

- Better flow of forces and less welding seams, as top chords are made of one bend plate

- Entire boom and stick are stress-relieved after welding

- Welding procedures allow for internal welding (double prep weld)

Swing System – Longer Component Life for Better Swing System Reliability

More Reliable Swing Component Life

Extending component life and ultimately improving machine uptime, our swing system includes a triple-race swing roller bearing with internal gearing connected to an automatic lubrication system.

For added reliability, all lube lines are located inside the roller bearing for maximum protection.

Service Friendly

Easier maintenance is afforded by the free accessibility of swing gears and rotary distributor.

Undercarriage – Tough and Long-lasting

Less Wear and Tear on Crawler Components

With the three batch updates Caterpillar introduces an all new Cat Heavy Duty undercarriage for the 6060 Hydraulic Mining Shovel.

Key Features of the Cat 6060 Heavy Duty Undercarriage

- Designed for high-travel applications.

– Significant tramming range increases without over-heating will improve productivity and lower operating costs.

– Eliminates complex central lubrication system with a maintenance free, oil filled, sealed-for-life design. - Cat exclusive sealed for life roller and idler system minimizes operating temperatures with reliable sealing and maximum roller and idler life.

– Cat Duo-Cone™ Seals help ensure lifetime lubrication to extend life.

– Cat HD tracks are through hardened for long wear life, unmatched structural support, and resistance to deformation. - With over 100 years of undercarriage innovation, you can count on Cat undercarriage parts to get the job done.

– Caterpillar manufactured and quality tested to ensure productivity and performance.

Safety – Designed with Your Safety as Our Top Priority

Sharing your commitment to safety, and driven by our commitment to Zero Harm, we work tirelessly to design the safest machines possible to protect your most important asset; your employees. That is why we updated the design of the 6060/6060 FS in accordance with the principles of MDG 41 and 15, and offer this standard, not as an option or upgrade.

Some examples of the safety-enhancing features of the Cat 6060/6060 FS hydraulic mining shovel include the following:

Machine Access

- All stairways have 45° angle for safe and comfortable access and movement about the machine.

- Slide down emergency egress ladder directly adjacent to the operator’s cab.

- Hydraulically operated boarding ladder with emergency lowering via nitrogen accumulator ensures that ladder remains operational even when engines shut off.

- Machine swing and propel capability is switched-off when ladder is in down position.

Service and Maintenance

- Improved routing and clamping of hydraulic hoses.

- Hydraulic hoses and electrical wiring are separated from each other for fire prevention.

- All service areas are accessible via anti-slip walkways, and trip hazards are minimized.

- All hot surfaces are covered to prevent burns.

Electrical System

- Cabinet with battery isolation switch, mounted on top deck directly above the battery box, allows quick and easy shut-off of voltage on the entire shovel.

- Cabinet contains a starter isolator which allows on-board voltage, but prevents starting of engines.

Emergency Shut-offs

- An easily accessible, standard shut-off switch located in the cab shuts down the electrical system in case of emergencies.

- Additional shut-off switches are located on the machine, in the machine house or accessible from the ground with pull ropes.

Precise Bucket Control

- Minimizing the potential for material spill on to the attachment or cab, the TriPower automatic roll-back limiter prevents the bucket from being curled back too far.

Serviceability – Designed to Get You Back to Work Fast

Lowering your operating costs and maximizing your hydraulic mining shovel's uptime and productivity is of supreme importance to us. To that end, we've made vital components more accessible and designed simpler systems to make maintenance activities quicker and easier.

Open, Spacious Access to Components

- Facilitating easier maintenance, exceptional accessibility is provided to systems like the swing motor, swing gearbox and rotary distributor in the well organized superstructure. The engine is accessible from both sides.

- Easily accessed by walkways on both sides, the boom-mounted main valve block, a feature unique to Cat hydraulic mining shovels, provides a clean layout and reduces the number of hoses leading from the superstructure to the attachment.

Simple Hydraulic System with Main Valve Block Positioned on Boom

- Ensuring neat organization for safe operation, easy inspection and fast service, the design of our hydraulic system significantly reduces the total number of frequently moving hoses from the superstructure to the attachment.

- Longer hose life via improved routing in accordance with MDG design standards.

Easy Ground-level Fuel and Fluid Replenishment

- Quick fuel and fluid replenishment is made easy with a retractable service station underneath the engine module, accessible at ground-level.

Improved Drive Train Troubleshooting

- Twin-engine design facilitates troubleshooting of drive trains, as one engine can be compared to the other.

Customer Support – Stay Up and Running with Service and Support from Our Unmatched Global Network

Commitment Makes the Difference

Cat dealers offer a wide range of solutions, services and products that help you lower costs, enhance productivity and manage your operation more efficiently. From the time you select a piece of Cat equipment until the day you trade or sell it, the support you get from your Cat dealer makes the difference.

Dealer Capability

Cat dealers provide the level of support you need, on a global scale. Dealer expert technicians have the knowledge, experience, training and tooling necessary to handle your repair and maintenance needs, when and where you need them.

Product Support

When Cat products reach the field, they are supported by a worldwide network of parts distribution facilities, dealer service centers and technical training facilities to keep your equipment up and running.

Cat customers rely on prompt, dependable parts availability through our global dealer network, ready to meet your needs 24/7.

Service Support

- Every piece of Cat equipment is designed and built to provide maximum productivity and operating economy throughout its working life. Cat dealers offer a wide range of service plans that will maximize uptime and return on your investment, including:

- Preventive Maintenance Programs

- Diagnostic Programs, such as Scheduled Oil Sampling and Technical Analysis

- Rebuild and Reman Option

- Customer Support Agreements

Application Awareness

Operating and maintenance costs are influenced by many application and site-specific factors, such as: material density and fragmentation, payload, bench height, truck positioning, ground conditions, amount of traveling and maintenance. Your Cat dealer can provide you with an understanding of the effects application characteristics and operating techniques have on maintenance and operating costs.

Operation

Your Cat dealer can arrange training programs to help operators improve productivity, decrease downtime, reduce operating costs and enhance safety.

Data not available.

Optional Equipment

- GENERAL

- Custom paint

- SUPERSTRUCTURE

- Hydraulic service crane on superstructure with auxiliary engine

- Oil change interval extension for engine oil up to 500 hours

- Two round containers for two standard 200 L (53 gal) barrels (instead of 1000 L (264 gal) grease container)

- Various cold-weather options

- CAB

- Dual (redundancy) heating ventilating and air conditioning system

- Cab heating

- Camera monitoring system

- UNDERCARRIAGE

- Track pad width 1600 mm (5 ft 3 in) or 1800 mm (5 ft 11 in)

- Cover plate under carbody (belly plate)

- Additional optional equipment available on request.