Overview

Originally designed by a road contractor for the construction industry, the Cat® TS185 Towed Scraper delivers outstanding performance and legendary durability. High-strength, abrasion-resistant steel in the scraper bowl minimizes wear. The rugged hitch, tongue, and structural design ensure long life in the toughest job site conditions. The exclusive walking-beam axle provides a smoother ride for the operator and a variable cutting edge angle for unmatched productivity. Designed to be pulled by Cat Track-Type Tractors or Challenger™ Tractors, the Cat TS185 Towed Scraper raises the standard.

Specifications

| Scraper Capacity - Heaped | — |

| Capacity - Struck | — |

| Rated Load | — |

Benefits & Features

Specifications

| Scraper Capacity - Heaped | — |

| Capacity - Struck | — |

| Rated Load | — |

| Width - Cut - To Router Bits | — |

| Depth of Cut - Maximum | — |

| Ground Clearance - Maximum | — |

| Cutting Edge Thickness | — |

| Depth of Spread - Maximum | — |

| Apron Opening | — |

| Hydraulic Services Required - Single Scraper | 3 |

| Hydraulic Services Required - Tandem Scraper | 6 |

| Steel Track-Type Tractor - Single Scraper | D8 |

| Steel Track-Type Tractor - Tandem Scrapers | D9 |

| Rubber Tracked Ag Tractor - Single Scraper | 298 - 373 kW (400 - 500 hp) |

| Rubber Tracked Ag Tractor - Tandem Scrapers | 373 - 447 kW (500 - 600 hp) |

| Rubber Tired Ag Tractor - Single Scraper | 298 - 373 kW (400 - 500 hp) |

| Rubber Tired Ag Tractor - Tandem Scrapers | 373 - 447 kW (500 - 600 hp) |

| Front Bowl Cylinder Bore | — |

| Front Bowl Cylinder Stroke | — |

| Rear Bowl Cylinder Bore | — |

| Rear Bowl Cylinder Stroke | — |

| Apron Cylinder Bore | — |

| Apron Cylinder Stroke | — |

| Ejector Cylinder Bore | — |

| Ejector Cylinder Stroke | — |

| Empty Weight | — |

| Distribution, Empty - Tongue | — |

| Distribution, Empty - Axle | — |

| Distribution, Loaded - Tongue | — |

| Distribution, Loaded - Axle | — |

| Tires - Quantity | 4 |

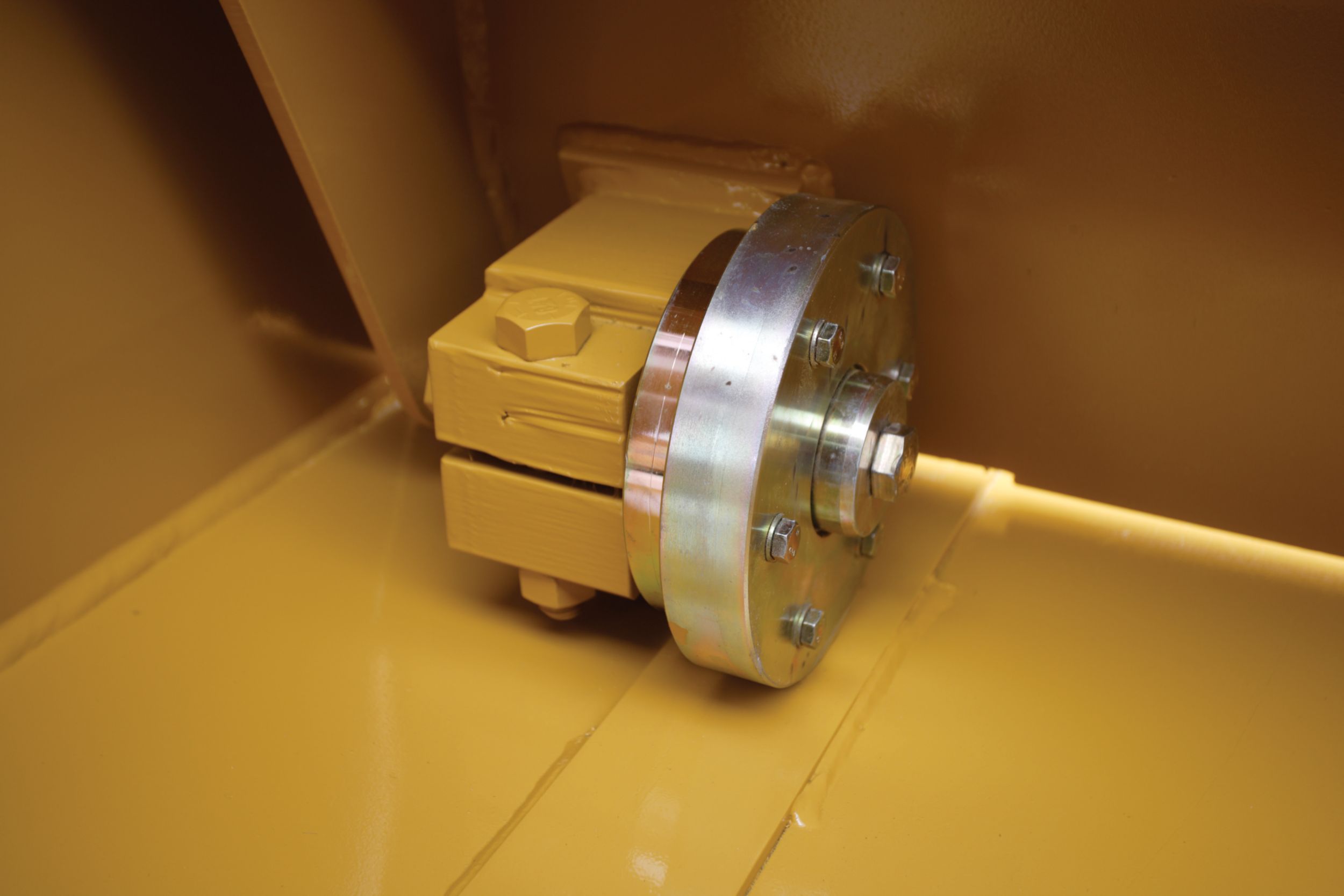

| Brake Type | Dry-Disc |

| Calipers, Lead - Quantity | 2 per side |

| Calipers, Trail - Quantity | 1 per side |

| Tire - Standard | 23.5R25 |

| Tire - Optional | 26.5R25 |

| Width - Inside of Bowl | — |

| Width - Outside Rear Tires | — |

| Width - Outside Bowl | — |

| Height - Overall Shipping | — |

| Height - Floor to top of Ejector | — |

| Height - Sidewall | — |

| Height - Ground to Cutting Edge - Maximum | — |

| Length - Maximum | — |

| Length - Floor | — |

Benefits & Features

Scraper Bowl

High-Strength Bowl Design

The scraper bowl is constructed using L-shaped box sections of high strength steel for superior strength and dent resistance. The floor is a box-section structure made from high-strength, abrasion-resistant steel for maximum strength during top loading and rigidity during intermittent push loading. High-strength, abrasion-resistant steel is used throughout the inside of the bowl for maximum wear resistance.

Center Lift Design

The center lift design improves the strength and durability by placing the hydraulic cylinders between the tongue and spreader tube. This eliminates the need for draft arms, reducing weight and complexity.

Cutting Edges

Common Cat® Wheel Tractor-Scraper cutting edges and router bits are used to ensure exceptional performance and great availability. The center cutting edge is in the stinger(drop down) position for good penetration and efficient material flow into the bowl. When worn, the cutting edges can be rotated by 180 degrees, doubling the life.

Ejector

The ejector is constructed from a single plate of high-strength, abrasion-resistant steel. The ejector extends beyond the front edge of the scraper floor to minimize carryback. To minimize wear, the ejector weight is carried on steel rollers supported by a wear strip welded to the bowl floor. At the sides, alignment is maintained by Ultra High Molecular Weight (UHMW) plastic guides.

Depth Indicator

A depth indicator is mounted on trailing scrapers to provide the operator a visual reference to scraper cut depth.

Tongue and Hitch

Hitches for Cat® Tractors

Robust hitches are available for Cat Track-Type Tractors and Challenger™ MTS800/MTS900 Series Tractors. See your Cat dealer for hitches for other pulling machines.

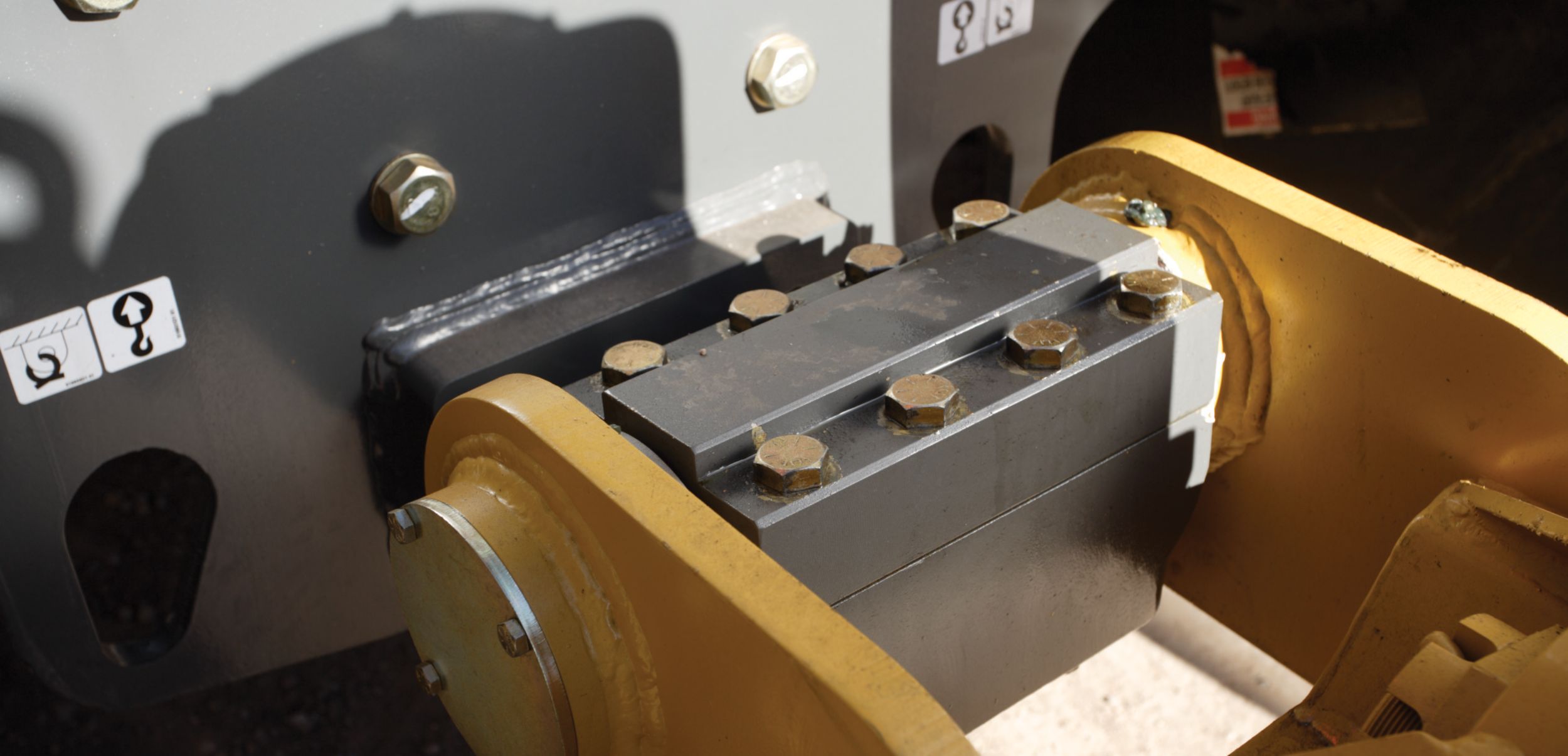

Rugged Hitch

To prevent pin wear, the hitch uses a massive 89 mm (3.5 in) pin securely held in place with eight bolts. The hitch platform, positioned between the pulling machine and the tongue, contains two pins that allow ± 45 degrees of side to side oscillation (or roll), ± 90 degree turns (yaw), and ± 27 degrees of uphill/downhill movement (pitch). An integrated stop block allows a 90 degree turning radius while preventing contact between the tongue and the pulling machine tires/tracks. An adapter is available to convert the scraper hitch for pulling drawn implements, such as disk harrows and sheepfoot compactor rollers.

Robust, Straight-Line Design

Built from 13 mm (0.5 inch) structural plate steel, the tongue is built to withstand the high drawbar forces imposed by track-type tractors pulling towed scrapers. The straight-line design eliminates draft arms, hydraulic cylinders, and lines located outside the width of the bowl, improving the overall strength to most effectively transfer the drawbar power to the cutting edges.

Countersunk Tandem Hitch

A countersunk hitch is provided in the push block of lead scrapers, allowing the scraper to be push loaded when a second scraper is not used.

Hydraulics

Hose and Couplings

Cat XT™-3 ES (Enhanced Spiral) hose is used because its exclusive cover is formulated and manufactured by Caterpillar to provide up to 20 times more abrasion resistance than industry-standard hose. Cat XT-3 ES hose works at half of the SAE's bend radius without sacrificing cold flex capability. As additional protection all exposed hydraulic lines are solidly secured with rubber-lined clamps, protecting the hoses from failure caused by rubbing. All hydraulic hose and lines use O-Ring Face Seal (ORFS) fittings for maximum leak prevention.

Steel Hydraulic Lines in Scraper Bowl Walls

Brake lines and hydraulic lines for the rear scraper in tandem arrangements use steel lines inside the scraper bowl walls, eliminating hose damage caused by material in the bowl or during top loading.

Hose Fittings

- Three hose fitting options are available:

- 19 mm (3/4 in) poppet-styl

- 13 mm (1/2 in) poppet-styl

- Threaded flat-face connectors

Attachments

Rubber Track Guides

Rubber Track Guides for Challenger MTS800 Series Tractors center the rubber tracks on roller wheels, and help prevent the track from moving into the machine or detracking, avoiding expensive downtime. The track guides extend the service life of the belt as the side-loading on the belt guide blocks is reduced. Detracking is generally caused by sharp turns, usually under load. The rubber track guides can minimize tractor damage caused by detracking, but are not a replacement for sound operating techniques. Your Cat Dealer can provide training in proper towed scraper operation.

Hydraulic Hose Hanging Tower Kit

The hydraulic hose hanging tower kit for Challenger MTS800 and MTS900 Series Tractors allows the hoses to move freely and eliminate entanglement while maintaining vertical alignment. This reduces hose fitting and valve wear for increased service life.

Innovation

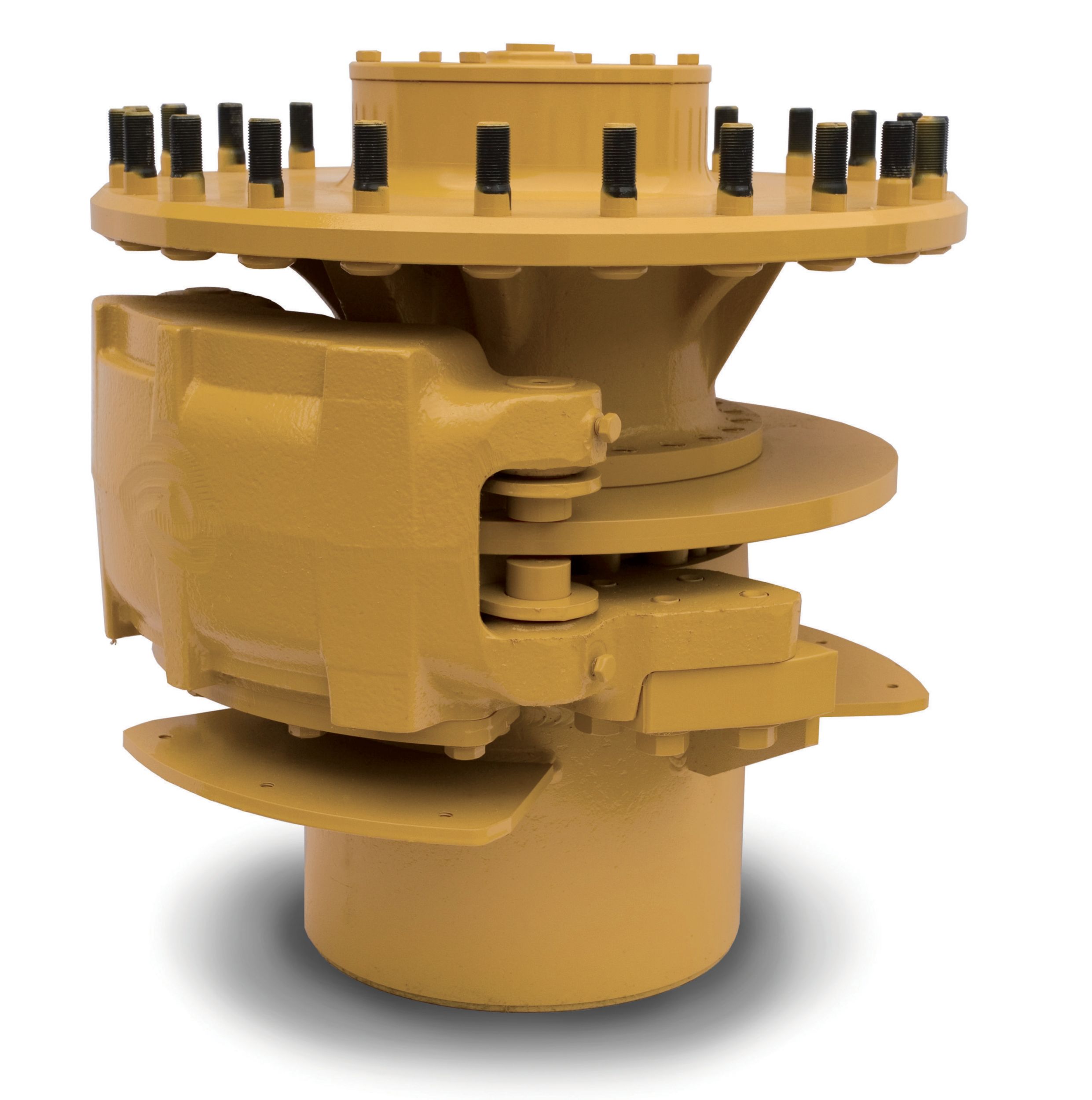

Walking-Beam Suspension

The TS185 uses a four-tire arrangement with independent walking-beam load transferring axles. The exclusive design gives the scraper a smoother ride, reduced side-to-side sway and easier finish grading.

Adjustable Cutting Angle

The TS185 is equipped with an additional pair of lift cylinders at the rear of the scraper. An experienced operator can use this exclusive feature to fine-tune the cutting depth for improved productivity. Steepen the cutting angle while drop cutting or during push loading. Use a shallower cut when loading lighter materials such as sand or dry topsoil.

Wheels, Brakes

Standard Brakes - Construction-Grade

Standard heavy-duty brakes bring a new level of safety to the job site. Each machine is equipped with four calipers. The hydraulically-actuated, dry-disc brakes are identical to the brakes used on Cat D400E Articulated Trucks.

Standard Radial Tires

Standard radial tires reduce rolling resistance and provide excellent flotation and durability. Heavy-duty, five-piece rims ensure a long service life. Wheel hubs are oil-filled and sealed with Cat Duo-Cone™ seals.

Customer Support

Your Cat dealer is read to assist you with your purchase decision and everything after.

- Make comparisons of machines with estimates of component life, preventative maintenance and cost of production

- Financing packages are flexible to meet your needs

- Your Cat dealer can evaluate the cost to repair, rebuild and replace your machine, so you can make the right choices

- Most Cat dealers offer operator training to help you get the most out of your machine investment

- For more information on Cat products, the variety of dealer services, and industry solutions, visit us at www.cat.com.

Data not available.

Standard Equipment

- BOWL

- Capacity, heaped, 23.5 yd³

- Capacity, struck, 17 yd³

- Center Lift System

- Cutting Edges, Reversible

- Router Bits

- UHMW Plastic Alignment Guides

- Ejector Roller System

- Variable Cutting Angle

- Apron Lock Mechanism

- HITCH AND TONGUE

- Hitch Pin, 89 mm (3.5 in) diameter

- Hitch platform

- Integrated stop blocks

- Rear hitch countersunk in push block for tandem operation (Lead)

- Literature Storage Container

- HYDRAULICS

- Cat XT™-3 ES Hose

- Hydraulic connections for tandem operation (Lead Scraper)

- Manual Lowering Valve

- ORFS Fittings

- Poppet-style Fittings, 19 mm (0.75 in)

- WHEELS AND TIRES

- Braking System (hydraulic)

- Walking-Beam Suspension

- 26.5 R25 Radial Tires (4)

- Five-Piece Rim

- Walking-Beam Transport Locks

- STRUCTURES

- Push Block

- Rear Tow Hooks

Optional Equipment

- HYDRAULICS

- Quick-Connect Fittings

- WHEELS AND TIRES

- Spare Rim