Overview

The Caterpillar M318 has improved serviceability, performance and rugged durability combine to maximize productivity. Better controllability, simplified service and a more comfortable operator station increase productivity and lower operating costs.

Specifications

| Engine Model | Cat 3116 DIT |

| Net Power | — |

| Gross Power | — |

Benefits & Features

Specifications

| Engine Model | Cat 3116 DIT |

| Net Power | — |

| Gross Power | — |

| Flywheel Power | — |

| Displacement | — |

| Travel Circuit | — |

| Normal | — |

| Implement/Travel Circuit | — |

| Maximum Travel Speed | — |

| Drawbar Pull | — |

| Maximum Gradeability | 57 |

| Creeper Speed - 2nd Gear | — |

| Hydraulic Tank | — |

| Hydraulic System - Including Tank | — |

| Cooling | — |

| Engine Crankcase | — |

| Rear Axle - Housing (Differential) | — |

| Front Steering Axle - Differential | — |

| Powershift Transmission | — |

| Fuel Tank | — |

| Fuel Tank Capacity | — |

| Maximum Reach - Ground Level | — |

| Travel Speed | — |

| Maximum Reach - Ground Level, VA Boom | — |

| Maximum Reach - Ground Level, One Piece Boom | — |

| Bucket Digging Force - VA Boom | — |

| Bucket Digging Force - One Piece Boom | — |

| Maximum Digging Depth - VA Boom | — |

| Maximum Digging Depth - One Piece Boom | — |

| Stick Digging Force - VA Boom | — |

| Stick Digging Force - One Piece Boom | — |

| Maximum Bucket Capacity | — |

Benefits & Features

Operator Station

Easy Access

Conveniently located grab irons and large steps mounted to the undercarriage allow easy access in and out of the cab.

Quiet Cab

The cab is resiliently mounted. Sound suppression panels reduce outside noise levels to a very low level.

Comfortable Seat

The suspension seat adjusts to weight and offers excellent lumbar support, adjustable height armrests and numerous seat adjustment.

Visibility

Wide, large windows help assure excellent visibility in all directions, which is especially critical when roading the machine or working on public roadways.

Ventilation

Strategically located vents circulate forced air, heat or defrost air for maximum comfort.

Controls

The control panel switches are conveniently located. Warning lights are clearly displayed on the upper portion of the control panel.

Electronic Control System

Hydraulic System

Closed center, variable flow, load-sensing hydraulic system.

Swing Pump

A separate dedicated variable displacement piston pump and fixed displacement piston motor power the swing mechanism.

Efficient and Expandable

Up to three optional hydraulic valves can be added to the main valve stack for additional hydraulic functions.

Control Panel

The right side console contains switches for the power mode selector, automatic engine control, lights, windshield wiper and washer and travel speed selector.

Integrated Electronic System

A microprocessor monitors and controls M318 parameters and functions.

Functions

Three power mode settings.

Automatic Engine Speed Control

When activated, this device reduces engine speed to a minimum during periods of inactivity which reduces noise and saves fuel.

Electronic Engine Speed Control

When activated, this device reduces engine speed to a minimum during periods of inactivity which reduces noise and saves fuel.

Protective Measures

Maximum engine power is reduced when engine temperature is too high or hydraulic oil temperature is too low or too high.

Engine

Rating

Conservative 104.4 kW/139 hp rating, high displacement to power ratio of 3.66 and low rpm operation ensure long life and exceptional reliability.

Direct-Injection

Direct-injection fuel system with adjustment-free pumps provides efficient, accurate fuel metering.

Long-Life Design

Long-life design includes large bearing surfaces, alloy steel valves, lightweight cam roller followers and easily replaceable crankshaft seals.

Torque Rise

The engine is designed for high torque rise at middle rpm which is suited for excavator applications.

Service

The engine is longitudinally mounted on the right for easy ground access for service/maintenance of the oil filter, oil filler, oil drain valve, fuel filter, V-belt tightener and dipstick.

Valve Cover

Valve cover and oil pan noise barriers, for maximum engine noise and emission reduction.

Undercarriage, Outriggers, Dozer Blade, and Axles

Undercarriage

Strong and durable welded frame structure built with large sections and thinner plates for maximum stiffness.

Optional Dozer Blade

A very useful addition for leveling and back-filling or clean-up work.

Optional Outriggers

For maximum stability when digging and lifting.

Axles

Heavy duty axles.

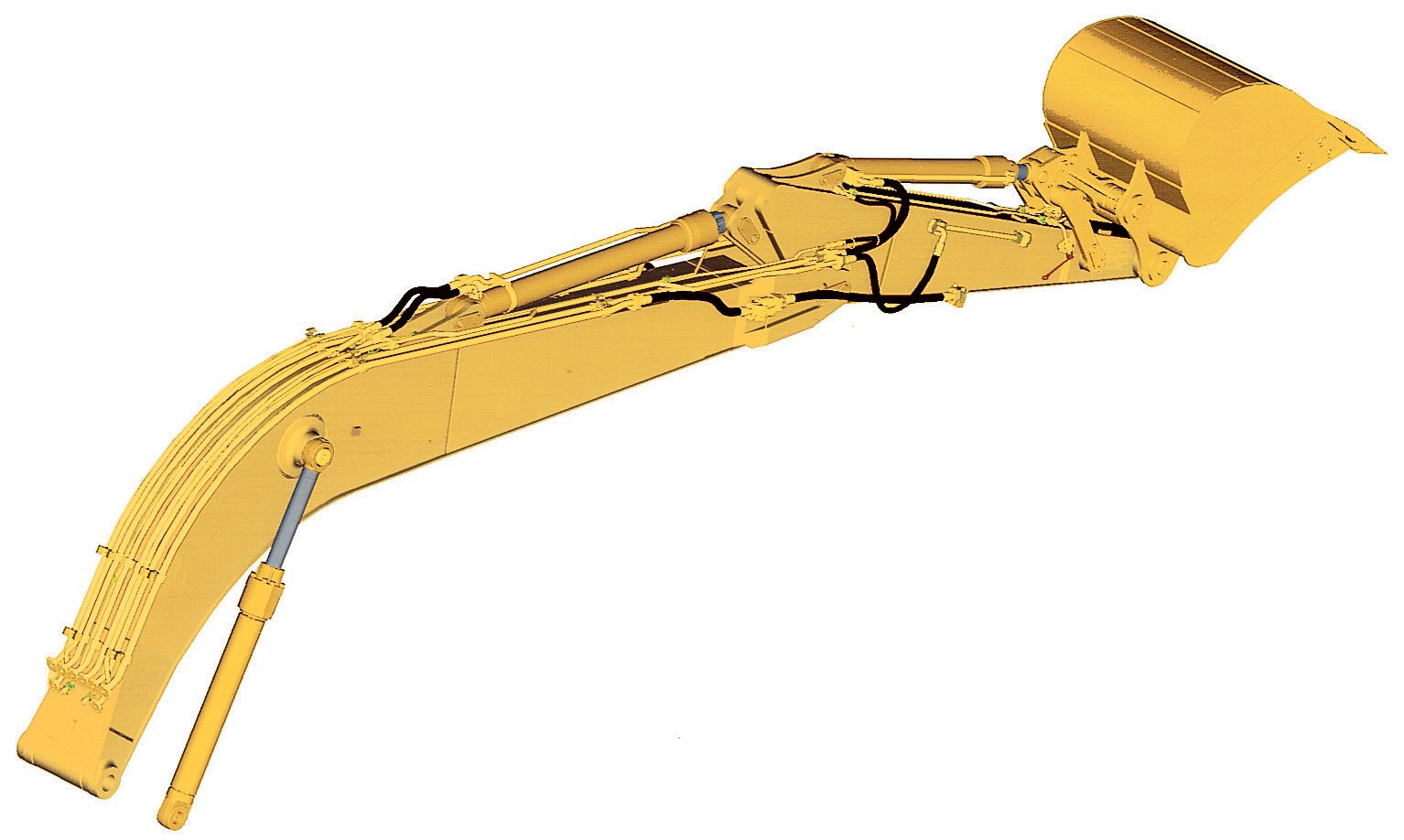

Booms, Sticks and Buckets

One-Piece Boom

One-piece boom is recommended for general applications and for hammer use.

Variable Angle (VA) or Hydraulically Adjustable Boom

The Variable Angle (VA) or the Hydraulically Adjustable Boom improves visibility and machine balance while roading. Good for work in tight quarters.

Sticks

Four sticks are offered to allow the machine to be tailored to the job.

Bucket Cylinder/Linkage Group

Lower power link has additional hole for lifting. The bucket cylinder/linkage group can be ordered with or without diverter valves which facilitate hydraulic connections when using a clamshell.

Buckets

General purpose, extreme service, as well as rigid and tilting ditch cleaning buckets are offered.

Hammer Lines

Factory installed Hammer Hydraulic Lines are available for booms and sticks. Proportional foot control switch is provided for maximum comfort and precision.

High Pressure Hydraulic Lines

Factory installed High Pressure Lines are available for booms and sticks. They are designed to function with 2-way hydraulic attachments such as shears and crushers at maximum working pressure and flow.

Low Pressure Hydraulic Lines

Factory installed Low Pressure Lines are available. They are designed to function with double-acting devices such as the ditch cleaning bucket tilt and clamshell rotation.

Data not available.