M322FNon-Current

M322F - 2015, Tier 4 Final, AUZ, NACD, Puerto RicoOverview

The new F Series generation is here to help you take on the wide variety of challenges you face every day, more easily and with more pleasure. F Series – Easier Than Ever.

Specifications

| Engine Model | Cat® C7.1 ACERT™ |

| Net Power | — |

| Maximum Travel Speed | — |

Benefits & Features

Specifications

| Engine Model | Cat® C7.1 ACERT™ |

| Net Power | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Maximum Torque - 1,400 rpm | — |

| Net Power (Maximum) - ISO 9249/SAE J1349 at 1,700 rpm | — |

| Net Power (Maximum) - ISO 14396 at 1,700 rpm | — |

| Net Power - Maximum - ISO 9249/SAE J1349 at 1,700 rpm - (PS) - Metric | — |

| Emissions | U.S. EPA Tier 4 Final |

| Ratings | — |

| Number of Cylinders | 6 |

| Net Power - Maximum - ISO 9249/SAE J1349 - (PS) - Metric | — |

| Net Power - Rated - ISO 9249/SAE J1349 | — |

| Net Power - Maximum - ISO 9249/SAE J1349 | — |

| Net Power - Rated - 80/1269/EEC | — |

| Net Power - Maximum - 80/1269/EEC | — |

| Net Power (Rated) - ISO 9249/SAE J1349 - (PS) - Metric | — |

| Engine Gross Power (Maximum) - ISO 14396 | — |

| Engine Gross Power (Maximum) - ISO 14396 - (PS) - Metric | — |

| Operating Weight - With Attachment | 20 560-24 700 kg (45,330-54,450 lb) |

| Weight - Counterweight - Optional | — |

| Weight - One-Piece Boom - Rear Dozer, Front Outriggers | — |

| Weight - Sticks - Medium (2500 mm/8'2") | — |

| Weight - One-Piece Boom - Front and Rear Outriggers | — |

| Weight - Counterweight - Standard | — |

| Weight - VA Boom - Rear Dozer Only | — |

| Operating Weight | 20 800-22 330 kg (45,856-49,229 lb) |

| Weight - Sticks - Long (2900 mm/9'6") | — |

| Weight - VA Boom - Front and Rear Outriggers | — |

| Weight - VA Boom - Rear Dozer, Front Outriggers | — |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Flow - Implement/Travel Circuit | — |

| Maximum Pressure - Auxiliary Circuit - Medium Pressure | — |

| Maximum Pressure - Implement Circuit - Travel Circuit | — |

| Maximum Pressure - Auxiliary Circuit - High Pressure | — |

| Maximum Pressure - Implement Circuit - Normal | — |

| Tank Capacity | — |

| Maximum Flow - Swing Mechanism | — |

| Maximum Pressure - Swing Mechanism | — |

| Maximum Flow - Auxiliary Circuit - Medium Pressure - Eco Mode | — |

| Maximum Flow - Auxiliary Circuit - High Pressure | — |

| System | — |

| Maximum Pressure - Implement Circuit - Heavy Lift | — |

| Maximum Flow - Auxiliary Circuit - Medium Pressure - Power Mode | — |

| Drawbar Pull | — |

| Forward/Reverse - 1st Gear | — |

| Creeper Speed - 1st Gear | — |

| Forward/Reverse - 2nd Gear | — |

| Maximum Gradeability (25 000 kg/55,115 lb) | 70% |

| Creeper Speed - 2nd Gear | — |

| Powershift Transmission | — |

| Fuel Tank - Total Capacity | — |

| Engine Crankcase | — |

| Front Steering Axle - Differential | — |

| Cooling System | — |

| Final Drive | — |

| Rear Axle - Housing (Differential) | — |

| Diesel Exhaust Fluid Tank | — |

| Standard | 11.00-20 (Dual Pneumatic) |

| Optional | 10.00-20 (Dual Solid Rubber) |

| Ground Clearance | — |

| Minimum Turning Radius - Outside of Tire | — |

| Minimum Turning Radius - End of VA Boom | — |

| Oscillation Axle Angle | ±8.5° |

| Minimum Turning Radius - End of One-Piece Boom | — |

| Maximum Steering Angle | 35° |

| Bucket Capacities | 0.6-1.43 m³ (0.78-1.87 yd³) |

| Maximum Digging Depth | — |

| Maximum Reach - Ground Level | — |

| Maximum Travel Speed | — |

| Diesel Exhaust Fluid | Must meet ISO 22241 |

| Vibration Levels - Seat Transmissibility Factor - ISO 7096:2000 - Spectral Class EM6 | Less Than 0.7 |

| Vibration Levels - Maximum Hand/Arm - ISO 5349:2001 | Less Than 2.5 m/s² (Less Than 8.2 ft/s²) |

| Engine Emissions | Tier 4 Final |

| Fluids (Optional) - Biodiesel Up to B20 | Meets EN 14214 or ASTM D6751 with EN590 or ASTM D975 Standard Mineral diesel fuels |

| Vibration Levels - Maximum Whole Body - ISO/TR 25398:2006 | Less Than 0.5 m/s² (Less Than 1.6 ft/s²) |

| Fluids (Optional) - Cat Bio HYDO™ Advanced | Readily biodegradable EU Flower eco-label certified |

| Operator Protective Structure - Top/Front Guards | FOPS (Falling Object Protective Structure) meets FOPS criteria ISO 10262:1998 and SAE J1356:2008 |

| Cab/Sound Levels | Meets appropriate standards as listed in "Sound Performance" |

| ROPS | ROPS (Rollover Protective Structure) offered by Caterpillar meets ROPS criteria ISO 12117-2:2008 |

| Spectator Sound - 2000/14/EC | — |

| Operator Sound - 2000/14/EC | — |

| Width | — |

| Blade Roll - Over Height | — |

| Blade Type | Parallel |

Benefits & Features

Sustainability

Fuel Efficiency and Reduced Exhaust Emissions

The engine meets Tier 4 Final emission standards, performs the same amount of work, while burning less fuel than the previous model, which means more efficiency, less resources consumption, and fewer CO2 emissions.

Quiet Operation

Outstandingly low sound levels, you won't believe your machine is running.

Transparent Technologies and Longer Service Intervals

- The new Eco Modes, Auto Engine Speed Control and Engine Idle Shutdown help further reduce your overall fuel consumption.

- Product Link™ allows remote monitoring of the machine and helps improve overall efficiency.

- Your Cat dealer can help extend service intervals, meaning fewer fluids and disposals, all adding up to lower costs.

Biodiesel and Biodegradable Hydraulic Oil

- The M322F has the flexibility of running on either ultra-low-sulfur diesel (ULSD) fuel with 15 ppm of sulfur or less or up to B20 biodiesel fuel blended with ULSD.

- Cat BIO HYDO™ Advanced HEES™ reduces the impact on the environment.

Cat Certified Used

This program is a key element in the range of solutions offered by Caterpillar and Cat dealers to help customers achieve growth at the lowest cost while eliminating waste. Used equipment is inspected, guaranteed and ready for work and customers will benefit from a Caterpillar warranty.

Engine

The Power and Performance You Need – Constant Power Strategy

Provides a quick response to changing loads, while delivering the same amount of power regardless of operating conditions.

The Power and Performance You Need – A Transparent Emission Solution That Works.

- The Cat C7.1 ACERT engine meets today's Tier 4 Final emission standards, and it does so without interrupting your job process. It is designed to be:

- Transparent: no operator intervention

- Durable: fit for life Diesel Particulate Filter

- Efficient: no work interruption, even in case of extended idling time

- Simple: minimum maintenance. Longitudinal engine installation, which further simplifies maintenance.

The Power and Performance You Need – Biodiesel Not a Problem

The engine can run on up to B20 biodiesel fuel that meets ASTM 6751 standards – all to give you more potential fuel-saving flexibility.

The Power and Performance You Need – Proven Technology

To assure that our technology will meet your expectations for reliable trouble-free service, we subjected these engines and technologies to extensive operating hours of test and validation.

Built-in Fuel Savers That Add Up

- Automatic Engine Speed Control: lowers engine speed when it is not needed.

- NEW Engine Idle Shutdown (when activated): turns the engine off when it's been idling for more than a pre-set amount of time.

- NEW Cooling System: variable speed and on-demand fan optimizing consumption.

- NEW enhanced Eco Mode: reduces engine speed while delivering the same power.

- Automatic shift to Travel Mode when you start riding: optimizes driveline performance while preserving fuel.

Premium Comfort

Legacy from the Renowned Cat Wheeled Excavators

Designed for the operator, our cabs are unique.

Ergonomic Layout

- Frequently used switches are centralized, kept to the minimum and ideally located close to the joysticks.

- Storage compartments are useful... when well designed. The lunch box provides sufficient room to store a hard hat. Several other areas include drink, phone, or key holders.

Comfortable Seat Options

Our seats provide all the comfort needed for a long day of work, including FULL adjustment. All seats are heated and air suspended. Automatic weight adjustment and air cooled seats are available.

Safety – Not an Option

ROPS/FOGS cabs, seat belt alarm, safety bar, sideview camera … among others.

Details That Make the Difference

Have a look at the cab; you will see it is through details that we improve pleasure of operating.

Smart Controls to Reduce Fatigue

- Features like ride control, SmartBoom or Joystick Steering will be precious to increase your productivity.

- New technologies that work transparently like the swing and auto travel lock or the automatic brake and axle lock, reduce the number of tasks you need to do.

Plug, Charge and Play Your Devices

- The 12V 10A power supply socket is conveniently located for charging your laptop, or a tablet.

- A CD/MP3 Radio with speakers and USB port is available.

Simplicity and Functionality

A Cab Just for You – Fully Adjustable

- Seat armrests, in height and angle

- Steering column adjustment, not only tilting fore/aft but also in height

- Hydraulic sensitivity of the machine to make it more or less aggressive

- Joystick controls, buttons and thumb wheels

- Automatic air conditioning

Incredibly Low Sound Levels, Less Fatigue

Operator sound level has been reduced thanks to a new cab design and increased cab pressure, which also prevents from dust entry. Add in new hydro mounts to fix the cab on the frame and you have a cab that's as quiet as any of today's premium cars.

Outstanding Visibility: See the Difference!

- Standard LED working lights and halogen roading lights

- Standard LED dome light

- All glass areas have been drastically increased

- Choice of 70/30 front windshield or one-piece windshield

- New wide angle mirrors including a lower mirror for better visibility to the ground

- Parallel intermittent (four speeds) wipers covering the whole windshield

Standard Rear and Side Wide Angle Cameras

Cameras let you see what's going on around. The image from the side camera is displayed on an additional wide color screen, offering the full view from the front to the rear of the machine. The rear camera is integrated into the counterweight for enhanced protection.

Large Color Monitor

Easy to read and in local language, the high resolution LCD monitor will keep you aware of any important information. “Quick Access” buttons allow a quick selection of favorite functions. The tool select function lets you preset up to ten different hydraulic attachments for quick tool changes.

The Next Generation

Make the Move to the Next Generation

Refinements. From the whole design to the smallest details. Convenient features, new advanced and transparent technologies, not only to reduce emissions but to further improve your daily experience when working with our products.

Easier Than Ever

Work like no other with our wheeled excavators. The F Series generation is made to help you take on the wide variety of the challenges you face every day, more easily and with more pleasure, to keep you on the road to your success.

Cruise Control

Cruise Control

- No need to press the pedal all the time.

- Choose the very speed you wish

- Press the quick access button on the monitor

- Enjoy the ride

It's as Easy as That.

Smart Technologies

Swing and Auto Travel Lock: As Fast, As Easy, As Safe

- No need for the operator to bend to engage the swing lock pin.

- Just press a button,

- Align the upper to the lower frame,

- Enjoy the ride: a green indicator confirms the swing and the implements have been automatically locked.

It's As Easy As That.

Integrated Pin Code – Switch Off and Relax

- No need to buy an optional security system to protect your equipment against theft.

- The pin code is integrated into the monitor (standard)

- Entering the right code allows the engine to start

The Machine Security System (MSS – optional) adds even more protection when needed.

Dig and Go Auto Axle Lock

The machine automatically detects when the service brake and axle need to be locked (like when digging), or unlocked (roading), hence removing the need for the operator to systematically press the pedal.

Brake and axle are released automatically by pressing the travel pedal again.

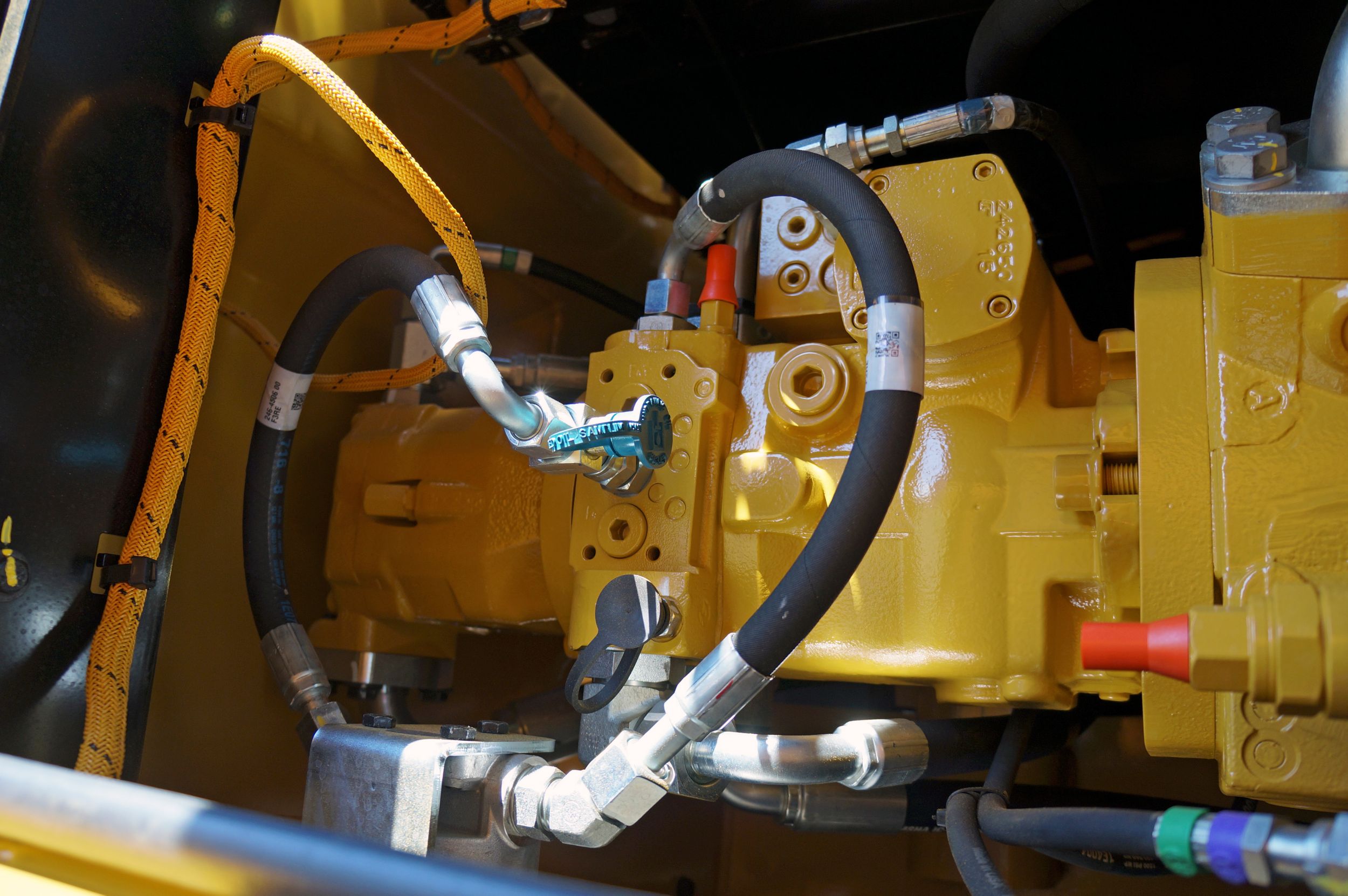

Hydraulics

When it comes to moving material quickly, you need efficient hydraulics – the type the F Series can deliver.

Efficient Design, Smart and Fast

- Simple Design: The new hydraulic valve compartment and routings offer a simple and clean design to help ensure durability. Everything is reachable from ground level.

- Smart Main Hydraulics: The system allows reducing the load on the engine when not needed, which translates into lower fuel consumption.

- Dedicated Swing Pump: A closed hydraulic circuit is dedicated to the swing only. Having two separate pumps, one for the swing and the other for the other functions allows faster and smoother combined movements.

Control Like No Other

- Electronic Pump Control – Controllability is one of the main attributes of Cat excavators, and one of the key contributors to this is the Electronic Pump Control (EPC) that's designed to improve response time and precision. It puts flow exactly where you need it, when you need it, which means a much smoother operation and greater efficiency.

- Adjustable Hydraulic Sensitivity – Allows you to adjust the aggressiveness of the machine according to the application.

- Stick Regeneration Circuit – Increases efficiency and helps enhance controllability for higher productivity.

Proportional Auxiliary Hydraulics, Tremendous Versatility

Medium pressure function (for tilting buckets or rotating tools), high pressure lines and circuit, hydraulic quick coupler circuit: they all come standard, which allows you to switch from one work tool to another, without the need to add lines and hydraulic circuits.

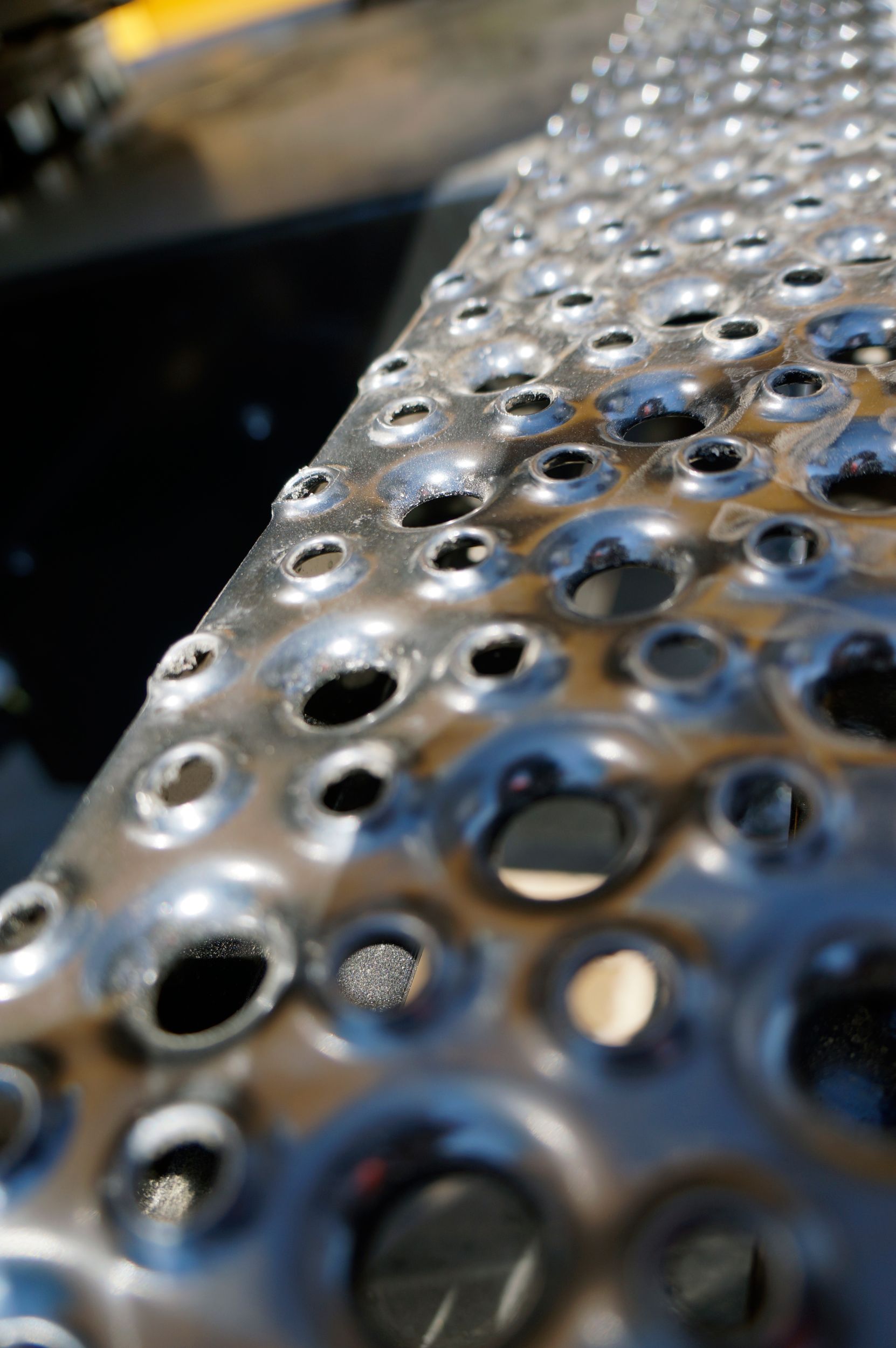

Undercarriage

Heavy Duty Axles

Long life with effective heavy duty axles. The transmission is mounted directly on the rear axle for protection and optimum ground clearance. The front axle offers wide oscillating and steering angles. The drive shaft offers longer service intervals (1,000 hours).

Advanced Disc Brake System

Minimizes the rocking effect when working free on wheels. The disc brake system acts directly on the hub instead of the drive shaft to avoid planetary gear backlash.

Joystick Steering

Keep both hands on the joysticks even when simultaneously moving the implements and repositioning the machine, by the use of the slider switch on the right joystick.

New Blade Design

- Parallel kinematic to keep the blade parallel to the ground, in every height position

- A profile that allows material to roll better and minimizes material packing

Booms and Sticks

Rugged Performance

Booms and sticks are welded, box section structures with thick, multi-plate fabrications in high stress areas for the tough work you do.

Flexibility

The choice of various booms and sticks provides the right balance of reach and digging forces for all applications.

Sticks

- Medium stick – 2500 mm (8'2") for greater crowd force and lift capacity

- Long stick – 2900 mm (9'6") for greater depth and reach

Booms

- Variable Adjustable (VA) – Improved right side visibility and roading balance. When working in tight quarters or lifting heavy loads, the VA boom offers the best flexibility.

- One-Piece Boom – Fits best for all standard applications such as truck loading and digging. A unique straight section in the curve of the side plate reduces stress flow and helps increase boom life.

SmartBoom

Rock Scraping

Scraping rock and finishing work is easy and fast. SmartBoom simplifies the task and allows more focus on stick and bucket, while the boom freely goes up and down without using pump flow.

Hammer Work

The front parts automatically follow the hammer while penetrating the rock. Blank shots or excessive force on the hammer are avoided resulting in longer life for the hammer and the machine. Similar advantages with vibratory plate compactors.

Truck Loading

Loading trucks from a bench is more productive and fuel efficient as the return cycle is reduced while the boom down function does not require pump flow.

Ride Control

The ride control system lets you travel faster over rough terrain with improved ride quality for the operator. Accumulators are acting as shock absorbers to dampen the front part motion. It can be activated through a button located on the soft switch panel in the cab.

Work Tool Attachments

Get the Most from Your Machine

If you have multiple tasks to get done, the M322F can help. You can easily expand all the possibilities it offers by utilizing any of the variety of Cat attachments.

Change Jobs Quickly

A quick coupler brings the ability to quickly change attachments and increase your flexibility. The new quick coupler circuit and lines are compatible with the Pin Grabber Coupler and do not require any change or addition to the machine.

Dig, Load, Finish and Compact

A wide range of buckets offers solutions for digging, trenching, loading and finishing works. The addition of a Cat Compactor will introduce your machine to utility work, site prep, road repair and pipeline work.

Move and Handle Material

Choose from one of three different thumb styles to work with your bucket and you have the instant ability to move and handle brush, rocks and debris.

Hammering Works

Our hammers include a buffer to improve your comfort and protect your machine from vibration. Fully enclosed, it is ideal when working in noise regulated areas.

Sort and Load

Grapples bring your machine into waste handling opportunities. Jaws open wide to move volumes, yet are nimble enough to pull a single copper wire out of a pile. Their 360° rotation capability allows you to place the grapple where you want it without moving the machine.

Scrap and Recycle

Shears also have the ability to rotate 360°. A pulverizer allows you to crush and reduce concrete.

Job Site Confidence

From the operators seat, visual and audible indicators help assure that the attachment is coupled. Your Cat excavator hydraulics, mechanisms inside the coupler, and digging forces all work together to assure the attachment stays engaged. The Cat Pin Grabber coupler is the secure way to decrease downtime by allowing quick attachment change and increase job site flexibility.

Power Match

Match your Cat hydraulic attachments to your Cat machine, and get the most out of the standard, built-in software. Attachment changes have never been easier!

Serviceability

Convenient Access Built In

You can reach routine maintenance items like fuel and engine oil filters and fluid taps at ground level while fuel and DEF tanks with engine air filter are accessible from the safety of the slip-resistant new service platform. Compartments feature wide composite service doors, designed to be more resistant to shocks, which all include gas struts to facilitate the opening. Components are now gathered in specific dedicated compartments, like the special electrical compartments.

A Smart Design for Any Temperature

The side-by-side and axial fan design allows greater cooling performance. The system is completely separated from the engine compartment to reduce noise and heat and all radiators are gathered in the same compartment while featuring easy-to-clean cores with a tilting device that requires no tool to unlock.

A Fresh Idea

Ventilation inside the cab allows outside air to enter through a fresh air filter. The filter is located on the side of the cab to make it easy to reach, and it is protected by a lockable door that can be opened with the ignition key.

Lube and Fuel Standard Features

An electric lubricator system is an available time-saving standard feature for greasing the whole upper carriage. Greasing points for the undercarriage are kept to a minimum and grouped. An electric refueling pump is also standard. The hose is stored in a dedicated tray, for more cleanliness. Add in the new electric lift pump removing the need to prime the system manually, the standard fuel and water separator and you get a machine that does the fastidious works for you.

Keep it simple.

Integrated Technologies

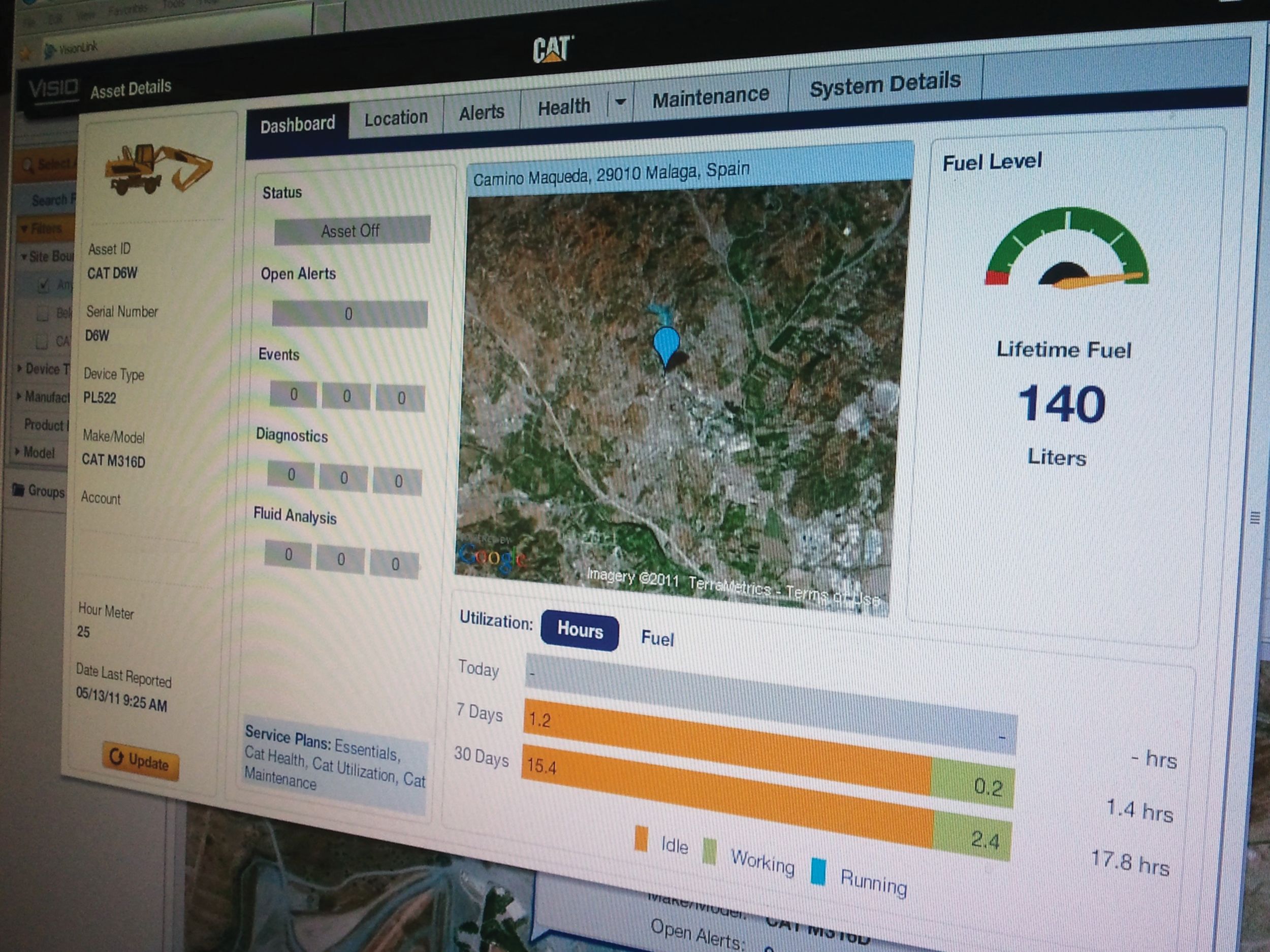

CAT® CONNECT

Cat Connect makes smart use of technology and services to improve your job site efficiency. Using the data from technology-equipped machines, you'll get more information and insight into your equipment and operations than ever before.

Cat Connect technologies offer improvements in these key areas: Equipment Management – increase uptime and reduce operating costs. Productivity – monitor production and manage job site efficiency. Safety – enhance job site awareness to keep your people and equipment safe.

Featured Cat Connect technologies include the following:

Link

Link technologies provide wireless capability to machines to enable two-way transfer of information collected by on-board sensors, control modules, and other Cat Connect technologies.

Manage Your Machine Remotely

Cat Product Link is a system that is deeply integrated into the machine monitoring system to take the guesswork out of managing your equipment. The system tracks location, hours, fuel usage, productivity, idle time, and diagnostic codes and shares it with you through VisionLink® to help you maximize efficiency, improve productivity, and lower operating costs.

Safety

Embedded Features

- Smart devices are embedded to offer as much safety as possible for your operators and help enforce safe behavior:

- Safety seat belt and warning indicators (monitor)

- Automatic swing lock

- Automatic brake and axle lock

- Safety lever, preventing exit when the implements are not locked out

- Emergency shut off switch and battery switch disconnect

- Adjustable travel alarm

- Lowering check valves

Safe and Quiet Cab

The all-new cab provides you with a safe environment. It also contributes to your comfort with limited vibrations and drastically reduced sound levels.

- Cab Ingress. We bring a solution to allow you to safely climb into the cab:

- Three longer access steps, aligned with the cab entry

- Anti-skid plates on all walkways and steps reducing slipping hazards

- Convenient door handrail

- Additional extended handrail, from the top to the bottom of the cab

- Tiltable console, not to obstruct entry into the cab

- Safety lever built into the tiltable console to make sure the way in and out is free of obstacle

Smart Lighting

- LED lights for all working lights for enhanced night-time visibility

- Halogen lights for front roading lights

- LED dome light for better illumination inside the cab

Great Views

- Enlarged glass gives you excellent visibility to the front, top, rear, and sides, even to the right

- Standard rearview camera gives you a clear field of view behind the machine through the monitor. Camera is integrated into the counterweight.

- Standard sideview camera, to check nothing is hidden to you from the front right hand side to the rear of the machine

- Lenses of all the cameras are wide angle and heated

- All mirrors are wide angle and allow view not only around the machine but also to the ground

Unmatched Visibility

- Visibility all around is critical, especially for machines which go on public roads.

- Increased skylight and windshield glass area

- Improved lighting with standard LED lights for all working lights

- Optional heated mirrors

- Great left hand side visibility with the new all glass door

- Halogen roading lights

- Wide rear window

- Reflecting red lights on rear and blade/outriggers

- Standard wide rearview camera

- Standard side camera and dedicated wide monitor

- Large right hand side window

- Mirrors, wide angle, with additional lower mirror for ground visibility

Complete Customer Care

Support You Can Count On

- From helping you to choose the right machine to knowledgeable on-going support, Cat dealers provide the best-in-sales and services.

- Best long-term investment with financing options and services

- Productive operation with training programs

- Preventive maintenance and guaranteed maintenance contracts

- Uptime, with best-in-class parts availability

- Repair, rebuild, or replace? Your dealer can help evaluate the best option.

Data not available.

Standard Equipment

- ELECTRICAL

- Alternator, 115A

- Lighting: – LED light package, including all working lights (compatible with falling object guard). Working lights include cab mounted lights (two front, one rear and one on the counterweight for the rear camera) – Boom working light – Cab interior LED light – Roading lights two front, halogen – Roading lights two LED modules rear

- Main shut-off switch

- Maintenance free batteries, heavy duty

- Signal/warning horn

- Electrical refueling pump

- ENGINE

- Cat C7.1 engine with ACERT Technology Tier 4 Final compliant

- Aftertreatment technologies including the Cat Emission Module (Cat EM) package

- Automatic Engine Speed Control (AESC), including one touch low idle

- Engine Idle Shutdown (EIS)

- Power mode selector

- Altitude 3000 m (9,842 ft)

- Automatic starting aid

- Fuel/water separator with water in fuel switch

- Electric fuel priming pump

- HYDRAULICS

- Adjustable hydraulic sensitivity

- Auxiliary boom and stick lines

- All Cat XT™-6 ES hoses

- Anti-drift valves for bucket and tool control/multi-function circuits

- Basic control circuits: – Medium pressure<ul><li>Two-way, medium pressure circuit, for rotating or tilting of work tools</li></ul>– Tool control/multi function<ul><li>One/two-way high pressure for hammer application or opening and closing of a work tool</li></ul>– Programmable flow and pressure for up to 10 work tools – selection via monitor – Quick coupler circuit and lines for hydraulic quick coupler – compatible with the Cat Pin Grabber Quick Coupler

- Boom Lowering Check Valve (BLCV), including overload warning device

- Heavy lift mode

- Load-sensing hydraulic system

- Electric Pump Control (EPC)

- Separate swing pump

- Stick Lowering Check Device (SLCV)

- Stick regeneration circuit

- OPERATOR STATION

- ROPS cab structure compliant with 2006/42/EC and tested according to ISO 12117-2:2008

- Adjustable armrests

- Air conditioner, heater and defroster with automatic climate control

- Cigarette lighter (24 volt)

- Beverage cup/can holder

- Bolt-on Falling Object Guards (FOGS) capability

- Bottle holder

- Bottom mounted intermittent (four speeds) wiping system that covers the upper and lower windshield glass

- Cameras: – Rear mounted wide angle camera (integrated into the counterweight) display through the cab monitor – Right side wide angle camera, mounted on the cooling hood, displayed on a dedicated large color monitor

- Coat hook

- Cruise Control System

- Fastened seat belt warning signal

- Floor mat, washable, with storage compartment

- FM Radio with CD player, speakers and USB port

- Fully adjustable suspension seat

- Instrument panel and gauges: – Information and warning messages in local language – Gauges for fuel level, engine coolant, Diesel Exhaust Fluid (DEF) and hydraulic oil temperature – Filters/fluids change intervals – Indicators for headlights, turning signal, low fuel, engine dial setting – Clock with 10-day backup battery

- Interior LED lighting with door switch

- Joystick pilot operated

- Laminated upper front windshield

- Left side console, tiltable, with lock out for all controls

- Literature holder in right hand side panel

- Mobile phone holder

- Parking brake

- Pin-code, engine start prevention

- Power supply, 12V-10A

- Rain protector (Not compatible with the falling objects guards)

- Rear window, emergency, tempered glass, with hammer

- Retractable seat belt, integrated into the seat

- Safety lever, integrated into the left console

- Sealed cab with positive filtered ventilation

- Skylight, laminated glass

- Sliding door windows

- Steering column, adjustable height and angle

- Storage area suitable for a lunch box

- Sunshade for windshield and skylight

- UNDERCARRIAGE

- All wheel drive

- Automatic axle/brake lock

- Creeper speed

- Electronic swing and travel lock

- Heavy-duty axles, advanced disc brake system and travel motor, adjustable braking force

- Oscillating front axle, lockable, with remote greasing point

- Tires, 11.00-20 16 PR, dual

- Spacer rings for tires

- Steps with toolbox in undercarriage (left and right)

- Two-piece drive shaft, extended maintenance intervals (1,000 hours)

- Two speed hydrostatic transmission

- OTHER EQUIPMENT

- Auto-lube, centralized greasing (implement and swing gear)

- Automatic swing brake

- Bucket linkage with diverter valve

- Counterweight, 3500 kg (7,716 lb)

- Engine emergency shutoff switch

- Mirrors, wide angle, frame and cab

- Product Link

- S·O·SSM sampling valves for engine oil, hydraulic oil and coolant

Optional Equipment

- AUXILIARY CONTROLS AND LINES

- Basic control circuits: – Second high pressure<ul><li>Additional two-way, high pressure circuit, for tools requiring a second high or medium pressure function</li></ul>

- SmartBoom

- HYDRAULICS

- Cat BIO HYDO Advanced HEES biodegradable hydraulic oil

- FRONT LINKAGE

- Booms: – One-piece boom, 5650 mm (18.6 ft) – VA boom (two piece), 5490 mm (18 ft)

- Sticks: – 2500 mm (8'2") – 2900 mm (9'6")

- ELECTRICAL

- Back-up alarm with three selectable modes

- Rotating beacon on cab

- OPERATOR STATION

- Joystick steering

- Seat, adjustable high-back, with vertical and horizontal air-suspension and head rest: – comfort, automatic weight adjustment, mechanical lumbar support, heated – the deluxe seat adds automatic height and weight adjustment, pneumatic lumbar support, premium fabric, heated and cooled

- Windshield: – One-piece high impact resistant (EN 356 P5A standard) – 70/30 split, openable

- Mirrors heated, frame and cab

- High pressure pedal

- Joystick pattern, changeable

- Falling Object Guards (top and front)

- UNDERCARRIAGE

- Rear blade only (Parallel blade 2.75 m [9 ft])

- Front blade/rear outriggers (Parallel blade 2.75 m [9 ft])

- Front outriggers/rear blade (Parallel blade 2.75 m [9 ft])

- Front and rear outriggers

- Travel restraint, for roading with a clamshell

- OTHER EQUIPMENT

- Cat Machine Security System (MSS)

- Cooling protection package for dusty applications (includes fine mesh for enhanced radiator protection and engine air precleaner)

- Counterweight, 4700 kg (10,362 lb)

- Ride Control

- Tires (see "Specifications")

- Attachments (see "Bucket Specifications and Compatibility" and "Work Tools Matching Guide")

- Cooling package (kit) with reversible fan and vibrating grill