Overview

The 906 Compact Wheel Loader is built to the same high standards as larger Caterpillar wheel loaders. This machine delivers Cat reliability, durability and efficient operation, even in the toughest working conditions.

Benefits & Features

Specifications

Benefits & Features

Overview

Performance and Versatility

The strong weight-power ratios result in fast acceleration and quick directional changes for excellent performance

Ease of Operation

Operator comfort and easy operation are designed into every aspect of the cab.

Serviceability

Quick access and superior design make the 906 Compact Wheel Loader easy to service.

Customer Support

Caterpillar dealers offer unmatched customer support.

Work Tools

To enable maximum utilization of the compact wheel loaders, Caterpillar offers a wide range of tools for the many and varied tasks demanded by customers.

Additional Counterweight

Improved productivity, lifting capability and handling and substantially increased tipping load are delivered from the additional counterweight bolted onto the rear axle.

Antifreeze

The standard antifreeze offers protection to temperatures down to -33F, whereas the optional antifreeze offers protection down to -58F.

Rear Hitch Tow Pin

The rear hitch tow pin offers the increased versatility for Cat Compact Wheel Loaders.

Fender Extensions

Extensions to the front fenders deflect dirt away from the machine and back to the ground when used in muddy applications.

Cab Mounted Working Lights

Four lights are mounted externally to the cab roof (2 front and 2 rear), offering additional lighting for working at dusk / night.

Rotary Beacon

A roof-mounted rotating flashing beacon offering increased visual awareness of the machine.

Operator Station

Excellent Viewing

Excellent visibility in all directions -- 360 degrees panoramic view.

Low Effort Controls

Low effort pilot hydraulics and an ergonomically designed joystick with adjustable wrist rest minimize fatigue.

SAE criteria

The cab also meets ROPS criteria SAE J1040 MAY94 and ISO3741-1: 1986, and ROPS criteria SAE J231 JAN81 and ISO 3449:1992.

Design Technology

Cat Compact Wheel Loaders have been designed with the aid of virtual reality.

Sound Levels

Cat Compact Wheel Loader cabs are designed to provide users with very low interior sound levels.

Dash/Instrument Panel

The specially designed dash/instrument panel consists of 2 standard gauges, 14 action and indicator lamps, 8 rocker switch locations, a lamp test switch and a digital hour meter.

Bucket/Work Tool Controls

The Cat Compact Wheel Loaders feature pilot hydraulic controls.

Seat Belt

A 2" seat belt is standard equipment on the Cat Compact Wheel Loader, whilst the 3" belt is a legal requirement in the States of Oregon and California in the USA and in British Columbia in Canada.

Power Train

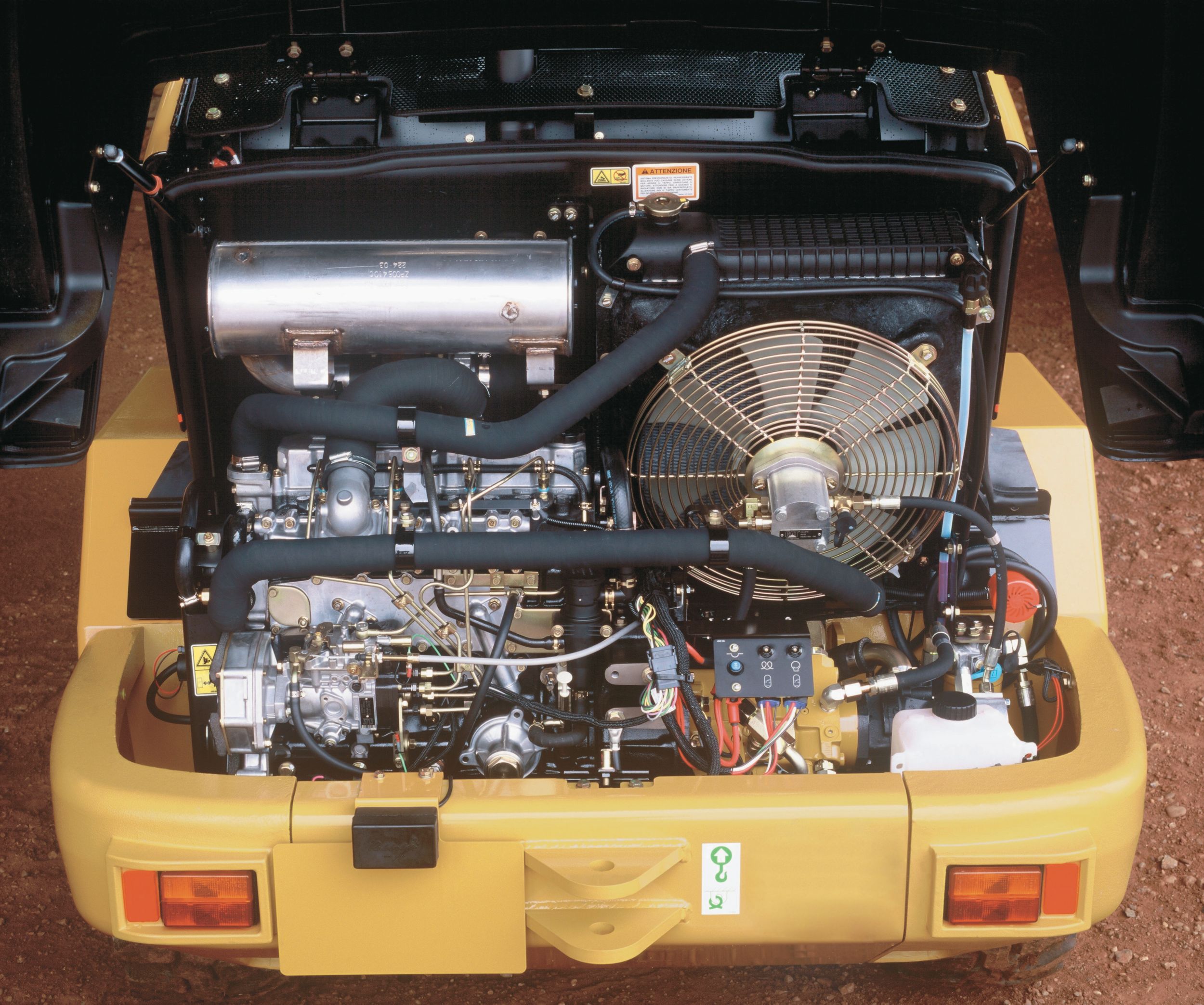

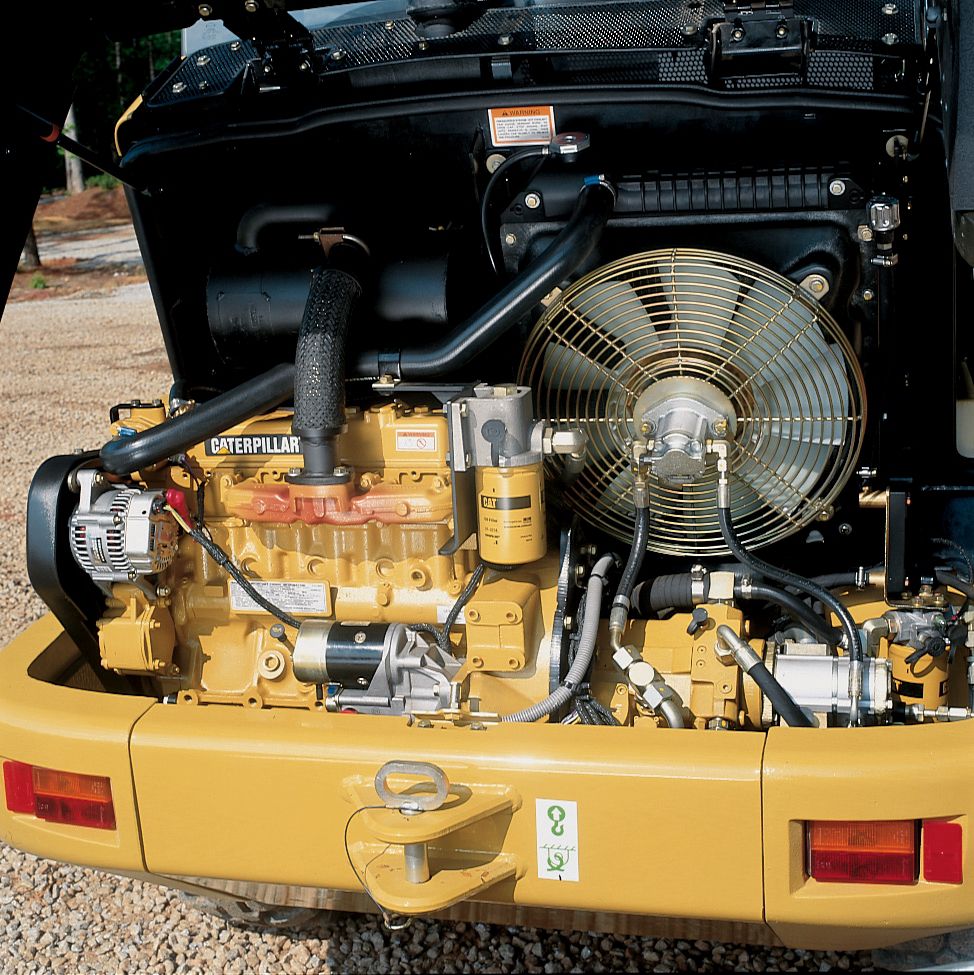

3034 engine

The 3034 incorporates many of the same heavy duty features that have helped make larger Caterpillar diesel engines the standard in the industry.

Radiator

The compact wheel loader has a unique cooling airflow path which provides optimum engine cooling while minimizing exterior noise levels.

Fuel Tank

The compact wheel loader fuel tank is not pressurized, decreasing system complexity and limiting the amount of fuel discharge if a leak occurs.

Transmission

Two-speed closed-loop hydrostatic transmission delivers smooth transition from full rimpull to runout. Precise inching control and smooth acceleration minimize operator fatigue.

Speed Control

In order to limit maximum travel speed while maintaining high engine rpm and hydraulic speed for applications such as truck loading, a rabbit/turtle (High/Low) switch is provided.

Axles

A limited slip differential (LSD) is standard for the Cat Compact Wheel Loader front axle, and a conventional differential is standard for the rear axle.

Battery

There are 2 optiona available. The 750 CCA/100Ahr battery is standard equipment. The optional 900CCA battery option offers the extra capacity needed in cold weather.

Engine Breather

Engine Enclosure Hood

Other Machines

Users will find the visibility to the rear of the machine significantly better with the Cat Compact Wheel Loaders than most other machines in this class.

Reaction Injection Molding

The Cat Compact Wheel Loader engine enclosure is manufactured using a state-of-the-art Reaction Injection Molding (RIM) process.

Durable Material

Dicyclopentadiene (DCPD) material used in the molding process is extremely durable and tough.

Stiffness/Impact Strength

The hood molding has an excellent combination of stiffness, impact strength, and low density.

Hood Understructure

The compact wheel loader understructure is molded of the same parent material, dicyclopentadiene and permanently bonded to the inside of the hood.

Engine Enclosure Design

The engine enclosure is designed as a solid piece, without any line-of-sight openings into the engine compartment.

Paint

The paint protecting the Cat Compact Wheel Loader is of the highest quality.

Engine Enclosure

Two different levels of sound suppression are offered in the engine enclosure of the Cat Compact Wheel Loader. The standard enclosure is fitted with sound suppression material.

Exhaust System

This option is dependent on whether a cab or canopy has been selected. The first option includes a standard exhaust system and is mandatory when ordering a cab. The second option includes a standard exhaust plus a mesh guard around the exhaust pipe. This is a mandatory option when a canopy has been selected.

Eco Drain Valves

Eco drain valves can be fitted to help prevent spillage when draining oil. Bio-degradable oil can be used to reinforce this envirnomental protection if the eco drain valves have been selected.

Hydraulic System

Control Valve

The implement valve is actuated by a closed center hydraulic pilot control valve.

Flow

Implement flow originates at the implement pump and is routed first through a steering priority valve, then through the implement valve to the tank.

Hydrostatic Charge Pump

The hydrostatic charge pump supplies flow to the pilot control valve and to a piston-type accumulator.

Accumulator

The accumulator supplies short-term flow for dead-engine situations.

Pilot Valve

The pilot valve is actuated by the joystick and the auxiliary hydraulic control lever in the operator compartment.

Lift & Tilt Functions

The Cat Compact Wheel Loader has standard lift and tilt functions. The hydraulically actuated QuickLock coupler is also standard.

Hydraulic Tank

The Cat Compact Wheel Loader hydraulic tank is not pressurized.

Rotationally Molded Nylon

The hydraulic tank is made from rotationally molded nylon 12.

Advantage

This is an advantage over conventional sheet metal tanks.

Damage Protection

The hydraulic tank is securely located at the heart of the machine.

3rd Valve Hydraulic Lines

This enables the use of Cat Work Tools requiring auxiliary hydraulic functions.

Lift Arm Check Valve

In the event of a hydraulic failure this option will prevent the front linkage from lowering.

Hydraulic Controls

A Return to Dig option is available for the Caterpillar Compact Wheel Loader.

VersaLink Loader

Design

The design of the VersaLink Loader Linkage allows ideal visibility forward and to each side of the work tool.

Unobstructed Visibility

This unobstructed visibility will insure the operator a clear view of the working environment during truck loading operations, material handling, and pallet fork work.

Productive Work Environment

Similarly in dozing and clean-up operations, the operator can see the ground behind the bucket to monitor grading.

Near-parallel Lift

The VersaLink Loader Linkage provides near-parallel lift for the pallet forks similar to the IT14G

Work Tool Position

The parallel lift characteristic of the compact wheel loader VersaLink Loader Linkage keeps the angle of the work tool with respect to the groundline relatively unchanged.

Tilt Cylinder

The tilt cylinder is sized such that any load that can be lifted in a bucket or with pallet forks can also be controlled over the full working range of motion of the work tool.

Strong Breakout Force

The VersaLink Loader Linkage delivers a very strong breakout force and presents the best reach in the compact wheel loader industry.

Unique Design

The unique design of the Versa Link Loader Linkage has superior torsional characteristics when compared to the slab lift arms of competitive machines.

Pin Joints

All pin joints on the VersaLink Loader Linkage contain induction-hardened pins turning in hardened steel sleeve bearings.

QuickLock Hydraulic Coupler

Force Distribution

The large front surface area of the QuickLock Hydraulic Coupler provides excellent force distribution when pushing material.

Maximum Visibility Design

The QuickLock Hydraulic Coupler is designed to provide maximum visibility around each side of the quick coupler, as well as through the center.

Work Tools

List of Work Tools

Work Tools Wire Harnesses

Supplies electrical power for valves on selected work tools.

Data not available.