Overview

Caterpillar engineers have designed and produced specialized machines with the objective of increasing productivity at every stage of the process. Added to that, our machines have been developed with an emphasis on stability, durability and ease of use. They also come with the backing of your local Cat® dealer. They can help you with finding the right machine and tools for the job and advise you how to get the most out of your equipment.

Specifications

| Engine Model | Cat® C13 ACERT™ |

| Net Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C13 ACERT™ |

| Net Power | — |

| Ratings | — |

| Operating Weight | — |

| Maximum Tool Weight (Over the Front) | — |

| Maximum Tool Weight (360°) | — |

| Machine Weight - UHD Configuration | — |

| Machine Weight - Retrofit Configuration | — |

| Maximum Tool Weight (Over the Side) | — |

| Shipping Length | — |

| Boom Height | — |

| Cab Height - With FOGS | — |

| Shipping Gauge - Retracted Position | — |

| Working Gauge - Extended Position | — |

| Ground Clearance | — |

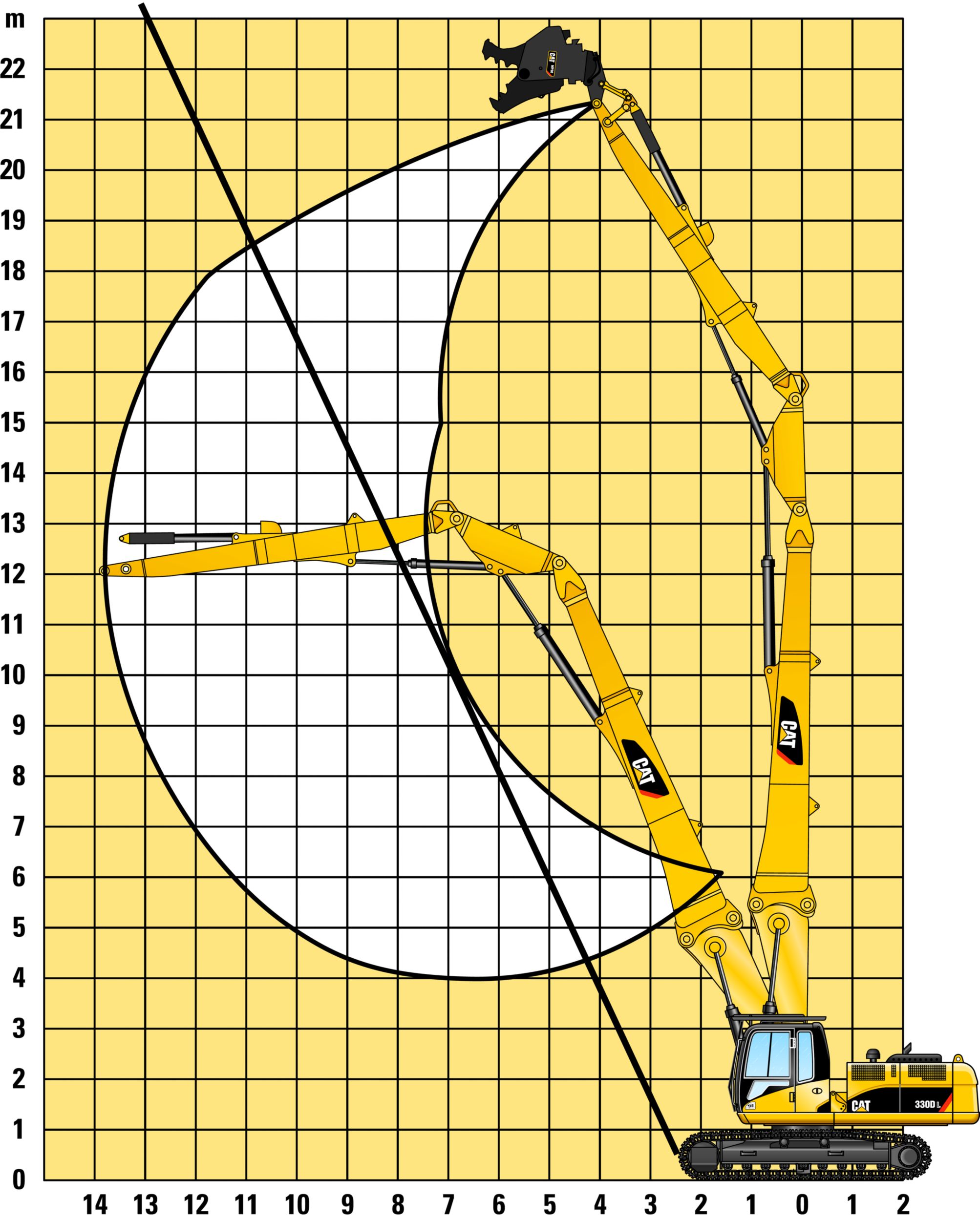

| Maximum Pin Height | 26 100-27 900 mm 1,028-1,098 in |

| Maximum Horizontal Reach | 16 400-18 150 mm 646-715 in |

| Maximum Allowable Angle from Vertical | — |

Benefits & Features

Reliability

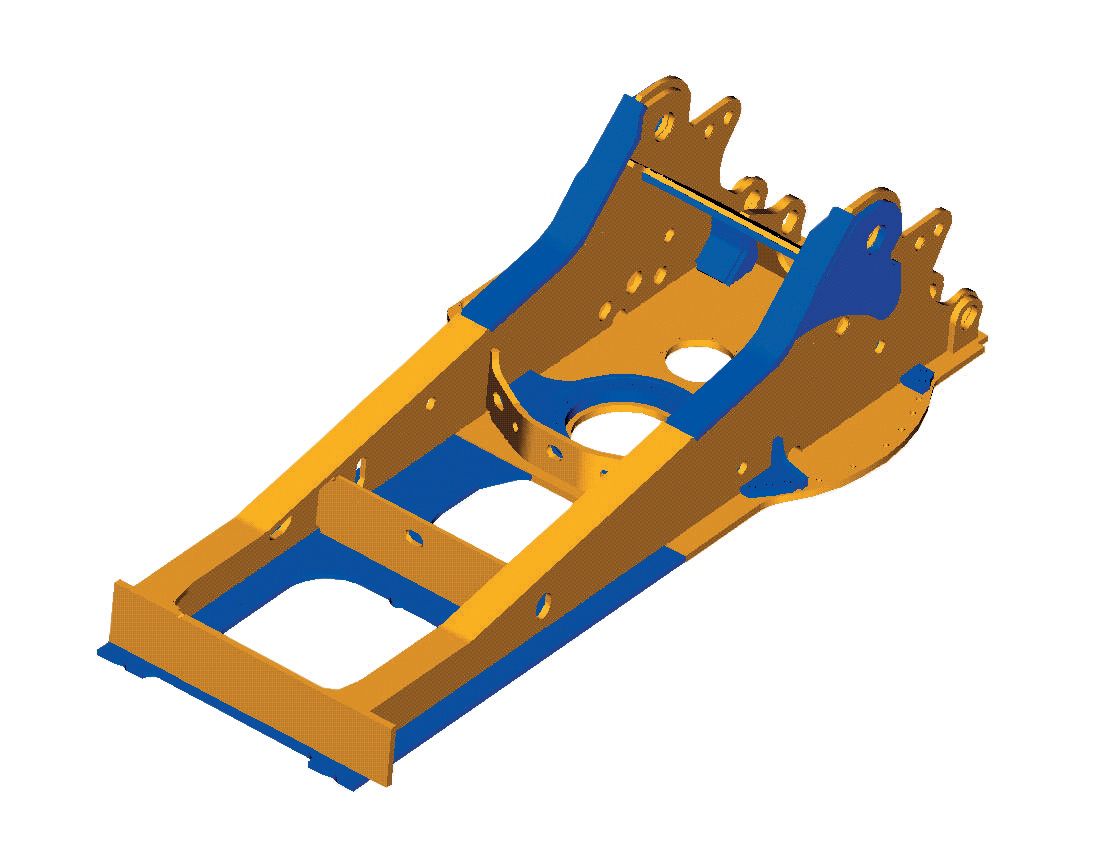

Upper Frame and Counterweight

Purposely designed and built for extreme conditions.

Front Parts

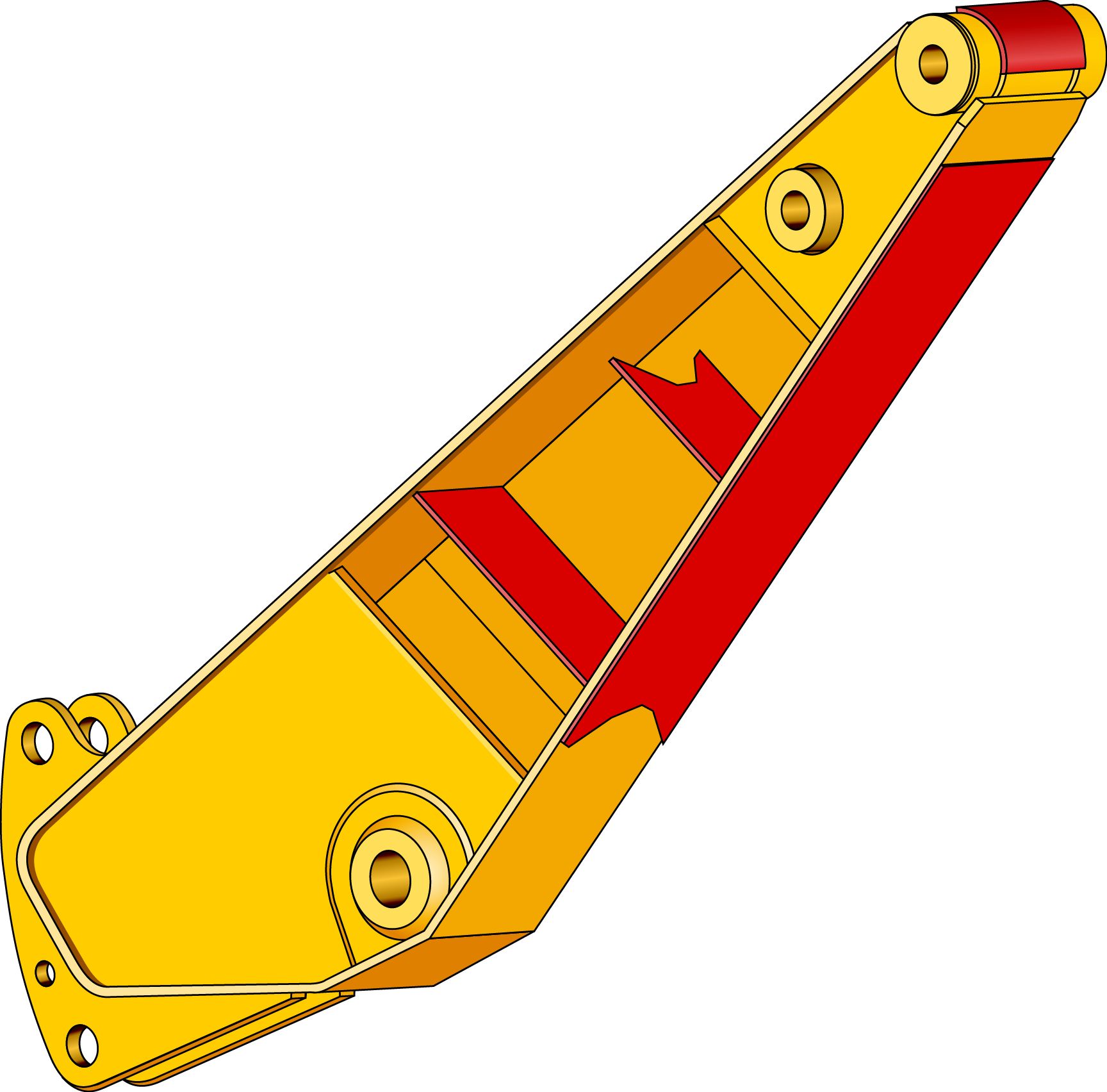

- All Caterpillar® booms and sticks have internal baffles which give the structures extra strength and durability. They are designed based on a precise finite element analysis that highlights all the potential stress areas under all possible load cases. These specific areas are then reinforced accordingly.Caterpillar excavator booms and sticks are built for performance and long service life.

- Castings and forgings are used at high stress areas such as boom nose, boom foot, boom cylinder and stick foot.

- Large, welded, box-section structures with thick, multi-plate fabrications in high-stress areas to better withstand torsional loads.

- All booms and sticks go through a stress relief heat treatment to maximize fatigue life and durability.

Tool Cylinder Protection

To prevent damage to the tool cylinder rod caused by falling concrete and debris, the tool cylinder is equipped with a heavy duty metal cover. Thanks to its unique construction, the cover protects the cylinder rod in every position.

Demolition Sticks

The Demolition sticks are made of thick plates (on top, bottom and side) and have additional internal baffles to improve their resistance to torsion stresses. They also feature hardened bores at all connections (connections with boom and tool linkage). Additional wear plates on the bottom side and around the nose extend the whole stick life.

Operator Comfort and Safety

Hydraulically Tiltable Cab

The hydraulically tiltable cab tilts back to further improve upward visibility and to allow the operator to adopt a more comfortable body position. The tiltable cab is integrated into the upper frame and therefore does not increase the machine's shipping height. Moreover, because of the integration into the upper frame, no tilt parts are exposed to the demolition environment. To reduce vibrations and sound, the cab shell is attached to the frame with viscous mounts.

Automatic Climate Control

Fully automatic climate control adjusts temperature and flow and determines which air outlet is best in each situation.

High Visibility Demolition Cab

The thick laminated safety glass front window is one-piece with a bottom mounted parallel wiper for excellent visibility. For enhanced upward visibility, the impact resistant top window extends completely to the rear and has a wiper and washer.

Falling Object Guard

The ISO 10262-1998 and SAE J1356 certified falling object guard on top and front of the cab is standard. The crossbars of the top guard are angled in line with the operator's sight for enhanced visibility of the work tool. The front guard swings out for easier windshield cleaning.

Productivity

Working Height

While the maximum pin height is given as a reference to compare machines, the actual “working height” is always different. An experienced operator will never work above a safety line that extends from the front edge of the tracks and follows a “1:2” rule (2 meters of vertical height for 1 meter of horizontal reach). Working under this line is generally accepted as a safety rule to avoid any risk of debris falling on the machine. Caterpillar UHD excavators have been purposely designed with the “1:2” line in mind and show therefore best working heights and enhanced performances along that line.

Dedicated UHD Tool Linkage

Because UHD applications require different working positions than standard applications, CAT engineers developed a purpose-designed linkage for the UHD front parts. Besides providing an optimized working envelope, this linkage also greatly improves the tool controllability.

Versatility

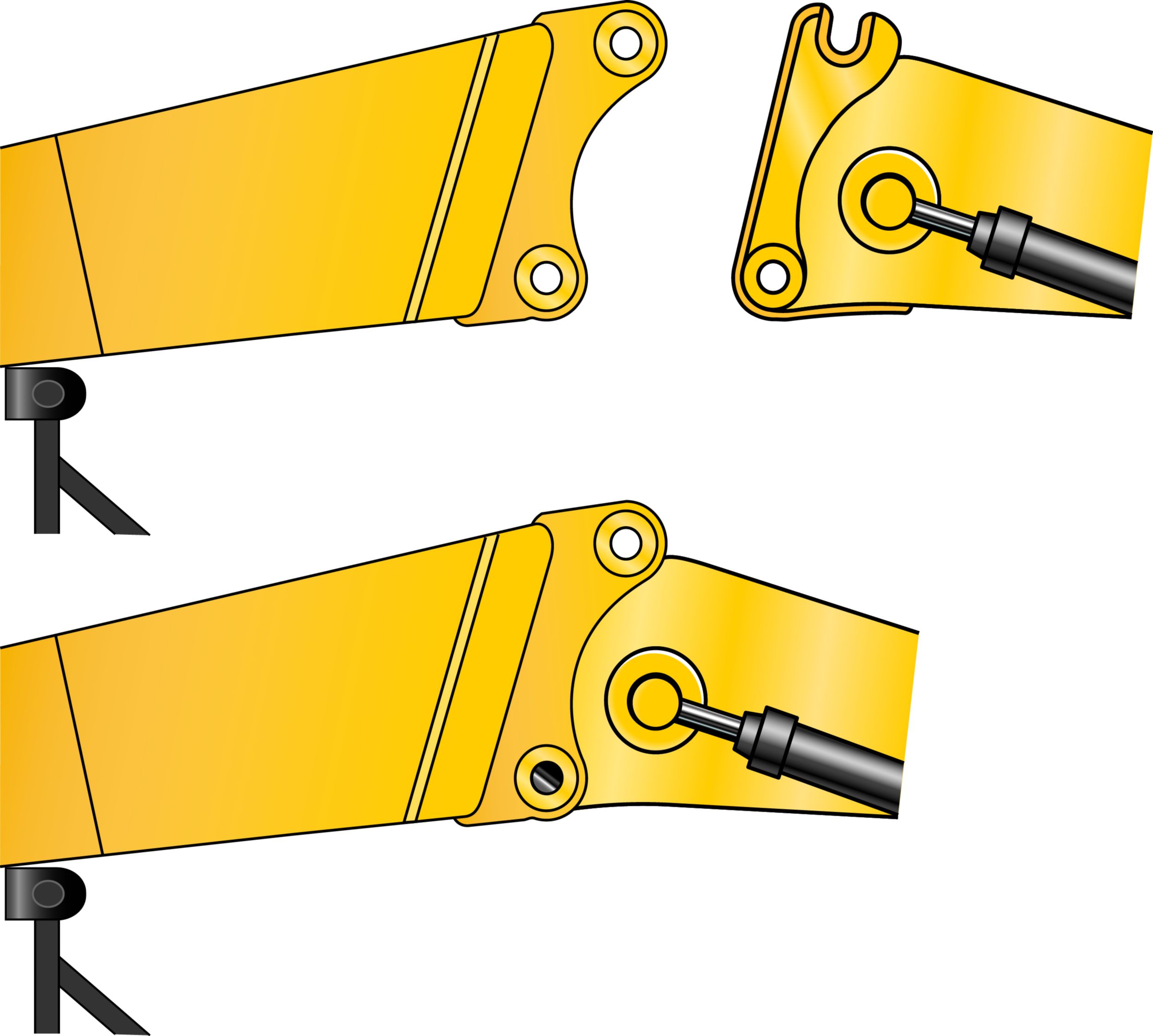

Retrofit (short 2P)

A short boom nose can be hooked onto the bottom foot. To maximize the machine's extreme versatility, this boom nose can be put in two different positions. The straight position is ideal for working in above ground level applications, such as low level demolition or sorting. The bent position can be used for applications such as digging or truck loading. Optional medium pressure lines also enable the use of tilting buckets and tool rotation.

Boom Hook System

The front parts are equipped with a reliable and safe hook system between the boom foot and boom nose. Compared to the traditional pin-mounted joint, the hook system significantly reduces the time needed to change between the Ultra-high front parts and the retrofit configurations. In principle, theboom hook system consists of a hook to pick up the front parts and a mechanical expander pin to secure them onto the boom foot. The absence of any hydraulic parts, as well as a full length heavy duty one-piece securingpin, ensure safe and reliable operation. The operator has an excellent view of the hook system from the cab to easily change the front parts.

Hydraulic Quick Disconnects and Face-to-Face Ball Valves

On 330D, the hydraulic lines between boom foot and boom noseare fitted with hydraulic quick disconnects to even further reduce the time needed to change the front parts. Oil spillage and contamination is reduced through the quick disconnects flat-face design. On larger models, face-to-face ball valves assure the unmatched reliability required for high hydraulic flows.

Tool Control System

Ten hydraulic pump flow and pressure settings can be preset on the monitor (Electronic Control System), eliminating the need to adjust the hydraulics each time a tool is changed. Selecting the proper setting from the monitor's menu instantly provides the operator with the correct amount of flow and pressure for the tool. The unique Cat proportional sliding switches provide modulation to the tool and make precision work easy.

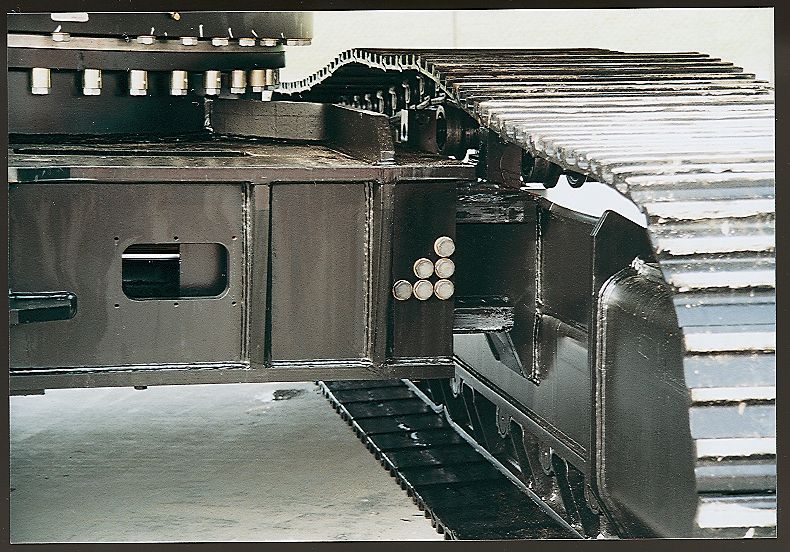

Undercarriage

Hydraulic Variable Gauge Undercarriage (HVG)

The hydraulic variable gauge undercarriage increases the stability through increased track gauge in working position, as well as by lowering the center of gravity of the machine. The non-bolt joint allows a change from shipping to working width, or reverse, in less than one minute. Standard on the 345C UHD.

Work Tools

Quick Couplers

With the addition of a coupler system, exchanging work tools is fast and easy - improving overall production, and increasing machine versatility. Couplers can connect to a wide variety of work tools including Grapples, Shears, and Multi-processors

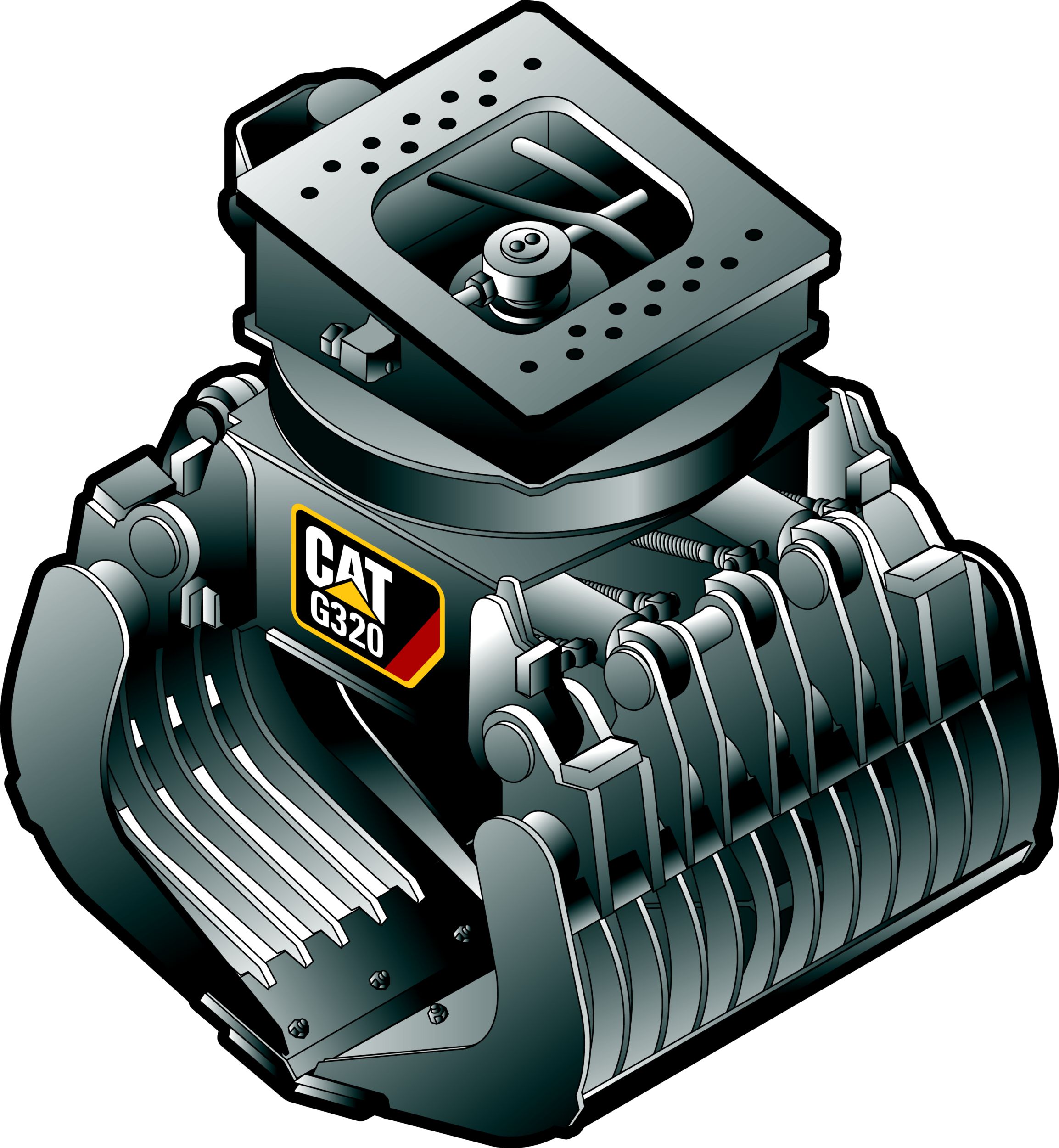

Sorting and Demolition Grapples

- Productive in Demolition

- Easily Positioned and Maneuvered

- Built for Durability

Multi-Processors

- Extreme Versatility

- Maximum Productivity

- Durable Work Tool

- Low Noise Level

Mobile Shears

- Complete Solution

- 360° Rotation, Efficient Jaw Design, Fast Cycle Times

- Built Durable

Data not available.

Standard Equipment

- Reinforced upper frame and heavier counterweight

- Hydraulically tiltable cab (integrated into the upper frame)

- Purpose-designed demolition cab, with impact-resistant front windshield, large high-resistant upper skylight, and FOGS

- Front windshield and top window wipers

- Boom Hook System with Hydraulic Quick Disconnects (330D) or face-to-face ball valves (345C, 365C, 385C)

- Tool cylinder protection guard (sliding steel box)

- Dedicated UHD tool linkage

- Boom, stick and tool cylinder lowering control devices with Caterpillar SmartBoom™ system and overload warning device