Specifications

| Operating Weight - With Cab | — |

| Weight - Drum with ROPS/FOPS | — |

| Weight - Drum with Cab | — |

| Weight - Drum with Sun Canopy | — |

| Compaction Width | — |

| Static Linear Load - With Cab | — |

| Static Linear Load - With ROPS/FOPS | — |

| Ground Clearance | — |

| Turning Radius - Inside Drum Edge | — |

| Travel Speed - Maximum | — |

| Gross Power | — |

| Engine Model | Cat C7.1 |

| Stroke | — |

| Bore | — |

| Overall Length | — |

| Overall Width - With Blade Option | — |

| Optional Blade Height | — |

| Wheel Base | — |

| Overall Width | — |

| Drum Width | — |

| Overall Length - With Blade Option | — |

| Drum Diameter | — |

| Height - With ROPS/FOPS or Cab | — |

| Nominal Amplitude - Low | — |

| Nominal Amplitude - High | — |

| Centrifugal Force - Minimum | — |

| Variable Frequency Option Range | 23.3 - 30.5 Hz (1400-1830 vpm) |

| Centrifugal Force - Maximum | — |

| Vibratory Frequency - Standard | 30.5 Hz (1830 vpm) |

| Tires | 23.1 x 26 |

| Fuel Tank Capacity | — |

Benefits & Features

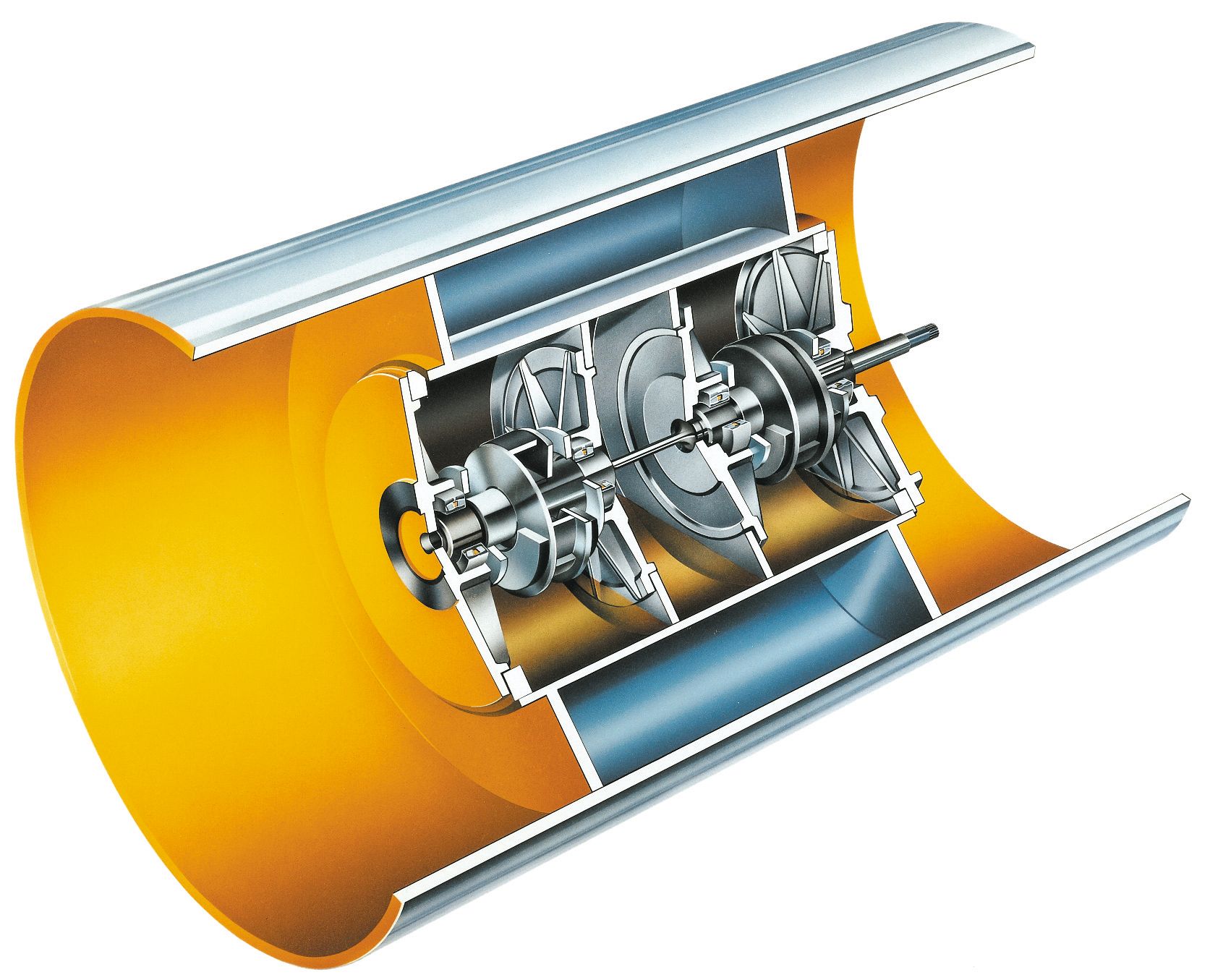

Enhanced Vibratory System

Universal Bumper

The universal bumper helps add weight to the drum as well as making it easier to equip the machine with the optional padfoot shell kit.

Reliable Power Train

Dual-pump Propel System

The exclusive Cat dual pump propel system provides steady hydraulic flow for unmatched gradeability and blade function and now has been enhanced with electronic control for even better performance. The dual pump propel system provides separate hydraulic flow to the rear wheels and the drum for exceptional tractive effort in thick lifts, soft underfoot conditions or steep slope applications and allows for superior control on a grade in forward and reverse.

Large Cooling Package

B-Series Vibratory Soil Compactors are equipped with a large cooling package and a variable speed fan. The large system helps to keep operating temperatures within optimal ranges. The variable speed fan reduces power draw by only operating at the speed that is necessary to cool the system. The reduced power draw contributes to more efficient use of fuel.

Automatic Speed Control

Automatic Speed Control is a feature that allows the operator to select a maximum working speed. Once selected, the speed can consistently be reached by engaging the propel lever to the full stroke. Consistent speed contributes to compaction quality by making it easier to maintain compaction uniformity.

Comfortable Operator's Environment

Operator's Seat

A new standard operator's seat design rotates to the right 20 degrees and integrates the propel stick and control console with LCD user display on the right armrest. The design allows the controls and display to comfortably follow the operator as the seat is rotated. The seat has a retractable seat belt. ROPS/FOPS configured machines will have a vinyl, all-weather seat. ROPS/FOPS Cab configured machines will have a cloth seat. A deluxe, high-back, air-ride seat is available as an option on Cab-equipped machines.

Easy to Service

Maintenance-free Hitch

The hitch features sealed-for-life bearings that never need greasing.

Data not available.