318D2 LNon-Current

318D2 L-2012,Tier2,LRC,APD(except ANZ & Ko),AMECIS,S.AmeOverview

Increased horsepower, improved controllability, and a comfortable operator station help make the Cat® 318D L Series 2 hydraulic excavator an industry-leading performer. Easy to operate with unmatched versatility, the 318D L Series 2 will help increase your productivity and lower your operating costs.

Specifications

| Engine Model | 3054CA |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | 3054CA |

| Flywheel Power | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Engine Power - ISO 14396 | — |

| Net Power - SAE J1349/ISO 9249 | — |

| Operating Weight | — |

| Operating Weight - Long Undercarriage | 17 000-17 800 kg (37,490-39,250 lb) |

| Operating Weight - Long Undercarriage - Reach Boom - 5.1 m (16'9"), R2.9 m (9'6") Stick, 500 mm (20") Triple Grousers Track Shoes, GD 0.76 m3 (1.00 yd3) Bucket | — |

| Operating Weight - Long Undercarriage - HD Boom - 5.1 m (16'9"), R2.9 m (9'6") Stick, 600 mm (24") Triple Grousers Track Shoes, GD 0.80 m3 (1.04 yd3) Bucket | — |

| Operating Weight - Long Undercarriage - Reach Boom - 5.1 m (16'9"), R2.9 m (9'6") Stick, 700 mm (28") Triple Grousers Track Shoes, GD 0.76 m3 (1.00 yd3) Bucket | — |

| Operating Weight - Long Undercarriage - Reach Boom - 5.1 m (16'9"), R2.9 m (9'6") Stick, 600 mm (24") Triple Grousers Track Shoes, GD 0.76 m3 (1.00 yd3) Bucket | — |

| Operating Weight - Long Undercarriage - HD Boom - 5.1 m (16'9"), HD 2.6 m (8'6") HD Stick, 600 mm (24") Triple Grousers Track Shoes, SD 0.73 m3 (0.96 yd3) Bucket | — |

| Operating Weight - Long Undercarriage - Reach Boom - 5.1 m (16'9"), R2.6 m (8'6") Stick, 500 mm (20") Triple Grousers Track Shoes, GD 0.76 m3 (1.00 yd3) Bucket | — |

| Operating Weight - Long Undercarriage - Reach Boom - 5.1 m (16'9"), R2.6 m (8'6") Stick, 700 mm (28") Triple Grousers Track Shoes, GD 0.76 m3 (1.00 yd3) Bucket | — |

| Operating Weight - Long Undercarriage - Reach Boom - 5.1 m (16'9"), R2.6 m (8'6") Stick, 600 mm (24") Triple Grousers Track Shoes, GD 0.76 m3 (1.00 yd3) Bucket | — |

| Swing Torque | — |

| Swing Speed | — |

| Maximum Drawbar Pull | — |

| Maximum Travel Speed | — |

| Maximum Slope | 35°/70% |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Pressure | — |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| Stick Cylinder - Bore | — |

| Stick Cylinder - Stroke | — |

| Bucket Cylinder - Bore | — |

| Bucket Cylinder - Stroke | — |

| Pilot System - Maximum Flow | 23.7 L/min (1,450 in3/min) |

| Maximum Pressure - Equipment | — |

| Main System - Maximum Flow - Total | — |

| Swing System - Maximum Flow | — |

| Cooling System | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| Fuel Tank Capacity | — |

| Swing Drive | — |

| Engine Oil - With Filter | — |

| Number of Shoes - Each Side | 44 pieces |

| Number of Track Rollers - Each Side | 7 pieces |

| Number of Carrier Rollers - Each Side | 2 pieces |

Benefits & Features

Operator Station

Operator Station

The ergonomically designed operator station is spacious, quiet, and comfortable, assuring high productivity during a long work day. All switches are located on the right-hand console for convenient access.

Monitor

The monitor is a full-color Liquid Crystal Display (LCD) that can be adjusted to minimize sun glare and has the capability of displaying information in 27 languages.

Joystick Control

Low-effort pilot-operated joystick controls are designed to match the operator's natural wrist and arm position for maximum comfort and minimum fatigue.

Seat

The standard suspension seat provides a variety of adjustments to suit the operator's size and weight including fore/aft height and weight. Wide adjustable armrests and a seat belt are also included.

Console

The consoles feature a simple functional design to reduce operator fatigue, ease of switch operation, and excellent visibility. Both consoles have attached armrests with tilting adjustments.

Cab Exterior

The cab shell features thick steel tubing along the bottom perimeter of the cab, improving resistance to fatigue and vibration.

Cab Mounts

The cab shell is attached to the frame with viscous rubber cab mounts, which dampen vibrations and sound levels while enhancing operator comfort.

Windows

To maximize visibility, all glass is affixed directly to the cab, eliminating window frames. The upper front windshield opens, closes, and stores on the roof above the operator with a one‑touch action release system.

Wipers

Pillar-mounted wipers increase the operator's viewing area and offer continuous and intermittent modes.

Engine

The Cat 3054CA engine has been designed to meet U.S. EPA Tier 2 and EU Stage II emission regulations. This engine incorporates a time-proven mechanical governor and a low-pressure fuel injection system that are major contributors to the improvement of fuel system robustness, high fuel efficiency, and ease of troubleshooting. High filtration performance from the primary filter incorporating a water separator and a secondary filter also help to improve fuel filtration system reliability.

Automatic Engine Control and Fuel Delivery

With a net power of 82 kW (110 hp) the 318D L Series 2 has been designed with fuel economy in mind and burns approximately 3% less fuel when compared with the larger 318D L depending on application.

Economy Mode

Available as a standard feature, economy mode allows you to balance the demands of performance and fuel economy while maintaining the breakout forces and lift capacity enjoyed at standard power.

Hydraulics

Outstanding Performance

- The 318D L Series 2 hydraulic system is designed for high efficiency and performance. The new compact design utilizes shorter tubes and lines to reduce friction and pressure drops, resulting in a more efficient use of power.

- Hydraulic snubbers at the rod end of the boom cylinders and both ends of the stick cylinders cushion shock, reduce sound, and increase cylinder life.

- A hydraulic cross-sensing system uses two hydraulic pumps under all operating conditions, improving productivity with faster implement speeds and quicker, stronger pivot turns.

Boom and Stick Regeneration Circuit

The boom and stick regeneration circuit saves energy during boom-down and stick-in operation, increasing efficiency and lowering operating cost.

Easy Operation

Operators do not need to learn different modes. An automatic boom and swing priority function automatically selects the best mode based on joystick movement.

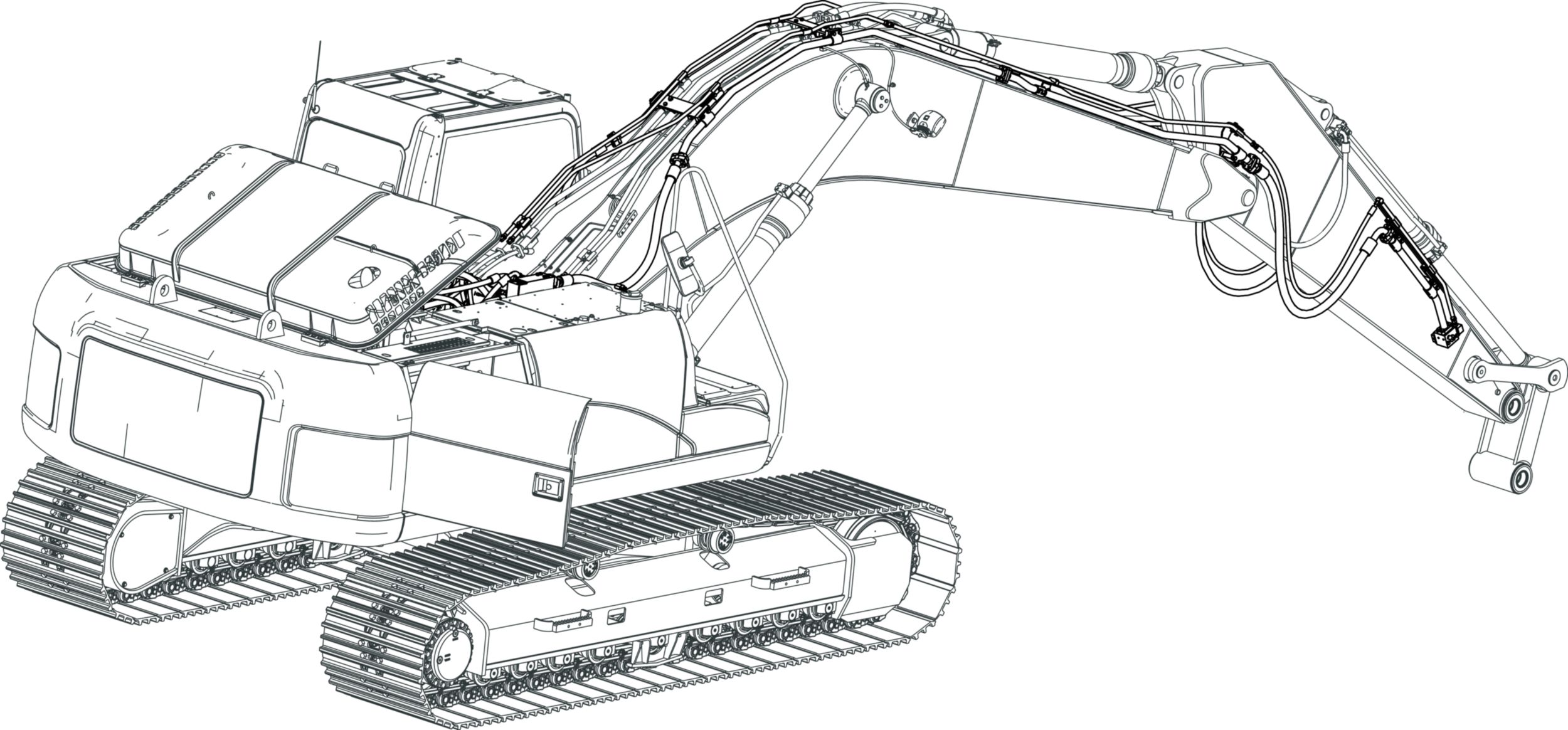

Undercarriage and Structures

Caterpillar uses advanced engineering and software to analyze all structures, creating a durable, reliable machine for robust applications. More than 70 percent of the structural welds are robotic and achieve additional penetration over manual welds. These structural components and undercarriage are the backbone of the machine's durability.

Carbody Design

X-shaped, box-section carbody provides excellent resistance to torsional bending. Robot-welded track roller frames are press‑formed, pentagonal units that deliver exceptional strength and service life. Integral to the track roller frame are the standard idler and center guards, which help maintain track alignment when traveling or working on slopes.

Grease Lubricated Track

Grease lubricated track seals protect the track link and deliver long track link pin and bushing inner wear life.

Travel Motors

Travel motors with automatic speed selection let the 318D L Series 2 automatically change up and down from high and low speeds in a smooth, controlled manner.

Front Linkage

Built for performance and long service life, Cat booms and sticks are welded, box-section structures with thick multi-plate high-strength steel fabrications.

Heavy Duty Stick*

A 2.6 m (8'6") heavy-duty stick has additional plates, new forged parts, and welded joints for increased durability, and digging force. *Offering varies for different regions.

Reach Stick*

A 2.6 m (8'6") and a 2.9 m (9'6") reach stick maximizes the digging envelope. It is made of high-tensile-strength steel using a large box-section design with interior baffle plates for increased durability. *Offering varies for different regions.

Heavy Duty Boom

The 5.1 m (16'9") heavy-duty reach boom is reinforced making it more durable and recommended for use in severe applications.

Reach Boom

The 5.1 m (16'9") reach boom features parts made from a new forging pattern and additional, thicker plates. A light attached to the left side offers improved visibility in dark and low‑light conditions.

Work Tools

An extensive range of Cat work tools for the 318D L Series 2 includes buckets, compactors, grapples, multi-processors, rippers, crushers, pulverizers, hammers and shears. Each is designed to optimize the versatility and performance of your machine.

Couplers

Quick couplers allow one person to change work tools in seconds for maximum performance and flexibility on a job site. One machine can move rapidly from task to task, and a fleet of similarly equipped machines can share a common work tool inventory.

CW Dedicated Coupler

The CW quick coupler can pick up any work tool and is equipped with a wedge-style locking system that fits the quick coupler tight to the tool hinges. Due to the tapered wedge design, there won't be any play during its entire life. Also it is interchangeable with different machine classes. The CW is highly suitable for harsh applications such as demolition and quarries.

Center-Lock™ Pin Grabber Coupler*

Center-Lock is the pin grabber style coupler and features a patent-pending locking system. A highly visible secondary lock clearly shows the operator when the coupler is engaged or disengaged from the bucket or work tool. *Offering varies for different regions.

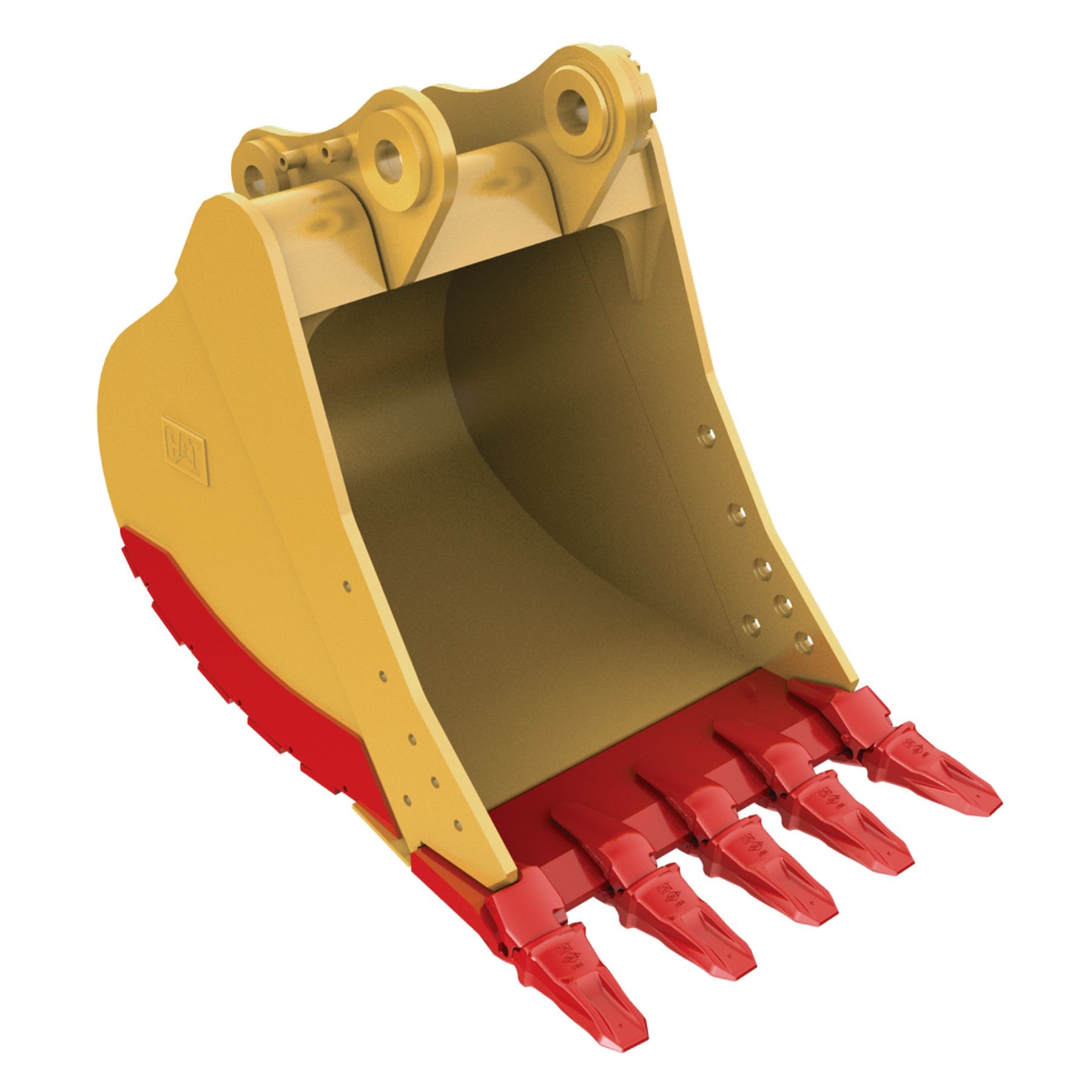

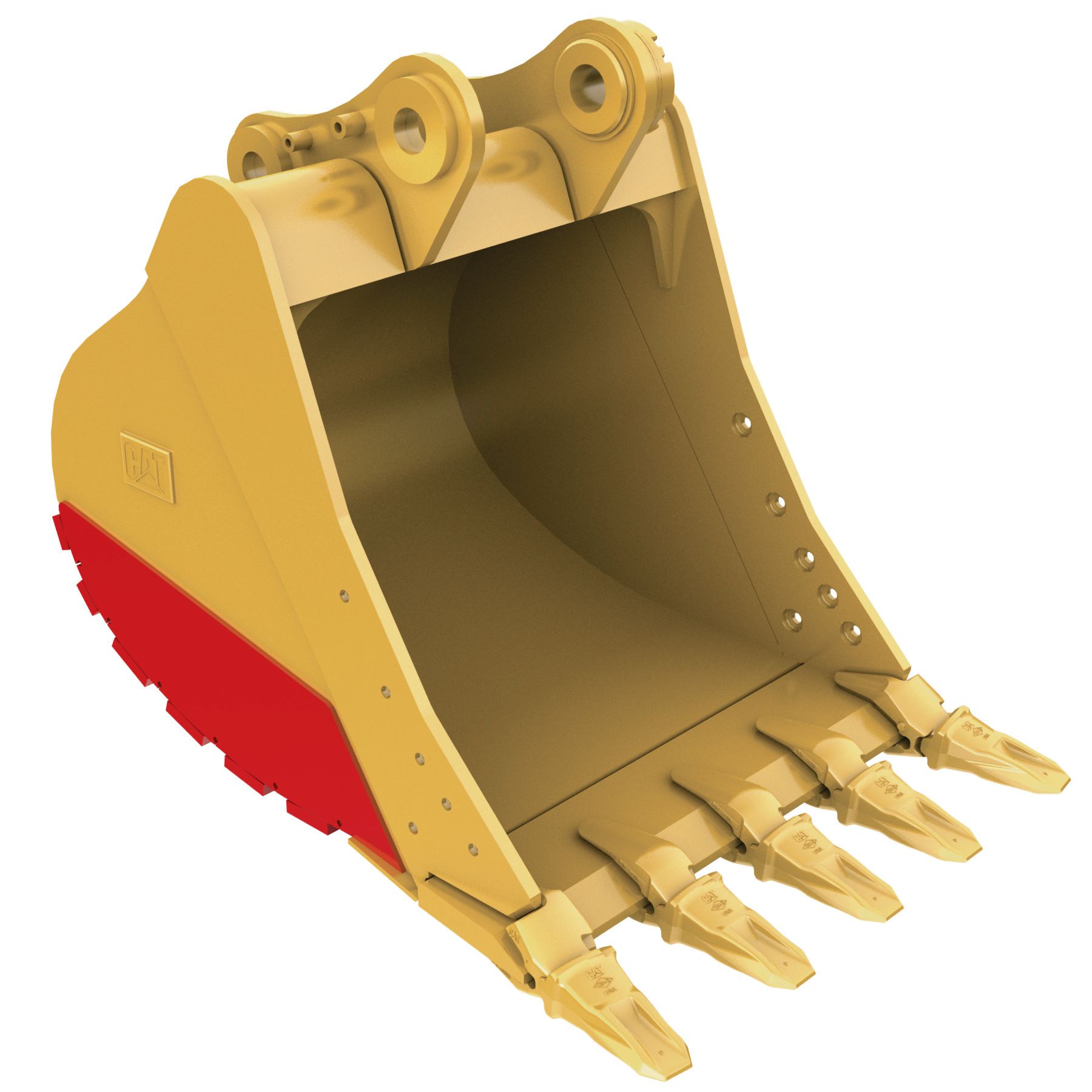

Buckets

Cat Buckets and Cat Ground Engaging Tools (GET) are designed and matched to the machine ensuring optimal performance and fuel consumption.

General Duty Buckets (GD)

These buckets are designed for digging in low-impact, moderately abrasive materials such as dirt, loam, gravel and clay.

Heavy Duty Buckets (HD)

HD buckets are a good starting point when application conditions vary. Especially when conditions include mixed dirt, clay and sand and gravel.

Severe Duty Buckets (SD)

These buckets are best suited to highly abrasive applications such as shot rock, sand stone and granite.

Hydraulic Kits

Caterpillar offers field-installed hydraulic kits that are uniquely designed to integrate Cat Work Tools with Cat excavators. Hoses and tubes are pre-made, pre‑shaped, and pre-painted to make installation quick and easy.

Comprehensive Product Support

All Cat work tools are backed up by a world-wide network of well-stocked spare parts depots and highly experienced after-sales service and support personnel. Work tools available vary by region. Contact your local Cat dealer for more information about the work tools available in your region.

Serviceability

Fast, Efficient Service with Extended Intervals

Most service points are at the ground level for easy access with extended intervals to increase machine availability.

Pump Compartment

A service door on the right side of the upper structure allows ground-level access to the pump, pilot filter, drain filter, and the engine oil filter.

Radiator Compartment

The left service door allows easy access to the engine radiator, oil cooler, air-to-air-aftercooler, water separator and first and second fuel filter. A reserve tank and drain cock are attached to the radiator for simplified maintenance. The air filter features a double-element construction for superior cleaning efficiency. When the air cleaner plugs, a warning is displayed on the monitor screen inside the cab.

Hydraulic Filter

The hydraulic return filter is an in-tank design with a service life of 2,000 hours. A sensor indicates through the in-cab monitor when the filter is plugged and needs to be replaced.

Fan Guard

The engine radiator fan is enclosed by fine wire mesh, reducing the risk of an accident.

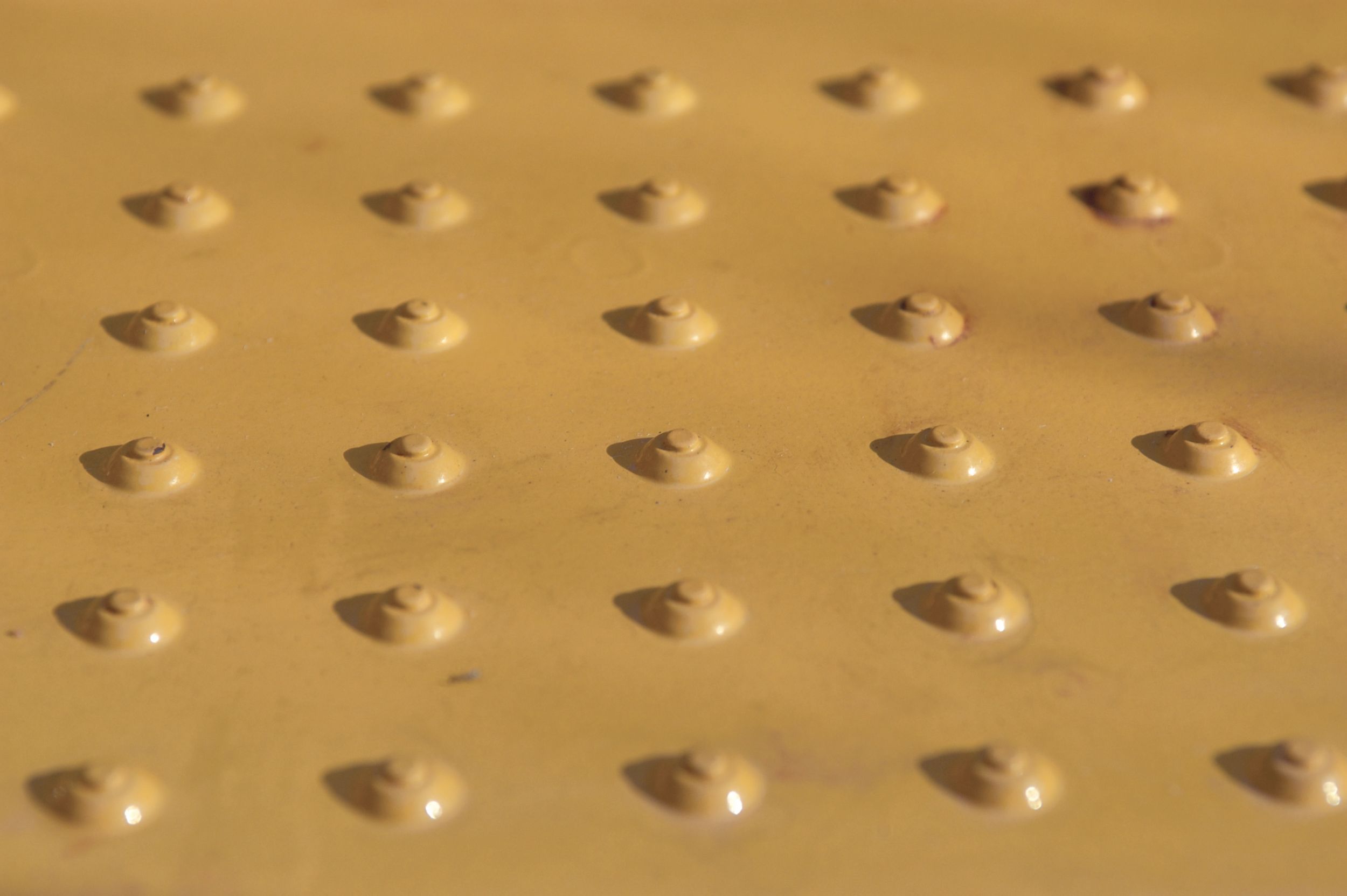

Anti-Skid Plate

Anti-skid plate covers top of storage box and upper structure to prevent slipping during maintenance.

Diagnostics and Monitoring

The 318D L Series 2 is equipped with S·O·SSM sampling ports and hydraulic test ports for the hydraulic system, engine oil, and for coolant. A test connection for the Cat Electronic Technician (Cat ET) service tool is located behind the cab.

Complete Customer Support

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. Save money with remanufactured components.

Machine Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements, machine attachments and operating hours? What production is needed? Your Cat dealer can provide recommendations.

Maintenance Services

Repair option programs guarantee the cost of repairs up front. Condition monitoring services and diagnostic programs such as scheduled oil sampling, coolant sampling, and technical analysis help you avoid unscheduled repairs.

Customer Support Agreements

Cat dealers offer a variety of product support agreements and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Replacement

Repair, rebuild, or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.

Standard Equipment

- ENGINE

- Diesel engine - Cat 3054CA with mechanical governor: - 2300 m (7,545 ft) altitude capability - 50 amp alternator, air intake heater - Tier 2 emission package

- 10 micron fuel filter

- 4 micron fuel pre-filter

- One touch low idle with AEC

- Remote engine oil filter

- Radial seal air filter, double element

- Two speed travel

- Water separator in fuel line with indicator

- Waved fin radiator with side by side type oil cooler

- Fix type A/C condenser

- 52° C (125.6° F) High ambient cooling

- Economy mode

- CAB

- Bolt-on FOGS capability

- Openable front windshield with assist device

- Pillar mounted upper windshield wiper and washer

- Front windshield glass split by 70/30

- Cab sliding upper door window

- Rear window, emergency exit

- Removable lower windshield with in cab storage bracket

- Openable skylight/metal hatch

- Interior lighting

- Standard joystick

- Laminated front upper windshield

- Seat high back, mechanical suspension with head rest

- Seat belt, retractable, 50 mm (2")

- Floor mat

- Bi-level air conditioner (auto) with defroster

- Windshield washer

- Coat hook

- Ashtray and lighter

- Beverage holder

- Literature holder

- Utility space for magazine

- Radio mounting

- Mounting for two stereo speakers

- Antenna flexible type

- Storage compartment suitable for lunch box

- Monitor: - Language display - Full graphic and full color display - Warning information - Filter/fluid change information - Machine condition - Error code and tool mode setting information - Full time clock on monitor

- Positive filtered ventilation

- Seat integrated control joystick

- Adjustable armrest

- Adjustable console

- Neutral lever (lock out) for all controls

- Travel control pedals with removable hand levers

- Capability of installing two additional pedals

- ELECTRICAL

- Circuit breaker

- Cat battery

- HYDRAULIC

- Hydraulic main pump

- High performance hydraulic return filter

- Regeneration control for boom and stick

- Boom lowering device for back up

- Boom drift reducing valve

- Stick drift reducing valve

- Reverse swing damping valve

- Automatic swing parking brake

- Auxiliary hydraulic valve

- Capability of stackable valves for main valve

- Capability of auxiliary circuit

- SECURITY

- Cat one key security system

- Signaling/warning horn

- Mirrors, rearview (frame - right, cab - left)

- Secondary engine shutoff switch

- Door locks

- Cap locks on fuel and hydraulic tanks

- Lockable external tool/storage box

- Rearview camera-ready

- LIGHTS

- Halogen boom light (left side)

- Exterior lights integrated into storage box

- COUNTERWEIGHT

- Counterweight without lifting eye (3170 kg/6,990 lb)

- UNDERCARRIAGE

- Grease lubricated track (GLT2)

- Idler and center section track guiding guard

- Towing eye on base frame

- Standard idler tension spring

- Guard, standard bottom

Optional Equipment

- ENGINE

- Cold weather batteries, -25° C (-13° F)

- Air precleaner

- HYDRAULIC

- Combined circuit

- Combined circuit with medium pressure

- Center-Lock quick coupler lines and control

- Joystick with modulation SW

- Boom and Stick high pressure, medium pressure and quick couple line options

- Control pattern quick-changer, four way

- CAB

- Seat with seat heater, high back, air suspension with head rest

- Pull-down sunscreen

- 12V-10A power supply with two cigar lighter type sockets

- UNDERCARRIAGE

- 500 mm (20") triple grouser shoes

- 600 mm (24") triple grouser shoes

- 700 mm (28") triple grouser shoes

- Track guiding guard - Full length

- FRONT LINKAGE

- Boom, 5.1 m (16'9")

- Heavy duty boom, 5.1 m (16'9")*

- Stick, 2.6 m (8'6")

- Stick, 2.9 m (9'6")

- Heavy duty stick, 2.9 m (9'6")*

- Bucket linkage

- Quick coupler

- *Offering varies for different regions.

- LIGHTS

- Cab lights

- Halogen boom light (right side)

- SECURITY

- Travel alarm*

- Rearview camera and right side mirrors

- Cab mirror

- *Offering varies for different regions.

- TECHNOLOGY

- Product Link, Satellite or Cellular*

- *Offering varies for different regions.

- GUARDS

- FOGS (bolt on)

- Guard, heavy duty bottom

- Swivel guard