Overview

The 793C Off-highway Truck is engineered for performance, designed for comfort, and built to last. The 793C is designed for high production, assuring lowest cost-per-ton hauling in mining applications. It has a reliable and durable operation and the rugged construction and easy maintenance guarantee extended life with low operating costs.

Benefits & Features

Specifications

Benefits & Features

Engine

High Displacement Engine

The Caterpillar 3516B high displacement diesel engine, with a longer piston stroke, new crankshaft, rods, pistons, and single stage turbochargers, is available for optimum performance in most applications.

3516B Engine

The Caterpillar 3516B engine (not available in North America) remains the natural choice for most high altitude applications above 2750 m (9,000 ft). It is designed for extended hours of service between scheduled overhauls and reduced operating costs.

Electronic Unit Injector

Both 3516B engines provide unmatched combustion efficiency.

Electronic Control Module (ECM)

Electronic Control Module (ECM) utilizes advanced engine management software to monitor, control and protect the engine utilizing self-diagnosing electronic sensors.

Aftercooler

Separate circuit aftercooler allows the aftercooler coolant to operate at lower temperatures than jacket water for a denser air charge in the combustion chamber.

Torque Rise

The torque rise provides high lugging force during acceleration and less down shifting on grade or in soft underfooting for faster cycle times.

Reliability and Durability

500 hour service interval for engine oil, oil and fuel filter changes, increasing mechanical availability and production.

Mechanical Power Train

Component Match

The CAT mechanical power train is designed for optimum component match. A wide application range is available in each gear.

Transmission/Chassis Control (TCC)

Transmission/Chassis Control (TCC) module communicates over the CAT Data Link with the engine ECM to manage engine speed during shifts for increased clutch life and operator comfort.

Torque Converter

Lock-up torque converter combines the maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive.

Transmission

Six-speed, planetary power shift transmission is designed for the high horsepower of the 3516B engine.

Final Drives

Large, differential and double-reduction final drives provide torque multiplication of 28.8:1 to further reduce stress on the drive train.

Steering System

The hydraulic steering system provides precise, controllable steering.

Rims and Wheels

Cat center mounted rims and cast rear wheels are mounted using studs and nuts to minimize maintenance and provide outstanding durability.

Engine/Power Train Integration

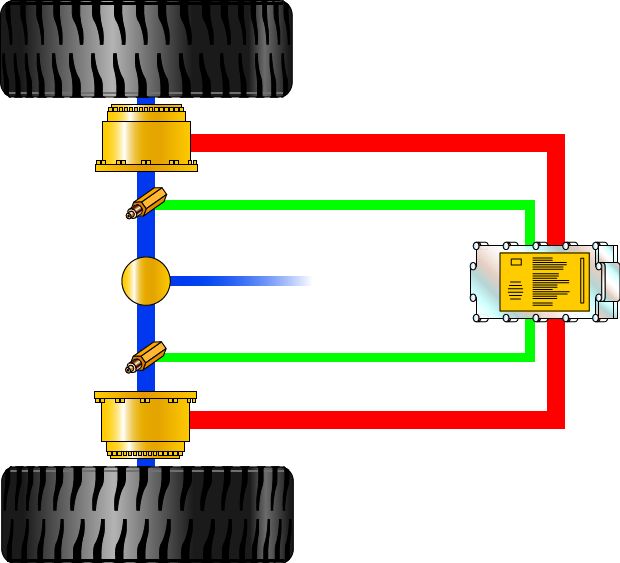

CAT Data Link

The CAT Data Link electronically connects the engine and transmission controls to optimize overall power train performance, reliability and component life for reduced power train operating costs.

Improved Diagnostics/Serviceability

The electronic engine and transmission controls provide enhanced diagnostic capability.

Integrated Braking Control (IBC)

Integrated Braking Control (IBC) combines braking control enhancements into one system for efficiency and simplification.

Brakes

Disc Brakes

Caterpillar four-wheel forced oil-cooled, multiple disc brakes are continuously cooled for exceptional,non-fading braking and retarding.

Oil-cooled Disc Brakes

Oil-cooled disc brakes are designed with large discs and plates for reliable, adjustment-free operation providing superior performance and service life in comparison to shoe-type and dry-discsystem.

Oil Film

An oil film prevents direct contact between the discs. The film absorbs the braking forces by shearing the oil molecules. The heat generated is transferred to the oil and carried away to oil coolers, extending brake life.

Pistons

A Caterpillar patented, two-piston design combines the service, secondary, parking brake, and retarding functions in the same robust system.

Fuel

No fuel is used during retarding. The engine provides additional retarding by running against compression on downhill hauls.

Four Corner Retarding

Four corner retarding with 60/40 percent split (rear/front) in braking effort provides superior control in slippery conditions.

Integrated Braking Control (IBC)

Production

Automatic Retarder Control results in increased production with faster downhill speeds. By maintaining consistently higher engine speeds, overall truck speed will be higher than a manually controlled truck.

Controllability

Automatic Retarder Control results in excellent controllability and reduced operator effort. Automatic brake modulation provides a smoother ride, better control in slippery conditions and allows the operator to focus more on driving.

Troubleshooting

Automatic Retarder Control results in faster troubleshooting and diagnosis with self-diagnostic capability and the ability to communicate with ET through the CAT Data Link.

Operator Fatigue

Automatic Retarder Control results in reduced operator fatigue resulting from ease of operation.

Engine Overspeed Protection

Automatic Retarder Control results in engine overspeed protection.

Automatic Retarder Control Production Advantages

Automatic Retarder Control can increase vehicle speed by as much as 15 percent over manual retarder control.

Traction Control System (TCS)

Traction Control System (TCS) improves traction and truck performance in poor underfoot conditions by electronically monitoring and controlling wheel slippage.

Structures

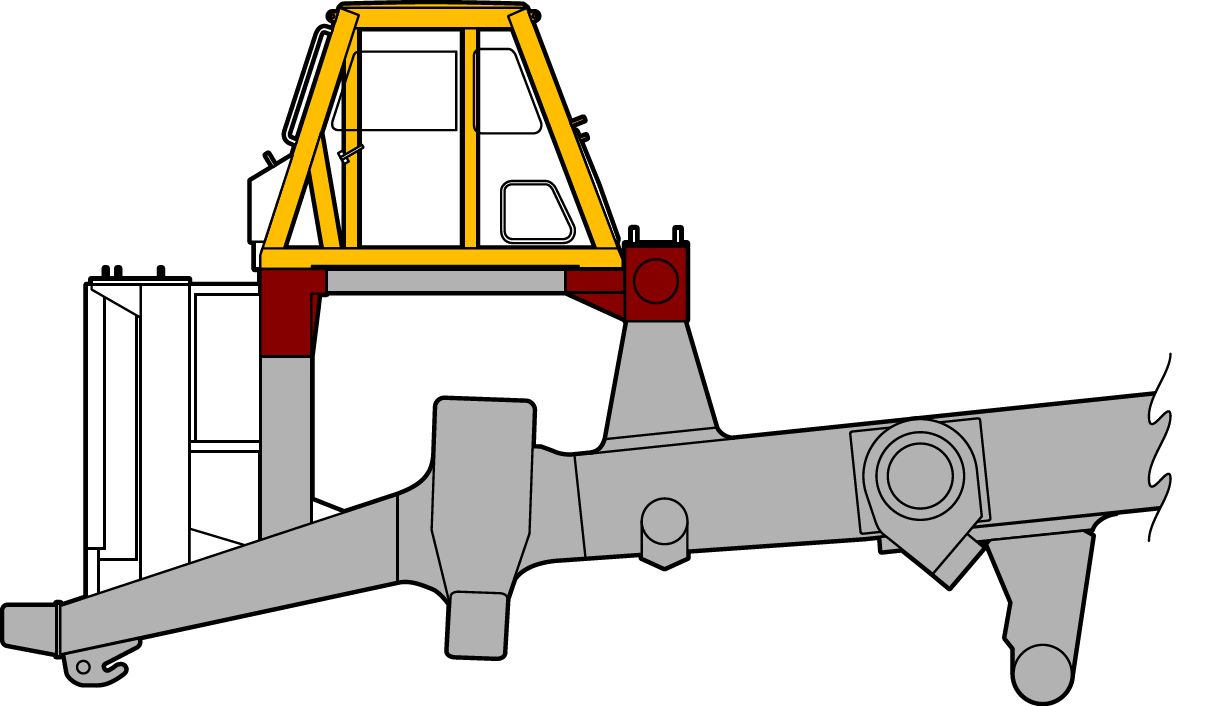

Frame

Box-section frame design and deep penetrating, continuous welds resist damage from heavy loads without adding extra weight.

Castings

Castings have large radii with internal reinforcing ribs to dissipate stresses that can cause fatigue and cracking.

Rollover Protection Structure (ROPS)

Rollover Protection Structure (ROPS) is integral to the cab and frame. The cab is resiliently mounted to the frame to reduce vibration and noise levels.

Suspension System

The suspension system is designed to dissipate haul road and loading impacts.

Truck Body Systems

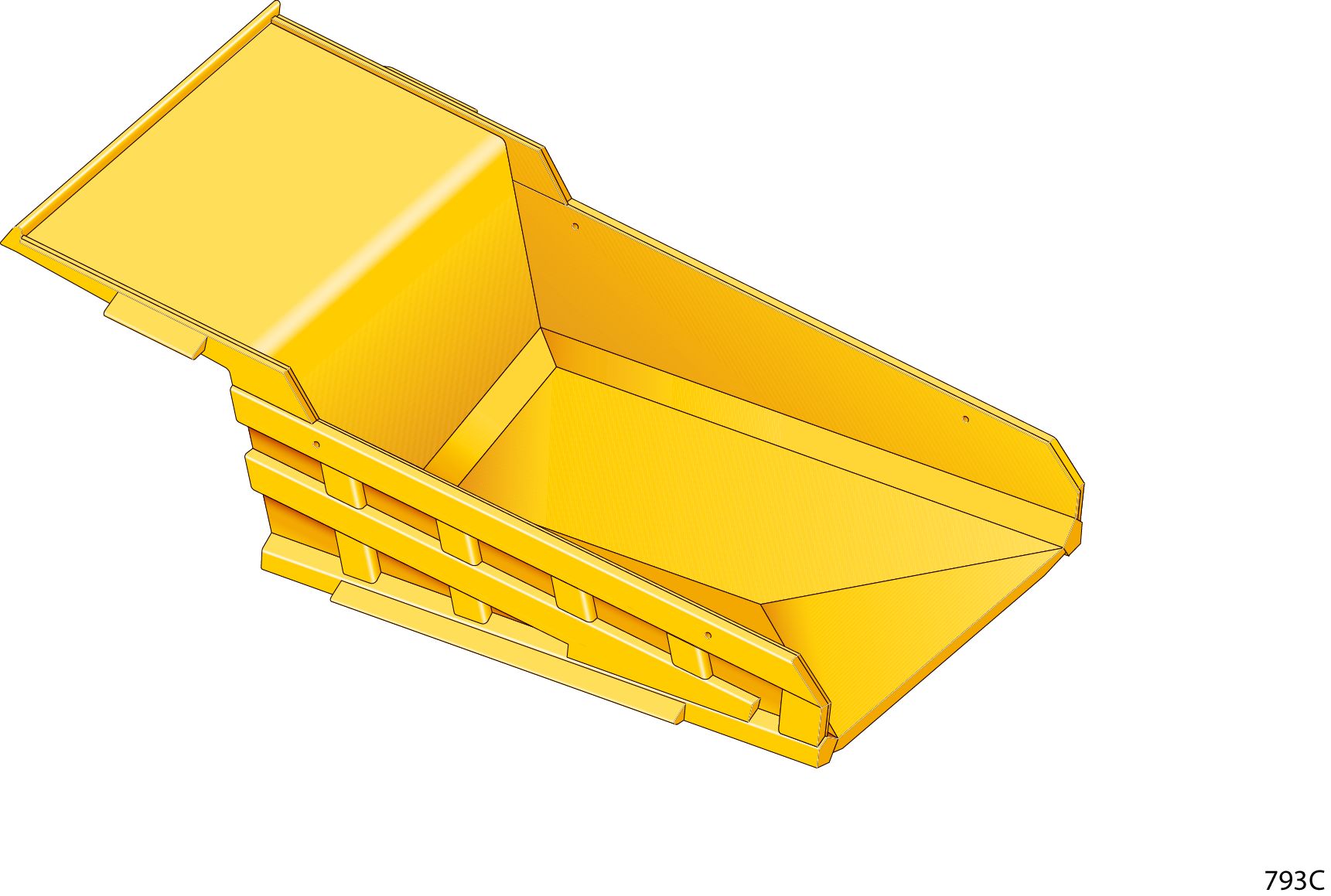

Dual-Slope Body Design

Dual-slope body design provides excellent load retention, a low center of gravity and clean dumping characteristics.

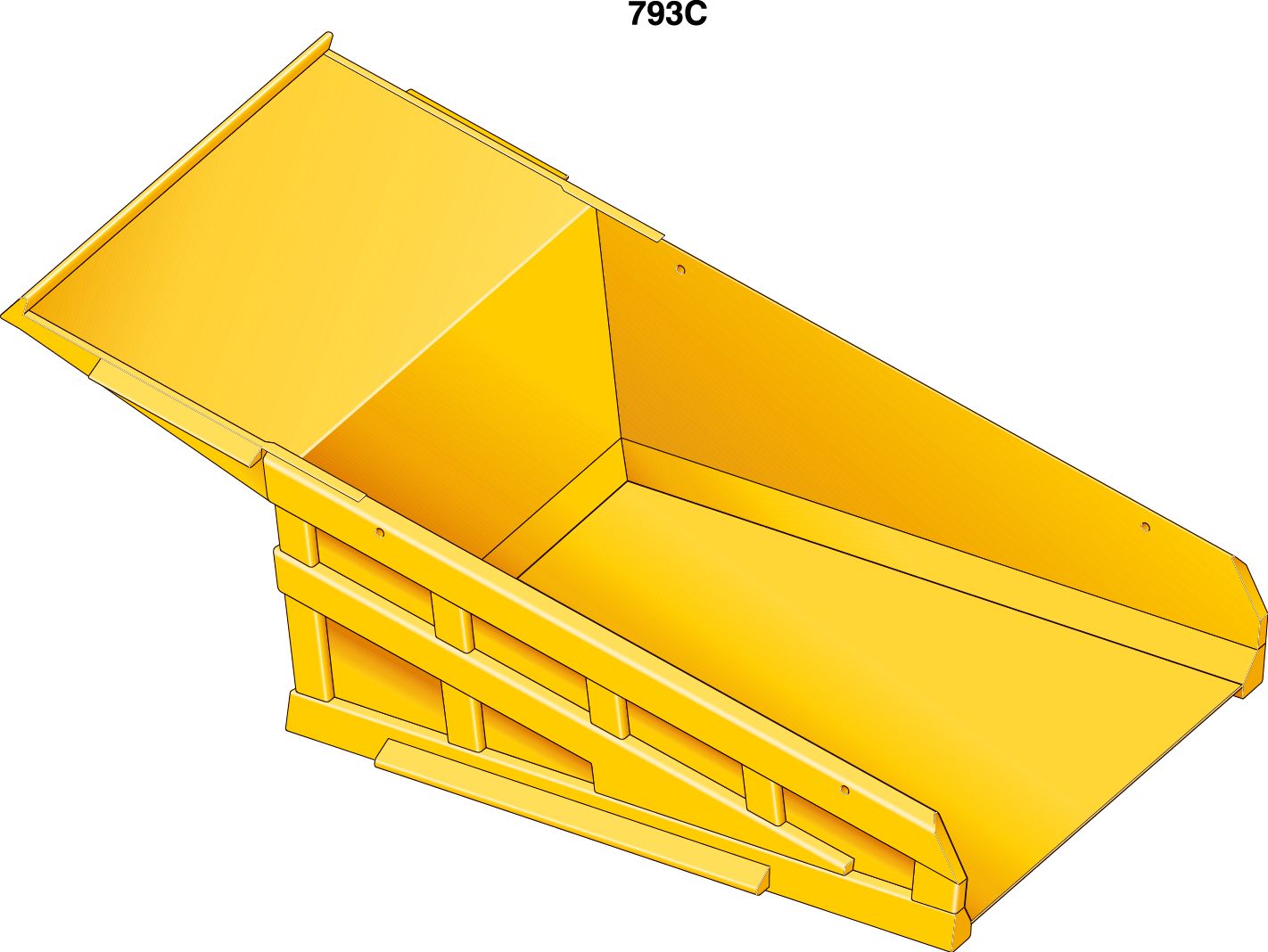

Flat Floor Body Design

Flat floor body design provides smooth, metered dumping and higher dump clearances.

Mine Specific Design

Mine specific design (MSD) bodies, specifically designed for each application, are available as a custom configuration to minimize weight and maximize productivity.

Custom Options

Custom truck body options are available to match individual mine applications. These products are specifically designed to match material hauled and provide an extended service life.

Miscellaneous Products

Miscellaneous products including wraparound tail extensions, sideboards, rock shedders, tumblebars, rockboxes, and liners are also available.

Wear Plates

Wear plates can be added where required, including the Caterpillar Mechanically Attached Wear Protection System (MAWPS).

Operator's Station

Visibility

Exceptional all-around visibility reduces strain and fatigue allowing confident maneuverings and increased productivity.

Cab

Integral, sound-suppressed ROPS/FOPS Cab is standard.

Seat

Ergonomically designed, air suspension seat is fully adjustable for operator comfort.

Hoist Control

Electric hoist control is mounted next to the operator's seat for ease of operation. This is a low effort control to minimize operator input.

Brake Pedal

Secondary brake pedal is located on the floor to provide easy operator control.

Displays

Vital Information Management System (VIMS) displays and operator key pad for precise machine status information.

Steering Wheel

Tilt and telescoping steering wheel improves operator access and comfort.

Transmission Console

Transmission console has been redesigned with backlit gear indicators and ergonomic shift knob.

Storage

Large storage compartment is located under the trainer seat.

Trainer Seat

Trainer seat has wide hip and shoulder room. A back rest and seat belt are standard. An optional air suspended seat is available.

Operator Window

Powered operator window is standard. Sliding trainer seat window is standard.

Operator Controls

Operator controls for turn signal, high beam, intermittent windshield wiper, windshield washer and horn have been redesigned for operator efficiency and comfort.

Heater and Air Conditioner

Standard heater and air conditioner have a more efficient design, permitting increased flow, modulation, and serviceability. These systems provide fresh, pressurized, temperature-controlled air circulation.

Radio

Radio ready cab prewired with power converter, speakers, wiring harness, and antenna. Provision for add-on communication systems.

Vital Information Management System (VIMS)

Caterpillar Designed System

Vital Information Management System (VIMS) is an integrated Caterpillar designed system that monitors machine performance to provide critical information on a real-time basis.

Gauge Cluster

Gauge cluster in the cab maintains a constant display of several, machine functions.

Vital Information Management System Keypad

Vital Information Management System keypad allows the operator or service technician to access through the message center, gauge values (real-time) and stored information. The keypad can also be used by service personnel to access diagnostic information.

Message Center

Message center displays operator requested information and utilizes a three-category warning system to alert the operator to an abnormal machine condition.

Alert System

The three-category alert system provides advisory information on an exception basis to the operator via the message center on abnormal machine conditions.

Trouble Shooting

The Vital Information Management System simplifies trouble shooting, reduces down time and lowers operating costs by allowing minor problems to be corrected before they cause extensive damage.

Production Management

Production management, a feature component of the Vital Information Management System (VIMS), enhances truck and loading tool effectiveness for improved fleet productivity and reduced operation and maintenance cost.

Off-Truck Software Package

The Vital Information Management System off-truck software program (VIMS-PC) allows service personnel to download a complete record of production information, machine data events and system diagnostics to a laptop computer.

Vital Information Management System

Trouble Shooting

VIMS simplifies trouble shooting, reduces down time and lowers operating costs by allowing minor problems to be corrected before they cause extensive damage.

Production Management

Production management, a feature component of VIMS, enhances truck and loading tool effectiveness for improved fleet productivity and reduced operation and maintenance cost.

Weight Production Management System

True Weight Production Management System utilizes suspension strut pressure differentials and a new algorithm to weigh the truck after it has moved away from the loader and has shifted into second gear.

Road Analysis Control

Road Analysis Control (RAC)(optional attachment) utilizes suspension strut pressure differentials to monitor haulroad conditions for operation and maintenance management.

VIMS Off-Truck Software

The VIMS off-truck software program (VIMS-PC) allows service personnel to download a complete record of production informantion, machine data events and system diagnostics to a laptop computer.

Customer Support and Serviceability

Parts Availability

Most Cat parts are immediately available off the shelf. Cat Dealers rely on our worldwide computer network to find parts instantly and minimize your machine downtime.

Flexible Financing

Your dealer can arrange attractive financing on the entire line of Cat equipment.

Machine Management Service

Cat Dealers help manage your equipment investments.

Literature Support

Operation and maintenance manuals are easy to use helping you get the full value of your equipment investment.

Remanufactured Components

Remanufactured components are economically available for many Caterpillar components.

Ground-level Access

Ground-level access provides convenient servicing to tanks, filters and compartment drains, as well as engine shutdown capability.

Electronic Technician

Caterpillar Electronic Technician (ET accesses machine data easily. It quickly runs tests, makes calibrations and retrieves system data to help find and correct problems before they become costly failures.

Maintenance Platform

The maintenance platform provides access to engine, air filters, steering hydraulic tank and battery compartment.

Automatic Lubrication System

The automatic lubrication system provides grease to necessary components on a regular basis to reduce maintenance and improve machine availability.

Fast Fill Service Center

Fast fill service center (Wiggins) features high speed fuel and oil exchange.

Scheduled Oil Sampling

Scheduled Oil Sampling valves speed sampling and analysis reliability.

Oil Renewal System (ORS)

Oil Renewal System (ORS) is an option available which extends oil change intervals and reduces waste oil handling by continuously burning oil from the sump through normal engine operation.

Cylinder Heads

Individual, interchangeable engine cylinder heads can be removed easily for visual inspection of internal parts.

In-frame Access

In-frame access allows maintenance and minor repairs without major component removal.

Quick Coupler Pressure Taps

Quick coupler pressure taps are located in most hydraulic systems providing clear, quick pressure checks and diagnostics.

Air Filters

Radial seal air filters are easy to change, reducing time required for air filter maintenance.

Electrical Connectors

Sealed electrical connectors lockout dust and moisture. Wires are color coded for easy diagnosis and repair. Wiring harnesses are braided and have a protective sheath to prevent damage.

Data not available.