Overview

Specifically designed for high production hauling in sound sensitive environments.

Benefits & Features

Specifications

Benefits & Features

Environmentally Responsible Design

Quiet Operation

Sound suppressed machinery plays a significant role in mitigating the impact of noise in the environment. With the development of the 793C XQ, Caterpillar leads the way in the production of sound reduced off-highway trucks for operation in sound sensitive mining areas. Designed specifically for regions with stringent noise limitations, sound power levels on the 793C were reduced approximately 9 dB(A) making the sound power level on the 793C XQ less than one-eighth the sound level of the standard truck. This effectively means that eight sound reduced trucks emit the same level of sound as a single standard truck, significantly reducing environmental impact and improving quality of life.

Sound Modeling

Through the use of the Caterpillar proprietary Sonic+ sound modeling software, sound treatment options were modeled for the complete truck system. Extensive sound testing was conducted to confirm effectiveness of the model and sound treatments. Optimum sound reduction was achieved by applying sound reduction treatments to the 793C XQ engine, cooling system, exhaust system and driveline.

Sound Treatments

Caterpillar applied various sound treatment options to reduce noise on the sound suppressed 793C XQ.

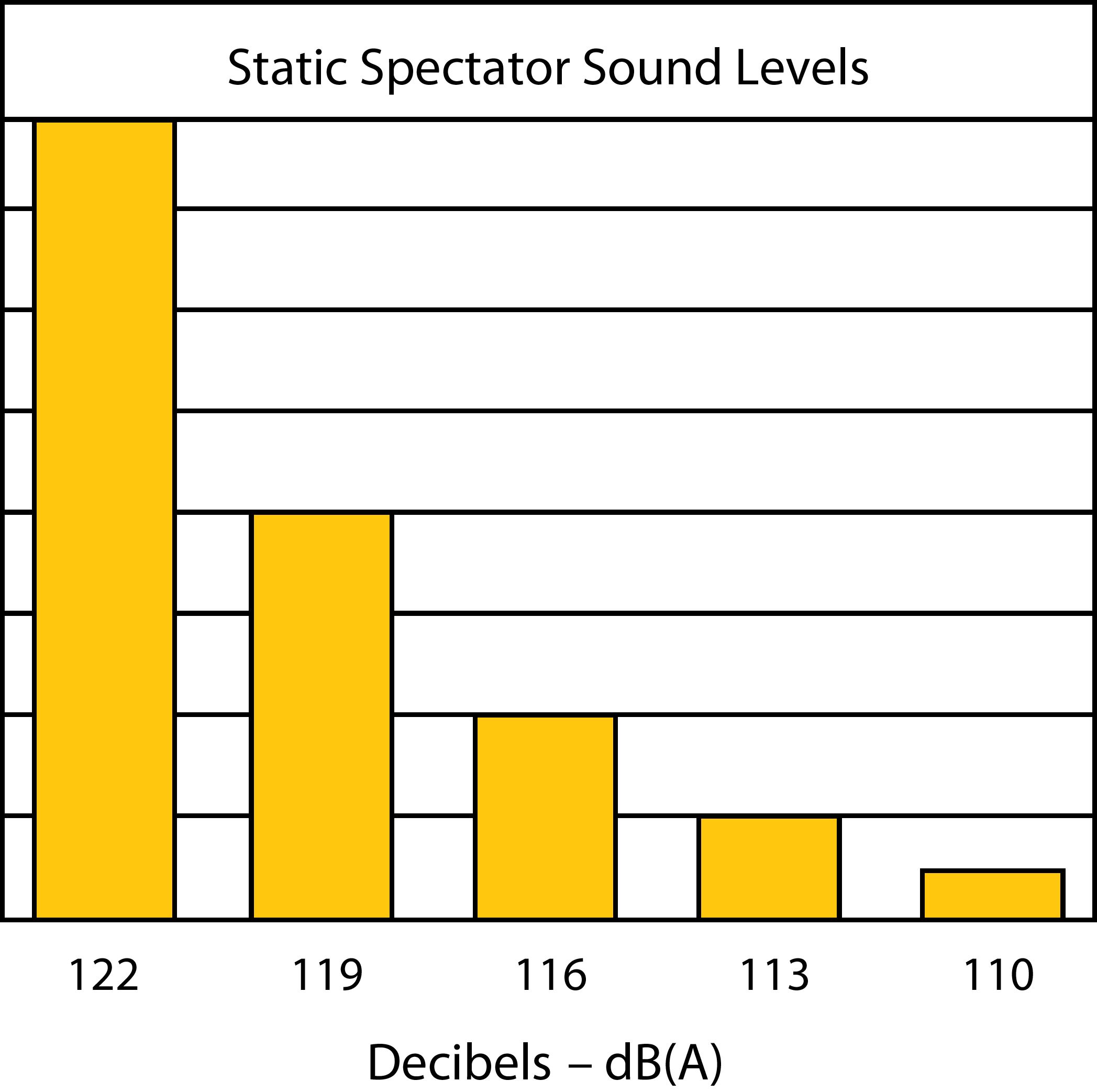

Sound Level Comparison

The static sound power level on the sound reduced 793C XQ was measured at approximately 112 dB(A) per ISO 6393 test method compared with a static level of approximately 121 dB(A) on the standard 793C. The graph below shows the logarithmic scale of decibels and how that slight reductions in decibels can make a tremendous impact on sound levels in the environment.

Engine

Electronic sound reduction

- Electronically controlled sound reduction treatments are used to reduce engine source noise while maximizing performance and lowering cost-per-ton. Modifications to the engine, such as reduced rpm ratings, are designed to help reduce engine noise levels. Electronically controlled sound reduction features include:

- 1600 rpm rated engine speed

- 1840 rpm top gear engine speed limit

- 1600 rpm maximum during body hoisting

- 1600 rpm limit in reverse

Mechanical sound reduction

Mechanical treatments are used in engine areas that emit the most sound. Valve, block, oil pan and camshaft covers are engineered to absorb sound and reduce engine noise. An engine enclosure lined with fire resistant, sound absorbing materials is used to reduce overall engine noise. Additional sound absorbing materials are used under the hood to create a sound barrier and keep engine noise from escaping into the environment.

Cooling System

Cooling System

The fan is a major noise contributor on mining trucks. And, a considerable amount of fan and engine noise can escape through the radiator. The addition of engine enclosures on the 793C XQ further increased the potential for added noise with greater cooling requirements. A sound suppressed cooling system was designed using proprietary Caterpillar software to model the effects of the engine enclosure on airflow and cooling efficiency. The result is a dual, side-by-side radiator design with two fans and a grill equipped with special sound absorbing materials.

Twin-Fan Radiator

The 793C XQ uses dual fans to increase cooling capacity while minimizing noise. The dual fans are quieter and more efficient than the single fan they replace. The smaller electronically controlled fans are driven by hydraulics instead of a belt driven direct drive system and provides variable speed control, which allows the fans to run only when necessary to maintain proper cooling. This design maximizes airflow and minimizes sound since the fans can operate at a slower rpm, which reduces blade tip noise. When conditions require less cooling, they are even quieter and conserve engine power for better hauling performance.

Grill

The specially engineered acoustic grill uses a patented grid of baffles to absorb sound from the engine and fan to keep noise from transmitting through the radiator. The grill is lightweight and modular for easy assembly, disassembly and serviceability. Formed metal channels are used to protect the sound absorbing materials from damage.

Exhaust System

Muffler

There is a direct correlation between the volume of the muffler and the sound emitted by the muffler. A high efficiency muffler, designed with more than twice the volume of the standard muffler, is used on the 793C XQ to substantially reduce exhaust sound levels. The design features dual inlets and single outlet for optimum sound reduction. The muffler is enclosed in a specially engineered sound barrier housing to further contain exhaust sound emissions. A specially designed muffler mounting with isolation mounts is used to reduce vibration.

Structures and Driveline

Structures

The Cat 793C XQ sound treatment package was designed from the ground up using a complete design approach since the addition of sound treatments could increase component weight and require structural changes. Caterpillar used static and dynamic finite element analysis of the frame and structures to ensure sound treatments would not compromise structural durability of the truck during redesign of the engine, cooling system, exhaust system and driveline.

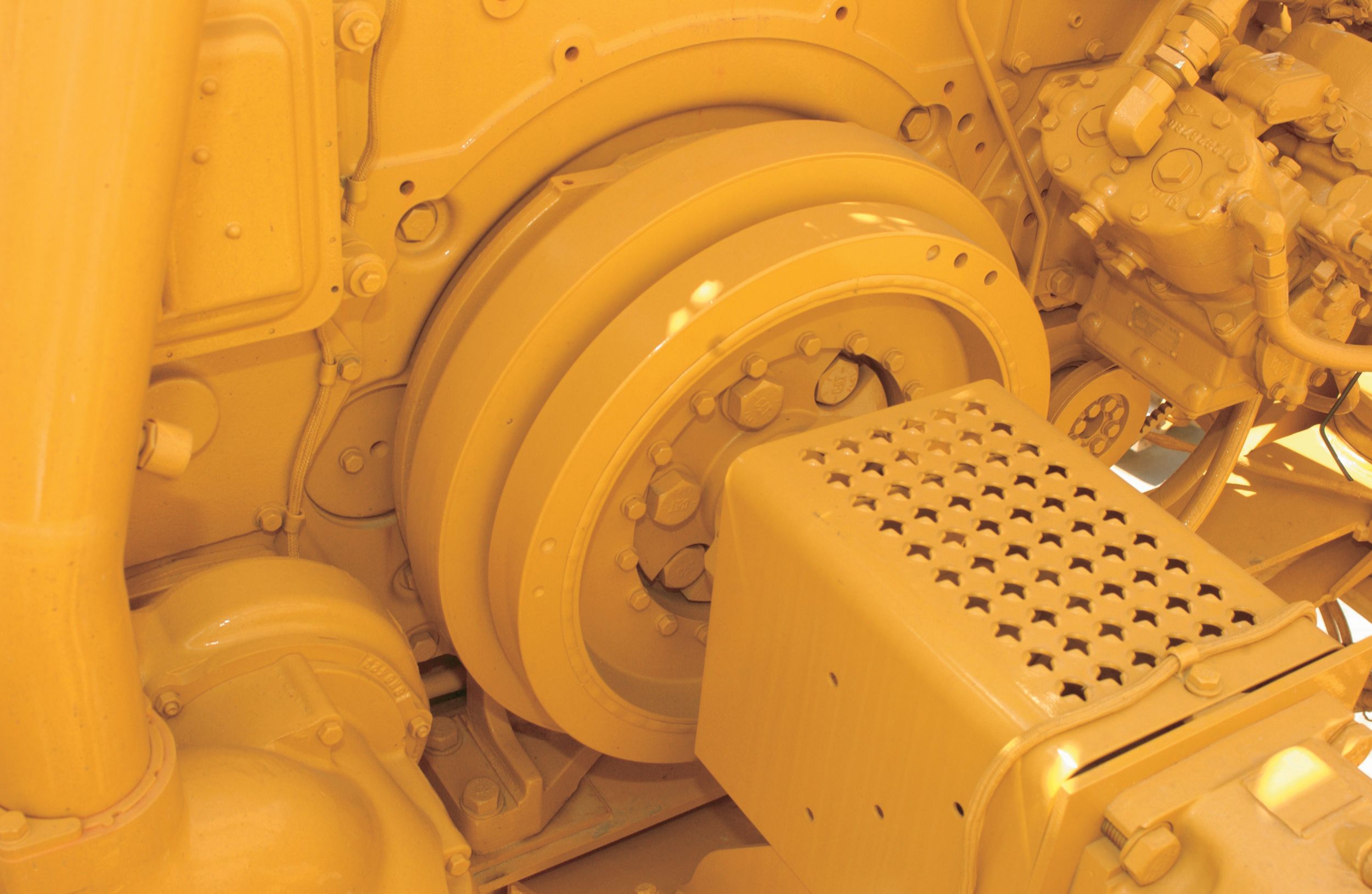

Driveline

Innovative sound barrier and damping materials, added to driveline components, effectively dampen vibration and reduce traveling structural noise from the driveline.

Serviceability

Service Access

The sound suppression system was designed with the service technician in mind. Sound treatments were engineered for easy access to daily service and maintenance points to keep the 793C XQ on the haul roads.

Snap Retainers

Snap retainers allow easy assembly, disassembly and replacement of sound suppression materials.

Data not available.

Standard Equipment

- Brake System

- Automatic Retarder Control

- Brake Release Motor (Towing)

- Engine Overspeed Protection

- Oil-cooled, Multiple-disc, Front and Rear

- Cab, ROPS, Insulated/Sound Suppressed

- Air Cleaner Service Indicator

- Air Conditioner

- Ashtray/Cigarette Lighter

- Coat Hook

- Diagnostic Connection Port

- Dome Courtesy Light

- Electric Engine Control Fault Indicator

- Electric Hour Meter/Tachometer

- Entertainment Radio Ready

- Heater/defroster, 11 070 kCal (43,930 Btu)

- Hoist, Body Control (Electric)

- Horn

- Quad-Gauge Panel

- Seat Belt, 75 mm (3 in) wide retractable

- Speedometer

- Steering Wheel, Tilt, Padded, Telescopic

- Storage Compartment

- Tachometer

- Tinted Glass

- Transmission Gear Indicator

- VIMS Keypad

- VIMS Message Center with Universal Gauge

- Window, Electric (Operator Only)

- Windshield Wiper, Intermittent Control and Washer

- Engine - Caterpillar 3516B HD EUI Diesel Engine

- Air Cleaner with Precleaner (4)

- Automatic Starter Protection

- Elevated Low Idle Control

- Ether Starting Aid (Automatic)

- Ground Level Engine Shutdown

- Low Altitude Certified

- Multi-point Oil Pressure Sensing

- Turbocharging (4) Aftercooled

- Ground Level

- Battery Disconnect

- VIMS Data Port

- Lighting System

- Back-up and Hazard Lights

- Directional Signals (Front and Rear LED)

- Engine Compartment

- Front Stair Access and Service Deck

- Headlights, with Dimmer

- Stop and Tail Lights (LED)

- Reservoirs (Separate)

- Brake

- Converter

- Cooling Fan

- Hoist/Steering/Transmission

- Sound Suppression

- Sound Suppressed Engine Compartment

- Silent Stream Grill

- Dual Cooling Fans

- Sound Reduction Electronic Technology

- Sound Reduced Muffler Arrangement

- Transmission

- 6-speed, Auto Powershift with Electronic Control (TCC)

- Body-up Reverse Neutralizer

- Body-up Shift Inhibitor

- Controlled Throttle Shifting

- Directional Shift Management

- Downshift/Reverse Shift Inhibitor

- Individual Clutch Modulation

- Lock-up Torque Converter

- Neutral Coast Inhibitor

- Neutral Start Switch

- Programmable Top Gear

- Vital Information Management System (VIMS)

- with Payload Monitor and MAX Payload and Speed Monitor

Optional Equipment

- Body, Dual Slope Attachments:

- Extensions, Body Side, 1416 kg (3,121 lb)

- Extension, Body Wraparound Tail, 1005 kg (2,215 lb)

- Liner, Entire Body, 11 076 kg (24,418 lb)

- Liner, Body Tail Extension, 442 kg (975 lb)

- Body, Flat Floor Attachments:

- Liner, Body, 0 kg (0 lb)

- Liner, Grid Rear 1/3 Sidewall, 254 kg (560 lb)

- Liner, Solid Rear 1/3, 1905 kg (4200 lb)

- Spare Rim with 6 in Flange

- 29 X 57 in used w/40.00R57 and 46/90R57 Tires, 1540 kg (3,400 lb)

- 32 X 57 in used w/40.00R57 and 46/90R57 Tires, 1610 kg (3,542 lb)

- Spare Rims with 5 in Flange

- 32 X 57 in used w/44/80R57 XDR Tires, 0 kg (0 lb)

- Tires for Rims with 6 in Flange

- 40.00R57 MX XDRB4**E4, 21 000 kg (46,200 lb)

- 40.00R57 GY RL-4B 4SL**, 22 100 kg (48,750 lb)

- 40.00R57 BS VELS E1A**E4, 21 400 kg (47,100 lb)