Overview

Design, manufacture and support of the 320C FM utilizes Caterpillar quality to provide reliable and durable machines for demanding logging environments.

Benefits & Features

Specifications

Benefits & Features

Configurations

Log Loader

Purpose-built 36' live heel front, heavy counterweight and high-wide/high drawbar undercarriage combine to optimize log loading and shovel-logging operations.

Delimber

Increased flow and horsepower in the 320C FM make for powerful and efficient stroke delimber operation.

Silviculture

When configured with the Special Application reach boom and stick and a variety of work tools, the 320C FM shows its versatility, from building right of way to reforestation.

Processor

Factory ready packages with heavy-duty roadside processing heads provide maximum efficiency in long log processing. Choose from standard gauge roadside configurations or high-wide/high drawbar for at-the-stump work.

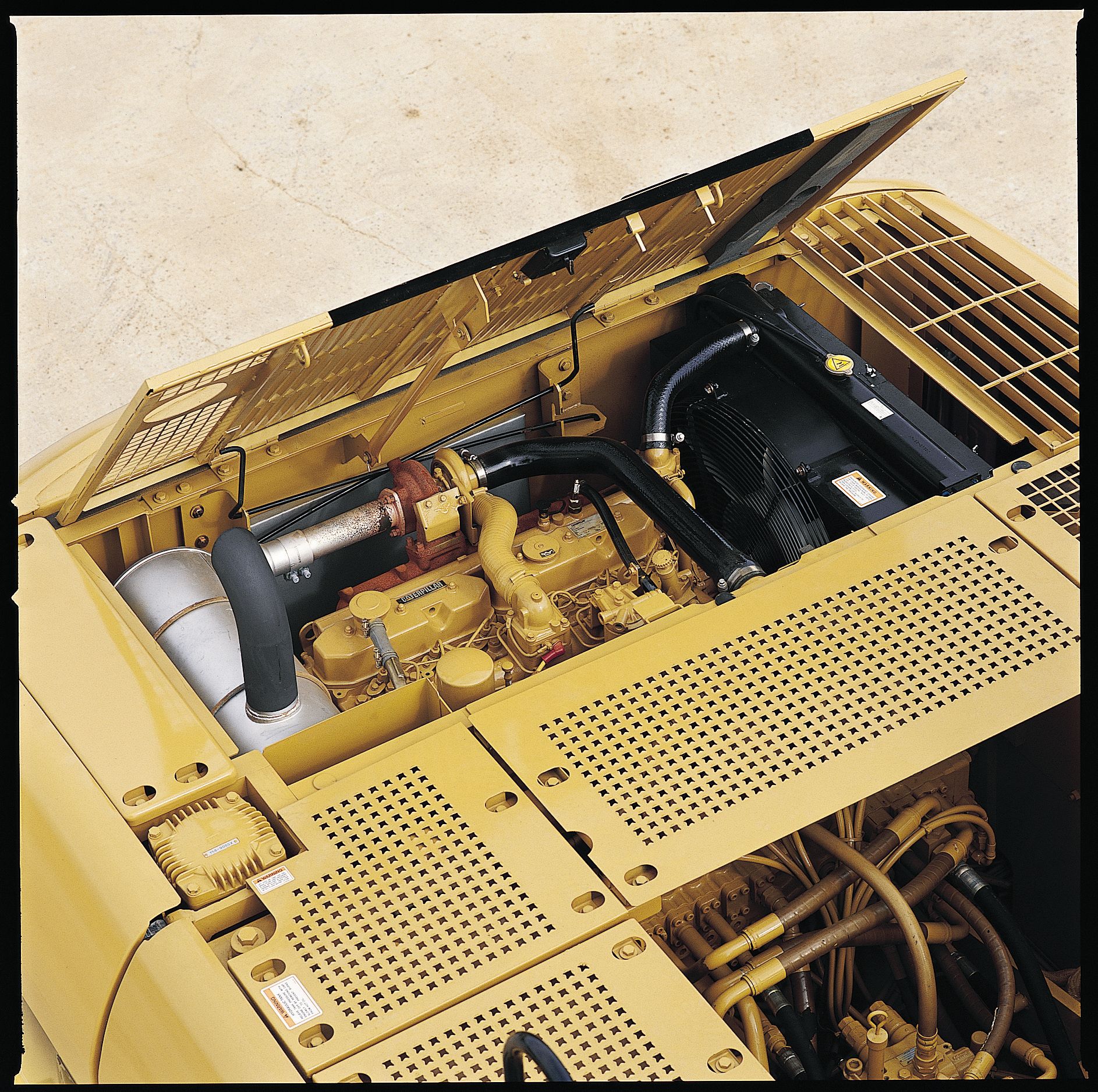

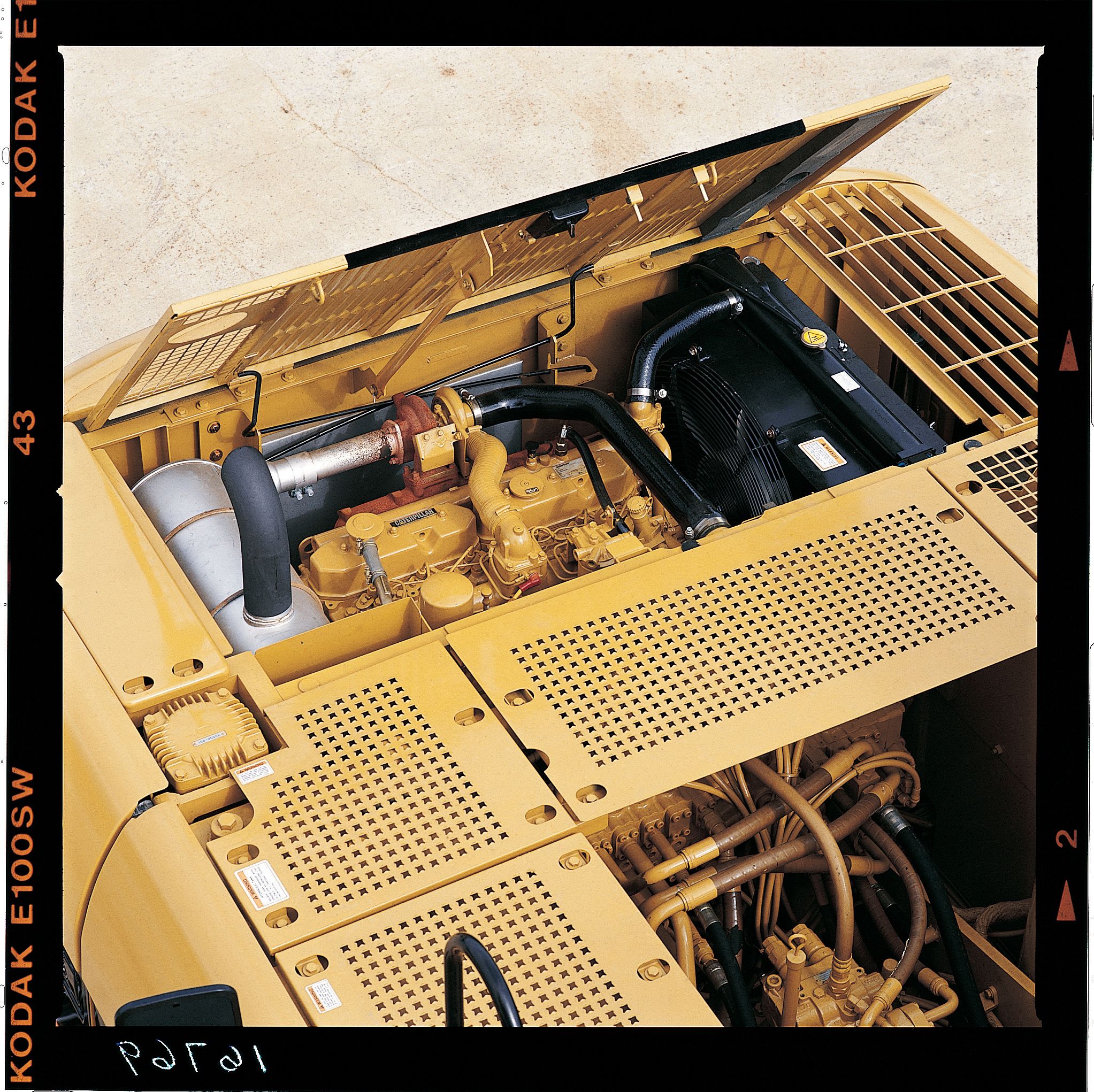

Engine and Hydraulics

Engine

Six cylinder turbocharged engine built for power, reliability, economy and low emissions will keep the machine up and running.

Hydraulic Cross Sensing System

Improves productivity with faster implement speeds and quicker, stronger pivot turns.

Optional Fine Swing Control

Optional fine swing control cushions swing start and stop for better implement control.

Hydraulic Cylinder Snubbers

The hydraulic cylinder snubbers at rod-end of boom cylinders and both ends of stick cylinders cushion shocks, reduce sound and increase cylinder life, keeping the machine working longer.

Controllability

The hydraulic system offers precise control to the 320C FM, reducing operator fatigue, improving operator effectiveness and efficiency.

High Drawbar Final Drives

Standard on the high-wide undercarriage, high drawbar final drives offer increased mobility in demanding off-road applications. The two-speed control can be manually shifted or set in automatic.

Structures

Linkages

Purpose-built forestry linkages include 11.0 m (36') reach, live heel boom and Special Application (SA) reach boom and stick.

Track Roller Frames

Robot-welded track roller frames are press-formed, pentagonal units to deliver exceptional strength and service life.

Heavy Duty Main Frame

Designed for maximum durability in forestry applications with reinforcements in the boom tower, boom cylinder pin and swing drive areas.

Undercarriage

Two forestry undercarriage options, standard gauge heavy-duty and high-wide/high drawbar, allow you to choose the right machine for your application. Both Cat undercarriages absorb stresses and provide excellent stability.

High-wide/High Drawbar Undercarriage

Increased ground clearance and drawbar pull allow better off-road capabilities, while increased track gauge improves stability in over-the-side applications.

Robotic Welding

Precision robotic welding ensures quality, increases rigidity, reduces internal stresses and enhances durability.

Rollers and Idlers

Sealed and lubricated track rollers, idlers and double-supported bottom rollers as carrier rollers provide excellent service life, to keep the machine in the field longer.

Operator Station

Interior Operator Station

The 320C FM operator work station is quiet with ergonomic control placement and convenient adjustments, low lever and pedal effort, ergonomic seat design and highly efficient ventilation.

Cab Exterior

Newly designed using asymmetrical steel tubing for improved resistance to fatigue and vibration.

Serviceability and Customer Support

Extended Service Interval

320C FM service and maintenance intervals have been extended to reduce machine service time and increase machine availability.

Radiator Compartment

The left rear service door allows easy access to the engine radiator and the oil cooler. A reserve tank and drain cock are attached to the radiator for simplified maintenance.

Integrated Catwalks

Designed to be integrated into the undercarriage house guards, the wide cat walks with "punched star" plate allow easy access to many service points.

Air Filter Compartment

The air filter features a double-element construction for superior cleaning efficiency. When the air cleaner plugs, a warning is displayed on the monitor screen inside the cab.

Ground Level Service

The design and layout of the 320C FM was made with the service technician in mind. Many service locations are easily accessible at ground level allowing critical maintenance to get done quickly and efficiently.

Swing-Out Oil Cooler

The oil cooler swings out horizontally for excellent cleaning access.

Pump Compartment

A service door on the right side of the upper structure allows ground-level access to the pump and pilot filter.

Capsule Filter

The hydraulic return filter, a capsule filter, is situated outside the hydraulic tank. This filter prevents contaminants from entering the system when hydraulic oil is changed and keeps the operation clean.

Diagnostics and Monitoring

The 320C FM is equipped with S•O•SSM sampling ports and hydraulic test ports for the hydraulic system, engine oil and for coolant. A test connection for the Electronic Technician (ET) is located behind the cab.

Anti-Skid "Punched Star" Plate

Anti-skid punched-star plate covers top of storage box and upper structure to prevent slipping during maintenance. The plate can be removed for cleaning.

Engine Inspection

Engine can be accessed from the upper structure or from under the machine. The engine and pump compartment are separated by a steel wall.

Handrails and Steps

Larger handrails and steps assist operator in climbing on and off machine.

Grease Lubricated Track

Grease lubricated seals protect the track link and deliver long track link pin and bushing inner wear life.

Fan Guard

Engine radiator fan is completely enclosed by fine wire mesh, reducing the risk of an accident.

Greasing Points

A concentrated remote greasing block on the boom delivers grease to hard-to-reach locations.

Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements? What production is needed? What is the true cost of lost production? Your Cat dealer can give you precise answers to these questions.

Purchase

Look past initial price, look at the value the 320C FM offers. Consider the financing options available as well as day-to-day operating costs.

Maintenance

Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured components.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training literature and other ideas to help you increase productivity.

Data not available.

Standard Equipment

- Operator Environment

- Purpose built forestry cab with 7 lights and all scratch resistant polycarbonate windows, ISO 8084 and SAE 1084 certified OPS, ISO 8083 and SAE J231 certified FOPS, ISO 10262 and SAE J1356 certified FOGS, OR-OSHA code 437-007-0775 TOPS and WCB G602/G603/G604/G608 standards.

- Seat KAB 528P/C, four-way adjustable suspension seat with adjustable armrest, retractable seatbelt and headrest

- Integrated seat, console and joystick type controls

- Language display monitor with gauges

- Warning information, filter/fluid change information, working hour information, machine condition, error code and tool mode setting information, start up level check for hydraulic oil, engine oil and engine coolant

- Full time clock on monitor (2 weeks)

- Seat mounted joystick with extra functions for grapple

- Fixed polycarbonate skylight with retractable sun shade, meeting SAE J1084

- Interior lighting

- 4 Front working lights, cab top mounted

- 2 Front working lights, riser mounted

- 1 Left side working light, cab mounted

- Lower and upper windshield wipers and washer

- Positive filtered ventilation, pressurized cab with bi-level air conditioner, heater and defroster with manual control

- Forced air fan

- 2 post mounted fresh air vents

- Behind seat storage tray with tie down points

- 2 CB radio mounts

- 1 Converter/2 sockets – 12V-10A power supply

- Radio/CD player (12V)

- 1 Fire extinguisher mount

- 1 Attachment computer control mount

- Secondary roof exit, openable from inside and outside

- 2 Coat hooks

- Ashtray with lighter

- Literature holder

- Cup holder

- Neutral lever for all controls

- Travel control pedals with removable hand levers

- Washable floor mat

- Horn

- Power Train

- - Cat 3066 T diesel engine with 24-volt electric starting and air intake heater

- - One-touch low idle

- - Straight line travel

- - Swing-out oil cooler

- - Two speed auto-shift travel

- - Water separator in fuel line

- Undercarriage

- - Heavy-duty swivel guard

- - 700 mm (28") double grouser shoes

- - Hydraulic track adjusters

- - Track-type undercarriage with grease lubricated seals

- Other Standard Equipment

- - Automatic swing parking brake

- - Auxiliary hydraulic valve (one)

- - Core hydraulic lines & controls with standard main valves on upper structures

- - Door locks, cap locks and Caterpillar one-key security system

- - Heavy-duty upper frame

Optional Equipment

- Booms and sticks:

- - SA reach

- - Log loader reel

- Bucket linkage:

- - 320C - B Family

- Counterweight:

- - Heavy

- - Standard

- Guards:

- - Corner guard, right front

- Hydraulic arrangements:

- - Rotating grapple

- - Harvesting head

- Track:

- - 600 mm (24") double grouser shoes

- - 700 mm (28") triple grouser shoes

- - 800 mm (32") triple grouser shoes