Overview

The C Series delivers a new level of performance by shortening cycle times and raising productivity. More work gets done faster. Breakthrough improvements in hydraulic system design enable operators to rapidly change work tools and accomplish more tasks quickly. Key innovations in system design make the C Series easier to use and maintain. Higher productivity, versatility and ease of service translate into a more profitable approach to getting work done.

Specifications

| Engine Model | Cat® 3066T |

| Net Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® 3066T |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Gross Power | — |

| Net Power - EEC 80/1269 | — |

| Net Power - SAE J1349 | — |

| Operating Weight | — |

| Operating Weight - Standard Undercarriage | — |

| Fuel Tank Capacity | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Drawbar Pull | — |

| Maximum Travel Speed | — |

| Main Implement System - Maximum Flow (2x) | — |

| Maximum Pressure - Equipment | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| B1 Family Bucket Cylinder - Bore | — |

| B1 Family Bucket Cylinder - Stroke | — |

| C Family Bucket Cylinder - Bore | — |

| C Family Bucket Cylinder - Stroke | — |

| Brakes | SAE J1026 APR90 |

| Cab/FOGS | SAE J1356 FEB88 ISO 10262 |

| Standard with Standard Undercarriage | — |

| Standard with Long Undercarriage - Triple Grouser | — |

| Optional (1) | — |

| Optional (2) | — |

| Optional (3) | — |

| Transport Width | — |

Benefits & Features

Engine and Hydraulics

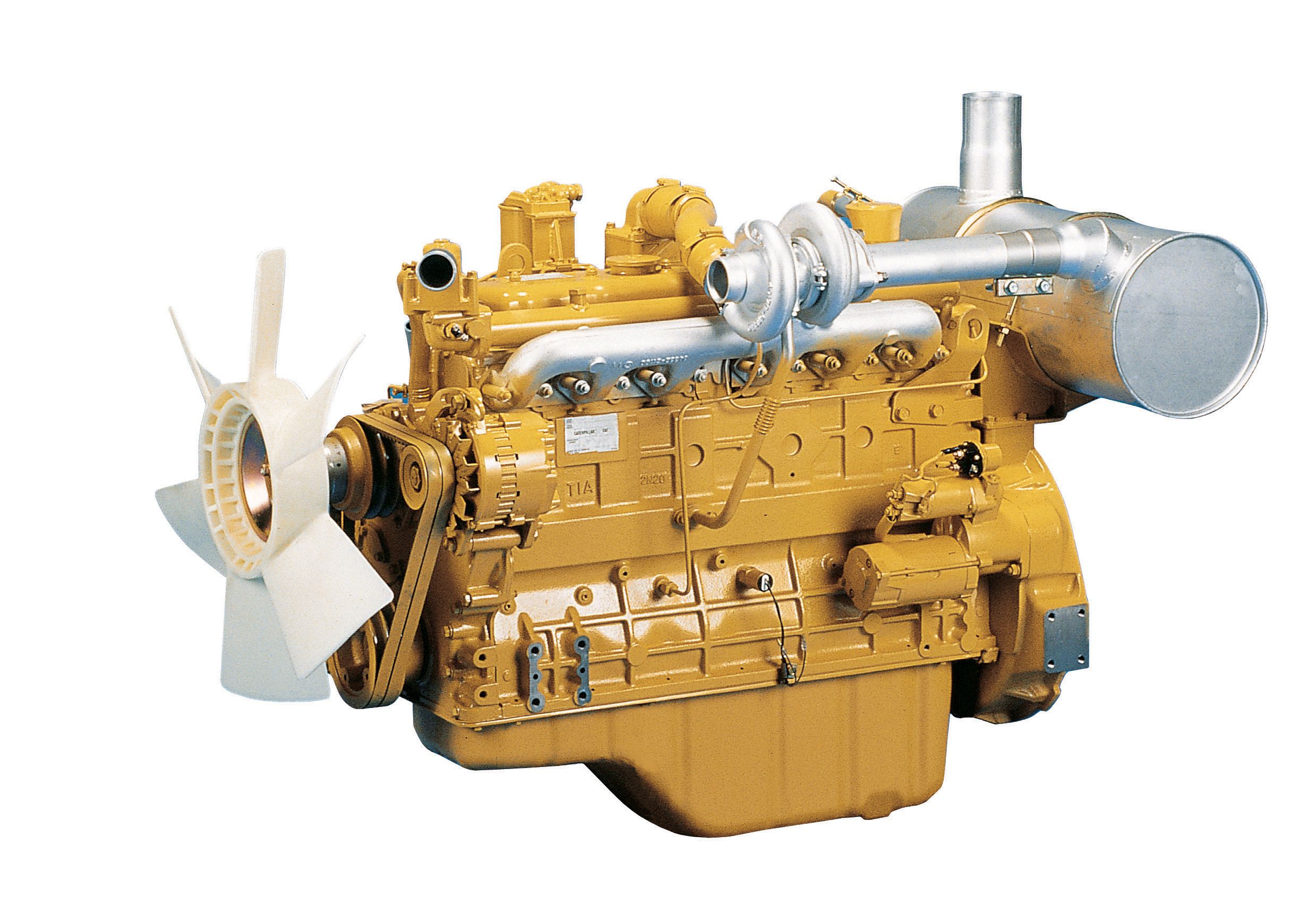

Engine

Six cylinder turbocharged engine built for power, reliability, economy and low emissions will keep the machine up and running.

Hydraulic Cross Sensing System

Improves productivity with faster implement speeds and quicker, stronger pivot turns.

Optional Fine Swing Control

Optional Fine Swing Control cushions swing start and stop for better implement control.

Hydraulic Cylinder Snubbers

The hydraulic cylinder snubbers at rod-end of boom cylinders and both ends of stick cylinders cushion shocks, reduce sound and increase cylinder life, keeping the machine working longer.

Controllability

The hydraulic system offers precise control to the 320C, reducing operator fatigue, improving operator effectiveness and efficiency, which ultimately translates into enhanced performance.

Boom and Stick Regeneration Circuit

Boom and stick regeneration circuit increases efficiency and reduces cycle times for higher productivity and lower operating costs.

Structures

Robotic Welding

Over 95% of the structural welds on a Caterpillar excavator are completed by robots. Robotic welds achieve over three times the penetration of manual welds.

Undercarriage

Durable Cat undercarriage absorbs stresses and provides excellent stability.

Booms and Sticks

Booms and Sticks

Built for performance and long service life, Caterpillar booms and sticks are large, welded, box-section structures with thick, multi-plate fabrications in high-stress areas.

Work Tools - Attachments

Buckets

Caterpillar buckets provide increased service life with reduced repair costs.

Heavy-Duty Rock (HDR) Buckets

Heavy-Duty Rock (HDR) buckets perform best when digging fragmented rock, frozen ground, caliche and highly abrasive materials. Additional, thicker wear plates extend beyond side plates for corner and rear dent protection. Sidebar protectors decrease sidebar wear.

General Purpose (GP) Buckets

General Purpose (GP) buckets are best for digging in soft to hard ground with low to moderate abrasive materials.

Ditch Cleaning (DC) Buckets

These are wide shallow buckets for bank forming, ditch cleaning and finishing.

Heavy-Duty (HD) Buckets

Heavy-Duty (HD) buckets for digging in moderate to hard abrasive materials feature large Ground Engaging Tools (GET), thick cutting edges and thick bottom and side wear plates to improve performance in demanding conditions.

Tool Control System

The optional Tool Control System maximizes work tool productivity by configuring hydraulic flow, pressure, and operator controls to match a specific work tool. System versatility enables a wide range of tools to be used. Up to five different tool settings may be pre-programmed and selected from the cab. Factory installed hammer and thumb circuits are also available as attachments.

Heavy Duty Power (HDP) Buckets

Designed to improve breakout force and machine cycle times, the Heavy Duty Power (HDP) Bucket compliments the General Purpose, Heavy Duty, and Heavy Duty Rock bucket lines.

Quick Couplers

The Pin Grabber Plus and the Dedicated Hydraulic Quick Couplers are available as field installed options. These attachments greatly enhance machine versatility by enabling the rapid changeover of a wide range of work tools in the field.

Work Tools

Choose from a variety of work tools such as hammers, shears, rotators, grapples or crushers. Ask your Cat dealer for information on attachments or special configurations.

Operator Station

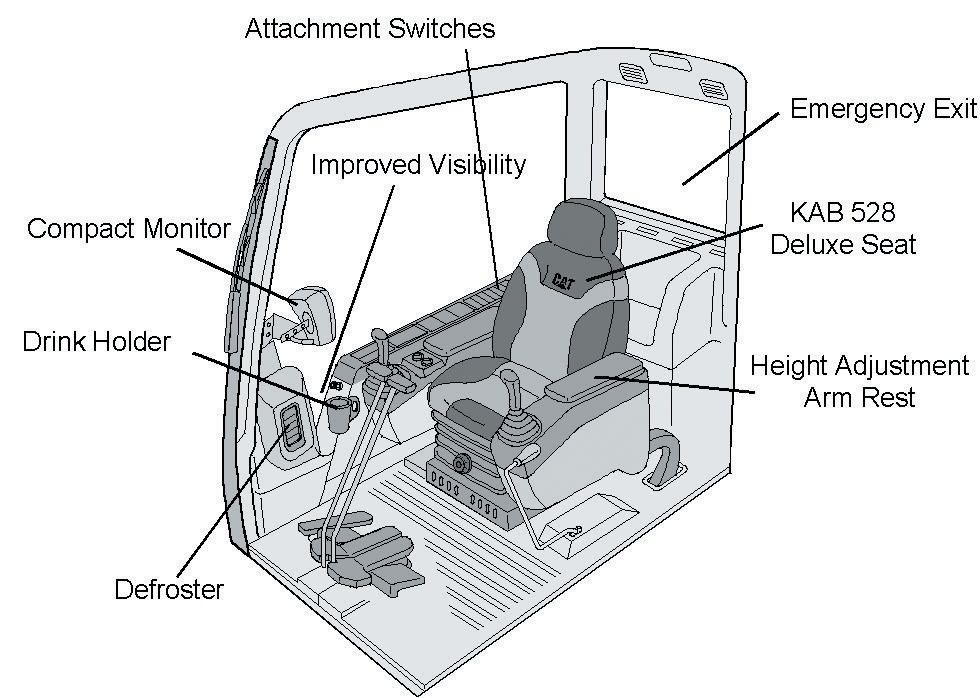

Operator Station

The 320C operator work station is quiet with ergonomic control placement and convenient adjustments, low lever and pedal effort, ergonomic seat design and highly efficient ventilation.

Redesigned Layout

Redesigned cab layout emphasizes simplicity and ease of use. Right-hand wall and console provide easy access to all switches, dials and controls.

Travel Controls

A large rubber-covered footrest at the side of the travel pedals allows the foot to easily grip the pedal. The travel lever stroke and force have been enhanced to improve the 320C's fine controllability, making the machine easier to operate.

Seat

New, two-tone seat offers soft and firm cushions for operator comfort. Reclining knob is located at the right side of the seat for easy adjustment.

Console

Redesigned consoles for simplicity and functionality. Both consoles have attached adjustable armrests.

Automatic Climate Control

Fully automatic climate control adjusts temperature and flow and determines which air outlet is best in each situation.

Upper Cab Door Window

The upper cab door window slides open, providing extra ventilation and allowing communication with people outside.

Skylight

A large polycarbonate skylight delivers excellent natural lighting and good ventilation. Standard sliding sunshade protects from direct sunlight.

Automatic Boom and Swing Priority Function

For simpler operation, work mode and power mode switches have been eliminated. Instead, the automatic boom and swing priority function selects the best mode, based on joystick movement.

Monitor

New, compact monitor enhances viewing while displaying a variety of easy to read and understand language-based information.

Attachment Controller

Five hydraulic pump flows and pressure settings can be preset on the monitor, eliminating the need to adjust the hydraulics every time a tool is changed and instantly providing the operator with the correct amount of flow and pressure for each tool. This feature is available with the optional tool control system.

Cab Exterior

Newly designed using asymmetrical steel tubing for improved resistance to fatigue and vibration. FOGS may be bolted-on directly to the cab.

Serviceability

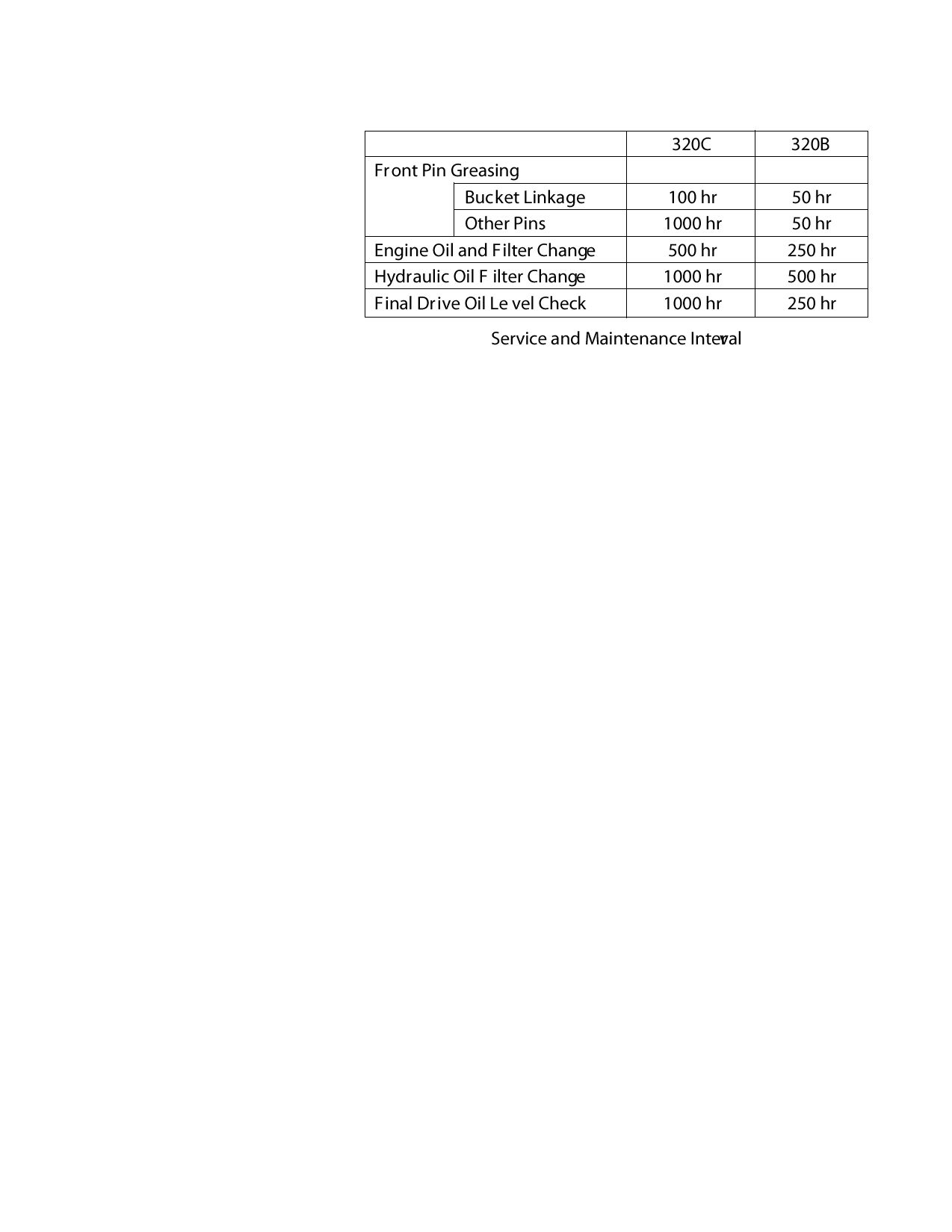

Extended Service Interval

320C service and maintenance intervals have been extended to reduce machine service time and increase machine availability.

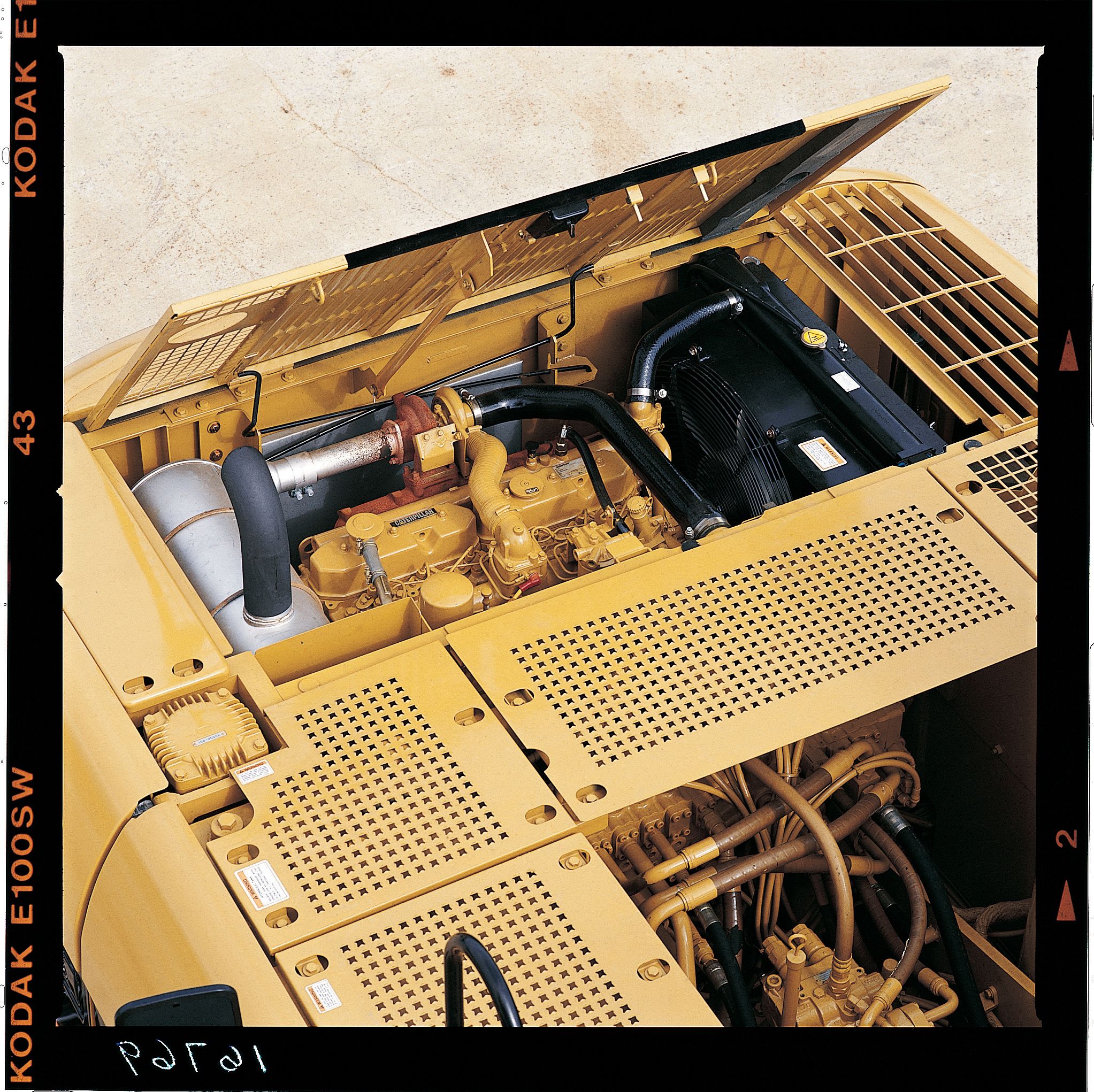

Radiator Compartment

The left rear service door allows access to the engine radiator and hydraulic oil cooler, which are side by side, and the high performance compact air-to-air aftercooler (ATAAC). Ample space between the ATAAC and the radiator/cooler is provided to allow access for cleaning.

Air Filter Compartment

The air filter features a double-element construction for superior cleaning efficiency. When the air cleaner plugs, a warning is displayed on the monitor screen inside the cab.

Ground Level Service

The design and layout of the 320C was made with the service technician in mind. Many service locations are easily accessible at ground level allowing critical maintenance to get done quickly and efficiently.

Swing-Out Condenser

The air conditioner condenser swings out horizontally for cleaning access.

Pump Compartment

A service door on the right side of the upper structure allows ground-level access to the pump and pilot filter.

Capsule Filter

The hydraulic return filter, a capsule filter, is situated outside the hydraulic tank. This filter prevents contaminants from entering the system when hydraulic oil is changed and keeps the operation clean.

Diagnostics and Monitoring

The 320C is equipped with S•O•SSM sampling ports and hydraulic test ports for the hydraulic system, engine oil and for coolant. A test connection for the Cat Electronic Technician (Cat ET) is located behind the cab.

Handrails and Steps

Larger handrails and steps assist operator in climbing on and off machine.

Anti-Skid "Punched Star" Plate

Anti-skid punched-star plate covers top of storage box and upper structure to prevent slipping during maintenance. The plate can be removed for cleaning.

Grease Lubricated Track

Grease lubricated seals protect the track link and deliver long track link pin and bushing inner wear life.

Fan Guard

Engine radiator fan is completely enclosed by fine wire mesh, reducing the risk of an accident.

Greasing Points

A concentrated remote greasing block on the boom delivers grease to hard-to-reach locations.

Complete Customer Support

Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements? What production is needed? What is the true cost of lost production? Your Cat dealer can give you precise answers to these questions.

Acquisition

Look past initial price, look at the value the 320C offers. Consider the financing options available as well as day-to-day operating costs.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training literature and other ideas to help you increase productivity.

Maintenance

Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured components.

Data not available.

Standard Equipment

- Cab

- AM/FM radio with speakers

- Ash tray with cigar lighter

- Bi-level air conditioner with defroster

- Coat hook

- Drink holder

- Fully adjustable suspension seat

- Heater and defroster

- Horn

- Hydraulic neutralizer lever for all controls

- Language display monitor with gauges

- Light, interior

- Literature holder

- Openable front windshield

- Openable skylight with sunshade

- Positive filtered ventilation

- Pre-wired for Product Link

- Retractable seatbelt

- Storage compartment

- Travel control pedals with removable hand levers

- Power train

- Cat 3066T diesel engine

- Water separator

- Undercarriage

- Hydraulic track adjusters

- Track type undercarriage with grease lubricated seals

- Idler and center section track guiding guards

- 800 mm (32 in) triple grouser shoes

Optional Equipment

- Stick and Boom combinations:

- Reach boom - 5.68 m (18 ft 7 in), std. & special application

- Mass boom - 5.20 m (17 ft 1 in)

- Long reach arrangement

- Track:

- 600 mm (24 in) triple grouser shoes

- 700 mm (28 in) triple grouser shoes

- 600 mm (24 in) double grouser shoes