Overview

Performance you can feel with the capability to work in the most demanding applications. Unmatched operator comfort and efficiency in a world class cab with revolutionary electronics and hydraulics for low-effort operation and increased productivity.

Benefits & Features

Specifications

Benefits & Features

Power Train

Engine

- Is a six cylinder, turbocharged and aftercooled 3406E Electronic Unit Injector (EUI) which is powerful enough for the most demanding work.

- Tier 2 compliant

- Four stroke engine features direct fuel injection for efficient, accurate fuel metering and excellent fuel economy.

- Oil cooled pistons and full-length, water-cooled cylinder liners maintain maximum heat tranfer for long component life.

- Turbocharging and ATAAC provide consistent, high horsepower, while ATAAC also provides for increased altitude capability.

Electronic Unit Injector (EUI)

Is a high-pressure, direct injection fuel system that is virtually adjustment-free. It electronically montiors operator and sensor inputs to optimize engine performance.

ADEM III Electronic Control Module

Along with the Caterpillar Monitoring System controls all major engine functions and regulates the timing, duration and pressure of the injected fuel. ADEM III also offers automatic altitude compensation, a cold mode start-up strategy and oil pressure and coolant warnings which result in precise engine speed control, superior cold start capability, low smoke and emissions in all operating conditions.

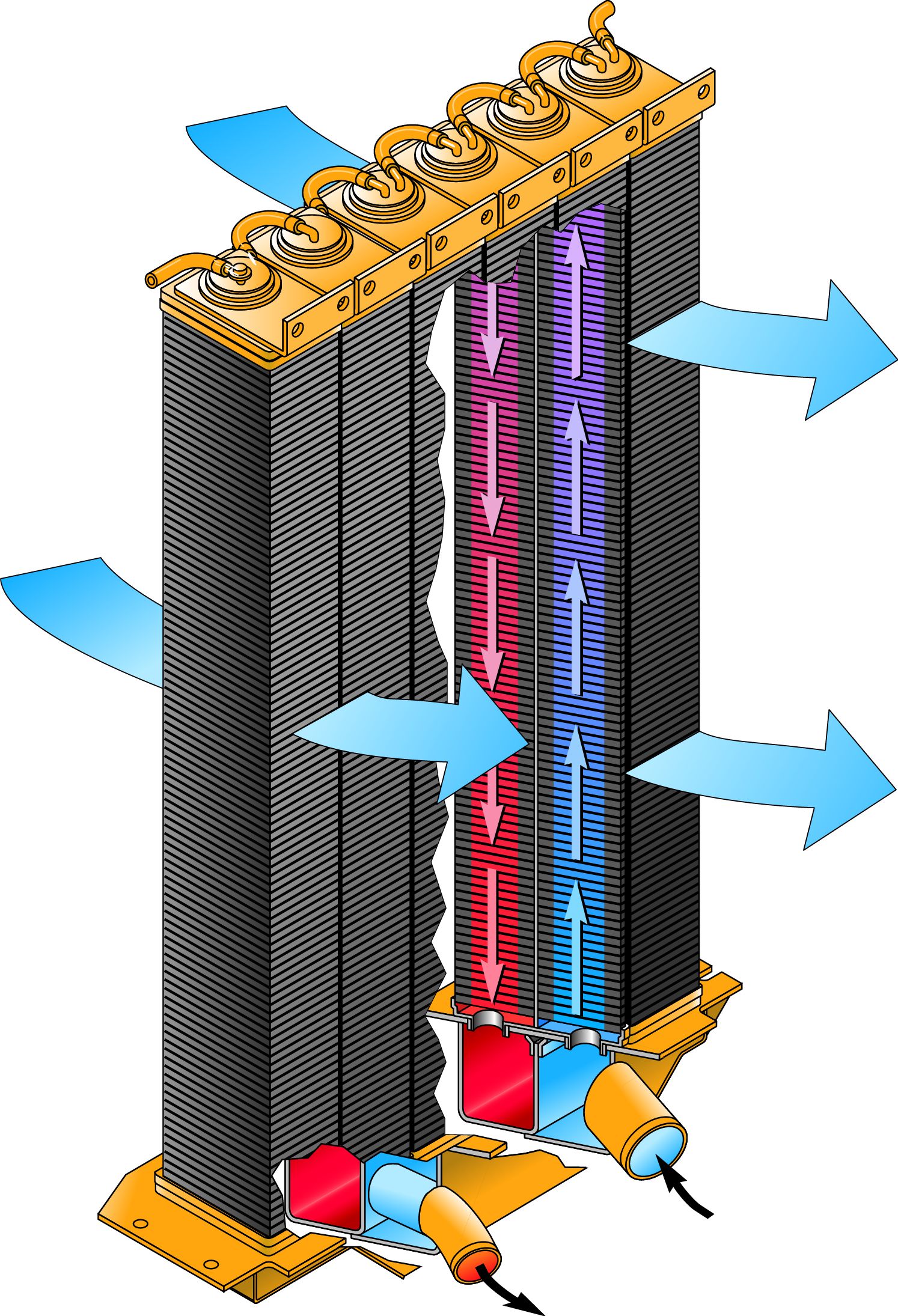

Cooling System

Is an electronically controlled, hydraulically driven on-demand fan system which reduces sound levels and increases fuel economy.

Separated System

The cooling system is isolated from the engine compartment and coupled with the variable rate fan, less air is required to pass through the system. This results in faster machine warm up in cold weather, increased fuel efficiency, less radiator plugging and lower sound levels.

Advanced Modular Cooling System

Utilizes an exclusive two-pass cooling system that provides significantly more cooling capacity than conventional radiator systems.

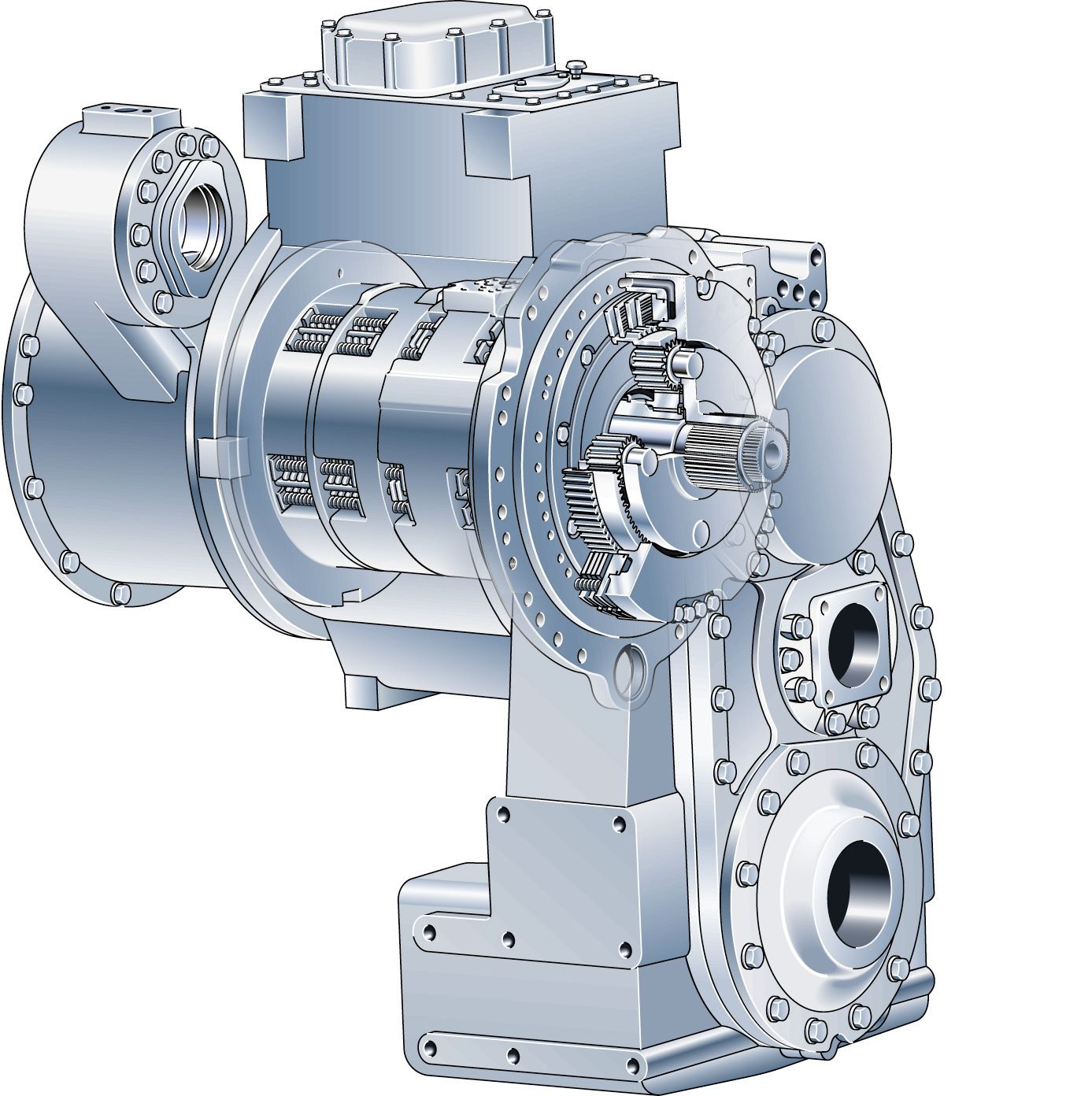

Powershift Transmission

Is heavy-duty, planetary driven and electronically controlled to provide smooth shifts that improve operator comfort and machine performance.

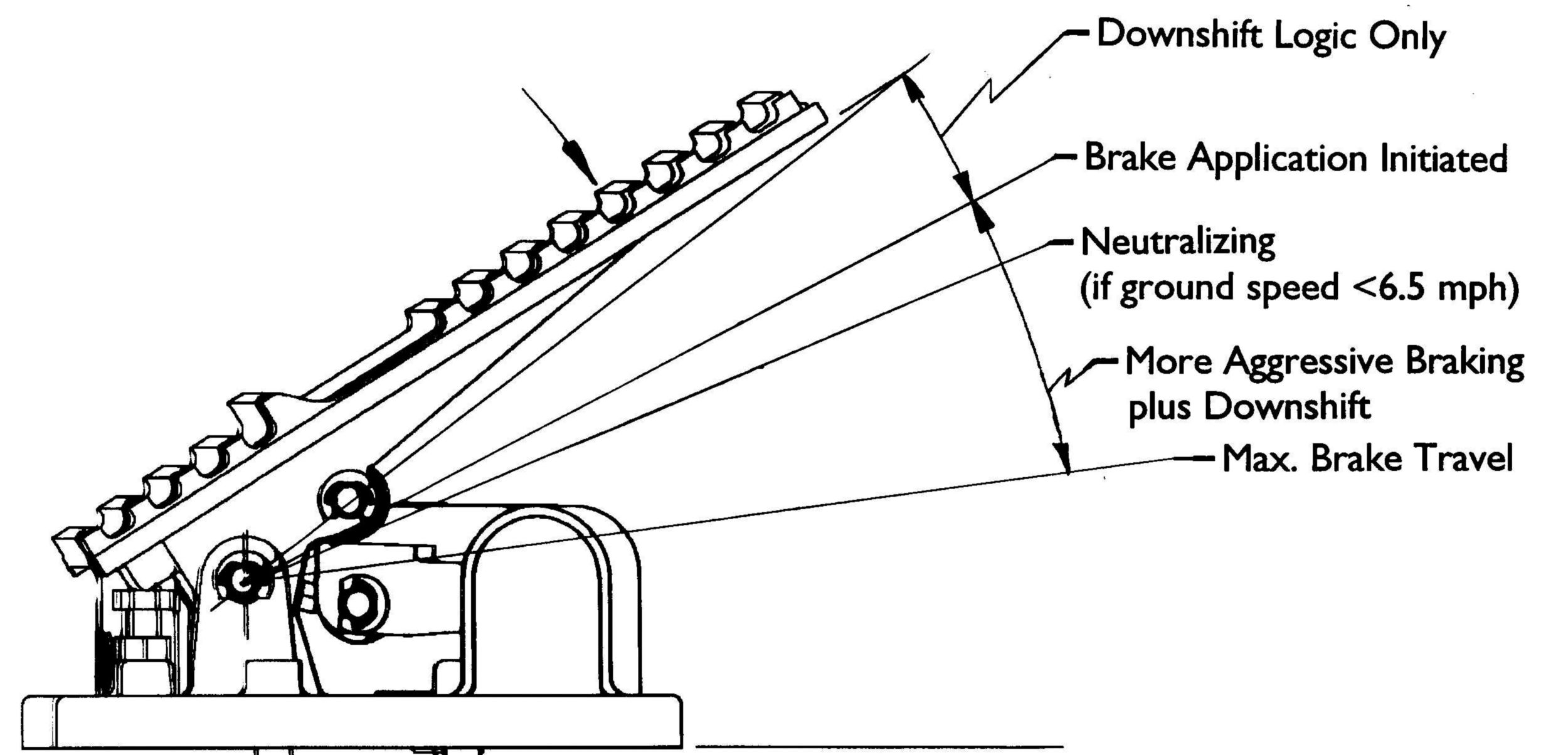

Integrated Braking System (IBS)

Is a Caterpillar exclusive feature that reduces axle oil temperatures, improves transmission neutralizer smoothness.

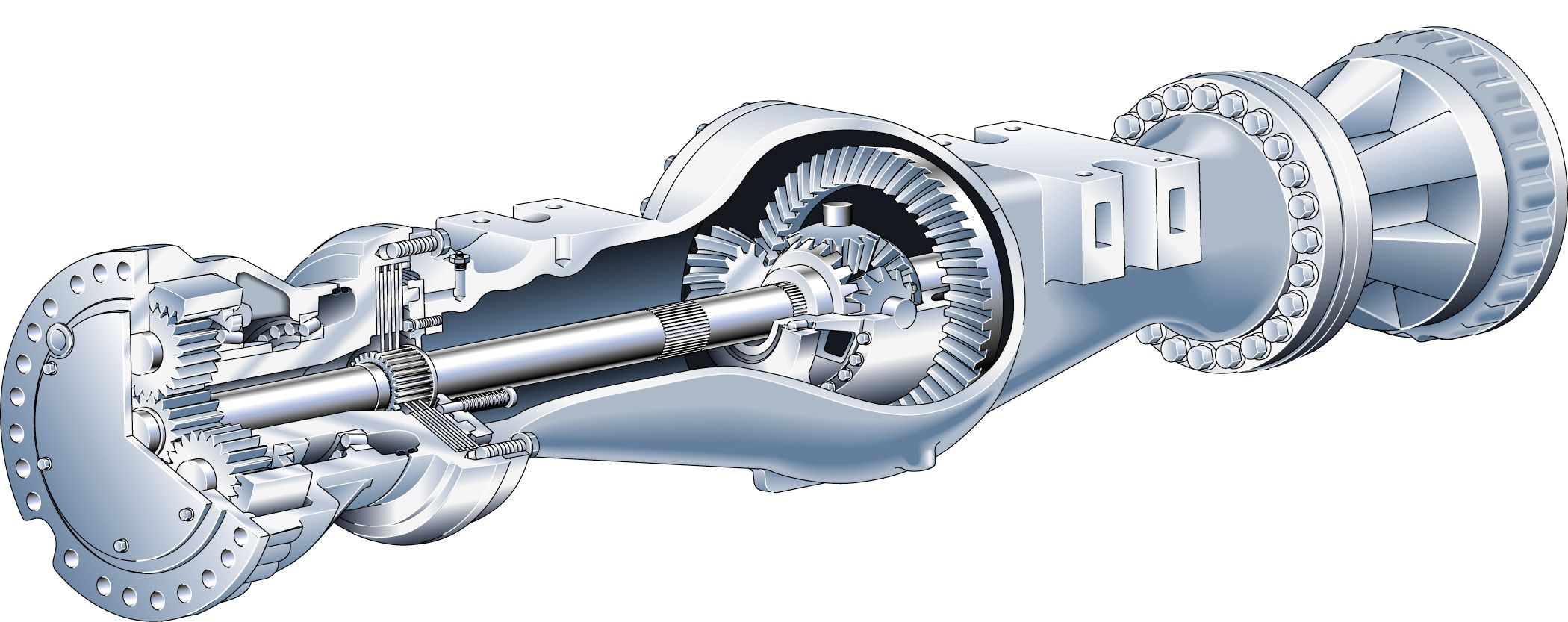

Axles

Are fixed on the front and oscillating +/- 13 degrees on the rear. The design meets the demands of Ride Control and autoshift that often result in higher speed load and carry applications.

External Axle Oil Cooler

Is available as a factory installed attachment for use in "high energy" applications, such as long distance load and carry in high ambient temperature conditions. With the availability of IBS, it is estimated that very few applications (five percent or less) and conditions will require AOC. Your Caterpillar dealer can perform an application analysis using Equipment Investment Analysis software to determine if an axle oil cooler is required.

Brakes

Braking can occur using either of the cab floor-mounted pedals. The left pedal also serves as the neutralizer and activates the IBS. This system eliminates the need for an air compressor and dryer, reducing the number of components and improving reliability.

Rims and Tires

Several tire options are available with Firestone, Goodyear and Michelin offering tread types for a wide range of conditions and applications.

Free Wheel Stator

Free Wheel Stator Torque Converter

The 980G Series II features a Free Wheel Stator Torque Convertor (FWSTC). A FWSTC improves machine power train efficiency in certain applications and contributes to the improved fuel efficiency of the 980GII. A torque converter provides a larger/broader output load potential than the engine can provide alone, reducing the need for very low speed gears and the number of gears required from a direct drive configuration.

Fixed Stator vs. Free Wheel Stator

The engine output shaft drives the torque converter's impeller. The impeller accelerates the torque converter fluid from low to high velocity, adding kinetic energy to the fluid. This energy is given up to a turbine causing the fluid to lose speed. The force of the oil that hits the turbine blades causes the turbine to rotate, driving the output shaft (input to transmission). The stator is a stationary reaction member between the turbine and impeller. The stator redirects the flow of oil as it leaves the turbine to increase the fluid's momentum as it returns to the impeller, increasing the unit's torque capacity. In conditions where demand placed on the torque converter is not extreme (output torque requirements equal to or less than input torque) such as when ground speed is high and resistance is low (machine slowing from high speed), turbine speed will be high relative to impeller speed. Oil passing through the turbine may then strike the back of the stator blades, eliminating the stator's ability to redirect and increase the oil's momentum. As a result, the stator actually lowers the efficiency of the system by increasing drag. Free wheel stator allows the stator to turn in the same direction as the turbine in this condition, minimizing drag on the converter and increasing efficiency.

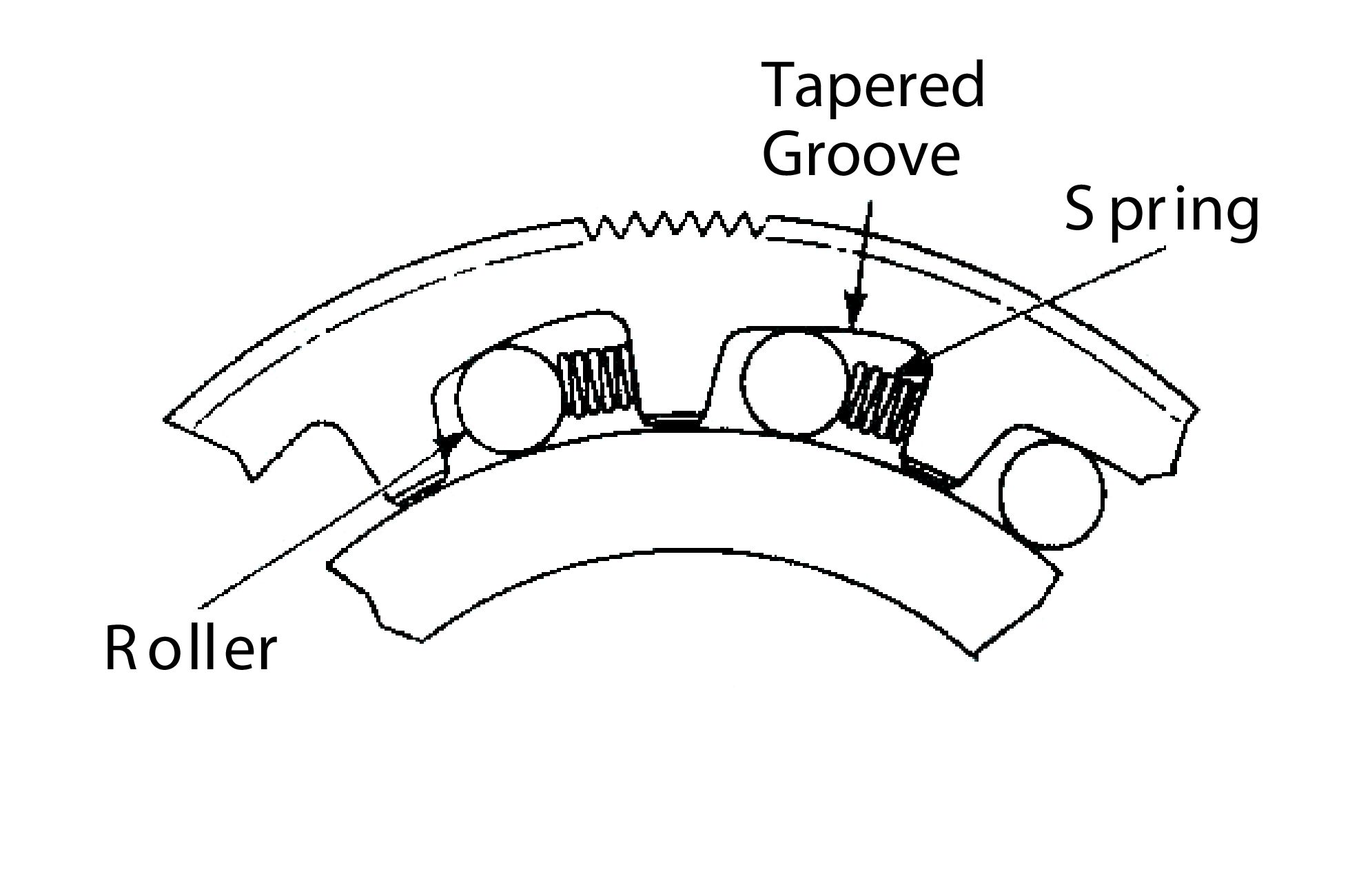

How Free Wheel Stator Works

The free wheel assembly is a one-way clutch consisting of cam, rollers), springs and carrier. The cam is spline connected to the stator so that when the stator tries to move in the opposite direction to the turbine, the rollers are forced into the narrow end of the tapered grooves, preventing the cam and stator assembly from rotating around the carrier. Since the carrier is held stationary, the stator cannot turn and the free wheel assembly is locked. As the speed of the turbine approaches 85 percent of the impeller speed, oil passing through the turbine strikes that back of the stator blades so that the stator starts to turn in the same direction of the turbine. The cam then rotates so that rollers occupy the wide end of the tapered grooves. The cam and stator assembly are then free to rotate around the carrier (freewheel), thereby reducing drag and increasing efficiency.

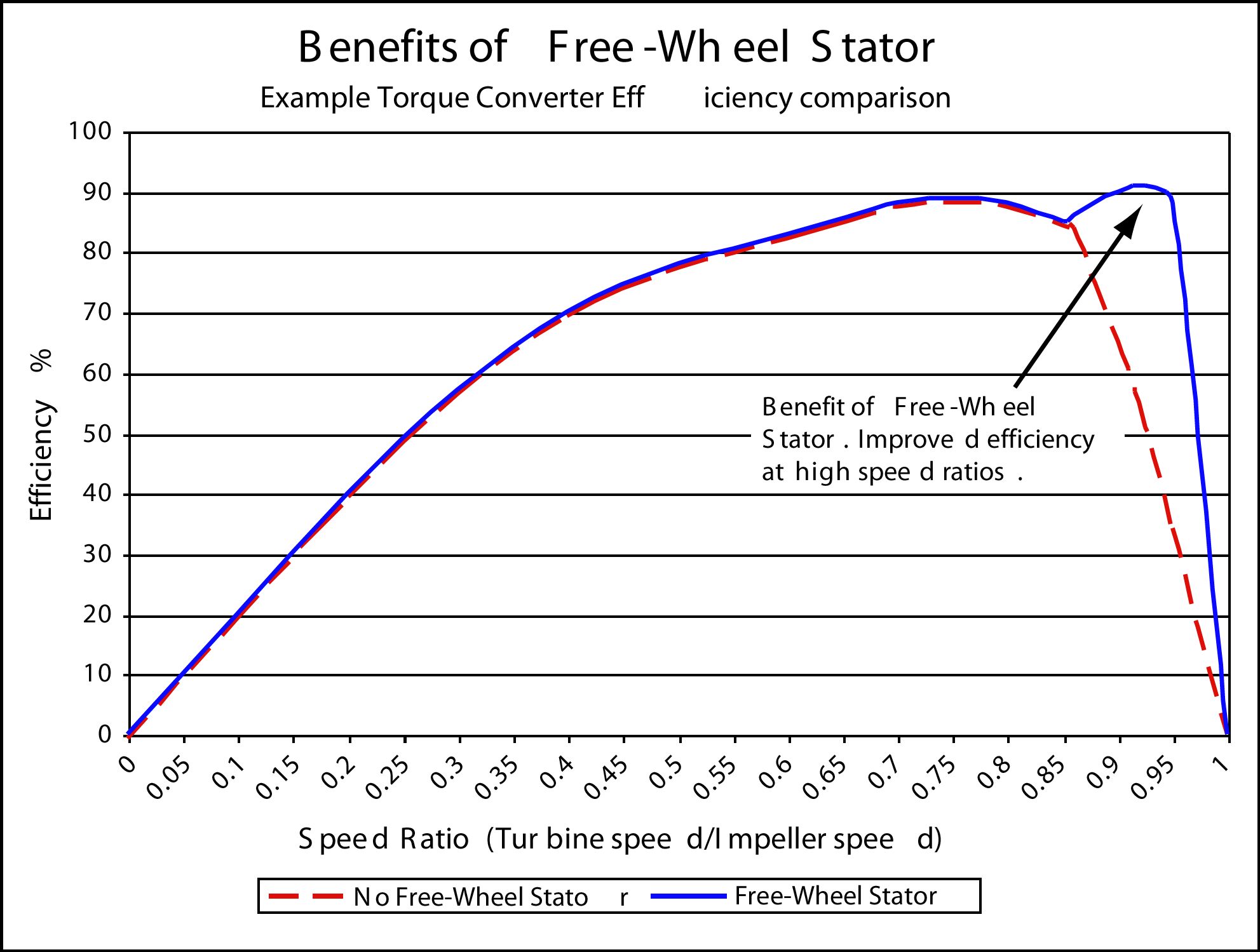

Free Wheel Stator Benefits

The graph represents the efficiency of a fixed torque converter relative to an equivalent converter with a free wheel stator. When the turbine/impeller speed ratio of the two converter types is below 0.85 they perform virtually the same. Once the speed ratio exceeds 0.85, the benefit of a free wheel stator is realized through reduced drag in the torque converter. This higher efficiency results in increased fuel efficiency.

Structures

Engine End Frame

Is a full box section frame with hitch plates at the front end that provides a strong, rigid structure which resists twisting and impact loads. Rear counterweight mounting, battery box and toolbox are located at the back of the frame area.

Spread Hitch Design

Provides excellent load distribution and increased bearing life with thick hitch plates and a butterfly plate that supports the hitch and increases torsional stiffness. The wide opening improves service access.

Non-Engine End Frame

Supplies a solid mounting base for the front axle, lift arms, lift cylinders and tilt cylinders. It is a fabricated four-plate loader tower that absorbs severe twisting, impact and loading forces.

Linkage

Lift arms are solid steel, providing superior strength with an excellent front end viewing area. The proven design offers excellent dump clearance and reach for exceptional matching to both on- and off-highway trucks. Z-bar linkage generates excellent breakout forces and good rack back angle for better bucket loading and material retention.

Counterweight

Is two pieces that are integrated into the machine design and styling. The rear bumper and single bottom slab make up the standard counterweight.

Operator Station

Entry and Exit

Rear hinged, full length doors are provided on both the right and left sides. Both are equipped with sliding windows as standard equipment.

Viewing Area

Is unmatched through a wide, flat front and distortion-free windshield that features bonded glass that reduces obstructions and provides an accurate and full view of the working area. Windshield wiper sweep is increased and wet-arm, front and back wiper washers ensure a clear view is maintained.

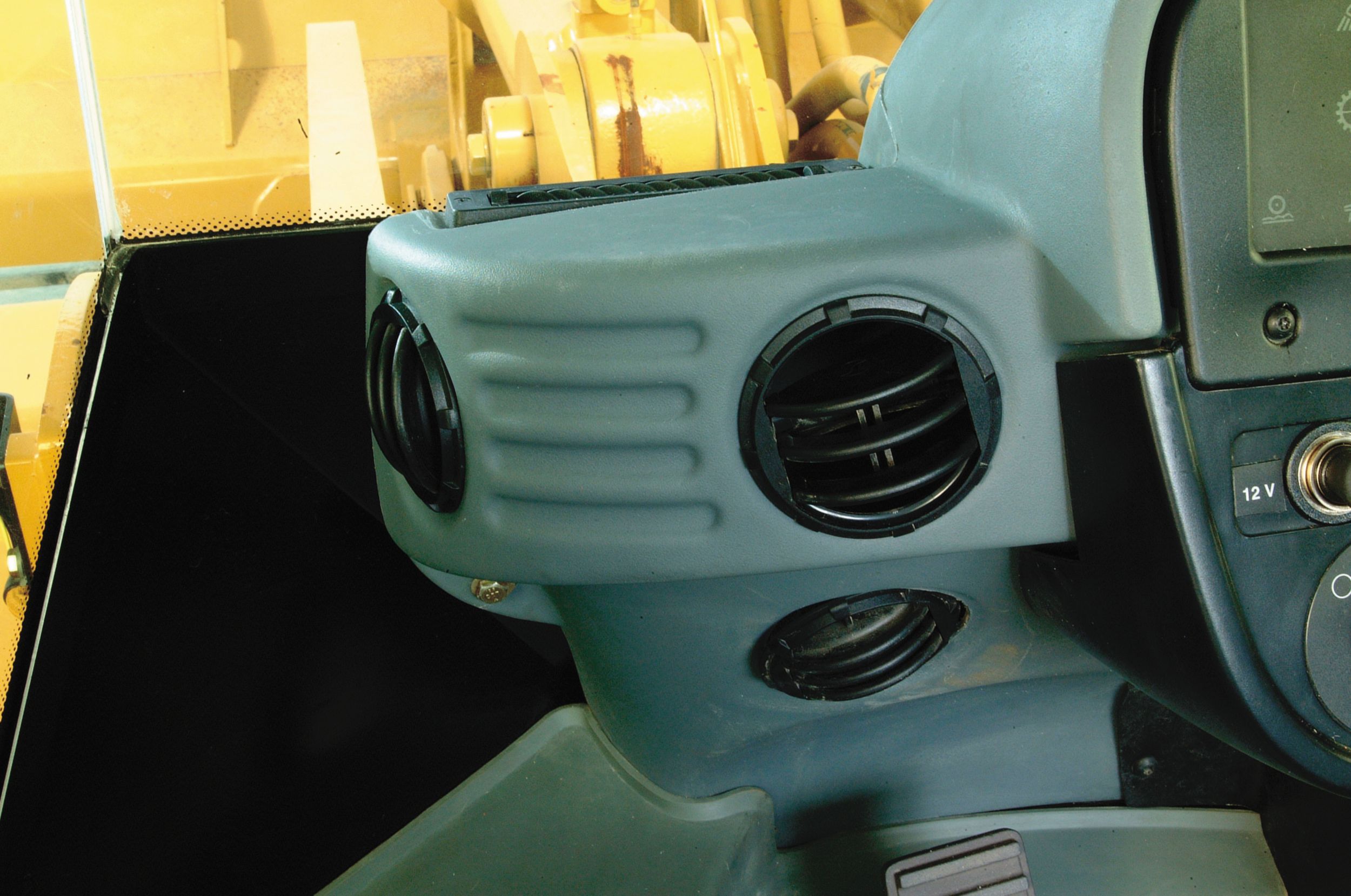

Ventilation/Air Conditioning

The pressurized air conditioning system features improved air flow and circulation. Higher velocity air can be directed toward the operator utilizing thirteen louvered vents. Heating, cooling and defrosting functions are included. All heating and air conditioning controls are located on the upper control panel within easy reach of the operator.

Seat

The new, Caterpillar C 500 Series Comfort air suspension seat replaces the Cat Contour Series seat and provides increased operator comfort with an automotive-syle lumbar support. The seat adjusts six ways to suit individual requirements.

Steering Controls

Command Control steering is a pilot operated, load sensing system that links the steering wheel and frame angle positions to provide the proper amount of steering control. The speed the machine turns is proportional to the steering wheel position. Benefits are precise control, quick response and reduced operator efforts in any application.

Steering Wheel

The semicircular shape improves visibility to the front dash and gauges. It includes the ergonomic, left hand Command Control steering grip. The steering column tilts and telescopes to adjust to personal preferences.

Transmission Controls

Are integrated into the steering grip on the Command Control wheel and provide all transmission controls. With Command Control steering and its +/- 70 degree steering, the operator can keep one hand on the transmission controls in all steering positions and can select forward, neutral or reverse with a three-position rocker switch. The grip rotates on the wheel like a spinner knob to provide smooth, constant effort steering. Thumb operated upshift and downshift buttons control manual shifting.

Shifting

The operator can choose manual or automatic shift modes for transmission shifting.

Ride Control System (Option)

Is a nitrogen oil accumulator in the hyraulic lift circuit that acts as a shock absorber to dampen forces from the bucket as the bucket and lift arms compress the nitrogen in the accumulator to improve machine stability and provide a smoother, more comfortable ride. It also contributes to increased frame and machine life by reducing shock loads into the structures.

Payload Control System

Is designed specifically for Caterpillar Wheel Loaders to provide on-the-go weighing and tracking of material, including the type and quantity loaded by individual trucks. It is available as a factory or dealer installed attachment.

Convenience Features

Include standard air conditioning, a heater/defroster, computerized monitoring system, redesigned dash panel and overhead instrument/control panel that puts all indicators and controls within easy operator reach. In addition, there is a tilt and telescoping steering column and a storage area for personal items, lunchbox and beverage holder.

Caterpillar Monitoring System

System Functions

Include continuous critical machine systems monitoring. A warning system provides the operator four categories or levels of warning, depending on the severity.

Self-Test

Verifies proper operation of the outputs (displays, indicator lamps and audible alarms). The operator must observe the outputs in order to determine whether the displays are operating properly.

Category 1 Warning

Is designed only to make the operator aware of a machine condition by having the alert indicator flash. The warning identifies a system in need of operator attention, including mechanical malfunction or performance parameters requiring operator technique alteration.

Category 2 Warning

Requires a change in machine operation to reduce excessive temperature in one or more systems.

Category 2-S Warning

Sounds a constant alarm to warn of a severe condition in one or more of the systems in Category Two. Immediate corrective action is necessary to prevent machine damage.

Category 3 Warning

Sounds the action alarm and flashes the alert indicator and action light signaling the operator to immediately shutdown the machine to prevent damage to a system and/or the entire machine.

Buckets and Work Tool Controls

General Purpose Buckets

Provide all around performance and are useful in stockpiling and rehandling applications, as well as excavating and bank loading where breakout force is required. General purpose buckets accept standard Caterpillar bolt-on cutting edges, and base edges are pre-drilled for the GET Corner Guard System. Several general purpose bucket combinations are available, ranging in capacity from 4.2 m3 (5.5 yd3) to 5.7 m3 (7.5 yd3) available. These combinations are based on four basic bucket sizes: 4.2 m3 (5.5 yd3), 4.7 m3 (6.0 yd3), 5.0 m3 (6.5 yd3) and 5.4 m3 (7.0 yd3), together with three variations of GET, teeth, teeth and segments and a reversible bolt-on cutting edge (BOCE).

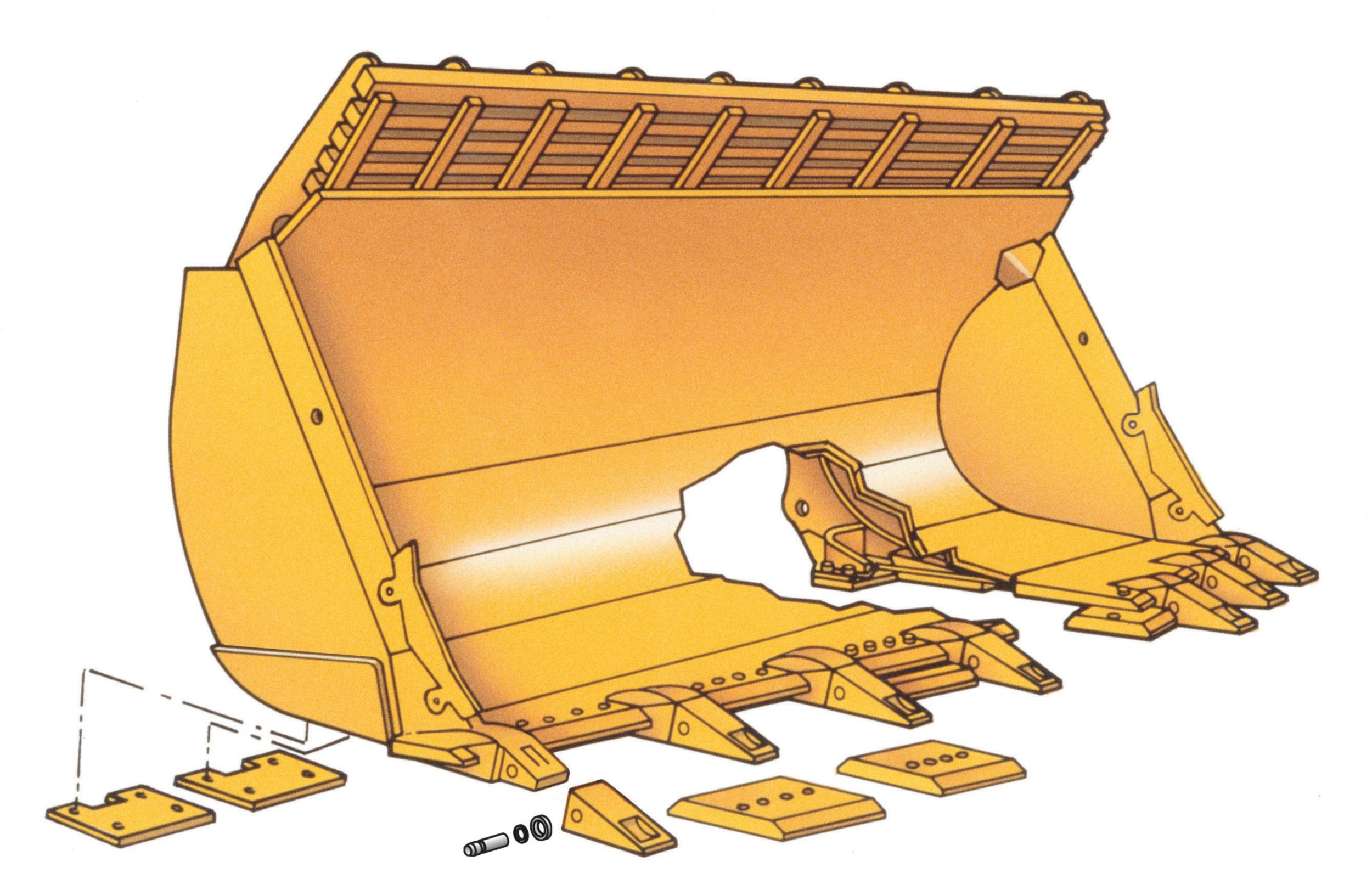

Rock Buckets

Are designed for use in face or bank loading and feature a high penetration spade edge for greater impact loads and/or increased material penetration. Added wear strips reduce the need for costly bucket rebuilds. Select from BOCE; penetration teeth; shouldered, double-strap sidebar protectors; and mechanically attached wear plates (MAWP) in place of standard wear plates to meet the needs of specific applications.

Heavy Duty Rock Buckets

Are recommended for use in face loading where high abrasion and high impacts are encountered. Available in straight edge or spade edge versions, they have a long floor for easy, quick loading and a large bucket radius for minimal resistance. These buckets feature additional wear protection items, including a thicker base edge, a four piece liner package, inner and outer side wear plates, bottom outside skid plates, hinge bracket wear plates and base edge wear plates. Eight buckets range in size from 4.2 m3 (5.5 yd3) to 4.8 m3 (6.25 yd3).

Bucket Construction

Caterpillar General Purpose and Rock buckets feature proven shell-tine construction for maximum performance and durability. Tines reinforce the bucket floor from the hinge plates to the cutting edge, forming box sections that provide protection against impact and twisting forces. Integral spill plates provide better material retention and maintain operator visibility. Rackback stops protect the buckets from damage and impact forces.

Specialty Buckets and Work Tools

- Several other specialty buckets and work tools are also available for specific applications, including:

- Coal Buckets

- Waste/Refuse Buckets

- Millyard Forks

- Logging Forks

- Block Handling Forks

- Wood Chip Buckets

- Slag Buckets

Ground Engaging Tools (GET)

Are offered by Caterpillar to suit the wide range of machine and application needs. Selection of the correct GET is essential for obtaining maximum performance and lowest cost per ton operating costs. Abrasion Resistant Material (ARM) for GET helps prolong component life three to four times.

Bucket Controls

Electro-hydraulic (E/H) bucket and work tool controls offer precise lift, tilt and auxiliary control with extremely low operator effort. The armrest and console can be moved vertically or fore and aft. The hydraulic control console can also be tilted, and the wristrest can be adjusted vertically.

Operation

Controls consist of two single axis levers that provide precise fingertip control. Electronic sensors and hydraulics precisely match lever position to the speed and position of the lift arms and bucket.

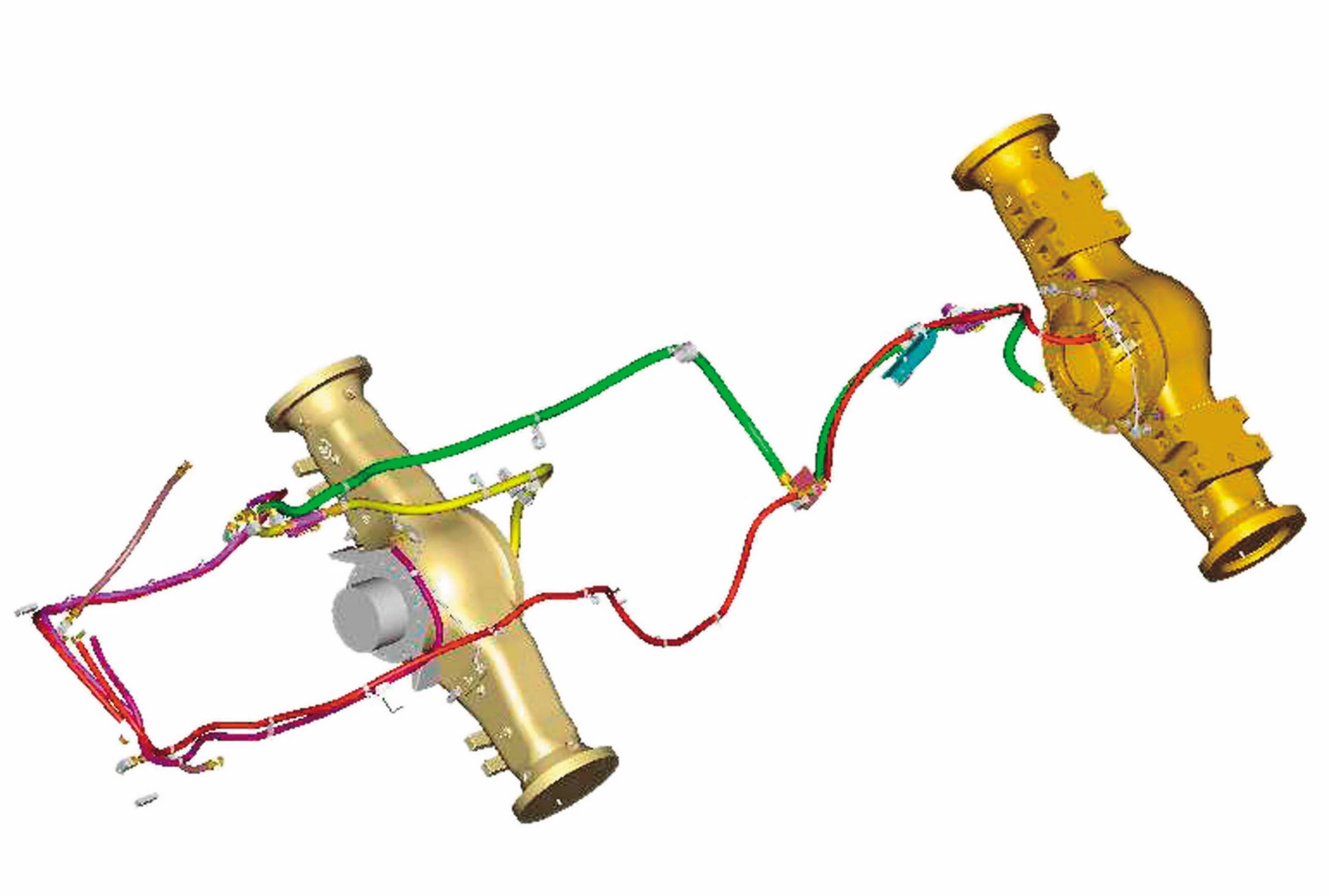

Electro-Hydraulics

Are controlled using CMS which relies on inputs and outputs to monitor lift positions, operator commands and control the pilot valve manifold. With electro-hydraulics, in-cab adjustable lift, lower and bucket kick-outs provide faster cycle times and eliminate the need for visual spotting by providing repeatable, programmable stops.

Tilt Linkage

Is fully integrated. A tilt position sensor enables in-cab adjustment of the tilt kick-out and improves system functionality. Together with new software, finer modulation hydraulic control of lift/lower, along with bucket dump/rack back functions is possible.

Serviceability

Ground Level Maintenance Points

Are located in the front hitch for the non-engine end frame and engine end frame. Remote grease lines from these areas culminate in one convenient central lube bank on the left side of the machine. U-joints are lifetime lubricated so the slip joint is the only drive line component requiring grease.

Sight Gauges

For the transmission oil, hydraulic oil and radiator coolant are easy to see and eliminate the risk of contaminants entering the system during daily checks.

Engine Compartment

Access is convenient through service doors and side panels that can be quickly lowered or easily removed

Non-Metallic Hood

Tilts for full access to the engine, cooling system and major components. An electric screw-jack, with manual backup, tilts the hood from closed to any position up to 70 degrees. The entire hood enclosure is removable using built-in lift points.

Ecology Drains

For the engine, transmission and hydraulic oil allow for simple and clean draining of fluids. Axle oil ecology drains are provided as factory installed options.

Coolant

System is factory filled with Caterpillar Extended Life Coolant, which can provide up to 6,000 hours between change intervals. A simple check at 3,000 hours is required to determine if additive is needed.

S·O·SSM Ports

Provide quick access to engine, transmission and hydraulic oils for representative analysis samples for S·O·S and to minimize chances for contamination. Following S·O·S program guidelines enables the owner to foresee many problems before they occur and schedule downtime for component repair or replacement.

Brake Wear Indicators

Allow a service technician to measure and track brake wear.

Swing-Out Grill

Gives access to the air conditioner and oil cooler cores - which also swing out 45 degrees for easy radiator cleaning.

Batteries

Four maintenance-free batteries sit securely in a built in battery box in the right rear frame with a lid that is sealed to prevent moisture from entering.

Removable Cab

Removal from the machine can be completed in about 45 minutes, and it is not necessary to remove or disconnect any hydraulic lines.

Caterpillar Monitoring System (CMS)

Provides a wealth of machine operation and performance feedback, along with diagnostic codes which a service technician can use to quickly troubleshoot problems.

Oil Change Intervals

Are every 500 hours with the use of CH-4 oil so downtime is less frequent.

Cat QuickEvacTM System (Option)

Is an exclusive Caterpillar on-board engine oil evacuation and prelubrication system that speeds the process of evacuating engine sump, allows for the purging of oil filters prior to removal and minimizes oil spills. It also enhances contamination control by ensuring complete filtration of new oil on engine refill.

Product Link Ready

Product Link

Utilizes a network of 28 satellites to communicate vital machine information and location to the dealer's personal computer via the dealer mailbox system. The system is designed to provide four position reports and one SMU report, which are viewed utilizing a software program residing on the PC, per day. In addition, users can obtain additional machine reports by transmitting a signal through the communication system to the individual unit, though this may incur additional monthly charges.

Product Link 151

- Is available as a dealer installed option and offers:

- Service meter hour update (one per day)

- Machine location update (four per day)

- DBS machine usage file integration

- Integrated mapping, route planning

- Product Watch configurable parameters for machine location and time operation

- Four sensor inputs (digital switch type)

Product Link 201

- Is available as a factory installed attachment. In addition to the Product Link 151 features, it includes:

- Event/diagnostic monitoring

- E-mail/pager alerts (interfaces with DBS Robot/AlertR function)

Versatility and Application Match

Bank Excavation

In packed earth, clay and rocky material offers excellent breakout and bucket fill with first gear loading.

Rock Excavation

- Excellent breakout force makes the 980G Series II an aggressive machine in rock excavation.

- Dump clearance allows loading of 36 tonnes (40-ton) off-highway trucks.

- Spade nose rock buckets feature two bolt corner guards and J400 teeth for better retention and added durability.

- Heavy-duty quarry buckets with additional protection are also available.

Material Handling

With more power, outstanding dump clearance and second gear performance, the 980G Series II loads both on- and off-highway trucks quickly and easily.

High Lift Arrangement (Option)

Provides an additional 221 mm (9 in) of dump clearance for special dump clearance needs.

Forest Machine Arrangement (Option)

Choose from large capacity millyard and other job-matched forks to sort, load and deck logs and timber. Preset the automatic fork positioner at any angle to eliminate visual spotting. Use the low profile millyard fork with widely spaced tines to hold and stabilize tree-length logs.

Waste Handling Arrangement

An optional guarding package is available for machines used in waste transfer or recycling stations. It offers an 826G hood, front driveshaft guard, headlight guards, heavy-duty engine and transmission mounts, hitch area guards, hydraulic and fuel tank guards, modified counterweight, modified front and rear frames, powered crankcase guard, powered power train guard, steel front fenders, steering cylinder guards and transmission dipstick.

Steel Mill Application Arrangement

Gives the added protection needed for extended life and lower operating costs in this rugged environment, including: additional guarding, chain clearance, extreme service transmission, fabricated rear bumper and counterweight, heavy-duty lift arms (T1 steel), heavy-duty engine and transmission mounts, hydraulic hose protection, insulated battery mounting, raised engine air precleaner, remote engine shutdown, remote parking brake release, greaseable linkage pins, steel cable ladder, Steel Command Control steering shaft cover, steel front fenders, transmission override, water glycol hydraulics (optional). Slag buckets are also available.

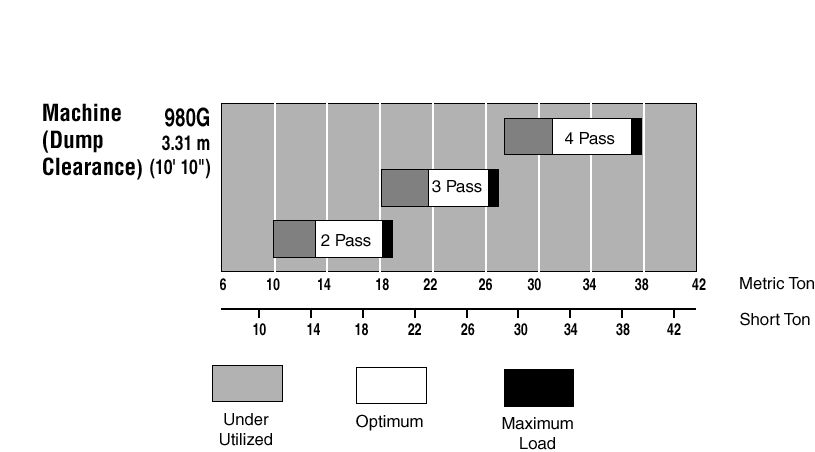

Truck Match

The 980G Series II is an aggressive first gear loader for face and bank excavation, but the versatility of a material handler was also designed into it. With increased rimpull and full match torque converter in second gear, the 980G Series II is an aggressive second gear stockpile loader. With ample dump clearance, it can easily load on-highway trucks in two to three passes and off-highway 36 tonnes (40 ton) trucks in four passes.

Bucket Match

General purpose, rock and heavy-duty quarry buckets are available with various GET configurations. The 5.7 m3 (7.5 yd3) General Purpose bucket can be used effectively in lighter materials ranging from 1305 to 1543 kg/m3 (2200 to 2600 lb/yd3) like crushed limestone. Depending on your material densities, choose a 5.4 m3 (7.0 yd3) General Purpose bucket with bolt-on cutting edge for even more stability.

Complete Customer Support

Machine Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers can estimate component life, preventative maintenance cost and the true cost of lost production.

Purchase

Look past initial price. Consider the financing options available as well as the day-to-day operating costs. Look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Customer Support Agreements

Cat dealers offer a variety of product support agreements and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers use a worldwide computer network to find in-stock parts to minimize machine downtime. Save money with genuine Cat Reman parts. You receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has training videotapes, literature and other ideas to help you increase productivity.

Maintenance Services

Choose from your dealer's range of maintenance services when you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM and Coolant Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.

Standard Equipment

- Electrical

- Alarm, back-up

- Alternator (65-amp, brushless)

- Batteries, maintenance-free (4) 740CCA

- Lighting system, halogen (6 total)

- Main disconnect switch

- Starter, electric, heavy-duty

- Starting and charging system (24-volt)

- Starting receptacle for emergency start

- Operator Environment

- Air conditioner/HVAC system

- Bucket/Work Tool function lockout

- Cab, pressurized and sound suppressed

- Cigar lighter and ashtray

- Coat hooks (2) with straps

- Controls, bucket/work tool electro-hydraulic

- Heater and defroster

- Horns, electric (steering wheel mounted)

- Computerized Monitoring System

- Lunchbox and beverage holders

- Mirrors, rearview (externally mounted)

- Seat, C-500 Series (cloth) air suspension

- Seatbelt, retractable, 76 mm (3 in) wide

- Steering column, adjustable, tilt and telescope

- Wet-arm, wipers/washers (front and rear)

- Window, sliding (left and right side)

- Power Train

- Brakes, full hydraulic enclosed wet-disc

- Engine, Cat 3406E diesel with ATAAC

- Fan, radiator, hydraulically driven, variable speed

- Filters, fuel/engine air, primary/secondary

- Fuel priming aid (electric pump)

- Fuel/water separator

- Muffler, sound suppressed

- Precleaner, engine air intake

- Radiator, Advanced Modular Cooling System (AMOCS)

- Starting aid (ether)

- Switch, transmission neutralizer lockout

- Torque converter (free wheel stator)

- Transmission, automatic planetary power shift (4F/4R)

- Variable Shift Control (VSC)

- Other

- Automatic bucket positioner, in-cab adjustable

- Counterweight

- Doors, service access (locking)

- Ecology drains for engine, transmission and hydraulics

- Fenders, steel front with mudflaps/rear with extensions

- Guard, power train and crankcase

- Hitch, drawbar with pin

- Hood, non-metallic power tilting

- Kickout, lift and tilt, automatc (in-cab adjustable)

- Linkage, Z-bar, cast crosstube/tilt lever

- Oil sampling valves

- Product Link Ready

- Sight Gauges:

- Vandalism protection caplocks

- Hydraulics

- Couplings, Caterpillar O-ring face seals

- Diagnostic pressure taps

- Hoses, XT

- Hydraulic oil cooler (swing-out)

- Steering, load sensing

- Tires, Rims and Wheels

- A tire must be selected from the mandatory attachments section. Base machine price includes a tire allowance.

- Antifreeze

- Premixed 50% concentration of Extended Life Coolant with freeze protection to -34° C (-29° F).