Overview

Revolutionary design, Caterpillar quality. Electro-hydraulic controls, increased power and torque rise on all new front linkage and unmatched operator comfort work together for increased performance and added durability to make the 988H an innovative, 21st century large wheel loader geared for maximum production in the toughest condition.

Specifications

| Net Power | — |

| Operating Weight | — |

| Bucket Capacities | 6.3-7.0 m3 |

Benefits & Features

Structures and Fabricated Box Boom

The articulated frame design features a high-torsion, compact, load-absorbing, front frame and a large, box-section, engine-end frame. Fabricated boom and linkage geometry increases dump clearance, provides improved breakout and lift forces and increases the viewing area to the bucket corners.

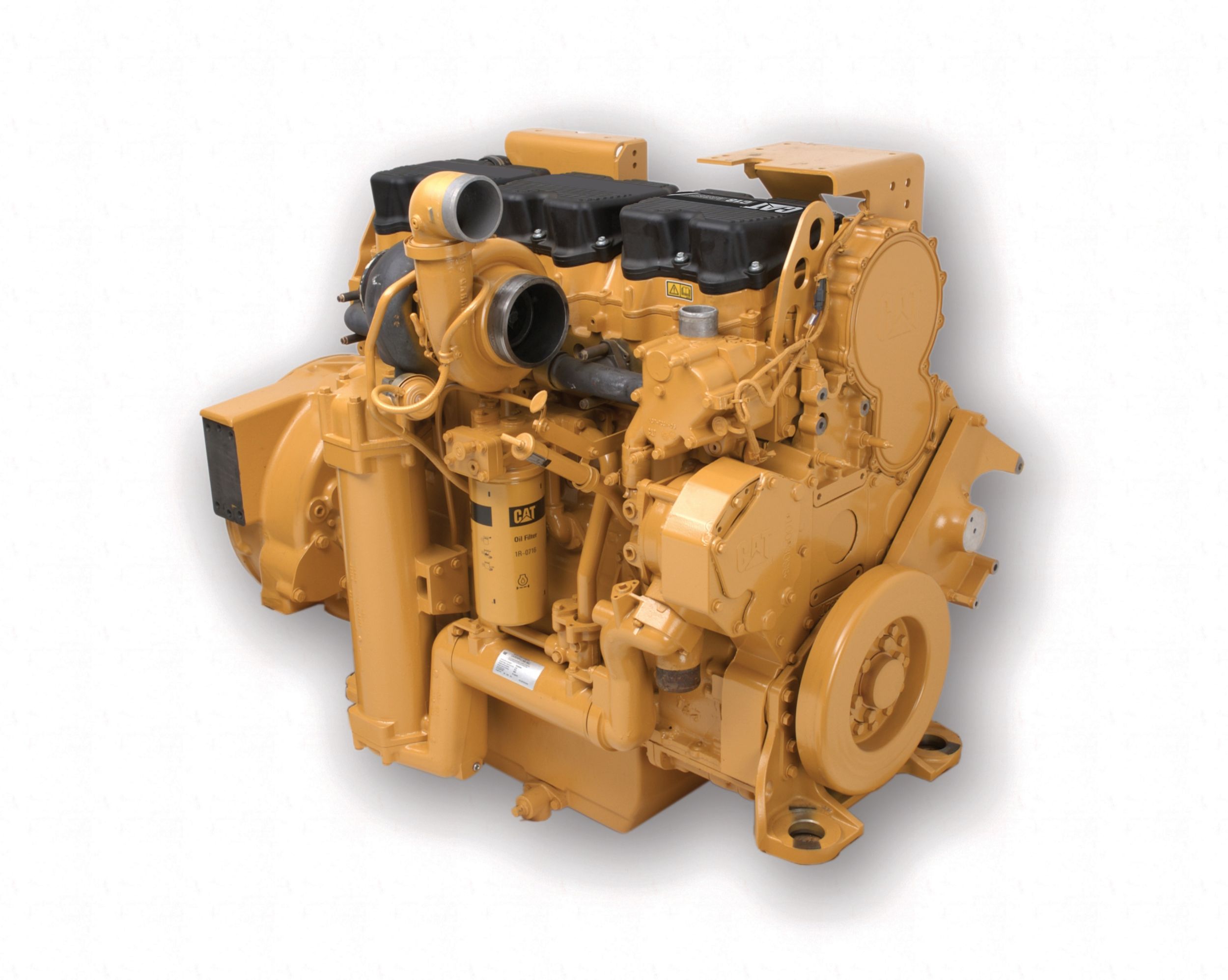

Power Train

The Cat C18 engine with ACERT™ Technology is EU Stage IIIA compliant. The Cat transmission and impeller clutch torque converter offer smooth, consistent shifting with fingertip control. Electronic controls help increase productivity.

Hydraulics and Electronic Monitoring

Innovative electro-hydraulics play a key role in performance of the 988H and provide low operator effort. Increased hydraulic efficiency improves lift and tilt cycle time for reduced overall cycle time. The tradition of reliable, high-performance Caterpillar hydraulics continues.

Specifications

| Net Power | — |

| Engine Model | C18 ACERT |

| Gross Power | — |

| Net Power - ISO 9249 | — |

| Gross Power - ISO 3046-2 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - EEC 80/1269 | — |

| Operating Weight | — |

| Rated Payload | — |

| Rated Payload - Standard | — |

| Converter Drive - Forward 1 | — |

| Converter Drive - Forward 2 | — |

| Converter Drive - Forward 3 | — |

| Converter Drive - Forward 4 | — |

| Converter Drive - Reverse 1 | — |

| Converter Drive - Reverse 2 | — |

| Converter Drive - Reverse 3 | — |

| Direct Drive - Forward 1 | Lock-up disabled |

| Direct Drive - Forward 2 | — |

| Direct Drive - Forward 3 | — |

| Direct Drive - Forward 4 | — |

| Direct Drive - Reverse 1 | — |

| Direct Drive - Reverse 2 | — |

| Direct Drive - Reverse 3 | — |

| Raise | — |

| Dump | — |

| Lower Float Down - Empty | — |

| Total Hydraulic Cycle Time | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic System Factory Fill | — |

| Hydraulic System - Tank Only | — |

| Height - Top of Exhaust Stack | — |

| Height - Top of Hood | — |

| Ground Clearance | — |

| Wheel Base Length | — |

| Overall Length - Std | — |

| Height - Top of Cab | — |

| Height - Top of Air Cleaner | — |

| Centerline of Rear Axle to Edge of Rear Bumper | — |

| Centerline of Front Axle to Hitch | — |

| Height - Center of Wheel | — |

| C-Pin Height | — |

| Rack Back Angle - Ground | — |

| Rack Back Angle - Carry | — |

| Height - Spillguard | — |

| B-Pin Height | — |

| Rack Back Angle - Maximum Lift | — |

| Dump Angle at Maximum Lift | — |

| Bucket Capacities | 6.3-7.0 m3 |

| Maximum Bucket Capacity | — |

| Maximum Single-Wheel Rise and Fall | — |

| Front | Fixed |

| Rear | Oscillating ±13° |

| Brakes | Meet SAE ISO 3450:1996 |

| Cab - ROPS/FOPS | Meets SAE and ISO standards |

| Sound Performance | Meets ANSI, SAE and ISO standards |

| Steering | Meets SAE and ISO standards |

| Total Steering Angle | — |

| Main Hydraulic System Output at 2010 rpm and 6900 kPa (1000 psi) | — |

| Relief Valve Setting | — |

| Cylinders, Double Acting - Lift, Bore and Stroke | 220 x 911 mm 8.7 x 35.9 in |

| Cylinders, Double Acting - Tilt, Bore and Stroke | 220 x 1770 mm 8.7 x 69.7 in |

| Pilot System - Gear-Type Pump Output at 2,010 rpm and 2500 kPa (363 psi) | — |

| Relief Valve Setting - Low Idle | — |

Benefits & Features

Structures and Fabricated Box Boom

The articulated frame design features a high-torsion, compact, load-absorbing, front frame and a large, box-section, engine-end frame. Fabricated boom and linkage geometry increases dump clearance, provides improved breakout and lift forces and increases the viewing area to the bucket corners.

Power Train

The Cat C18 engine with ACERT™ Technology is EU Stage IIIA compliant. The Cat transmission and impeller clutch torque converter offer smooth, consistent shifting with fingertip control. Electronic controls help increase productivity.

Hydraulics and Electronic Monitoring

Innovative electro-hydraulics play a key role in performance of the 988H and provide low operator effort. Increased hydraulic efficiency improves lift and tilt cycle time for reduced overall cycle time. The tradition of reliable, high-performance Caterpillar hydraulics continues.

Operator Station

Experience a new level of efficiency, comfort and productivity with one-hand STIC operation, a large cab, low-effort, fingertip lift and tilt controls, improved visibility, reduced sound levels, improved ventilation and easier entry and exit.

Buckets and Ground Engaging Tools

Choose between 6.3 m3 and 7.0 m3 capacity buckets, spade edge and straight edge buckets and various Ground Engaging Tools to match job conditions. Cat buckets retain the proven shell-tine construction design for unmatched durability.

Bucket Match

Improve machine performance and increase stability by selecting the right bucket for your application and material density.

Application Truck Match

Increased performance and good pass matching make the 988H a versatile performer.

Maintenance and Serviceability

Most daily maintenance checks are performed from the machine's left side, facilitating quick start up. Case drain filters for main hydraulic, steering and fan pumps protect against contamination, and remote pressure taps contribute to improved serviceability. Easy access to major components enhance serviceability and increase uptime.

Customer Support

Your Cat dealer offers a wide range of services that help you operate longer with lower costs.

Data not available.