Overview

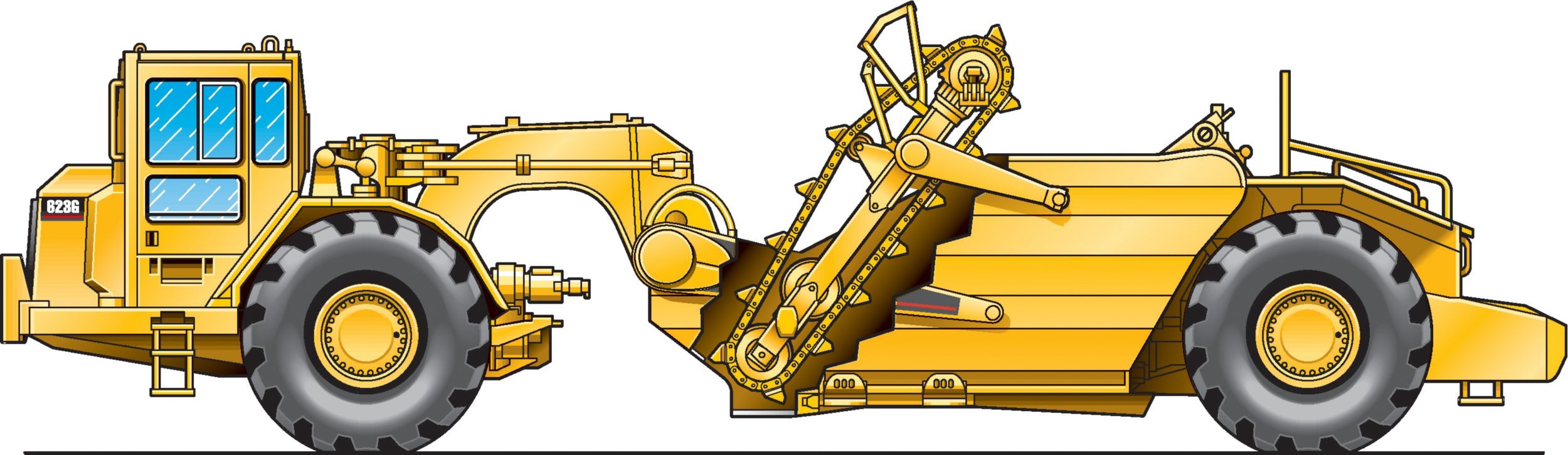

Quick loading, high travel speeds and the ability to load and spread on the run yield fast cycle times, allowing Cat Elevating Scrapers to consistently deliver high productivity at the lowest cost per ton.

Specifications

| Net Power - Tractor/Scraper | 246 kW (330 hp) |

| Capacity Heaped | — |

| Travel Speed - Maximum | — |

Benefits & Features

Power Train – Engine

Electronically controlled Caterpillar® engines with ACERT technology, modular radiator with 9 fins per inch, and an Electronic Control Module maximizes power to the cutting edge and exceptional haul road speed.

Power Train – Transmission

Planetary powershift transmission delivers excellent load capability. Redesigned front and rear axles accommodate wider brake shoes and drums. The neutral coast inhibitor and programmable top gear reduce wear while increasing machine performance.

Electronic Controls

Electronic controls improve machine response and provide advanced diagnostic capabilities that result in better machine availability. The Product Link option allows remote monitoring of location, machine system status, and alert indicators.

Specifications

| Net Power - Tractor/Scraper | 246 kW (330 hp) |

| Tractor Engine | C15 ACERT |

| Net Power - Gears 1-2 | — |

| Net Power - Gears 3-8 | — |

| Gross Power - Gears 1-2 | — |

| Gross Power - Gears 3-8 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power | — |

| Travel Speed - Maximum | — |

| 1 Forward | — |

| 2 Forward | — |

| 3 Forward | — |

| 4 Forward | — |

| 5 Forward | — |

| 6 Forward | — |

| 7 Forward | — |

| 8 Forward | — |

| Reverse | — |

| Bowl Cylinder Bore | — |

| Bowl Cylinder Stroke | — |

| Floor Cylinder Bore | — |

| Floor Cylinder Stroke | — |

| Ejector Cylinder Bore | — |

| Ejector Cylinder Stroke | — |

| Steering Circuit | — |

| Scraper Circuit | — |

| Cushion Hitch Circuit | — |

| Supplemental Steering Circuit | — |

| Relief Valve - Steering Circuit | — |

| Relief Valve - Implement Circuit | — |

| Compensator Settings - Cushion Hitch Circuit | — |

| Compensator Settings - Elevator Circuit | — |

| Capacity Heaped | — |

| Rated Load | — |

| Capacity - Struck | — |

| Depth of Cut - Maximum | — |

| Width - Cut - To Router Bits | — |

| Ground Clearance - Maximum | — |

| Cutting Edge Thickness | — |

| Hydraulic Penetration Force | — |

| Depth of Spread - Maximum | — |

| Length - Overall | — |

| Width - Flight Face | — |

| Length - Flights | — |

| Spacing of Flights | — |

| Number of Flights | 15 |

| Width - 180° Turn | — |

| Steering Angle - Right | 90° |

| Steering Angle - Left | 85° |

| Hydraulic Output | — |

| Fuel Tank | — |

| Crankcase | — |

| Transmission | — |

| Differential | — |

| Final Drive - Each | — |

| Wheel Coolant - Each | — |

| Cooling System | — |

| Hydraulic Reservoir | — |

| Total Operating - Empty | — |

| Front Axle | — |

| Rear Axle | — |

| Total Shipping | — |

| Tractor Shipping | — |

| Scraper Shipping | — |

| Total Operating - Loaded | — |

| Front Axle Weight - Loaded | — |

| Rear Axle - Weight - Loaded | — |

| Height - Overall Shipping | — |

| Length - Overall Machine | — |

| Width - Overall Machine | — |

| Height - Top of Cab | — |

| Height - Scraper Blade Maximum | — |

| Width - Tractor | — |

| Width - Inside of Bowl | — |

| Width - Rear Tire Center Lines | — |

| Width - Outside Rear Tires | — |

| Rim Radius | — |

| Front of Tractor to Front Axle | — |

| Wheel Base | — |

| Rear Axle - Rear of Machine | — |

| Ground Clearance - Tractor | — |

Benefits & Features

Power Train – Engine

Electronically controlled Caterpillar® engines with ACERT technology, modular radiator with 9 fins per inch, and an Electronic Control Module maximizes power to the cutting edge and exceptional haul road speed.

Power Train – Transmission

Planetary powershift transmission delivers excellent load capability. Redesigned front and rear axles accommodate wider brake shoes and drums. The neutral coast inhibitor and programmable top gear reduce wear while increasing machine performance.

Electronic Controls

Electronic controls improve machine response and provide advanced diagnostic capabilities that result in better machine availability. The Product Link option allows remote monitoring of location, machine system status, and alert indicators.

Operator Station

Convenient control placement and a comfortable work environment are keys to high productivity. Features include Single Lever Implement Control, an air seat suspension and improved instrumentation.

Structures

Superior structural design delivers state-of-the-art ride, capacity, and material control while assuring the durability and reliability customers expect from Caterpillar.

Scraper Bowl

Caterpillar Scraper bowls deliver large loads with better retention, excellent material flow, fast cycle times and high productivity. Relocating the implement valve to the draft tube improves access and serviceability.

Elevator Mechanism

The elevator mechanism conditions material as it works, lifting material off the cutting edge and carrying it to the top of the load for true self-loading capability. The 623G is ideal for windrowing, blending material as well as breaking up vegetation in stripping operations.

Serviceability

The latest electronic monitoring systems, grouped service points, and rugged Caterpillar components simplify maintenance and minimize downtime. New two-piece access doors open easily and stay open for better access.

Customer Support

The best parts availability and the best service capability will help keep your equipment working.

Data not available.