Overview

Your long-term success is our goal here at Cat, so we’ve developed our 772G to be more productive and economical for our customers for years to come. Equipped with new transmission controls, the 772G is built for heavy-duty, off-road applications and delivers quick haul cycles with automotive-quality shifting and comfort. The 772G is also built with a Cat C18 diesel engine and with our fuel saving strategies, you can adjust engine power to meet your specific needs. Ideal pass match options for the 772G are the Cat 986K or the 988K Wheel Loader and the 390F L Hydraulic Excavator. When you consider its fuel efficiency and performance, the 772G is the right Off-Highway Truck for all generations.

Specifications

| Nominal Payload Class (100%) | — |

| Engine Model | Cat® C18 |

| Top Speed - Loaded | — |

Benefits & Features

Specifications

| Engine Model | Cat® C18 |

| Rated Engine Speed | — |

| Gross Power - SAE J1995:2014 | — |

| Net Power - SAE J1349:2011 | — |

| Net Power - ISO 9249 | — |

| Number of Cylinders | 6 |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Torque - SAE J1349 | — |

| Engine Power - ISO 14396 | — |

| Target Gross Machine Operating Weight | — |

| Chassis Weight | — |

| Body Weight | — |

| Target Gross Machine Weight | — |

| Nominal Payload Class (100%) | — |

| Top Speed - Loaded | — |

| Body Capacity - SAE 2:1 | — |

| Target Payload Capacity | — |

| Not to Exceed Payload (120%) | — |

| Maximum Payload Class (110%) | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Forward - 4 | — |

| Forward - 5 | — |

| Forward - 6 | — |

| Forward - 7 | — |

| Reverse | — |

| Differential Ratio | 2.74:1 |

| Planetary Ratio | 4.80:1 |

| Total Reduction Ratio | 13.14:1 |

| Brake Surface - Front | — |

| Brake Surface - Rear | — |

| Brake Standards | ISO 3450:1996 |

| Pump Flow - High Idle | — |

| Relief Valve Setting - Raise | — |

| Relief Valve Setting - Lower | — |

| Body Raise Time - High Idle | — |

| Body Lower Time - Float | — |

| Body Power Down - High Idle | — |

| Struck | — |

| Heaped 2:1 (SAE) | — |

| Struck | — |

| Heaped 2:1 (SAE) | — |

| Front Axle - Empty | — |

| Front Axle - Loaded | — |

| Rear Axle - Empty | — |

| Rear Axle - Loaded | — |

| Rear axle - Oscillation | — |

| Empty Loaded Cylinder Stroke Rear | — |

| Empty Loaded Cylinder Stroke Front | — |

| Fuel Tank | — |

| Cooling System | — |

| Differential - Final Drives | — |

| Steering Tank | — |

| Steering System - Including Tank | — |

| Torque Converter - Transmission System | — |

| DEF Tank | — |

| Brake Hoist System | — |

| Crankcase | — |

| Brake/Hoist Hydraulic Tank | — |

| Standard Tire | 21.00R33 (E4) |

| ROPS Standards | ROPS (Rollover Protective Structure) for cab offered by Caterpillar meets ISO 3471:2008 ROPS criteria. |

| FOPS Standards | FOPS (Falling Objects Protective Structure) meets ISO 3449:2005 Level II FOPS criteria. |

| Sound Standards (1) | Hearing protection may be needed when operating with open operator station & cab for extended periods or in noisy environment. |

| Sound Standards (3) | Operator Equivalent Sound Pressure Level (Leq) is 74 dB(A) when ISO 6396:2008 is used to measure the value for an enclosed cab. |

| Sound Standards (2) | Exterior sound pressure power level for standard machine measured according to tests specified in ISO 6395:2008 is 115 dB(A). |

| Turning Diameter - Front | — |

| Steering Standards | ISO 5010:2007 |

| Steer Angle | — |

| Turning Circle - Clearance Diameter | — |

| Inside Body Depth - Maximum | — |

| Height - Top of ROPS | — |

| Overall Body Length | — |

| Inside Body Length | — |

| Overall Length | — |

| Wheel Base | — |

| Rear Axle - Tail | — |

| Ground Clearance | — |

| Dump Clearance | — |

| Loading Height - Empty | — |

| Overall Height - Body Raised | — |

| Operating Width | — |

| Centerline Front Tire Width | — |

| Engine Guard Clearance | — |

| Outside Body Width | — |

| Inside Body Width | — |

| Front Canopy Height | — |

| Rear Axle - Clearance | — |

| Centerline of Rear Dual Tire Width | — |

| Overall Tire Width | — |

Benefits & Features

Power Train

Engine

- Our new G Series truck is equipped with a Cat C18 diesel engine. We recently celebrated 85 years in the engine business, and the work we've put into these U.S. EPA Tier 4 Final/EU Stage IV engines is the culmination of that experience. This C18 engine has been updated to meet global emission standards. Caterpillar equips every U.S. EPA Tier 4 Final/EU Stage IV engine with industry leading electronic controls, fuel delivery, air processing and aftertreatment. The results are an engine that conserves fuel, manages emissions and facilitates greater diagnostics. For this G Series truck, engine software modifications are allowing the truck to get more work done at lower speeds and at greater fuel economy. We've balanced this change with the addition of 10% more torque for putting a greater percentage of the power to the ground. With our new transmission controls working in tandem with the engine, this truck is delivering significantly greater performance on grade and doing it more economically. One additional and significant change for G Series is the 772G's ability to work at full power in higher altitudes. This truck has a 23% increase in altitude capability, allowing it to climb to just short of 3000 meters or close to 10,000 feet without affecting performance. Here are a few additional key features of the C18:

- The convenience of automatic voltage charging.

- Key on fuel priming reducing service costs.

- Cold start up elevated idle for peak performance at shift start.

- Programmable engine idle shutdown saving fuel and reducing emissions.

- Delayed engine shutdown allows all systems to cool and initiate purging prior to engine shut off.

- The convenience of new service access points to the top of the engine.

- Available with an optional engine brake for long downhill grades.

- Fuel efficient power under all load conditions with Cat MEUI™-C fuel injectors.

Transmission

The Cat planetary power shift transmission is an automatic, 7-speed transmission built for heavy-duty off road applications including those with long uphill grades. This transmission is managed with APECS, a strategy that provides an exceptionally smooth ride and allows power to carry through the shift points for excellent performance and speed on grades. In addition to delivering a quick and responsive truck, APECS is managing clutch pressures for long-life reliability. With its Cat power train components running in 7th gear, the 772G has a top speed of 79.2 km/h (49.2 mph).

What to Expect from APECS

- We attribute many of the performance improvements on this truck to our integrated power train, and in particular our APECS transmission control strategy.

- Faster cycle times on grade - we've added part throttle shifting to maintain power through the shift. This prevents loss of momentum as the truck shifts under load.

- Fuel savings - part throttle shifting has the benefit of saving fuel - it no longer needs to apply fuel towards overcoming lost momentum between shifts.

- Automotive ride quality - with torque shift management and part throttle shifting, operators will hardly notice the shift as it's noticeably smoother, reducing the fatigue factor of a long day behind the wheel.

- Long term durability - torque shift management controls the hydraulic pressures inside the transmission, eliminating pressure spikes and reducing wear to the clutches.

Emission Controls

Our goal in designing our U.S. EPA Tier 4 Final/EU Stage IV solution was to first provide our customers with a product that meets applicable emission standards and secondly make it simple to operate, maintain and manage. With dozens of Cat products using similar systems, we've designed parts commonality and ease of use into our solution. For the 772G specifically, you will add DEF fluid (Diesel Exhaust Fluid) to a small tank next to the fuel tank. This tank holds 27 liters fluid (approximately 6 gallons), 21 liters usable fluid of DEF and is filled at the same intervals as the fuel tank. The rest of the process is automatic and hands free to your operator. The systems and components of our solution use Selective Catalytic Reduction to control emissions, and they are purpose built for the applications you'll use them in. For cold environments, the system is heated, and for hot environments, the system is cooled. Our solution has three stages; NOx reduction in the engine is achieved by reintroducing a very small percentage of cooled exhaust gas back through the combustion chamber. With mandated low sulfur diesel fuel in today's diesel engines, the exhaust is less corrosive and poses fewer risks to engine life. Our reintroduction of an exhaust mixture lowers combustion temperatures controlling NOx production. Exhaust gases leaving the engine are first routed through a diesel particulate DPF filtration system to reduce particulate matter. The system will then control any remaining NOx by injecting diesel exhaust fluid (DEF) into the exhaust stream. This mixture will undergo selective catalytic reduction, ammonia reduction - eventually breaking down the NOx into inert nitrogen gas and water.

Fuel Saving Strategies

Standard Economy Mode

G Series can adjust engine power based on your individual needs. Fuel savings are achieved by reducing power between 0.15 to 15 percent during all phases of operation.

Adaptive Economy Mode

New for G Series, this feature requires a customer-set baseline for production. Then, as the truck goes through the haul cycle and can hold a steady state, it constantly evaluates opportunities to reduce power and save fuel against your baseline. It's fully automatic with no special operation required.

Auto Neutral Idle

As the 772G idles in a forward gear, such as waiting for the loader or crusher, the transmission will automatically slip into a neutral state that is more fuel efficient. As soon as the operator releases the brake or applies throttle, the truck shifts instantly back into the forward gear.

Engine Idle Shutdown

When your G Series truck is in park and idles for more than a preset time, the truck will initiate engine shutdown to conserve fuel. This feature can be time adjusted or turned on or off according to your specific needs.

Performance

- In addition to the shift quality, fuel efficiency and performance benefits of APECS, there are several key safety functions being performed by this technology:

- Reverse shifts are speed controlled to reduce risk to the operator and the truck's power train components. The shift from forward to reverse will only be executed at truck speeds below 4.8 km/h or 3 mph. Once the truck is in reverse, the truck can go 16.7 km/h (10.4 mph). If this is too fast for your job site conditions, you can limit the speed setting for Reverse.

- To further protect the transmission, the truck will automatically regulate engine speed during directional shifts.

- Coasting at high speeds will limit lubrication of the transmission. To avoid this, APECS will only shift to neutral at or below speeds of 8 km/h or 5 mph.

- Second gear start is a new feature for G Series trucks. It allows the truck to bypass first gear and take off in second gear. This option works well on mostly level and solid underfoot conditions. As the truck pulls away, it has plenty of torque in second gear, and will use less fuel by avoiding the short term but high engine speed demands of first gear. As the truck traverses the haul road and first gear becomes necessary, the truck will automatically drop down into first gear without additional intervention.

- When in first gear, the 772G locks up the torque converter to produce maximum available rimpull.

Speed Limiting Advantages

Speed limiting is a simple way to reduce risk on your haul roads. With speed limiting, the truck maintains your speed limit while running in its most efficient gear and corresponding engine speed. When you compare this to locking out gears, it can reduce your fuel use, noise levels and wear to power train components.

Brake Performance

An important differentiator for Cat trucks is their outstanding brake performance. The design principle is one of long life and excellent performance in quarry, mine and earthmoving applications.

Hydraulically Actuated Brakes

Cat trucks are equipped with hydraulically actuated, rear brakes and caliper-disc front brakes. Each truck offers primary service brakes, hydraulic retarding and a parking brake. Two hydraulic accumulators provide the pressure required for the service brakes. The second accumulator acts as a back up. On the rear axle, the oil-cooled, multiple disc brakes have large discs that provide fade resistant performance. The parking brake is applied on the rear brakes and can hold the machine, with rated load, on a 15 percent slope. In turn, the service brakes are designed to hold the truck on slopes of 20%.

Automatic Retarding Control (ARC)

Automatic retarding control is standard on the 772G. ARC electronically controls braking on grade to maintain the engine speed at approximately 2,200 rpm (adjustable from 1,950 to 2,200 rpm in increments of 10). ARC is deactivated when not in a retarding situation. This feature does the work of controlling truck speed on long downhill hauls without constant input from the operator; it's smooth for greater control and provides faster cycle times over manual retarding. ARC will automatically engage to prevent engine over speeding at any time during truck operation.

Cat Engine Brake

Caterpillar offers an optional engine brake. The Cat engine compression brake works in conjunction with the ARC braking system to release pressure in selected cylinders to “brake” the machine during the compression stroke of the engine. By working in combination with ARC, the system reduces wear on brake components and allows the machine to travel up to 35% faster on downhill grades. This Caterpillar manufactured component is built for long, carefree service. It requires no tune-ups and no maintenance, except periodic valve lash checks, which are done as part of the routine engine maintenance. An on/off switch is located in the dash to disable the Cat compression brake.

Traction Control System

New Traction Control System

- We've made significant updates to the performance capabilities of our traction control system. Our new system has:

- Faster response time to wheel slip by using the hydraulic service brakes, reducing spin and tire wear.

- Activation at slower speeds returning tractive effort sooner.

- A steering sensor that helps the truck differentiate between wheel slip and fast turns for accurate engagement.

- Constant modulation between both rear wheel groups using the hydraulic service brakes helps manage traction to the current ground conditions.

Truck Bodies

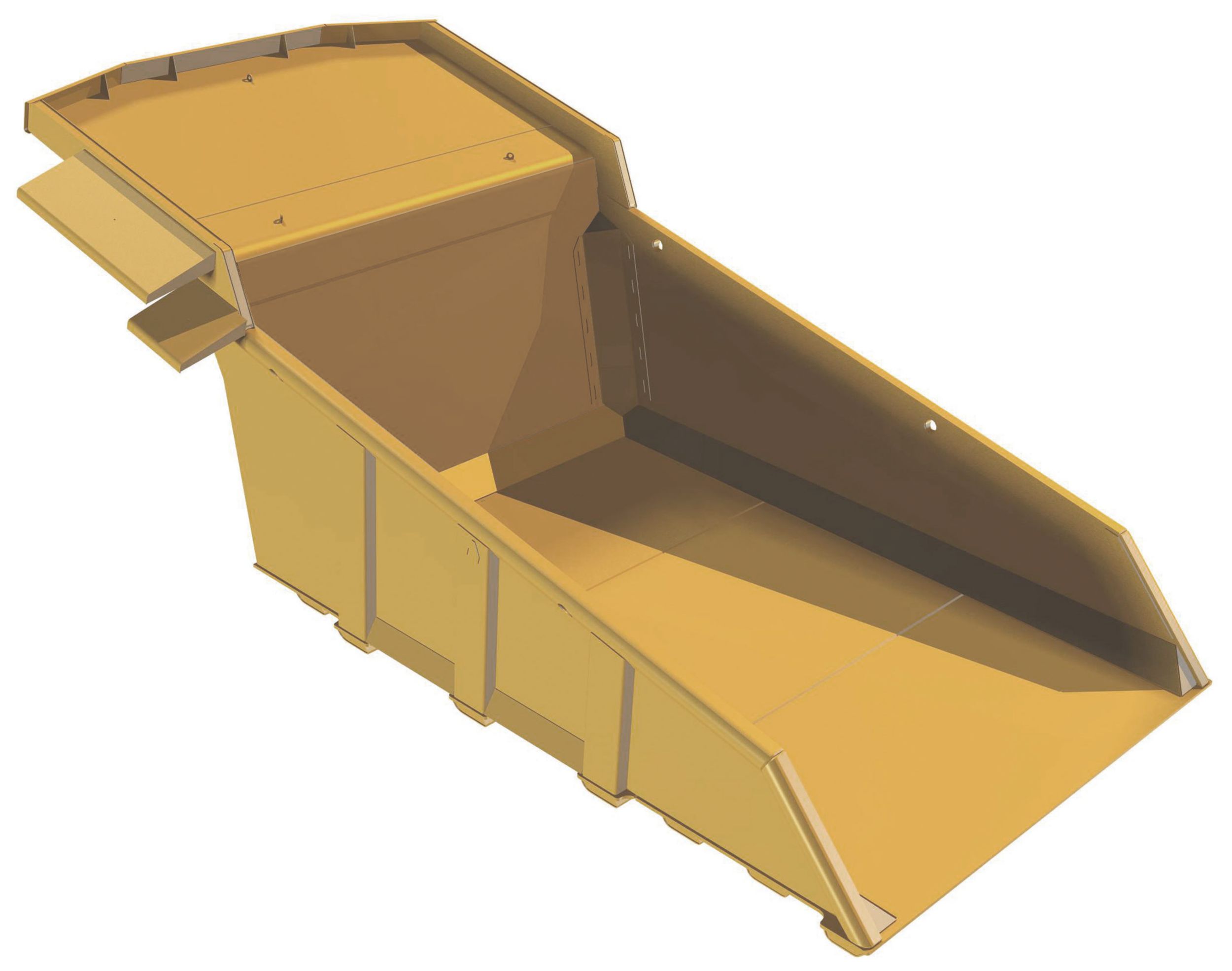

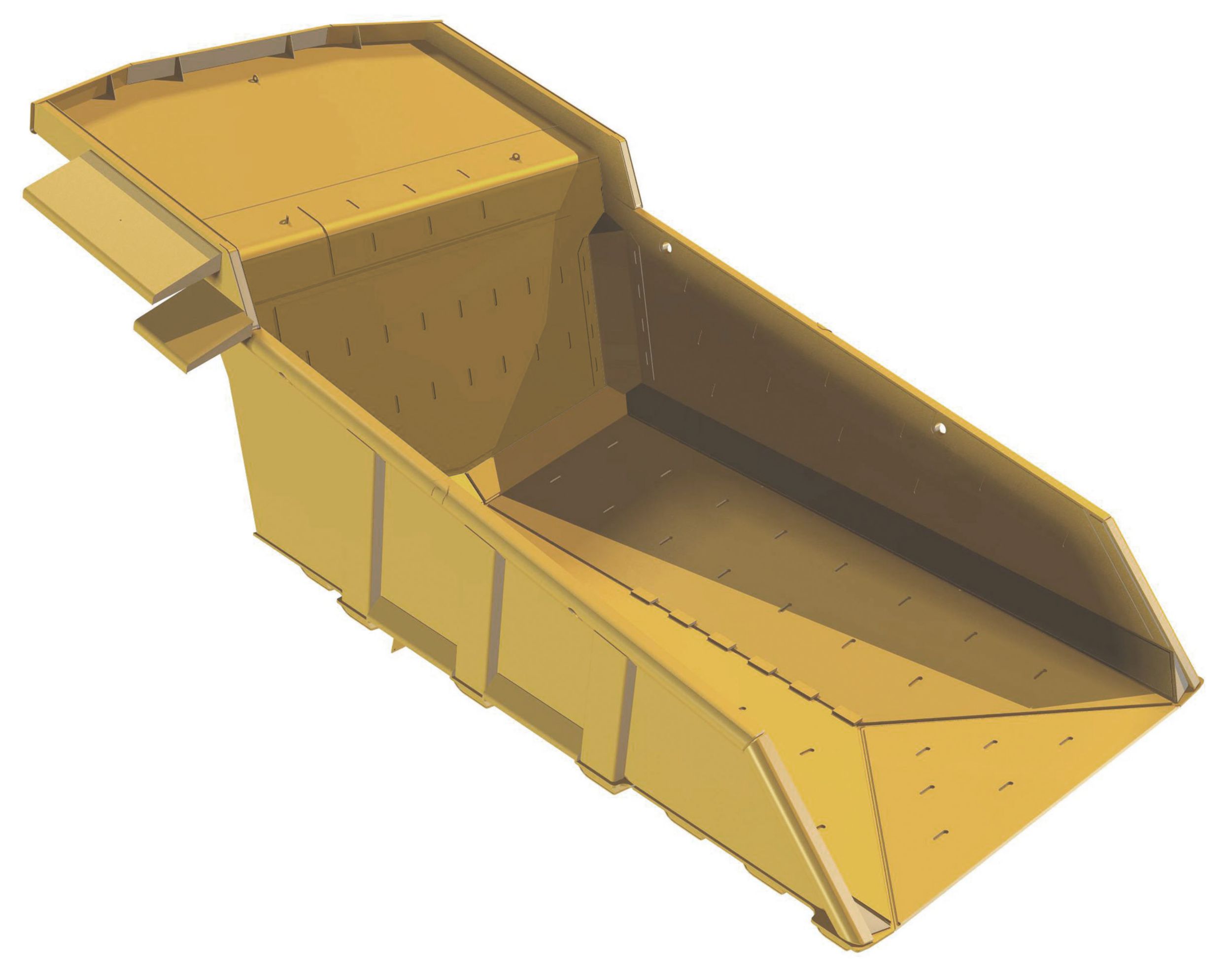

The goal of our body designs is to provide rated payloads on each haul. Since no two job sites are alike, we offer two body designs, optional side boards for lightweight materials, and two liner options to protect your investment and achieve the best possible wear life.

Flat Floor and Dual Slope Bodies

- Both of our body designs, with the exception of the Quarry body, are manufactured with base steel thicknesses of 16 mm (0.62 in) on the floor. This robust design can be augmented with an additional 16 mm (0.62 in) steel lining or a rubber liner option depending on your material type and job site conditions. When choosing a body type, consider the following:

- Flat floor bodies are ideal for delivering product to a crusher as the material unloads in a controlled manner.

- Dual slope bodies are designed to center the load for stability and retention on grades.

Steel Liner

Caterpillar offers a single, 16 mm (0.62 in) steel liner that can be added to the flat floor and dual slope bodies to protect against high impact and highly abrasive materials.

Quarry Body

Caterpillar offers a purpose-built quarry body for soft limestone applications. This body has a 25 mm (0.98 in), 400 BNH steel floor and does not require additional liners if kept in limestone.

Rubber Liner

Customers who are loading extremely hard material that has high impact characteristics should consider a factory-installed rubber liner system. Rubber has three times the impact resistance of steel, and it will absorb some of the noise associated with loading high impact material. Rubber liners should not be considered for applications that include clay, cohesive material or hot material. Rubber liners should never be used with body heat.

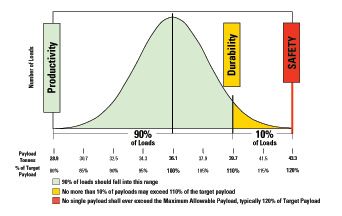

10/10/20 Payload Management Policy for Optimal Machine Life

Consistently overloading any truck will affect component life, reduce tire life, increase haul road maintenance and most importantly negatively impact your cost of doing business. Caterpillar's 10/10/20 payload guidelines are in place to help you maximize the availability of your trucks and manage your hauling costs. For optimum availability and component life, Caterpillar recommends that no more than 10% of payloads exceed 110% of target payload. Payloads in excess of 120% of nominal payload will exceed the truck's design parameters. Please consult with your dealer for more information on how this policy works.

Manufacturing and Design

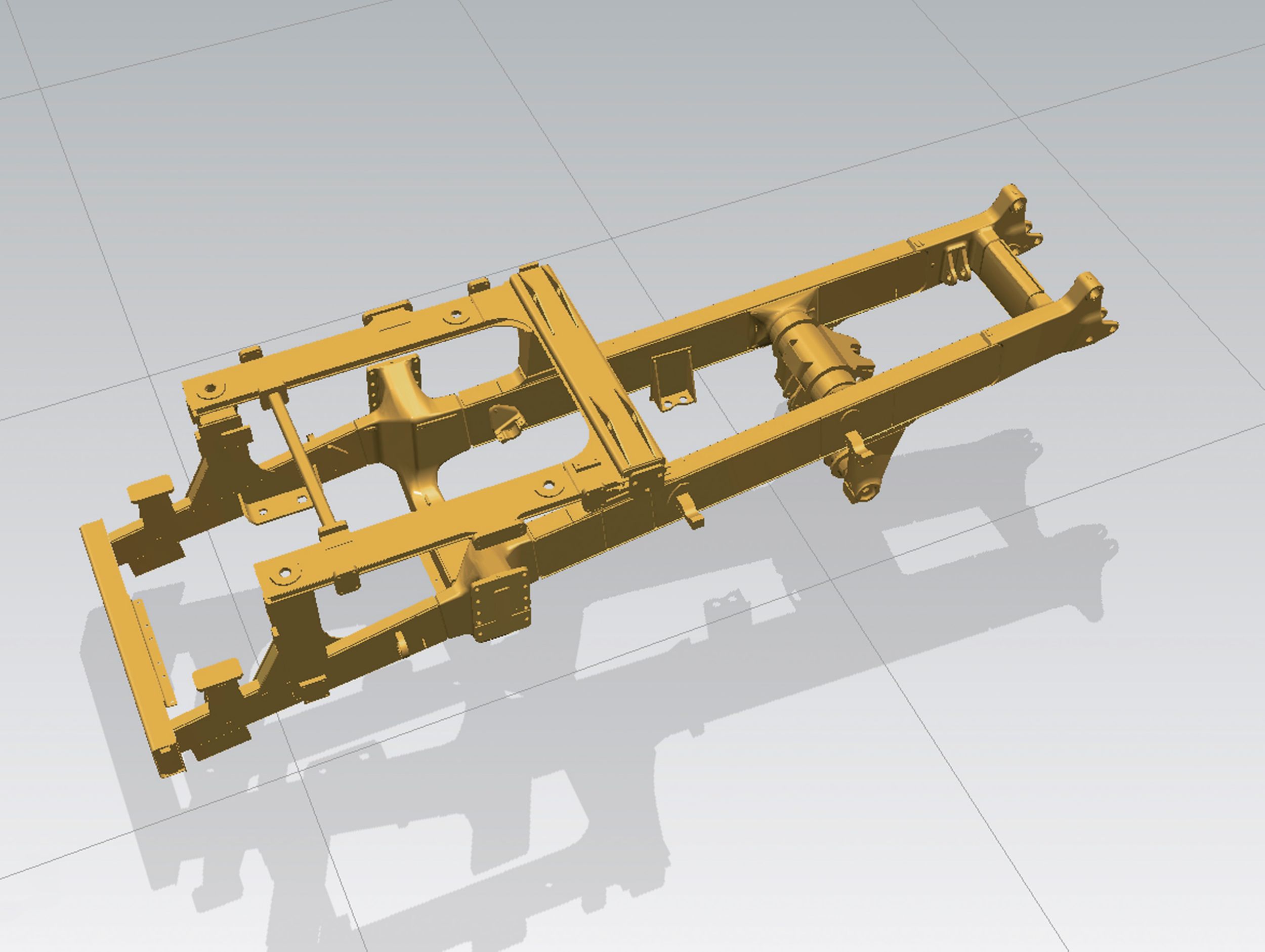

Cat trucks are manufactured in Decatur, Illinois, where our facility has seen significant updates and is a flag ship for manufacturing at Caterpillar. Because reliability starts with clean parts, our assembly areas are in a dedicated building separate from fabricating. The assembly area is well lit, clean and contamination controlled. Our expert welders work on rotating platforms that provide ergonomic and thorough weld capability on our frames. All of our trucks are checked during design for ease of assembly, manufacture and serviceability. We follow up with process and quality checks at each assembly station using the Andon system, and additional quality inspections are made at the end of the assembly line and at the dealership before it is delivered to you.

Structures

- Our frames have 50 years of hard-core experience behind their design, but with new tools available, we are able to improve and validate our frames using the latest technology. One thing that hasn't changed is the frame's ability to handle the high stresses of being loaded and hauling at high speeds. We continue to strategically combine castings and box section construction to manage application forces.

- We use the strength of castings in the frame to help isolate and dissipate the highest loads. Our castings are one reason why our frames live second and third lives. Technology helps us analyze the quality of our castings, their fill rate when poured and subsequent cooling characteristics.

- The 772G frame is purpose built for its weight class. This design philosophy provides the best possible load capacity, tire life, and handling.

- We've reverted back to an inboard hoist cylinder design that was extremely successful on the 769D, allowing us to package Tier 4 equipment in a way that keeps loads balanced along the frame and maintains truck handling.

- Our use of mild steel for the frame keeps field repairs simple

- Our frame is designed to provide excellent angle of approach with its front bumper placement. The truck is easy to climb onto and off of, and steps are strategically placed to make this as effortless as possible.

Key Systems and Components

- Steering - Apart from its excellent turning performance and reliability, our steering linkage is designed to provide important handling feedback to the operator and maintain tire alignment.

- Front suspension is provided by nitrogen over oil king pin struts. These struts play a key role in accurately determining payload for our TPMS feature. Maintaining proper strut pressures for the front tires, and robust cylinders on the rear axle. In addition to dampening haul road bumps, our suspension components are minimizing loads to the frame and keeping the load in the truck body. We also use strut pressures to gauge when the truck is at target payload - data that is fed into our payload management system. Both suspension systems are durable, legacy designs, but for G Series, we've inverted the rear cylinders to minimize debris at the rod end. These cylinders allow the rear axle to oscillate, maintaining wheel contact with the ground over rough terrain.

Operator Experience

A truck is only as productive as its operator. To that end, we have updated the 772G with some key features to help old and new operators be comfortable and confident while operating the truck.

Comfort

- Convenient automatic temperature control and powered left side window.

- Low effort access getting in and out of the cab with ample stand up room.

- Cat Comfort Series III seat with air suspension and excellent adjustability.

- Noise reduction technology with interior sound levels of 74 dB(A)

Confidence

- Standard ROPS and FOPS protection built into the design of the cab and certified to ISO 3471:2008 and ISO 3449:2005 Level II.

- Optional camera and cab display providing visibility behind the machine.

- Integrated trainer seat for task training new operators.

- Emergency egress route through the right side window.

- Fluid level monitoring warning inside the cab.

- Advisor display delivers important machine information to the operator.

- Excellent mirror and headlight coverage to both sides of the machine.

- Easy to read and understand instrument cluster.

- Four point operator seat belt harness for security.

Control

- Outstanding braking performance with the options of Automatic Retarder Control, engine compression braking and standard primary and secondary service brakes.

- Slope holding capability on grades up to 16%.

- Updated and highly effective traction control system.

Instrument Cluster

The instrument cluster is used by the operator for quick and simple machine information at a glance. This display also warns the operator with solid lights (Category 1 Warnings) or flashing lights (Category 2 or 3 Warnings) as well as an audible alarm when an event is occurring.

Advisor Display

Advisor display provides a larger display area and a more user-friendly operator interface. The viewable screen area of the Advisor display is 86.4 mm × 115.2 mm (3.4 in × 4.5 in).

VIMS

We've made our Vital Information Management System (VIMS) standard because it's important. With VIMS on board, you can access production data, machine health and truck operation statistics. With this data you can make informed decisions on operator training, haul road efficiency and scheduled service intervals. In addition, VIMS reports on event logging, idle time and fuel use. VIMS information is available through the Advisor display inside the cab. Portals to connect and download the data are on the front bumper and inside the cab.

Monitoring Your Payload and Tires

The Truck Payload Management System communicates to the loader operator using red and green lights to indicate when target payloads are on board. In addition, the system will store up to 2,400 payload and cycle time data points that are reported through VIMS. TKPH/TMPH calculates tire condition. It will warn the operator when the design limits are being approached, and it can be programmed to derate the truck to preserve tire life.

Pass Match

- Caterpillar offers loading tools that match your application and material types as well as your production requirements. Like the 772G, these machines are designed with important input from our customers and long hours of validation in the field. Whether your individual needs require a front shovel, an excavator or a wheel loader, Caterpillar has the model size, buckets and ground engaging tools to help you load the 772G quickly and efficiently. The 772G can be reasonably pass matched with these Cat loading tools. The number of passes will be determined by bucket size and material density.

- Wheel Loaders: The 980, 986 are ideal Cat wheel loader options for the 772G with approximately 4 passes each.

- Hydraulic Shovels: Cat models can include the 6015 at 4 passes and the 6018 at 2 passes.

- Hydraulic Excavators: Cat models can include the 385 and 390 at 4-5 passes.

Simple Service

- Your Cat G Series truck is designed to provide operators and technicians with easy access to common service points like engine lockout, machine system lockout, fluid level sight gauges, grease fittings and access to the engine for regularly scheduled maintenance.

- Engine oil and filter change interval is 500 hours under normal operating conditions

- Hydraulic filters have a 1,000 hour life under normal operating conditions

- VIMS trend analysis can track machine health and operation

- A brake wear indicator is standard

- Automatic lubrication is available as optional equipment

- New bumper-mounted ground-level access to fuses and breakers, ET and VIMS ports in right side service center

- The radiator and cooling cores are aluminum and modular offering easy cleaning or replacement

- Oil sampling ports are provided for quick and clean collection for analysis

- Fuel system features electric priming

- Fast fill fuel is optional

Customer Support

- When you purchase a Cat machine, you have both Caterpillar and your Cat dealer standing with you. The resources available to you by working closely with your Cat dealer are extraordinary. With capabilities that range from complete service agreements, to site support to production studies to our global parts networks, we are committed to you, your business and making sure your equipment is running at peak efficiency. Whether you need a rental machine, operator training, assistance with financing or a machine rebuilt, our dealers have the experience, people and application knowledge to help you succeed. For more information about our services, our company, our dealers and the services we can provide, please reach out to your local Cat dealer, or visit us at one of the following web sites:

- www.finance.cat.com

- www.safety.cat.com

- www.mining.cat.com

- www.Caterpillar.com

- www.Cat.com

Safety and Sustainability

Safety

- As we design a truck, we take the safety of the operator and personnel working on the ground very seriously.

- Ground level and platform accessible daily check points

- Excellent visibility

- Solid, stable walking/working platforms with good traction, material shedding, handrails

- Emergency egress from within the cab through a sliding right-side window

- Ground level electrical service box for lockout/tag out, steering system lockout

- Secondary steering, engages automatically

- Two levels of braking (service, secondary) and a red foot pedal for secondary brakes

- ROPS/FOPS structures in cab

- Brake wear indicator on all oil cooled brakes

- Four point harness operator seat belt

- Trainer seat with lap belt

- Body up gear limiting

- Haul road speed limiting

- Automatic Retarder Control, smooth predictable performance

- New Traction Control System, returns the truck to solid footing sooner

- In cab fluid level monitoring for operator

- TKPH/TMPH - Tire Monitoring System

- Truck Production Monitoring System (TPMS) providing payload, fuel, segment and cycle time information

- Engine overspeed protection using ARC

- Three levels of warning for parameters outside of their working zones

- Ground level fuel shut off switch to stop the engine

Sustainability

- By producing aggregate and minerals for new roads, bridges and energy, we bring about progress for our communities. Cat trucks are being designed to do this work with less of an impact on the environment, by being quiet, using less fuel, emitting fewer emissions and incorporating solid, long-life designs and components. The 772G model contributes with:

- Seven fuel saving strategies that also contribute to fewer emissions.

- Components that can be remanufactured and replaced with Reman parts.

- Durability for second and third work lives.

- High concentrations of recyclable materials.

Data not available.

Standard Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- ELECTRICAL

- Alarm, backup

- Alternator, 115 ampere

- Auxiliary jump start receptacle

- Batteries, maintenance-free, 12V (2), 190 amp-hour

- Electrical system, 24V

- Lighting system: - Backup light (halogen) - Directional signals/hazard warning (front and rear LED) - Headlights, (halogen) with dimmer - Operator access courtesy lights (Developing Market Only)

- PRODUCT LINK™ COMMUNICATIONS

- Product Link Ready

- GUARDS

- Driveline

- Engine crankcase

- OPERATOR ENVIRONMENT

- Air conditioning

- Ashtray and cigarette lighter

- Coat hook

- Cup holders (4)

- Diagnostic connection port, 24V

- Entertainment Radio Ready: - 5 amp converter - Speakers - Antenna - Wiring harness

- Gauges/indicators: - Air cleaner service indicator - electronic - Brake oil temperature gauge - Coolant temperature gauge - Hour meter - Tachometer - Engine overspeed indicator - Fuel level - Speedometer with odometer - Transmission gear indicator

- Heater/defroster (11 070 kCal/43,930 BTU)

- Hoist lever

- Horn, electric

- Light - dome

- Light - courtesy

- Messenger, display unit

- Mirrors

- Power port, 12V

- ROPS cab, insulated/sound suppressed

- Seat, Cat Comfort Series III: - full air suspension - four point harness

- Steering wheel, padded, tilt and telescopic

- Storage compartment

- Sun visor, tinted glass

- Throttle lock

- Windshield wiper (intermittent) and washer

- POWER TRAIN

- Air-To-Air Aftercooler (ATAAC)

- Air cleaner with precleaner (1)

- Automatic cold mode idle control

- Electric start

- Turbocharger

- Braking system, hydraulic actuated: - Automatic Retarder Control (ARC) (utilizes rear oil-cooled, multiple disc brakes) - Brake release motor (towing) - Caliper-disc (front) - Oil-cooled, multiple disc (rear) - Parking - Secondary - Service

- Transmission: - 7 speed automatic powershift - Body up shift inhibitor - Controlled throttle shifting - Directional shift management - Downshift inhibitor - Neutral start switch - Neutral coast inhibitor - Reverse shift inhibitor - Reverse neutralizer during dumping - Programmable top gear selection

- SUSPENSION SYSTEMS

- Suspension, front and rear

- OTHER STANDARD EQUIPMENT

- Body safety pin (secures body in up position)

- Body down indicator

- CD ROM parts book

- Fan, hydraulic demand

- Fuel tank (530 L/140 gal)

- Guard, engine compartment

- Guard, mud

- Ground level battery disconnect

- Ground level engine shutdown

- Ground level grease fittings

- Reservoirs (separate): - Brake/converter/hoist - Steering - Transmission/torque converter

- Rims 15 × 33

- Rock ejectors

- Service platform, left and right side

- Supplemental steering (automatic)

- Tie down eyes

- Tow hooks (front)/Tow pin (rear)

- Vandalism protection locks

- ANTIFREEZE

- Extended Life Coolant to -35° C (-30° F)