345B MH Series IINon-Current

345B MH Series IIOverview

345B MH Series II Material Handler

Benefits & Features

Specifications

Benefits & Features

The Caterpillar® 345B Series II Material Handler

Caterpillar Designed and Built, 1.9 m (6'5") Cab Riser

The cab riser gets your operator to an operating height with excellent visibility for loading or unloading your processing equipment, trucks and rail cars. Access to the cab is provided by a platform which extends around the riser to allow windshield cleaning. The cab riser can also be manually tilted forward 90° for shipping.

25 kW Hydraulically Driven Generator Set

Powers magnets up to 1829 mm (72 in) in diameter. A Caterpillar state-of-the-art electronic magnet controller and generator are linked to provide trouble free service. The new controller completely eliminates traditional contactor maintenance and it is supported and warranted through your Cat dealer.

Cat Material Handler Hydraulic Systems

Are specifically designed to meet your hydraulic attachment requirements. The grapple open/close circuit works with the other implement circuits to deliver smooth, simultaneous, multi-function control. The rotate circuit provides a separate 38 L/min (10 gpm) gear pump and fully adjustable control valve, which allows this configuration to meet various grapple manufacturer's flow requirements. A separate fixed displacement gear pump is used to provide the hydraulic power to run a 25 kW generator system.

A New Cab Mounted Magnet System Monitor/Control

- Provides system information through a series of indicators, lights and a rotary selector switch, to the operator. The indicator lights provide the following information:

- Magnet “On”: Magnet is turned on.

- Generator “Hot”: Generator is over heated and must be cooled down. The generator should be run under “no load” until the indicator turns off.

- Voltage Fault: Voltage too high or too low. May indicate service is required.

- Ground Fault: The magnet, generator or cable is grounded. Service is required.

- Over 75% Duty Cycle: The “magnet on” time exceeds 7.5 minutes in a ten minute time frame indicating the operator technique needs to be adjusted.

Rotary Selector Switch

Allows the operator to optimize the magnet performance for different grades of scrap from within the cab.

Easy Clean-out Engine and Hydraulic Cooling Cores

Are provided for operating in debris-laden environments. The oil cooler and condenser slide outboard, providing ample space between the oil cooler and radiator cores for easy and efficient cleaning.

Wide 3720 mm (12'21/2") Track Gauge

Provides the over-the-side stability required to handle heavy loads and improve productivity. Carbody plates are 5 mm thicker than standard, high strength swing bearing bolts plus larger box-section height team up to provide superior joint retention and durability in material handling applications.

345B MH Two-piece Fronts by Caterpillar

The two-piece fronts meet your material handling needs with excellent lift performance and working range in both close and full reach.

The Cat Two-piece Front

Offers a maximum horizontal reach of 16.6 m (54'0") from swing center and a maximum vertical pin height of 16.2 m (53'2") at 8.4 m (27'6") from the swing center. The two-piece fronts are an excellent match for a 1.5 m3 (2.0 yd3) scrap grapple.

Booms and Sticks

Are built for performance and long service life.

Cat Orange Peel Grapples

The 2.0 CYD (1.53 cu. m) Orange Peel Grapple is constructed with four wear-resistant steel tines and fully replaceable tips for excellent service life.

Hydraulic Cylinders

Enclosed within each tine for maximum protection. Mechanical stops prevent the cylinders from bottoming-out, and hydraulic cushioning provides additional protection. The grapple's tines penetrate deep into piles and close tightly to retain maximum loads for superior productivity in material handling applications.

Engine

Cat 3176C ATAAC Engine

Continues its tradition of powerful, efficient performance, unmatched reliability and durability.

Advanced Diesel Engine Module Fuel System

Controls the engine for optimal fuel injection, increased fuel efficiency, extended component life.

Turbocharged and Aftercooled

Turbocharged and aftercooled to increase engine power by burning fuel with greater efficiency.

Two-Piece Pistons

Two-piece piston design provides excellent strength with the steel crown and aluminum skirt for reduced weight.

Engine Oil S•O•SSM Sampling Valve

Is provided on the engine oil filter head.

Automatic Engine Speed Control with Convenient One-touch Command

- Three-stage control maximizes fuel efficiency and reduces sound levels.

- When placed in the “OFF” mode, if a no-load condition or light-load condition continues more than three seconds, the automatic engine control reduces engine speed by a maximum of 100 rpm.

- When placed in the “ON” mode, if a no-load condition or light-load condition continues more than three seconds, the automatic engine control reduces engine speed from high idle to 1300 rpm. (This feature is deactivated when the genset is running.)

- At any time, the generator is not running, the operator can activate a switch on the top of the right control lever to reduce the engine speed to 1000 rpm. This feature, referred to as one-touch idle, can be used both to conserve fuel and to reduce engine sound levels. Activate switch again to return to previous level.

Structures

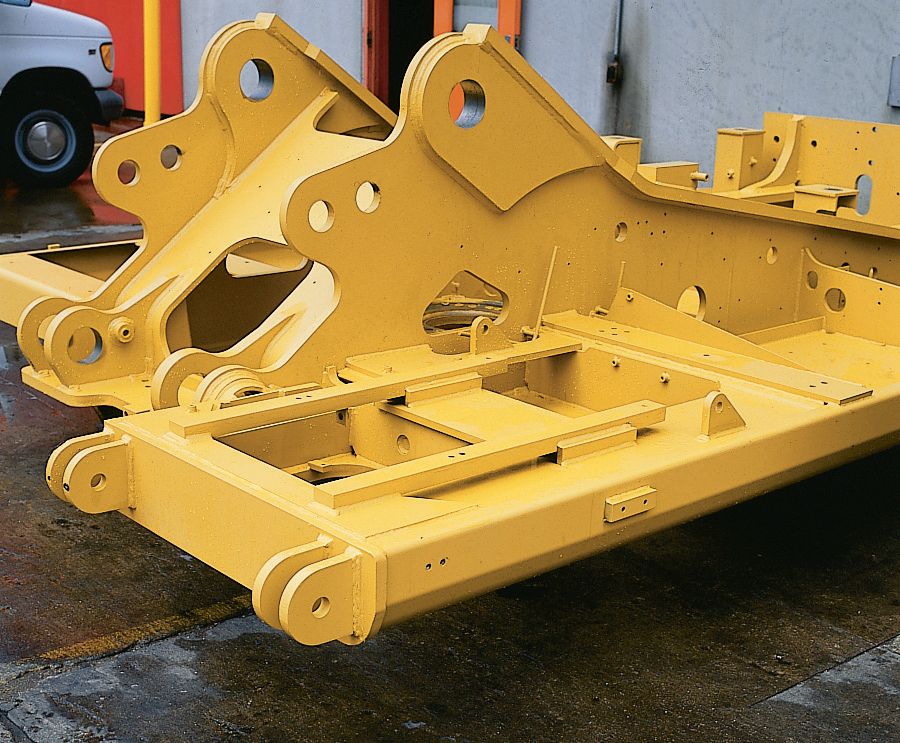

Advanced Carbody Design

- Advanced carbody design (1) stands up to the toughest applications.

- Modified X-shaped, box-section carbody provides excellent resistance to torsional bending.

- Upper structure weight and stresses are distributed evenly across the full length of the track roller frame.

- Track roller frames may be extended to provide 4470 mm (14'8") overall width with 750 mm (30") track shoes. Track frames are bolted to the carbody and may be removed for shipping.

- Robotic welding helps ensure consistent, high-quality welds throughout the manufacturing process.

Thicker Carbody Plates

Thicker carbody plates (2) and increased box-section height for increased weight and load capacities.

Robot-welded Track Roller Frames

Are press-formed, pentagonal units to deliver exceptional strength and service life.

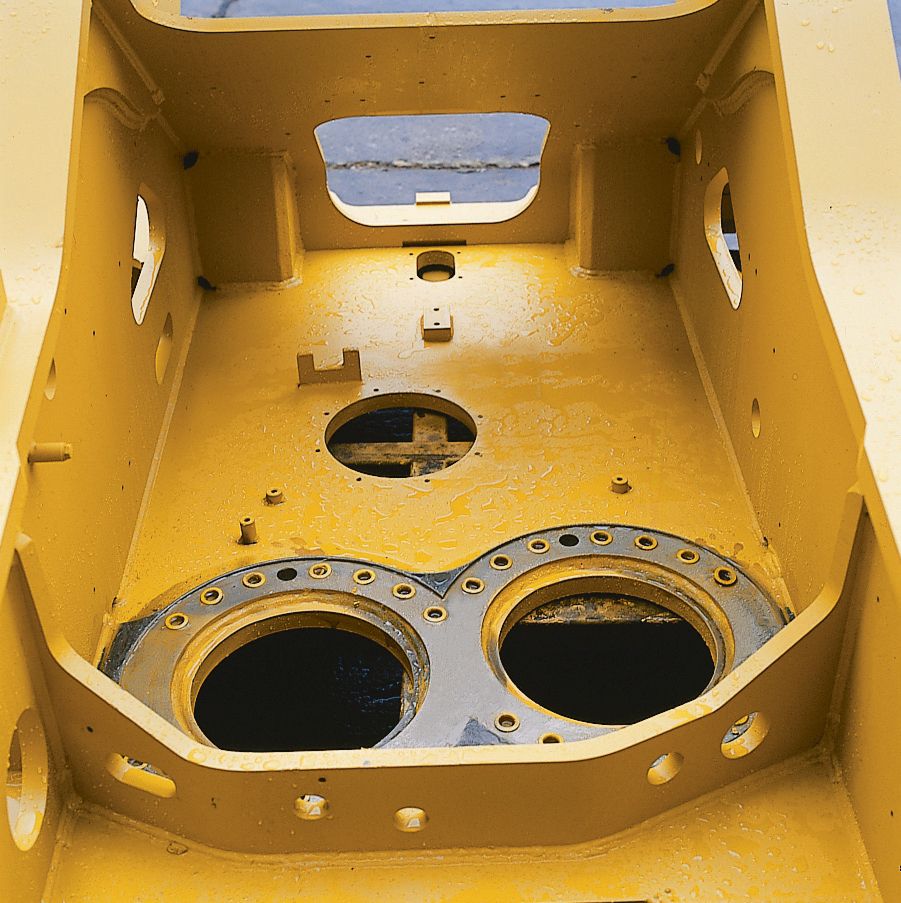

Upper Frame

- Is specifically designed for the scrap and material handling market. It is built of higher strength material and thicker steel sections to handle the increased swing loads developed with the longer fronts and heavier counterweights used in material handling.

- Boom tower doubler plates (3) add reinforcement for increased side loads and payloads.

- Box-section reinforcement of the cab outrigger frames (4) support cab risers.

- Box-section cylinder mounts (5) help handle increased torsional loads and payloads.

- Horizontal mounting plates (6) provide more surface area for swing drive and swing bearing mounting bolts to handle increased loads and movement.

- Outer frame utilizes curved side rails, which are die-formed, for excellent uniformity and strength throughout the length.

- Inverted U-channels span the width of the main frame and are formed, rather than fabricated, for superior strength and reduced weight.

- Boom foot and engine mount areas are reinforced for additional strength.

- Sheet metal supporting structure is improved by integrating the mounting into upper frame structure.

Serviceability

Faster, Easier Maintenance

This means improved uptime and a better value.

More Ground Level Service Points

There are more ground level service points for fuel-water separator, engine oil filter, battery, radiator fluid level, window washer fluid level and pilot system filter.

Improved Filters and Filter Locations

- The improved filters and filter locations make maintenance easier.

- Two hydraulic capsule filters are mounted outside hydraulic tank. New design avoids spills and contamination during replacement. Indicator in cab signals when the filter needs to be replaced, extending filter service life.

- Radial seal air cleaner has double layered filter core for better filtration. No tools required to change. Operator is alerted to clogs.

- Engine oil filter is located in the pump compartment for easy access. Filter opening faces up to avoid spills during changes.

- Pilot hydraulic system filter keeps contaminates away from the pilot system. This system includes a Scheduled Oil Sampling port to simplify sampling.

- Swing and travel motor case drain filter removes contaminants, keeping them from returning to the tank.

Water Separator

The water separator removes water from fuel even when under pressure and is located in the radiator compartment for easy access.

Remote Greasing Block

The remote greasing block on the boom and stick and two grease points for the swing bearing deliver grease to hard to reach locations.

Electronic Power Unit Control

The electronic power unit control has diagnostic capabilities for Cat Dealer's use.• Dealer service technicians can quickly and easily diagnose and adjust machine components, maximizing uptime.

Complete Customer Support

Customer Support Agreements

Cat Dealers offer a wide range of services under a customer support agreement when equipment is purchased. The dealer will help choose a plan that can cover everything from machine and attachment selection to replacement for the best return on your investment.

Selection

Make detailed comparisons of the machine being considered before a purchase. How long do components last? What is the cost of preventative maintenance? What is the true cost of lost production? Your Cat Dealer can give precise answers to these questions.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Maintenance

Choose from a wide range of maintenance services at the time you purchase a machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

Cat Dealers utilize a world-wide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured parts. Receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Data not available.

Standard Equipment

- Cab, sound suppressed, includes:

- Ash tray

- Cigar lighter

- Coat hook

- Compartments:

- Drink holder

- Floor mat

- Heater with defroster

- Horn, signaling/warning

- Hydraulic/starting systems lock lever

- Instrument panel

- Joysticks, pilot-operated, adjustable

- Lights, interior

- Radio mount

- Seat, adjustable suspension

- Seat belt, retractable

- Skylight, opening

- Travel controls,

- Windshield wipers and washers

- Lights, working:

- Boom, left side (1)

- Cab-mounted (2)

- Frame-mounted (1)

- Mirrors:

- Cab, left

- Frame, right

- Track shoes:

- 750 mm (30") triple grouser

Optional Equipment

- Cab Guard System

- Operator protection top and front

- Grapple, Caterpillar 2.0 CYD

- (1.53 cu. m) four tine, Orange Peel