422ENon-Current

422E - 2009, Tier 3, APD, AME, EU, CISOverview

Developed with over 20 years experience in the Backhoe Loader industry, the 422E is designed to exceed customer expectations.More performance, versatility and comfort than ever before gives the 422E the edge needed in a harsh and competitive environment. Along with you, it's up to the challenge. See your Cat dealer and try out The Next Generation of Backhoe Loaders from Caterpillar.

Specifications

| Power - Net | — |

| Operating Weight - Nominal | — |

| Operating Weight - Maximum | — |

Benefits & Features

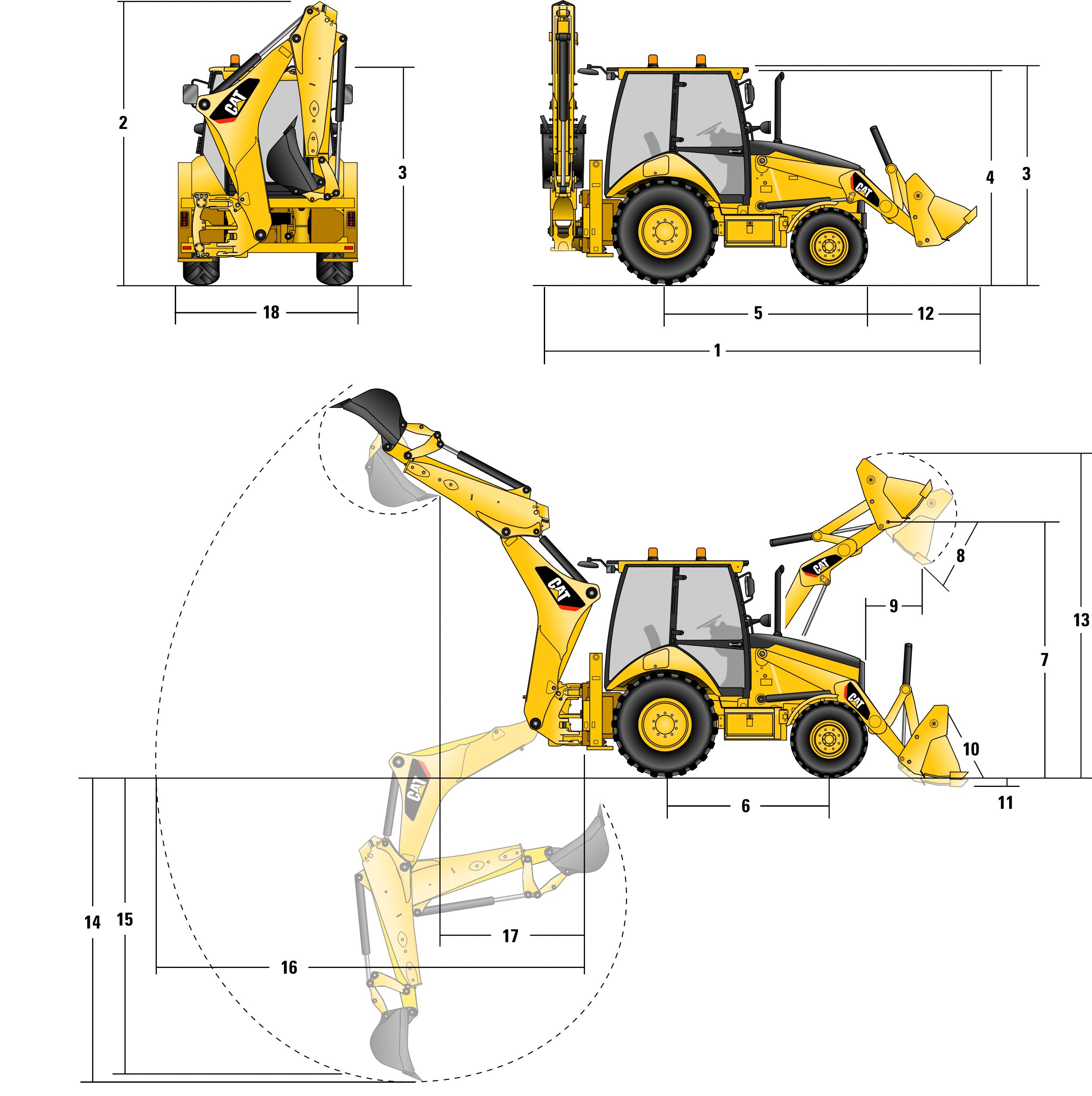

Specifications

| Power - Net | — |

| Engine Model | 3054C DIT |

| Engine Displacement | — |

| Optional Power - Net | — |

| Gross Power | — |

| Bore | — |

| Stroke | — |

| Operating Weight - Nominal | — |

| Operating Weight - Maximum | — |

| Dig Depth - Standard | — |

| Dig Depth - E-Stick | — |

| Bucket Dig Force - Standard | — |

| Bucket Dig Force - E-Stick | — |

| Stick Dig Force - Standard | — |

| Stick Dig Force - E-Stick | — |

| Reach from Swing Pivot | — |

| Loading Height | — |

| Loading Reach | — |

| Hydraulic Pump Capacity | — |

| Hydraulic System Pressure | — |

| Type | Load-sensing, closed-center system |

| Pump Type | Variable-flow, axial-piston |

| Lift Capacity at Full Height | — |

| Dump Height at 45 Degrees | — |

| Dig Depth | — |

| Overall Transport Length | — |

| Overall Length - Loader on Ground | — |

| Overall Transport Height | — |

| Overall Width | — |

| Height - Top of Cab | — |

| Height - Top of Exhaust Stack | — |

| Height - Loader Hinge Pin | — |

| Ground Clearance | — |

| Rear Axle - Centerline to Front Grill | — |

| Front Wheel Tread Gauge | — |

| Rear - Wheel Tread Gauge | — |

| Wheel Base | — |

| Hydraulic System | — |

| Cooling System | — |

| Fuel Tank | — |

| Engine with Oil Filter | — |

| Transmission | — |

| Rear Axle - Including Planetary | — |

| Hydraulic Tank | — |

| Type | Front wheel |

| Power Steering | Hydrostatic |

| Cylinders - Bore | — |

| Cylinders - Stroke | — |

| Cylinder Rod Diameter | — |

| Forward - 1st | — |

| Forward - 2nd | — |

| Forward - 3rd | — |

| Forward - 4th | — |

| Reverse - 1st | — |

| Reverse - 2nd | — |

| Reverse - 3rd | — |

| Reverse - 4th | — |

Benefits & Features

Features

Lower Operating Costs

The 422E has improved Stabilizer and E-Stick wear pad adjustment. External wear pad adjustment ensures easy maintenance of the Stabilizer and E-Stick, lowering operating costs. This equates to less machine downtime and more convenience for the operator.

All Wheel Braking

All Wheel Braking is standard on all AWD 422E Backhoe Loaders. When driving in two wheel drive, applying the brakes engages four wheel drive, maximizing brake effectiveness.Releasing the brakes returns the transmission to two wheel drive. This is particularly useful when roading. This effective system works well in hazardous, slippery or steep surfaces. Braking modes are controlled by the All Wheel Drive switch.

Improved Weight Distribution

The 422E has been designed with improved weight distribution. The design coupled with a slightly longer wheel base ensures optimum balance and handling, particularly when roading. This is achieved with no loss in turning circle.

Excavator Controls

The 422E is offered with a choice of excavator controls Backhoe (SAE), Excavator (ISO) or universal controls (X pattern). This ensures the 422E will suit any type of operator.

Large Fuel Tank

Responding to customer needs, a large 160 liter fuel tank with the Cat engine and efficient hydraulic system ensures longer periods between fill ups and less inconvenience.

Electro-Deposition Coating

Your 422E has been protected by an undercoat of electrodeposited (E-Coat) primer, which completely seals each metallic component and offers a superior degree of protection from damage and corrosion. Coupled with the high solids polyurethane top coat, your 422E will stay looking good for longer, ensuring optimum resale value.

Work Station

The 422E Cab is Designed with Today's operator in Mind. The E-Series cab is designed to provide maximum comfort, ease of operation, and with modern styling meets the requirements of today's operator.The design incorporates curved glass for improved interior space and visibility. A wide cab provides a spacious environment for better performance when turning the seat from one mode of operation to the other. Cab comfort is enhanced with the first-class Cat suspension seat, reducing fatigue. An easy to open single rear piece window provides the operator with excellent ventilation and superb visibility. The rear wiper easily cleans a large area of the rear screen to ensure excellent visibility of the working area when working in wet or dusty conditions.Excellent ergonomics ensure that all controls are within easy reach of the operator, and tinted glass is standard in all cabs.Other features such as remote stabiliser controls, large adjustable vents throughout the cab, and clear gauges provide the operator with a comfortable operating environment designed to reduce operator fatigue and increse productivity.

Operator Comfort

Vibration

Caterpillar understands that backhoe loaders work in some of the harshest environments. By controlling normal machine vibrations caused by these harsh conditions, operator efficiency and productivity are improved. The 422E has features, both standard and optional, that reduce vibration.

Operator Controls

Optimal cab ergonomics are vital to assist the operator in their quest for best productivity. Pressure compensated, well placed levers ensure low efforts and good controllability.

HVAC System

The 422E benefits from an optional, powerful air conditioningsystem, which with good ventilation flow to the operator, ensures the operator stays cool in the highest of working temperatures. The ventilation system also provides plenty of demisting, defrosting, heating capability.

Work Lights

The 422E has adjustable front and rear work lights. This allows the operator to direct the light wherever needed, providing maximum illumination to the work area, whatever the ambient light conditions.

Cab Air Filter

The 422E has an easy access cab air filter, situated within the right hand rear fender. The cab air intake is positioned high up to minimise dust intake into the air filter.

Cab Mounts

The cab is attached to the mainframe with resilient mounts, reducing vibration and sound, providing the operator with an all round comfortable working environment.

Cat Suspension Seat

The major interface between the machine and the operator is optimal, and the Cat suspension seat provides the operator with a comfortable working platform to ensure high levels of productivity with the minimum of fatigue.

Cab and Canopy Options

The 422E is available with either a fully glazed cab or an open canopy, providing the best choices to suit individual operator needs. There is a cab-basic and cab-standard, plus a canopy standard and a canopy plus.

Loader

Improved Loader Performance

The 422E Single Tilt Loader is available with either a General Purpose or Multi Purpose bucket. Work tool visibility is excellent with the narrow sloping hood and divergent loader arms allowing a clear line of sight to the bucket edges. A large torque tube provides torsional stiffness, needed when grading or picking up irregular shaped heavy objects with the loader bucket.

Ride Control

Caterpillar's proven Ride Control system is an option designed to reduce machine pitching and bouncing giving operators a smooth ride in all applications, including load and carry, roading, or simply moving around the jobsite. An accumulator acts as a shock absorber to reduce machine pitching and provide a smoother ride over rough terrain. The system is engaged by a switch on the front console.

Return to Dig

Your 422E is equipped with a standard Return To Dig system. This system reduces loading cycle times by bringing the loader bucket back to the dig position automatically when lowering the arms. By the time the loader arms have been lowered to ground level, the bucket is in the correct position ready for the next load.

Backhoe Performance

Excavator-style Backhoe

The Cat excavator style boom has more than just good looks. Whether close-up truck loading on a single road carriageway or digging over obstacles such as walls, the excavator boom outperforms the rest. Combine the versatility with the powerful breakout forces, the controllability of the load sensing, flowsharing hydraulic system and the 422E is capable of producing high levels of productivity with the minimum of operator effort. The boom is a narrow design, ensuring maximum visibility to the work tool.

Extendable Stick

The 422E is available with an extendable stick that increases dig depth and reach capability increasing the machine's versatility and utilisation. A sliding inner section design keeps the wear pads out of the dirt, extending adjustment and replacement intervals. When wear pad adjustment is necessary the adjustment bolts are easy to access taking minutes to adjust, without the need to disassemble the E-Stick. Auxilary line, for operating worktools have been routed so that they are protected from damage when working in the narrowest of trenches.

Slider Frame and Swing Frame

The 422E is designed to make necessary maintenance easy to perform. The E-Series cast slider frame has exterior lock clamps, with no backhoe disassembly needed when servicing. The Swing Frame/Boom Foot pins have replaceable bushings in the bores.

Cat Cushion Swing

The 422E is equipped with Cat Cushion Swing, which enables very fast trenching by damping the boom oscillation down when returning to trench with the hoe.

Hydraulics

Hydraulic Performance

It's rare that you'll be working at full production 100% of the time, so why should the machine be working flat out, using more fuel, making more noise, and increasing wear? The 422E has a load-sensing, closed center hydraulic system, which closely matches power and flow to the demand needed by the job in hand. So whether you're in full trenching mode, or delicately digging around services, you are in total control. In applications such as loading and carrying, speed is important, and the system will match the flow needed to get the job done quickly and efficiently. As there is minimal demand on the system unless needed, there are less parasitic power losses enabling more power to be available for rimpull-providing better loading and roading performance.

Flow Sharing Valves

The 422E features flow-sharing hydraulic valves, ensuring that the correct flow of oil reaches the implement cylinders, providing greater control and eliminating oil starvation when operating multiple functions, such as grading with the backhoe.

Hardware

The 422E is equipped with a highly efficient variable displacement piston pump. Reliable high performance hydraulic hose is constructed from two strong steel braided layers and O-ring face seal fittings provides a robust system ensuring excellent durability and resistence to damage from pressure spikes and hydraulic pulsing.

Work Tools

Buckets

- Cat offers a huge variety of hoe buckets to meet your requirements, including:

- Standard Duty Bucket. Used in easy to penetrate, low impact, moderately abrasive materials.

- Heavy Duty Bucket. Used for digging fragmented rock, frozen ground and highly abrasive materials.

- Extreme Service Bucket. Used in highly abrasive, high impact soil.

- High Capacity Bucket. Same durable construction as the HD bucket, but longer tip radius provides increased fill capacity.

Durability

- Cat backhoe buckets offer superior durability with the following features:

- Thick cutting edges.

- DRS (Diagonal Retention System) ensures easier replacement of pin on teeth and greater strength.

- Thick wear material on the side plates for better reinforcement and less wear.

- ID plates on all buckets showing part number, GET sizes and machine compatibility.

Sizes

Work tools are available in a full range of sizes, from a 9”/228 mm Cribbing bucket for cable trenching, a range of Ditch Cleaning buckets, right up to large capacity 36”/914 mm buckets for mass excavation.

Quick coupler

A Cat quick coupler is available for easy hoe bucket changes.

Hydro-mechanical Work Tools

- Caterpillar has designed a range of hydro-mechanical tools carefully matched to the machine for optimum performance, including:

- H65 Hydraulic Hammer

- Auger

- Vibratory Plate Compactor

- Cold Planer

Power Train

Cat Engine

The 422E is available with either the 3054C naturally aspirated and turbocharged engine that meets Stage II emission regulation EU Directive 97/68/EC or the C4.4 Turbocharged After Cooled engine that meets Stage IIIA EU emission Directive 2004/26/EC. A choice of power rating enables the performance of the machine to be matched to customer needs. All engines are reliable 4 cylinder, 4 stroke direct injection diesel engines equipped with standard glow plug for optimum cold weather performance.This provides reliable starting performance down to -18 C. Allengines feature a reliable gear driven water pump and a durablepoly vee front end auxiliary drive belt that is automatically tensionedfor longer life reducing operating costs.

40 kph Power-Shuttle Transmission

The 422E comes equipped with 40 kph Power-Shuttle transmission, improving roading speed and providing better spacing between gear ratios. It utilizes a constant mesh, synchronized, four speed system. The forward/reverse lever on the steering column is placed for easy direction changes on the move, and the gear selection is from the floor mounted shift lever.

Axles and Brakes

The heavy duty Cat rear axle is an enclosed design with a wet multi-plate Kevlar braking system. This system is oil immersed and self adjusting, and allows operation in the harshest environments. The system has dual brake pedals for split braking for good maneuverability in confined working areas.

High Ambient Cooling

The 422E is equipped with a High Ambient (HA) engine cooling package, allowing the machine to be operated in temperatures up to 50° C.

Air Filter

A dry type axial air cleaner with an integral pre-cleaner and automatic integrated dust ejection system extends the life of the air filter life when working in dusty conditions reducing service time and costs.

Serviceability

Reduced Maintenance

The 422E is equipped with a flip open hood, allowing access to all check/fill points, air cleaner, washer bottles, visual indicators etc. The E-Series carries on the tradition with sealed for life axle oscillation, driveshaft universal joints, trunnions etc. Daily maintenance, which can be a chore for the busy operator, is kept to a minimum on the 422E.

Boom and Stick Design

The Boom and Stick design allows all wear adjustment to be done with Stick in-situ, using a simple adjustment mechanism. The Stabiliser legs are also externally adjustable, reducing machine down time and inconvenience.

Cat Filters

All Cat filters are vertically mounted for spill free servicing and reduced oil contamination. They are also low micron filters, filtering even the tiny particles from the oil and keeping the engine, transmission and hydraulic system running smoothly for years.

Scheduled Oil Sampling

Your Cat dealer will be able to provide the Caterpillar S•O•SSM. This enables your dealer to analyze wear before problems arise, so that premature failure can be avoided, and corrective action can take place to reduce costs and downtime.

Customer Support

Customer Support Agreements (CSA's)

Your Cat dealer can offer a comprehensive range of CSA's which can be individually tailored to suit your finances and requirements. Dealers can offer a range of options from a full Preventative Maintenance with S•O•S package to a Parts Only CSA. Protect your valuable investment and know exactly what your monthly payments will be to help you run your business.

Finance

Have you explored the range of options available from your dealer to finance your machine? They can offer a selection of attractive packages tailored exactly to your requirements.

Machine Selection

Your dealer can help guide you with your machine purchase decision, based on your requirements and help keep operating costs to a minimum. Is the machine you have in mind exactly the best for your job, or could other attachments be more suitable?

Data not available.

Standard Equipment

- Cat 3054C* engine (56 kW) or Cat C4.4 **engine (70 kW)

- *Standard for less regulated countries, meets Stage II EU Emission Directive 97/68/EZ**Standard for regulated countries, meets Stage III EU Emissions Directive 2004/26/EZ

Optional Equipment

- Attachments, front loader

- General purpose bucket 1.0 m³

- Multi purpose bucket 1.03 m³

- 1.03 m³ with forks

- Attachments, backhoe work tools

- Quick Coupler (mechanical)

- *Cat 3054C DIT engine (68.5 kW)

- *Standard for less regulated countries, meets Stage II EU Emission Directive 97/68/EZ

- Counterweights

- Bumper

- Base

- Stackables

- Cutting edge, bolt on

- Single piece

- Two piece

- Guards

- AWD driveshaft

- Teeth (GP/MP)

- Rear lights, roading

- Hydraulic valves, loader

- 3rd valve for GP/MP

- Hydraulic valves (auxiliary)

- Standard stick

- Extendible stick

- Hydraulic lines

- Hammer lines to stick

- Quick disconnects

- Lights

- Number plate, rear

- Roading

- Working, 8 lights

- Operators station

- Canopy