299D3 XE

299D3 XE - 2019, Tier 4 Final, NACD, EU, APD, ANZPOverview

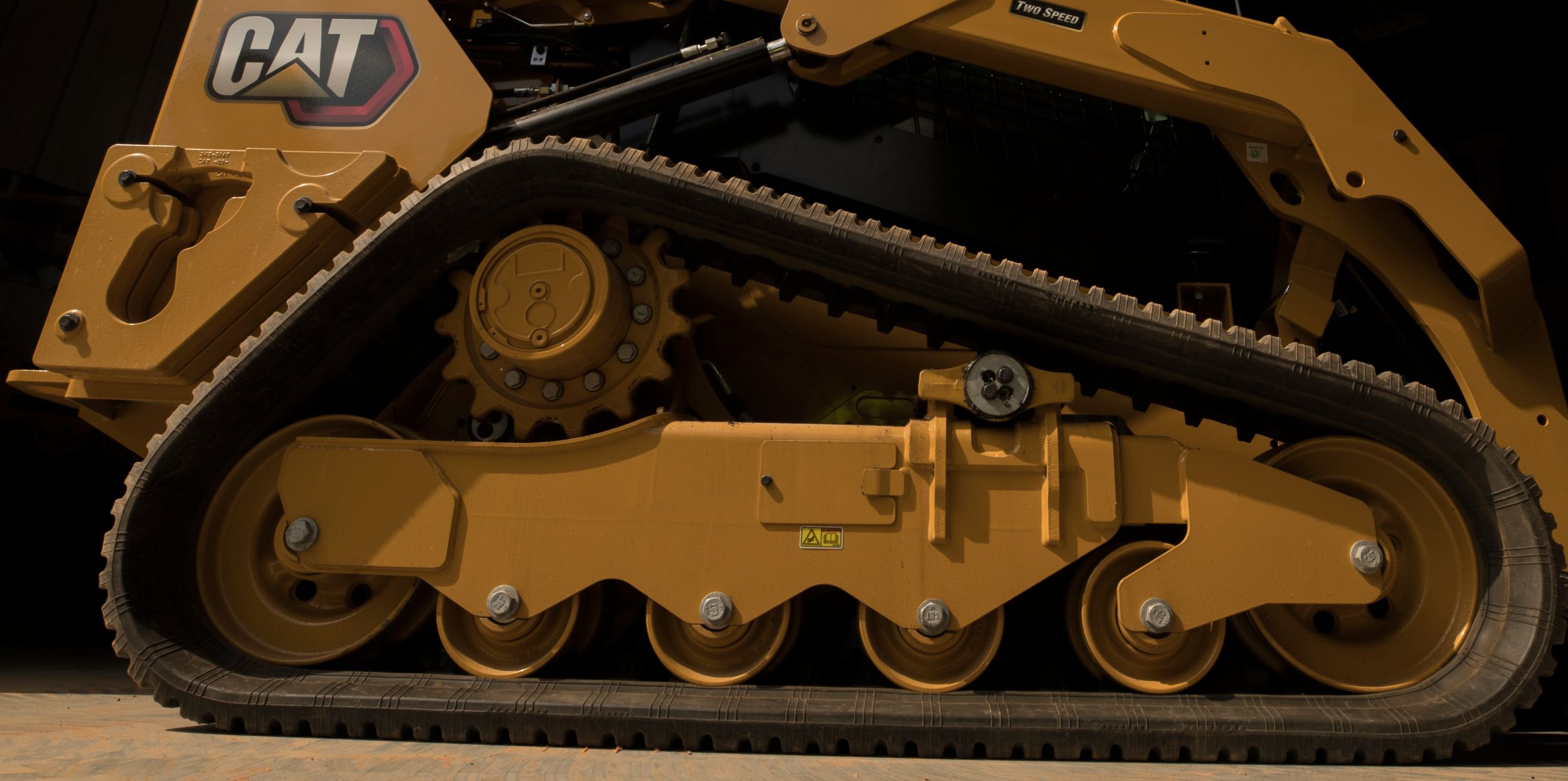

The Cat® 299D3 XE Compact Track Loader, with its powerful engine, high output hydraulic system, high lift forces, vertical lift design and torsion axle suspension, provides the maximum performance for work tool productivity, digging, truck loading and material handling in a wide range of underfoot conditions and applications.

Specifications

| Gross Power - SAE J1995 | — |

| Rated Operating Capacities - 35% Tipping Load | — |

| Operating Weight | — |

Benefits & Features

Quiet and Comfortable

The industry leading sealed and pressurized cab option provides the operator with a cleaner and quieter operating environment with excellent work tool visibility. Continuing the industry leading trend, the D3 Series also includes as standard, seat mounted adjustable joystick controls for operator comfort.

Maximum Performance

High performance power train provides maximum performance and production capability through the Electronic Torque Management system, standard two speed travel and an electronic hand/foot throttle with decel pedal capability.

Making Your Job Easier

Cat® “Intelligent Leveling” system provides industry leading technology, integration, and available features such as dual direction self level, work tool return to dig, and work tool positioner.

Specifications

| Gross Power - SAE J1995 | — |

| Net Power - SAE 1349 | — |

| Displacement | — |

| Bore | — |

| Stroke | — |

| Net Power - ISO 9249 | — |

| Net Power | — |

| Peak Torque - 1,500 rpm - SAE J1995 | — |

| Engine Model | Cat C3.8 DIT (turbo) |

| Rated Operating Capacities - 35% Tipping Load | — |

| Ground Contact Area | — |

| Ground Pressure | — |

| Tipping Load | — |

| Breakout Force - Tilt Cylinder | — |

| Breakout Force - Lift Cylinder | — |

| Rated Operating Capacity with Optional Counterweight | — |

| Ground Pressure - With 450 mm/17.7 in Track | — |

| Note | Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, two speed, ride control, enclosed cab with glass door, side windows, air conditioning, air ride seat, advanced display, rearview camera, 1,000 CCA battery, dual direction self level, 2036 mm (80 in) low profile bucket, 400 mm (15.7 in) tracks, triple flange front/rear idlers, no optional counterweights and manual quick coupler (unless otherwise noted). |

| Rated Operating Capacities - 50% Tipping Load | — |

| Ground Contact Area - With 450 mm/17.7 in Track | — |

| Operating Weight | — |

| Note | Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, two speed, ride control, enclosed cab with glass door, side windows, air conditioning, air ride seat, advanced display, rearview camera, 1,000 CCA battery, dual direction self level, 2036 mm (80 in) low profile bucket, 400 mm (15.7 in) tracks, triple flange front/rear idlers, no optional counterweights and manual quick coupler (unless otherwise noted). |

| Length - Track on Ground | — |

| Overall Length - Track | — |

| Height - Top of Cab | — |

| Ground Clearance | — |

| Departure Angle | 33° |

| Maximum Dump Angle | 54° |

| Maximum Overall Height | — |

| Bucket Pin Height - Carry Position | — |

| Turning Radius from Center - Coupler | — |

| Reach - Maximum Lift/Dump | — |

| Length - Without Bucket | — |

| Turning Radius from Center - Machine Rear | — |

| Turning Radius from Center - Bucket (racked) | — |

| Bucket Pin Reach - Maximum Lift | — |

| Clearance at Maximum Lift and Dump | — |

| Rack Back Angle - Maximum Height | 81° |

| Vehicle Width (400 mm/15.7 in tracks) | — |

| Bucket Pin Height - Maximum Lift | — |

| Length - With Bucket on Ground | — |

| Maximum Reach - With Arms Parallel to Ground | — |

| Note | Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, two speed, ride control, enclosed cab with glass door, side windows, air conditioning, air ride seat, advanced display, rearview camera, 1,000 CCA battery, dual direction self level, 2036 mm (80 in) low profile bucket, 400 mm (15.7 in) tracks, triple flange front/rear idlers, no optional counterweights and manual quick coupler (unless otherwise noted). |

| Roll Back Angle | 25° |

| Standard Flow Mode - Loader Hydraulic Pressure | — |

| Note | *When equipped with Cat 400 Series work tools. |

| Standard Flow Mode - Hydraulic Power - Calculated | — |

| Standard Flow Mode - Loader Hydraulic Flow | — |

| Hydraulic Flow - XE - Hydraulic Power (calculated) | — |

| Hydraulic Flow - XE - Maximum Loader Hydraulic Flow* | — |

| Hydraulic Flow - XE - Maximum Loader Hydraulic Pressure | — |

| ROPS | ISO 3471:2008 |

| FOPS | ISO 3449:2005 Level I |

| Travel Speed - Forward or Reverse - One Speed | — |

| Travel Speed - Forward or Reverse - Two Speed | — |

| Cooling System | — |

| Engine Crankcase | — |

| Fuel Tank | — |

| Hydraulic System | — |

| Hydraulic Tank | — |

| Diesel Exhaust Fluid (DEF) Tank | — |

| Inside Cab* | — |

| Outside Cab** | — |

| Note (2) | *The declared dynamic operator sound pressure levels per ISO 6396:2008. The measurements were conducted with the cab doors and windows closed and at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. |

| Note (3) | **The labeled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC. |

| Note (1) | Cab and Rollover Protective Structures (ROPS) are standard in North America and Europe. |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 0.81 kg of refrigerant which has a CO2 equivalent of 1.158 metric tonnes. |

Benefits & Features

Quiet and Comfortable

The industry leading sealed and pressurized cab option provides the operator with a cleaner and quieter operating environment with excellent work tool visibility. Continuing the industry leading trend, the D3 Series also includes as standard, seat mounted adjustable joystick controls for operator comfort.

Maximum Performance

High performance power train provides maximum performance and production capability through the Electronic Torque Management system, standard two speed travel and an electronic hand/foot throttle with decel pedal capability.

Making Your Job Easier

Cat® “Intelligent Leveling” system provides industry leading technology, integration, and available features such as dual direction self level, work tool return to dig, and work tool positioner.

A Smooth Ride

A standard, fully independent torsion axle suspension combined with the Speed Sensitive Ride Control system improves operation on rough terrain, enabling better load retention, increased productivity and greater operator comfort.

Optimized Machine Capability

Maximize machine capability and control with the available Advanced Display, providing on-screen adjustments for implement response, hystat response and creep control. Also features multi-language functionality with customizable layouts, security system and rearview camera.

Sustainability

- The Cat® C3.8 engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 7% biodiesel FAME (fatty acid methyl ester). Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Cat® Extended Life Coolant and long-life HYDO Advanced hydraulic fluids not only reduce downtime but help decrease the amount of fluid and filters that are replaced over the life of the machine.

- Boost productivity with Cat technologies like work tool positioner, return to dig, and Cat Smart Attachments.

- Save fuel and reduce your greenhouse gas emissions with efficiency features such as foot throttle pedal and cooling system demand fan.

Data not available.

Standard Equipment

- ELECTRICAL

- 12 volt Electrical System

- 100 ampere Alternator

- Ignition Key Start/Stop Switch

- Lights: Gauge Backlighting, Two Rear Tail Lights, Two Rear Halogen Working Lights, Two Adjustable Front Halogen Lights, Dome Light

- Backup Alarm

- Heavy Duty Battery, 1,000 CCA, with Battery Disconnect

- OPERATOR ENVIRONMENT

- Gauges: Fuel Level, DEF Level, Hour Meter

- Operator Warning System Indicators: Air Filter Restriction, Alternator Output, Armrest Raised/Operator Out of Seat, Engine Coolant Temperature, Engine Oil Pressure, Air Inlet Heater Activation, Hydraulic Filter Restriction, Hydraulic Oil Temperature, Park Brake Engaged, Engine Emission System

- High Back Cloth Seat with Air Suspension, Heated with Recline and Lumbar Support and Fully Adjustable Seat Mounted Controls

- Fold In Ergonomic Contoured Armrest

- Control Interlock System, when operator leaves seat or armrest raised: Hydraulic System Disables, Hydrostatic Transmission Disables, Parking Brake Engages

- ROPS Cab, Enclosed, Tilt Up

- FOPS, Level I

- Top, Rear and Side Windows

- Headliner, Deluxe

- Floor Mat

- Interior Rearview Mirror

- 12 volt Electric Socket

- Horn

- Hand (Dial) and Foot Throttle, Electronic with Decel Feature

- Advanced Display with Rearview Camera: Full Color, 127 mm (5 in) LCD screen; Advanced Multi-operator Security System; On-screen Adjustments for Implement Response, Hystat Response and Creep Control

- Storage Compartment with Netting

- POWER TRAIN

- Cat C3.8, Turbo Diesel Engine, Meeting Tier 4 Final and Stage V Emission Standards

- Air Cleaner, Dual Element, Radial Seal

- S·O·SSM Sampling Valve, Hydraulic Oil

- Filters, Cartridge-type, Hydraulic

- Filters, Canister-type, Fuel and Water Separator

- Radiator/Hydraulic Oil Cooler (side-by-side)

- Spring Applied, Hydraulically Released, Wet Multi Disc Parking Brakes

- Hydrostatic Transmission, Two Speed Travel

- Suspension – Independent Torsion Axles (4)

- Speed Sensitive Ride Control

- OTHER

- Engine Enclosure, Lockable

- Extended Life Antifreeze, –37° C (–34° F)

- Machine Tie Down Points (6)

- Support, Lift Arm

- Hydraulic Oil Level Sight Gauge

- Radiator Coolant Level Sight Gauge

- Radiator, Expansion Bottle

- Cat ToughGuard™ Hose

- Auxiliary, Hydraulics, Continuous Flow

- Heavy Duty, Flat Faced Quick Disconnects with Integrated Pressure Release

- Split D-Ring to Route Work Tool Hoses Along Side of Left Lift Arm

- Electrical Outlet, Beacon

- Belly Pan Cleanout

- Variable Speed Demand Fan

- Steel Imbed Rubber Track – 400 mm (15.7 in) with Triple Flange Idlers (front and rear)

- Product Link™ PL240, Cellular

- MANDATORY EQUIPMENT

- Quick Coupler, Mechanical or Powered

- High Visibility Seat Belt, 50 mm (2 in) or 75 mm (3 in)

- PERFORMANCE PACKAGE:<br>– Performance Package H3: XE Hydraulics, Dual Direction Electronic Self Level (Raise and Lower), Work Tool Return to Dig, Work Tool Positioner, and Electronic Snubbing (Raise and Lower)

- COMFORT PACKAGE:<br>– Enclosed ROPS with A/C (C3): Foot Throttle, Headliner, Heater and Defroster, Side Windows, Cup Holder, Radio Ready, Air Ride Seat (High Back and Heated) and Door (Glass or Polycarbonate)

Optional Equipment

- OPTIONAL EQUIPMENT

- Beacon, Rotating

- Engine Block Heater – 120V

- Oil, Hydraulic, Cold Operation

- Paint, Custom

- Variable Speed Demand Fan with Reversing Functionality

- External Counterweights

- Product Link PL641, Cellular

- Bluetooth® Radio with Microphone (AM/FM/Weather Band Receiver with USB and Auxiliary Input Jack)