Overview

The Cat® 973D Track Loader is the only track loader in this size class. Furthermore, it leads the industry in operator comfort, performance and versatility. Designed to be productive, this machine will give you complete satisfaction in a wide range of tough applications in the most efficient and productive way. Its design also delivers strength and durability with excellent control and unmatched ease of operation. Discover how much more you can get with this one work force machine ...

Specifications

| Flywheel Power | — |

| Operating Weight | — |

| Capacity - General Purpose | — |

Benefits & Features

Specifications

| Flywheel Power | — |

| Engine Model | Cat® C9 ACERT™ |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - Cat | — |

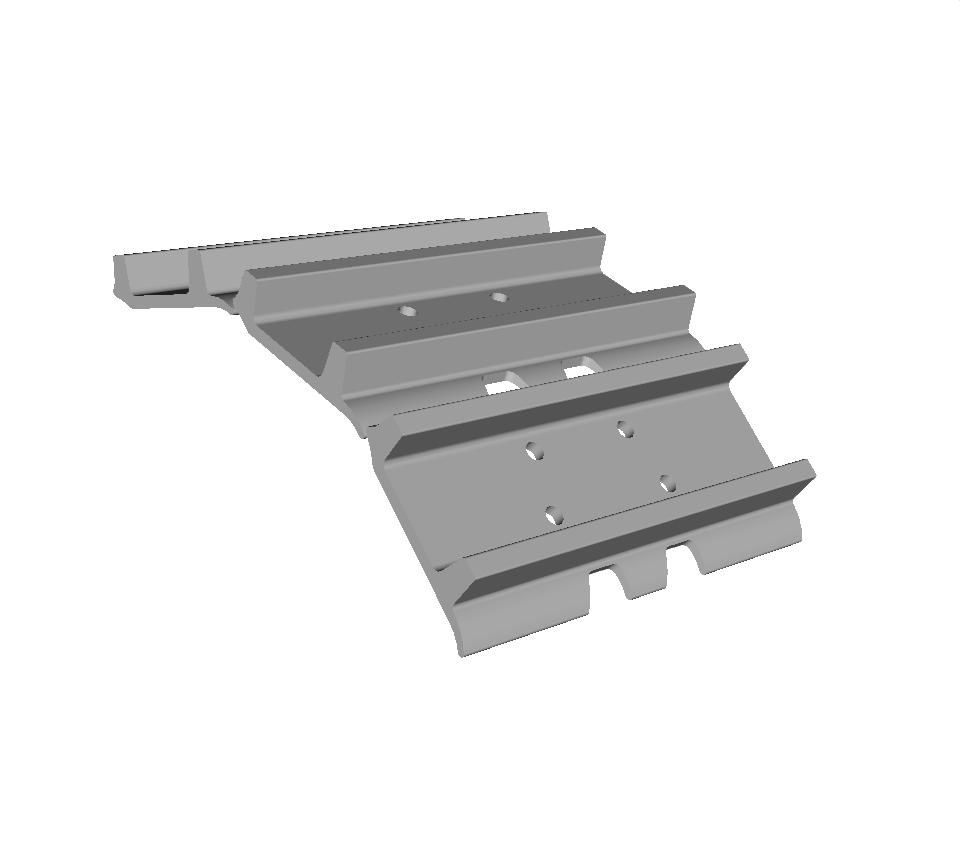

| Track Shoe Type | Double Grouser, Extreme Service |

| Track Shoe Width - Standard | — |

| Track Shoe Width - Optional | — |

| Track Rollers - Each Side | 7 |

| Number of Shoes - Each Side | 40 |

| Track on Ground | — |

| Ground Contact Area - Standard Shoe | — |

| Ground Contact Area - Optional Shoe | — |

| Ground Pressure - Standard Shoe | — |

| Ground Pressure - Optional Shoe | — |

| Grouser Height - Double Grouser | — |

| Track Gauge | — |

| Type | Hydrostatic drive with infinite machine speeds up to 11 km/h (6.8 mph) |

| Drive Pump | Two, variable-displacement, slipper-type axial piston pumps |

| Track Motor | Two, variable-displacement, bent axis piston motors |

| Maximum System Pressure | — |

| Type | Closed Center Load Sensing |

| Relief Valve Setting | — |

| Cycle Time - Dump | — |

| Output - Maximum | — |

| Float Down | — |

| Cycle Time - Raise | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase - With Filter | — |

| Final Drive - Each | — |

| Hydraulic System - Equipment, Power Train and Tank | — |

| Hydraulic Tank | — |

| Pump Drive Box | — |

| Pivot Shaft | — |

| Type | 24V DC |

| Battery Capacity | 1400 CCA |

| Battery Voltage | 12 |

| Battery Quantity | 2 |

| Alternator | 95 amp, Heavy-Duty, Brushless |

| Operating Weight | — |

| Shipping Weight - Without Bucket | — |

| Capacity - General Purpose | — |

| Capacity - Multi-Purpose | — |

| Bucket Width - General Purpose | — |

| Bucket Width - Multi-Purpose | — |

| Maximum Travel Speed | — |

| Type | Parallelogram |

| Overall Width/Beam | — |

| Shank Cross Section | 74 x 175 mm 2.9 x 6.9 in |

| Ground Clearance | — |

| Penetration | — |

| Ripping Width | — |

| Cylinders - Bore | — |

| Cylinders - Stroke | — |

| Addition to Machine Length Due to Ripper in Transportation Position | — |

| Ripper Weight - With 3 Shanks | — |

| Ramp Angle | — |

| Number of Pockets | 3 |

| Penetration Force - Ground Level | — |

| ROPS/FOPS | ROPS/FOPS |

| Brakes | Brakes |

| Cab | Cab |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg of refrigerant which has a CO2 equivalent of 2.717 metric tonnes. |

Benefits & Features

Engine

Cat® C9 Diesel Engine

The Cat® C9 is an 8.8 liter (537 in³) displacement, six-cylinder, in-line configured engine with hydraulically actuated electronic fuel injection or HEUI™. The 196 kW (263 hp) rated net power engine meet the latest worldwide emissions standards (10% more than C-series). It uses ACERT™ Technology that provides advanced electronic control, precision fuel delivery and refined air management. This proven technology with thousands of hours in field operations, results in outstanding performances with a constant net horsepower.

Electronic Control ADEM™ A4

The Advanced Diesel Engine Management System continuously monitors important engine conditions and functions. ADEM™ A4 manages fuel delivery to get the best performance per liter of fuel. The controller uses sensors in fuel, air intake, exhaust and cooling systems and provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs. ADEM A4 is the electronic brain of the machine that ensures optimal performance.

On-Demand Fan

This system offers numerous benefits, including better cooling performance, reduced plugging, enhanced cold weather operation and improved fuel economy. To reduce fan noise, the cooling fan is driven from a friction disc clutch, which is electrically controlled.

Hydraulics

Hydrostatic Drive

The electronically controlled Hystat drive provides quick response for shorter cycles times and increased productivity. The Hystat drive also offers independent power and efficient control of each track, with fast acceleration and infinitely variable speeds. The operator can command smooth machine turns and counter-rotation.

Load-Sensing Hydraulics

The 973D features a load sensing hydraulic system that automatically adjusts to operating conditions to provide only the hydraulic flow required by the implement for improved fuel efficiency. This modular hydraulic system delivers precise control with low effort operation and allows simultaneous lift, tilt and travel.

Position Sensing Cylinder

Position Sensing Cylinders (PSCs) are designed to allow for “smart” hydraulic systems. PSCs improve productivity by enhancing operator control. Operator can set lift and tilt kickouts at any position according to the applications without leaving the cab. Electronics within the cylinder allow the hydraulic system to be linked into the machine's electronics. This link enables the system to track the cylinder stroke, reducing operator effort, and increasing productivity. PSCs allows the machine to use advanced automatic features for smooth start and stop cylinder motion, reducing vibration in the cab.

Automatic Kickouts

The standard programmable automatic kickouts provide flexibility and productivity for precise load and dump target heights. Tilt and lift kickouts are set by positioning the bucket or work tool and setting a rocker switch in the cab.

Operator Station

Designed for Comfort

The D-Series cab is designed for operator comfort, convenience and to provide an excellent view to the bucket, tracks and ripper. In particular, the air-suspension seat is ergonomically designed, fully adjustable and vibration-isolated for maximum operator comfort and control. The seat-mounted electro-hydraulic controls provide less vibration for the operator, and they allow combined seat and controls adjustment. The workstation is spacious, quiet and comfortable, assuring high productivity all day long.

Electro-Hydraulic Implements Controls

The new electro hydraulic implement controls provide the operator with responsive, smooth and precise control of bucket and lift arms. A choice of joystick or two-lever control for bucket lift and dump is available as an option.

Hydrostatic Drive System Controls

This accurate control system allows quick machine travel speed, on-the-go directional changes and counter rotation. A choice of V-lever and joystick for speed and steering control is available through the price list.

Messenger

The 973D comes standard with Cat Messenger, providing real-time machine performance and diagnostic data. Messenger uses a LCD screen to display graphic and text information on machine health, including operating hours, total fuel, fuel consumption rate and total distance. Through Messenger, operator can create his own profile and set Hystat, implement and steering reactions.

Undercarriage

Oscillating Undercarriage

The undercarriage on the 973D features an oscillating track roller frame design which decreases ground shock to the machine, increases machine stability, and provides a smoother, more comfortable ride for the operator.

Proven Reliability

Track link design consists of specially heat-treated steel forgings with different degrees of hardness induced into the steel. This feature increases links' life and lowers owning and operating costs. A two-piece master link helps servicing the track chain and reduces down time. All those features help increase loader productivity throughout its life.

Maximize Your Productivity

The standard double grouser shoes are designed for good traction, easy turns and bending. However the 973D is available with several shoes options to best match to the job conditions. Any details count, and a single track shoe can make the difference.

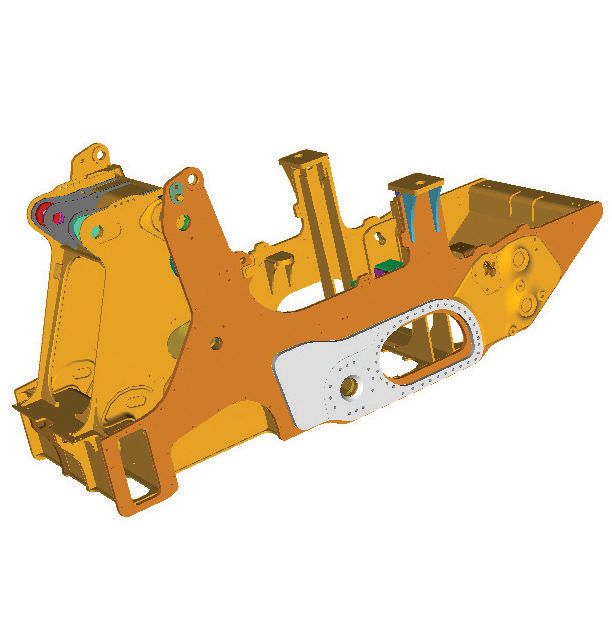

Structures

Mainframe and Loader Tower

The D-series Main Frame and Loader Tower are made of single, slab rails with reinforced crossing, with castings and forgings incorporated at points of high stress. This particular design distributes those stresses over wider areas for longer structural life.

Durability Over Years

Structures are designed to provide durability and extended service life to support multiple rebuilds.

Work Tools

Wide Range of Buckets

The combination of the right bucket with the right machine will provide the best possible performance in your particular application. The General Purpose (GP) bucket is designed for excellent loadability and long life in applications such as hard bank excavating, stripping, and stockpile loading. The Multipurpose (MP) bucket is designed for a broad range of applications, such as loading, stripping, clearing, bulldozing, picking up debris, and fine grading. The bucket clamps hydraulically to grip or handle other tough-to-grasp materials. For special applications, Caterpillar also provides buckets with special features such as Landfill GP/MP Buckets, or Slag Bucket designed to work in the extreme conditions of a steel mill, including moving slag and skulls.

Parallelogram Ripper

The multi shank parallelogram ripper adds extra versatility and force to expand the machine's range of applications. The ripper beam has three pockets for holding ripper shanks, and its design allows the machine to rip frozen ground, asphalt and even hard soils or rock. Longer shanks deliver more work per pass making the machine more productive.

K Series™ Tooth System

The K Series tooth system matches customer expectations for tip retention, easy change-outs and long-term sharpness. The K Series tooth system also features a lower-profile shape that maintains better sharpness as it wears. This means better penetration, improved productivity and less strain on the machine.

The All-Purpose Performer

General Construction Package

973D is a one-machine workforce that can tackle any task in any jobsite, from general construction to industrial or quarries.

Waste Handling Standard and Extreme Service Packages

On both packages, substantial guarding, debris barriers, cooling system enhancements and precleaners are added to enhance the life and performance of the 973D. The WH standard package should be selected for jobs in landfills, transfer stations or material recovery facilities. The WH ES will be a better fit for transfer stations, demolition sites, severe applications, or when maximum protection is desired.

Steel Mill Package

The steel mill package protects the 973D and its operator against extreme conditions to allow the machine to handle hot slag in steel mill operations. This special package features additional guarding for critical components, sealed undercarriage, heat shields for fuel tank, power train and hydraulics, silicone seals and heat resistant windshield, remote parking brake release and fire-resistant fluids. The Steel Mill Arrangement provides the best protection available for this extremely difficult application.

Wide Gauge Package

The 973D Wide Gauge is designed to work in soft underfoot conditions. The track gauge is widened and wider track shoes installed. A wider bucket also increases productivity, especially in grading and backfilling.

Additional Solutions

Other custom solutions can be designed to address your specific need. Feel free to contact your Cat dealer for more information.

Value Package

Rear Protection Package

Includes standard rear grill and bumper for general construction.

Rear Protection Heavy Duty Package

Includes heavy duty grill and bumper for restricted working space.

Ripper Package

Includes three curved shanks parallelogram ripper with replaceable tips, and protection grill and steps to climb on the machine by the ripper.

Maintenance Deluxe Package

This package makes easy and allows fast engine oil change. Provide connection for quick evac and fuel sediment flush.

Lights Additional Package

This package includes four more lights guarded.

Protection Windshield and Lights

This package includes a windshield screen and four additional lights.

Striker Bar Package

Striker bar keeps trash from climbing on the tracks and damaging the fender and move back. Also includes steps for a safer access from the rear.

Counterweight Package

Provides counterweight to move back the machine center of gravity and steps for safer Striker bar keeps trash from climbing on the tracks and damaging the fender and move back. Also includes steps for a safer access from the rear.

Contact custom products for waste handling and other specific application requirements.

Serviceability

Tiltable Cab

This feature makes the maintenance and the repairs easier. By tilting the cab, you can access to the drive train and perform complete service of the hydraulic system. Standard cab offers 90° tilt capability using an external lifting device while a hydraulic jack is available enabling 30° tilt on the jobsite.

Convenient Service Features

- All service points are accessible from ground level on the right side of the engine. Large doors give you an exceptional access to filters and service points. The following features help you to easily service your loader:

- Fuse panel with ET port: Located to the inside of the cab, on the rear right side console, the fuse panel also includes the ET port.

- Gauge control cluster and self-diagnosis Electronic Hydraulic control (EHC): They work together to warn against faults to reduce downtime.

- S•O•SSM Fluid Taps: Simplifies drawing fluid samples for Schedule Oil Sampling and reduces sample contamination.

- Quick-Connect Fittings: The quick-connect hydraulic grouped pressure taps allow quick diagnosis of the hydrostatic drive and the implement hydraulic systems.

- Ground Level Shutdown: Mounted behind a cover at the rear of the machine, a switch allows the machine to be shut down from ground level in emergency situation.

Product Link

Product Link

- Product Link uses wireless and satellite technology to gather and transmit essential information, related to machine usage, maintenance and location. This information is easily accessible through Equipment Manager. Product Link is able to:

- Report current equipment parameters (machine hours, location and fuel consumption).

- Show all elements of machine maintenance and keep machine history.

- Predict when is a service is needed.

- Alert you to potential and immediate issues.

Benefits to Your Business

- Maximize machine uptime and maintain productivity.

- Simpler, more efficient fleet management.

- Faster service response and quicker resolution time.

- Better maintenance planning.

Support

- Your Cat dealer is ready to assist you with your purchase decision and everything after.

- Make comparisons of machines, with estimates of component life, preventative maintenance and cost of production.

- Financing packages are flexible to meet your needs.

- Your Cat dealer can evaluate the cost to repair, rebuild and replace your machine, so you can make the right choice.

- For more information on Cat products, dealer services and industry solutions, visit us at www.cat.com.

Data not available.

Standard Equipment

- ELECTRICAL

- Alternator, 95 amps, 24 V, heavy duty brushless

- Alarm, backup

- Horn, electric

- 2 Maintenance free batteries, 1,400 amps

- Converter 24V/12V

- Switch, main disconnect

- Starter, electric (24V)

- Four halogen lights, two forward facing, roof mounted; two rearward facing, integrated in A/C unit

- OPERATOR ENVIRONMENT

- Pressurized, sound suppressed, ROPS/FOPS cab

- Cab with tinted glass and side sliding window

- Air conditioning and heating

- Heater, defroster with automatic temperature control

- Seat, fabric-covered, air suspended

- Seat-mounted controls

- Seat belt, retractable

- Electronic Monitoring System

- Gauges for:

- Electro-hydraulic implement control joystick

- Radio ready, includes 24 to 12V converter, speakers, antenna and two 12 volts power outlets

- Mirror rearview

- Coat Hook

- Adjustable armrest

- Transmission control, Joystick or V-lever and steering pedals

- Storage lockable compartment under armrests

- Floor mat, rubber, heavy duty

- Windshield washers and wipers, front and rear

- Durable metal roof

- Parking brake switch and "brake-on" indicator light

- POWER TRAIN

- Caterpillar C9 ACERT diesel engine

- Modular cooling system for engine air intake, oil and water

- 24 volt electric starting

- Electronically controlled, on-demand fan cooling system

- Extended Life Coolant

- Fuel priming pump electric

- Electronic Hydrostatic Control (EHC) for transmission with travel and work modes

- Closed Loop Hystat transmission with DSR Software

- Muffler, under hood

- Water separator

- UNDERCARRIAGE

- 2160 mm/85 in track gauge

- End Section Track Guiding guards

- Hydraulic Track Adjuster

- EWL track (40 sections, 215 mm /8.5 in pitch)

- Five piece sprocket track

- Seven track rollers, lifetime lubricated

- Conventional idlers, lifetime lubricated.

- Oscillating track roller frames

- Two carrier rollers per track

- Track Master Link

- Guard, idler

- OTHER STANDARD EQUIPMENT

- Sound Suppression, Exterior

- Z-bar loader linkage

- Load sensing variable displacement implement pump

- Implement cylinders with integrated positioning sensors

- Operator programmable lift and tilt kickouts

- Engine enclosure with lockable doors (5 mm/0.2 in perforated holes)

- Hinged radiator grill

- 6.35 fins per inch radiator and cooler cores

- Ecology Drains

- Hydraulic Oil, HYDO Advanced 10

- Cab, tilt jack, hydraulic

Optional Equipment

- ELECTRICAL

- Beacon, rotating

- POWER TRAIN

- Tank fuel, fast fill

- HYDRAULIC

- Hydraulic oil, biodegradable

- BUCKET

- General Propose, Slag

- BUCKET ATTACHMENTS

- Teeth, extra duty, 8

- Teeth, penetration, 8

- Cutting edge, bolt-on

- UNDERCARRIAGE

- Track, 500 mm (19.7 in), flat

- Track, 500 mm (19.7 in), alternates flat and DG GR shoes

- Track, 675 mm (26.6 in), Trap Hole

- DBL GR

- TRPL GR

- SGL GR ES

- GUARDS

- Guard, tilt cylinders

- Guard, track roller

- OTHER ATTACHMENTS

- Radio AM/FM, CD

- Heater, engine coolant, 120V

- Heater, engine coolant, 240V

- Product Link

- Machine Security System

- Antifreeze, -50° C (-58° F)

- 973D VALUE PACKAGES

- Rear protection STD

- Rear protection HD

- Ripper package

- Maintenance package, deluxe

- Lights additional, package

- Protection, windshield, lights

- Striker bar package

- Counterweight package

- Hydraulic 2W, Joystick

- Hydraulic 3W, MP Joystick

- Hydraulic 3W, GP Joystick

- Hydraulic 4W, MP joystick

- Hydraulic, 2W, 2 levers

- Bucket GP, 3.0 m³ (3.98 yd³), package

- Bucket MP, 2.8 m³ (3.6 yd³), package

- Bucket GP, 3.0 m³ (3.98 yd³), package

- Bucket GP, landfill, package

- Bucket wide, 3.3 m³ (4.37 yd³), package

- Bucket GP, 3.0 m³ (3.98 yd³), HD, pack

- Bucket MP ES, 2.8 m³ (3.6 yd³), package

- Bucket MP, landfill, package