Overview

Caterpillar 16H Motor Grader blends productivity and durability to give you the best return on your investment. The Cat 3406E engine, power shift transmission and load-sensing hydraulics are designed to work together to deliver top productivity in all applications.

Specifications

| Blade Width | — |

| VHP - Gears 1-3, Net | — |

| Engine Model | 3406 TA |

Benefits & Features

Specifications

| VHP - Gears 1-3, Net | — |

| Engine Model | 3406 TA |

| Displacement | — |

| Speed at Rated Power | — |

| Base Power (All Gears) - Net | — |

| Derating Altitude | — |

| Pump Type | Variable displacement, piston |

| Pump Output | — |

| Maximum System Pressure | — |

| Standby Pressure | — |

| Top Speed - Forward | — |

| Top Speed - Reverse | — |

| Turning Radius - Outside Front Tires | — |

| Steering Range - Left/Right | 50 |

| Articulation Angle - Left/Right | 20 |

| Forward - 1st | — |

| Forward - 2nd | — |

| Forward - 3rd | — |

| Forward - 4th | — |

| Forward - 5th | — |

| Forward - 6th | — |

| Forward - 7th | — |

| Forward - 8th | — |

| Reverse - 1st | — |

| Reverse - 2nd | — |

| Reverse - 3rd | — |

| Reverse - 4th | — |

| Reverse - 5th | — |

| Reverse - 6th | — |

| Reverse - 7th | — |

| Reverse - 8th | — |

| Fuel Capacity | — |

| Cooling System | — |

| Hydraulic System - Total | — |

| Engine Oil | — |

| Differential - Final Drives | — |

| Tandem Housing - Each | — |

| Circle - Diameter | — |

| Front-Top/Bottom Plate - Width | — |

| Front-Top/Bottom Plate - Thickness | — |

| Front-Side Plates - Width | — |

| Front-Side Plates - Thickness | — |

| Front-Linear Weights - Minimum | — |

| Front-Section Modulus - Minimum | — |

| Height - Front Axle Center | — |

| Front Axle - Wheel Lean - Left/Right | 18 |

| Front Axle - Total Oscillation per Side | 32 |

| Height | — |

| Width | — |

| Sidewall Thickness - Inner | — |

| Sidewall Thickness - Outer | — |

| Drive Chain Pitch | — |

| Blade Width | — |

| Height | — |

| Thickness | — |

| Arc Radius | — |

| Cutting Edge Width | — |

| Cutting Edge Thickness | — |

| Width | — |

| Circle Centershift - Right | — |

| Circle Centershift - Left | — |

| Moldboard Sideshift - Right | — |

| Moldboard Sideshift - Left | — |

| Maximum Blade Position Angle | 90 |

| Blade Tip Range - Forward | 40 |

| Blade Tip Range - Backward | 5 |

| Maximum Shoulder Reach Outside of Tires - Right | — |

| Maximum Shoulder Reach Outside of Tires - Left | — |

| Maximum Lift Above Ground | — |

| Maximum Digging Depth | — |

| Height - Top of Cab | — |

| Ground Clearance - Rear Axle | — |

| Length - Front Tire to Rear of Machine | — |

| Length - Front Axle to Moldboard | — |

| Length - Front Axle to Mid Tandem | — |

| Width - Tire Center Lines | — |

| Width - Outside Rear Tires | — |

| Width - Outside Front Tires | — |

| Gross Vehicle Weight - Maximum | — |

| Gross Vehicle Weight - Base | — |

| Operating Weight - Typically Equipped - Total | — |

Benefits & Features

Power Train

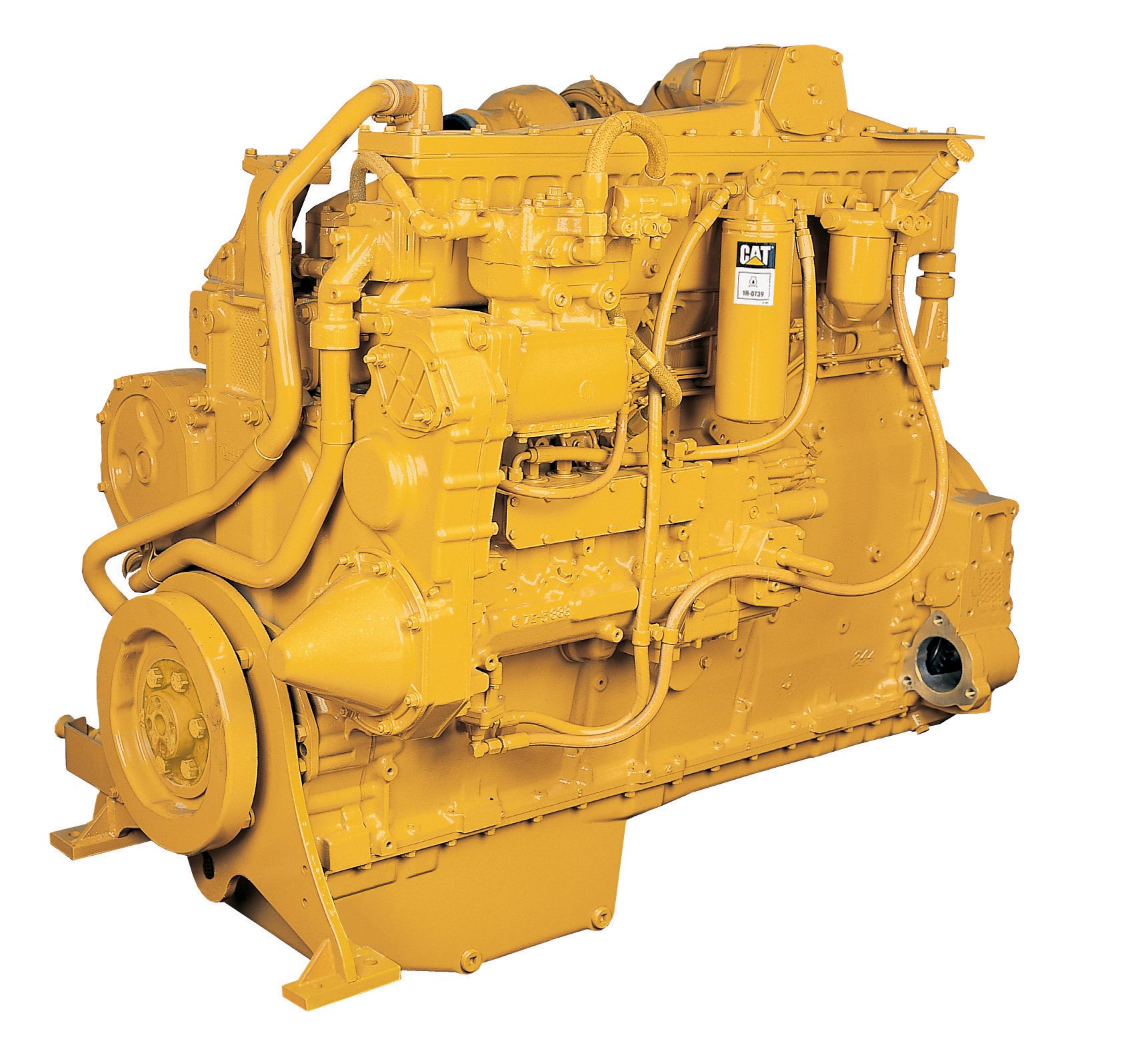

Cat 3406C Engine

The Cat 3406 engine offers superior lugging performance, fuel efficiency and reliability.

Lugging Performance

High torque output and high torque rise make the 3406 engine very responsive.

Fuel Efficiency

High fuel injection pressures ensure proper mixing of fuel and air.

Extended Engine Life

The large bore-stroke design and conservative power rating help minimize internal stresses and increase component life.

Power Shift Transmission

Caterpillar designs and builds transmissions specifically for Cat motor graders.

Direct Drive

Direct drive delivers superior fuel efficiency and better "feel" of blade loads, material hardness and ground speed.

Gear Selections

Eight forward speeds and eight reverse speeds give the operator a wide operating range.

Planetary Design

Large-diameter clutch packs and oil cooling help dissipate heat, resulting in extended transmission life.

Inching Capability

Low pedal effort and excellent modulation provide precise control of machine movements when using the inching pedal.

Dual Air System

The dual air system supplies braking capacity to each side of the machine.

Oil Disc Brakes

Caterpillar designs and builds multi-disc brakes that are completely sealed and adjustment-free.

Ether Starting Aid

Ether starting aid comes standard on the 16H to help ensure engine starting in the extreme cold.

Hydraulics

Power On Demand

Normally, the variable displacement pump idles at near-zero output.

Implement Control Valves

Implement control valves are designed and built by Caterpillar specifically for motor graders.

Low Operator Effort

Implement controls are designed to reduce operator fatigue.

Balanced Flow

When the operator uses several controls at one time, flow is proportioned to ensure all implements can operate simultaneously. If hydraulic demand exceeds pump capacity, cylinder velocities will be reduced by the same ratio.

Independent Oil Supply

Large independent oil supply prevents cross-contamination and provides proper oil cooling, which means less heat build-up and extended component life.

Blade Float

Blade float is incorporated into the blade lift control valves.

Drawbar, Circle & Moldboard

Rugged Construction

The drawbar features an A-frame, box-section design for high strength.

Efficiency

The tall moldboard and large throat clearance help move material more quickly and efficiently.

Replaceable Wear Items

Tough, durable nylon composite wear inserts are located between the drawbar and circle, and between the support shoes and circle.

Circle Drive Slip Clutch

The circle drive slip clutch protects the drawbar, circle and moldboard from shock when the end of the blade encounters hidden objects.

Blade Lift Accumulators

Optional blade lift accumulators absorb vertical shocks encountered when the moldboard contacts immovable ogjects.

Operator's Station

Visibility

Exceptional visibility helps improve operator confidence and productivity in all grader applications.

Quiet Cab

With the doors closed, interior sound level stays low. The quiet environment keeps the operator alert and focused.

Reduced Strain and Fatigue

Low efforts on all pedals, hydraulic controls and the transmission shifter reduce operator strain and fatigue.

Roomy Interior

Extra leg and foot room create a spacious, open cab.

Contour Series Suspension Seat

The optional contour series suspension seat features fold-up armrests and a retractable seat belt.

Comfort

Optional air conditioner and heater arrangements create a comfortable work environment for the operator.

Electronic Monitoring System

The electronic monitoring system checks important machine systems and provides the operator with three levels of warning.

Features of Comfort

Comfort and convenience are designed into every feature.

Serviceability

Maintenance

Easy access to service areas speeds up maintenance and ensures that routine service is performed on time.

Power Train Components

Power train components feature a modular design so you can remove the engine, transmission or final drives independently for quick servicing.

XT Hose

Caterpillar designs and manufactures its own heavy-duty XT hose and installs it in all high-pressure circuits. It's resistance to abrasion, coupled with its exceptional strength and flexibility, help minimize maintenance and extend life.

O-Ring Face Seals

O-ring face seals create a reliable seal and are used in all hydraulic circuits to minimize the possibility of oil leaks.

Extended Life Coolant (ELC)

Extended Life Coolant (ELC) extends coolant life. A single addition of ELC™ Extender is the only maintenance required.

Separate Wiring Harnesses

Separate wiring harnesses connect all electrical components.

S-O-S

S-O-SSM oil and coolant sampling valves provide a fast, convenient means of obtaining fluid samples and improve analysis reliability.

Environmentally Responsible Design

Quiet Cab

The cab is sound suppressed. The resiliently mounted engine and transmission result in less engine noise and vibration to the operator.

Dry Machine

Lubricant fill points and filters are designed to minimize spillage. O-ring face seals, XT hose and Cat hydraulic cylinders protect against leaks.

Low Emissions

The engine arrangements meet current regulations of the U.S. Environmental Protection Agency, California Air Resources Board and European Union.

Ozone Protection

To help protect the earth's ozone layer, air-conditioning units use R-134a refrigerant, which does not contain chlorofluorocarbons (CFC's).

Complete Customer Support

Selection

Make detailed comparisons of the machines you are considering before you buy.

Purchase

Look past the initial price. Consider the financing options available as well as day-to-day operating costs and dealer services.

Operation

Improving operating techniques can boost your profits.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment.

Product Support

You will find nearly all parts at our dealer parts counter.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the costs involved so you can make the right choice.

Data not available.