Overview

Cat® Backhoes are used in typical backhoe applications such as digging footings, basements, and drainage ditches, utility trenching, back-filling, and maintaining slopes and embankments in construction, industrial, and landscaping settings. They are ideal for demolishing concrete when paired with Cat B4/B6/H45/H55/H65 hammers.

Specifications

| Maximum Digging Depth | — |

| Operating Weight | — |

| Overall Length | — |

Benefits & Features

Smart Attachment

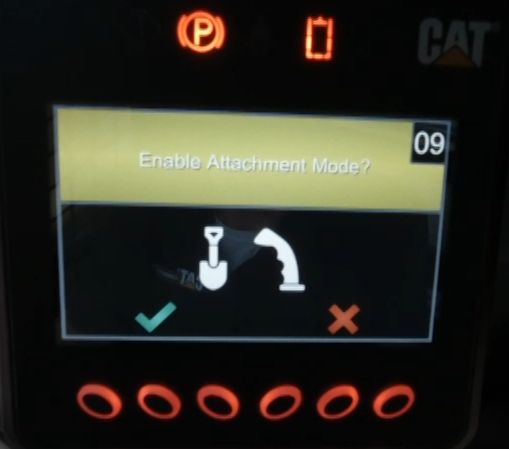

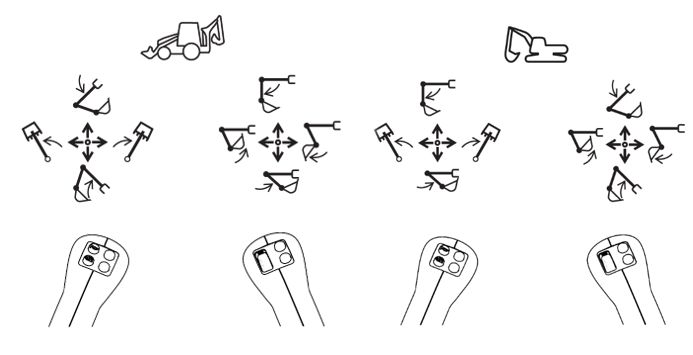

The BH130 Smart Backhoe does more than just turn an indicator light on in the cab; although it does that, too. The first step is attachment recognition. The D3 host machine recognizes that there is a BH130 attached to the machine. This activates a dedicated machine display to allow options for the BH130 to be selected. And as a Smart attachment, the BH130 allows for pattern change. That is, the existing machine joysticks are re-purposed to perform functions on the attachment.

Application

Used in typical backhoe applications such as digging footings, basements, and drainage ditches, utility trenching, back-filling, and maintaining slopes and embankments in construction, industrial, and landscaping settings.

Integrated Controls

Allows operator to use BH130 from within the safety of the cab, without the need to remove the door or any additional hardware.

Specifications

| Maximum Digging Depth | — |

| Operating Weight | — |

| Overall Length | — |

| Stabilizer Spread - Operating Position | — |

| Digging Depth at 610 mm (2 ft) | — |

| Digging Depth at 4220 mm (8 ft) | — |

| Straight Wall Digging Depth | — |

| Overall Operating Height | — |

| Loading Height | — |

| Loading Reach | — |

| Reach From Swing Pivot at Ground Line | — |

| Swing Arc | 180 degrees |

| Bucket Rotation | 183 degrees |

| Bucket Breakout Force | — |

| Stick Breakout Force | — |

| Boom Pivot Height | — |

| Ground Clearance | — |

| Transport Height | — |

| Transport Width | — |

| Required Hydraulics | Standard Flow |

| Optimal Hydraulic Flow | 50-86 L/min (13-23 gpm) |

| Optimal Hydraulic Pressure | 180-230 bar (2600-3340 psi) |

| Total Side Shift Travel | — |

| Interface Type | Skid Steer Coupler |

Benefits & Features

Smart Attachment

The BH130 Smart Backhoe does more than just turn an indicator light on in the cab; although it does that, too. The first step is attachment recognition. The D3 host machine recognizes that there is a BH130 attached to the machine. This activates a dedicated machine display to allow options for the BH130 to be selected. And as a Smart attachment, the BH130 allows for pattern change. That is, the existing machine joysticks are re-purposed to perform functions on the attachment.

Application

Used in typical backhoe applications such as digging footings, basements, and drainage ditches, utility trenching, back-filling, and maintaining slopes and embankments in construction, industrial, and landscaping settings.

Integrated Controls

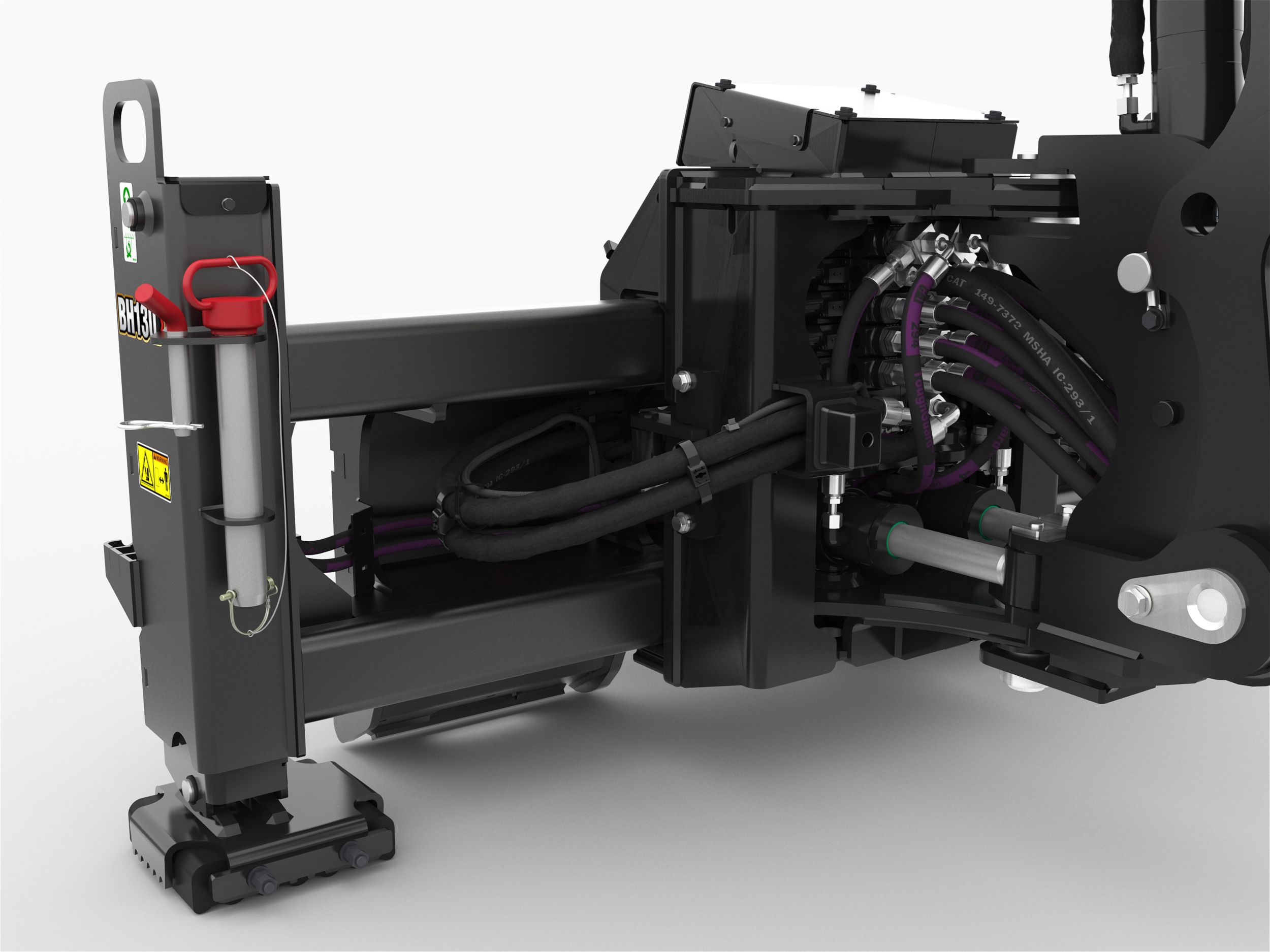

Allows operator to use BH130 from within the safety of the cab, without the need to remove the door or any additional hardware.

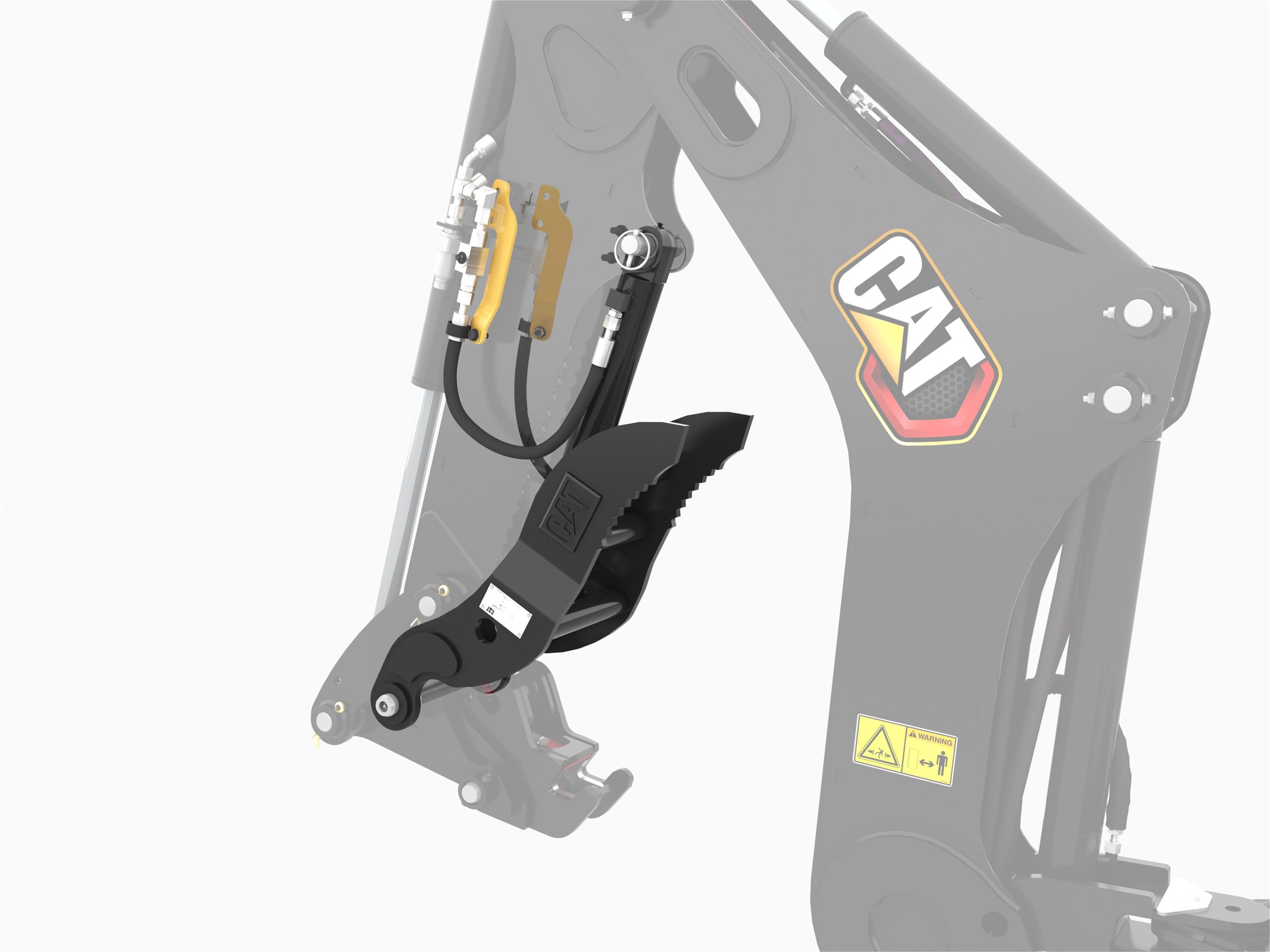

Compatible with 3 Ton Excavator Attachments

Cat® 3-ton (35-35 mm pin diameter) excavator attachment can be easily used with the BH130.

Mode Selection/Toggle

With the BH130 Smart Backhoe attached, the host machine has two modes: Machine Control mode and Attachment Control Mode.

Auxiliary Hydraulics

Auxiliary hydraulic lines provide auxiliary flow to the end of the stick to operate Mini Hydraulic Excavator hammers, augers, ditch cleaning buckets, thumbs, and vibratory plate compactors.

Pattern Selection

Operator can easily switch the backhoe control pattern to their preference. (Backhoe-SAE, Excavator-ISO). A left lit mode light on the BH130 indicates Backhoe pattern mode, while a right lit mode light indicates excavator mode.

Thumb Mounting

The BH130 comes standard with thumb mounting provisions.

Hydraulic Side Shift

Operated hydraulically, the backhoe attachment can shift left and right quickly and easily without leaving the cab. Allows the backhoe to be used close to walls and other obstacles.

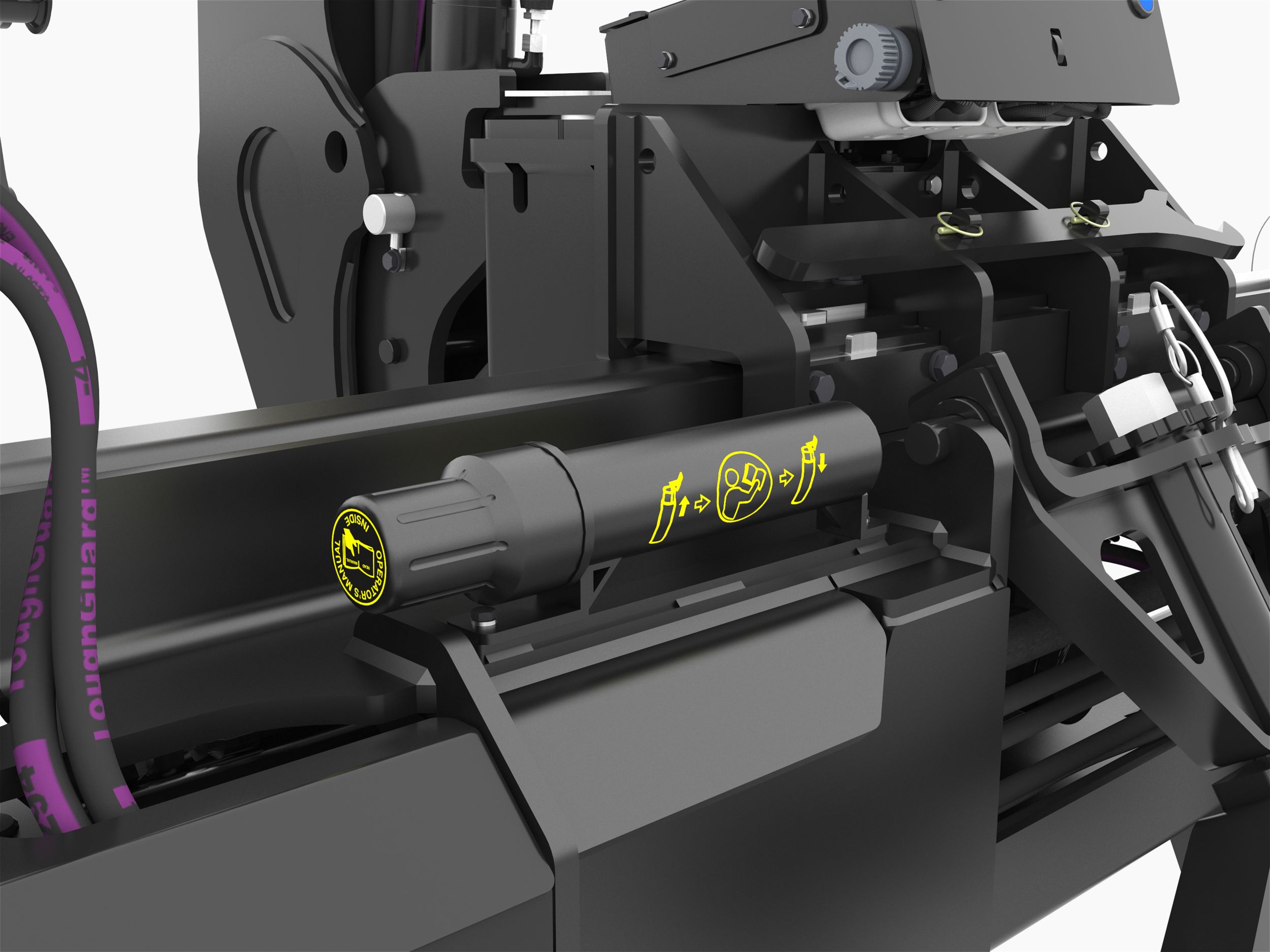

OMM Container

Tool mounted and sealed from the elements, this holder includes all the operation manuals and maintenance guides required for proper operation of the tool.

Data not available.