5.3m3 (6.9 yds3) for R1600H

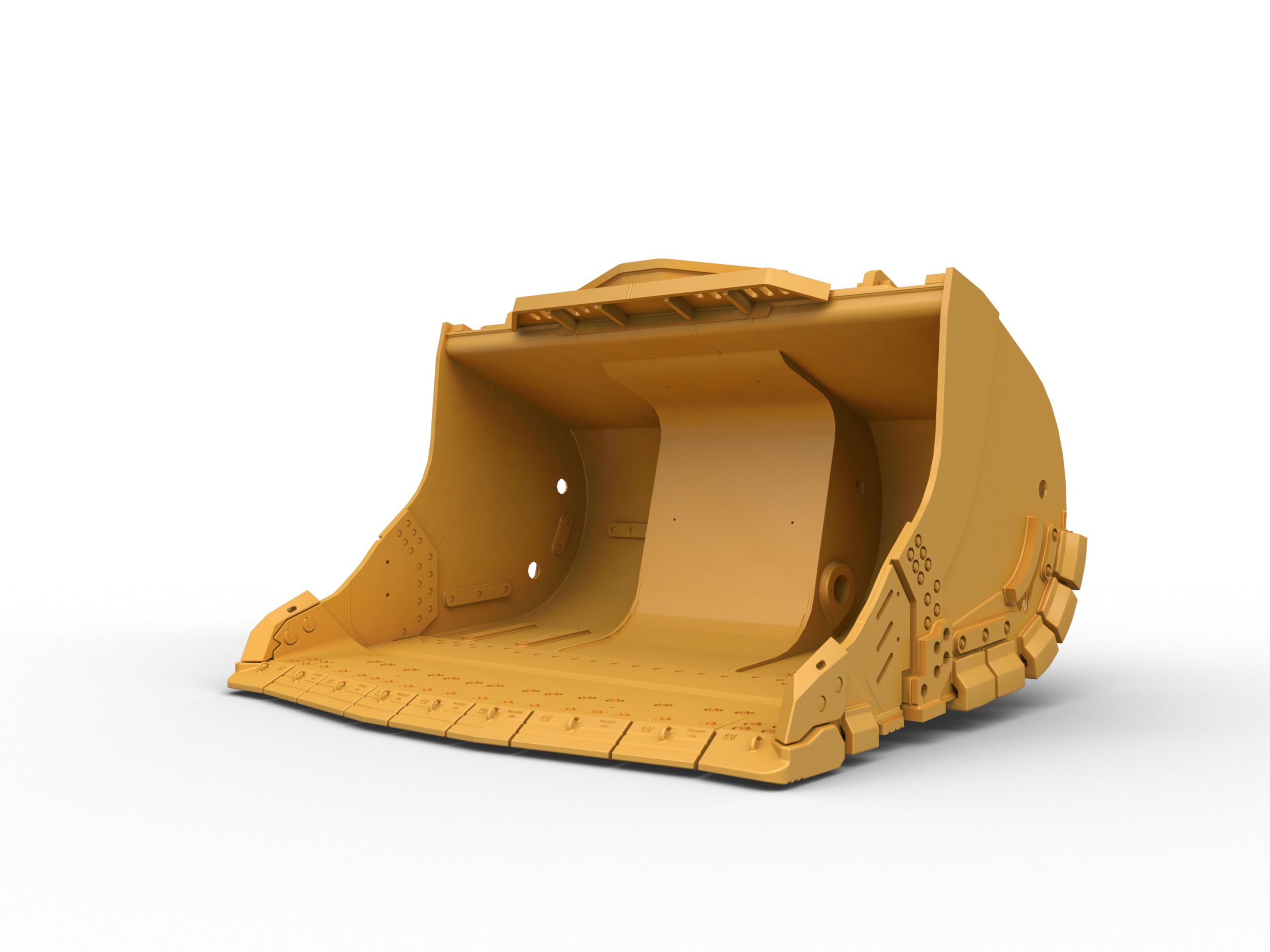

Bolt-together Bucket 5.3m3 (6.9 yds3) - R1600HOverview

Designed specifically to reduce time and costs associated with transportation, assembly and rework procedures for underground mining, the Cat® bolt-together bucket is the solution to lower repair costs, reduced machine down time and higher machine productivity.

Specifications

Units:

| Bucket Group Part Number | 598-8733 |

| Machine Model | R1600H |

| Ground Engaging Tool (GET) System | Modular Weld-on (MWO), Bolt-on Half Arrow (BOHA) |

Benefits & Features

Operational Safety

Optimized Bucket Design and Strong Materials

Higher Durability and Reduced Service Intervals

January 20, 2025

Specifications

Units:

| Bucket Group Part Number | 598-8733 |

| Machine Model | R1600H |

| Ground Engaging Tool (GET) System | Modular Weld-on (MWO), Bolt-on Half Arrow (BOHA) |

| Bucket Capacity | — |

| Weight - Base Bucket | — |

| Width - Base Bucket | — |

| Height - Base Bucket | — |

| Depth - Base Bucket | — |

| Weight - Bucket with MWO GET | — |

| Width - Bucket with MWO GET | — |

| Height - Bucket with MWO GET | — |

| Depth - Bucket with MWO GET | — |

| Weight - Bucket with BOHA GET | — |

| Width - Bucket with BOHA GET | — |

| Height - Bucket with BOHA GET | — |

| Depth - Bucket with BOHA GET | — |

Benefits & Features

Operational Safety

- The Cat bolt-together bucket has the same strength and toughness you would expect of any Cat standard bucket, but requires no skilled maintenance operators for underground welding, resulting in lowered safety risks and quicker repair times.

- Multiple components allow for ease of the bucket transportation and assembly.

- Less frequency of bucket replacement, due to the higher wearing consumables e.g., edges, shrouds easier to replace as they simply bolt on.

Optimized Bucket Design and Strong Materials

- Bucket materials, design and fabrication are specially made for the demanding underground environment and abrasive materials to be moved.

- Improved thicknesses on the bucket design provides improved strength and an increase in rigidity to the bucket assembly, aiding edge installation and removal.

- Higher grade material (400BHN) is used for the bucket assembly components.

- Higher grade wear protection Ground Engaging Tools (GET) on the removable shroud assembly.

Higher Durability and Reduced Service Intervals

- This bucket allows for more edge replacement cycles before the bucket assembly for major repairs. Improved wear life leads to improvement in cost saving and productivity.

- Bucket design also takes bucket weight into consideration, targeting a stronger bucket and balanced weight for overall machine performance improvements.

- Cat GET also offer great competitive advantages.

Modularity Benefits and GET Options

- Buckets are modular design and can be assembled quicker.

- Multiple Cat GET and attachments available with this bucket. Three Edge Options (Bolt-on Half Arrow [BOHA], Modular Weld-on [MWO], Durilock [Three Segment Options]) and shroud segments, resulting in reduced downtime and accelerated repair. The rock guard reduces rock spillages over the back of the bucket, therefore reduces the chances of damaging the boom / lift arm and components etc..

- Caterpillar offers the bucket and a full suite of GET options. Caterpillar and our Cat dealers offer one stop shop which means less accounts.

- All these GET and attachments are modular design – easy and quick to install and remove.

Cat Buckets Suit Cat Loaders Best

- Cat branded buckets are built in the same factory as our machines and go through the same strict quality controls.

- Best suit Cat machine balance, support better machine performance – penetrating, loading, support high breakout force.

- Multiple offerings to suit your unique mining application. The Cat bolt-together buckets are currently available for the Cat R1600H (R1600G), R1700G, R1700 and R1700 XE loaders.

- The Cat bucket is supported by Cat Global dealer network.

Data not available.